overshot oil and gas free sample

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

I debated on where to go next, but at the end of the day the most widely used fishing tool has to be an overshot. Some will say why not a spear? Well if you must ask, always go with the strongest fishing tool you can run to catch the fish. And if you run a spear, never plug the I.D. of your fish by breaking it off. Done with that!

The info that follows has been taken from the manuals published on overshots. I realize that paper manuals are a thing of the past, yes, yes at one time fishing tool hands carried massive catalog brief cases full of reference material. Now you have the luxury of your laptop loaded with information. If you have never sat down and read an overshot manual, now might be a good time.

The overshot is highly versatile and efficient tool. There are several different types of overshots, however each overshot is designed to engage a specific size of tubing, pipe, coupling, tool joint, drill collar or smooth OD tool.

The original overshot was developed by Bowen Oil Tools, which is now part of NOV. One thing I will point out is that in the catalogs you will see more than one assembly number for a given OD of Overshot, this came about due to the two locations developing their own variations. I found this information on NOV’s website and thought it was interesting to share.

In the early 1930s, the consequences of the stock market crash prompted S.R. Bowen to consider starting a company in Houston, where oil exploration and drilling was accelerating. In the early spring of 1934, his son Walter and a friend formed Bowen Company of Texas.

Bowen™ became a leader in innovation with the creation of the first overshot, the Series 150, in 1935. This tool set the standard for fishing equipment, and the quick acceptance of the tool assured the company partners that their business would be successful. The company continued to create new products, building a reputation for their well tool design and construction.

Currently there are several manufacturers of overshots, NOV (Bowen), Rubicon (Logan) and Applied Oil Tools (Gotco). These overshots are designated by a series number as follows:Series 10 - Sucker Rod Overshot

Overshots may be identified by one of the following, known as “type”:Full Strength (FS) - engineered to withstand all pulling, jarring and torsional strain

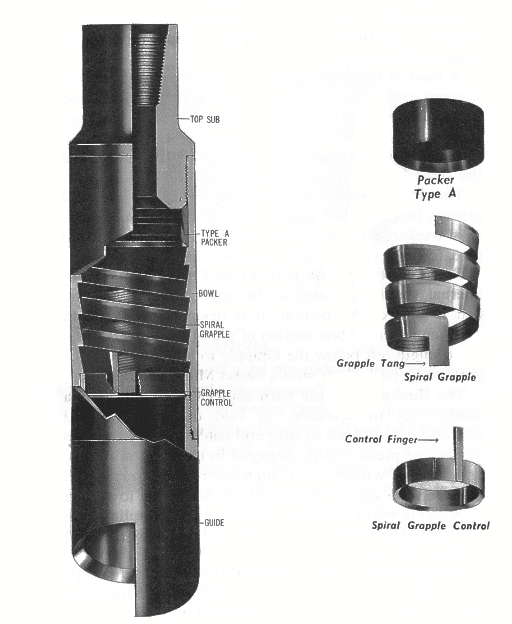

The basic overshot (from top down) consists of a top sub, a bowl, grapple, control, and a guide. In addition to the basic components, some overshots (Series 10 and 150) can be dressed with either a:Spiral grapple used if the fish diameter is near the maximum catch of the overshot, or a

The Series 150 Overshot features the ability to packoff on the fish. When the circulating packoff is not used, the fluid circulates down the drillpipe, aroundthe top outside of the fish, through the slip or grapple assembly, around the guide shoe and up the annulus.

When the circulating packoff is used, the annular space between the top outside of the fish and the inside of the lower part of the overshot is packed off, diverting the fluid flow down into the fish, making it easier to release and recover the fish. Packoffs usually are not high pressure devices but will often withstand sufficient pressure to establish circulation through the fish. Third party high pressure packoffs are available from various sources.

The extension can be installed between the top sub and the bowl of the Series 10, 70, and 150 overshots. It is used to extend the overshot bowl to:Allow the grapple to catch farther down on a fish that may be necked down at the top by having been pulled in two, or latched by an overshot and released several times, or to

A stop ring must be used where a fish OD reduces immediately below the catch area to allow the grapple to bite on full-size pipe.Example - catching a Hydril upset or EUE collar. If the upset of collar should pass completely through the grapple, the overshot may not be releasable.

If a stop ring is needed and the grappledoes not have a built-in stop, a stop ring can be run above the grapple, in the area between the Top Sub pin and the Grapple.

The Series 10 Sucker Rod Overshot is designed to engage and recover sucker rods, couplings, and similar items from inside tubing strings.Basket grapples are recommended for fishing for hardened and ground boxes (Sucker Rod Box).

The Series 20 Sucker Rod Overshot is a short catch tool which provides a means for engaging the exposed portion of a fish too short to be engaged with a Series 10 overshot.Uses basket grapples only

The Series 70 Short Catch Overshot is designed to engage the exposed portion of a fish too short to engage with Series 150 overshots.Uses basket grapple only

The Series 150 Releasing and Circulating Overshot is used to engage, packoff, and retrieve twisted-off lost tubing, drillpipecoupling, tool joint, casing or other similar fish.

Special Grapples:Nitraloy grapples may be available from some vendors. It is available only in the most popular sizes and is not commonly used on standard pipe.

A right hand wicker grapple converts a normal right release overshot to left hand release. This grapple is used where you expect to apply excessive right hand torque to release a packer, safety joint, etc. Note: Overshot will have to be released by left hand rotation.

Grapple Controls:Basket Grapple control packers have built in packoffs. These packoffs will hold various amounts of pressure, depending on the size of the fish and the condition of the packoff after engaging the fish.

High Pressure Packoff Assemblies:The High Pressure Packoff Assembly is an accessory to the Series 150 Overshots. It is used when high pressure circulation to the fish is required. It consists of a packoff sub with packing and packing rings and is installed between the top sub and bowl of the overshot. By running the packoff sub above the bowl, this design prevents the application of high internal pressures to the overshot bowl. The design of the High Pressure Packoff Assembly allows pressures two to three times the standard overshot packoff to be applied to the fish.

This information comes directly from the NOV manual for the Wide Catch Overshot. This is probably the first and only change to this common tool I know of in my career.

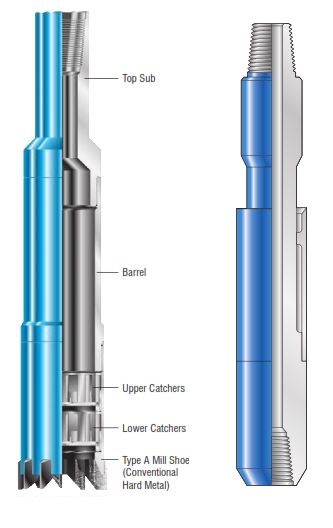

The Wide Catch Overshot provides the strongest tool available to externally engage, pack-off, and pull a fish that has been significantly worn. This tool has similar rugged design features and construction as the industry standard, Bowen Series 150 overshot, with the ability to interchange the Bottom Guide with the full range of existing components used with the standard Bowen Series 150 overshot.

In service, the Wide Catch Overshot (WCOS) takes a positive grip over a large area of fish and is capable of withstanding heavy pulling, torsion, and jarring strains without damage to the tools or the fish.

The WCOS has been designed to significantly increase the catch range of the OD of the fish to be caught, compared to the standard overshot. This enables a greater opportunity for a successful fishing operation in a reduced number of trips, thus reducing overall intervention costs for the operator. In addition to the large catch range, the WCOS has the ability to seal across very large extrusion gaps at both standard and high pressure and provide full circulation through the fish, should it be required.

New coarse threads have been introduced at the connection between the top sub and bowl to allow for quick assembly while maximizing the torsion and tensile strength.

Connections between the Top Sub/Bowl and Extension Sub have been designed to create a seal. This will prevent the connection from washing out should the overshot be required to be flowed through for a long period of time. In order to lock the Top Sub/Extension Sub to the Bowl from backing off during operation, set screws have become standard and will gall the threads should the connection break free.

The operation of all overshots is identical. The exception being that the Series 150 carries a packoff which provides circulation through the fish. First, determine that the overshot is properly assembled and dressed with the proper size grapple. Make up the overshot on the fishing string (normally it is run connected to the bottom of the bumper sub) and run it into the well. As the top of the fish is reached make sure circulation has been established to clear overshot ID of any plugging. Lower the overshot onto the top of the fish with no rotation at first. A 5,000 pound set down weight will be sufficient to engage the grapple. While lowering the overshot over the top of the fish watch for pressure build up, shut off pumps if any pressure build up is noticed. Should any back pressure be noticed, release the back pressure to allow the grapple to engage the fish. By elevating the string it can be determined, if the grapple went over and engaged the fish. If unable to work overshot over top of fish without rotation, then slowly rotate the fishing string to the right and gradually lower the overshot over the fish. Combined rotation and lowering over top of the fish are important to keep the grapple in the release position. This provides the maximum clearance between the grapple and fish. While lowering the overshot over the top of the fish, watch for torque build up and an increase in pump pressure. A pump pressure build up indicates the overshot has gone over the top of the fish thereby reducing the flow area. Stop rotation (continued rotation could dull the wickers of the grapple) enabling the grapple to set. Allow the right hand torque to slack out of the string and then pull on the string by elevating the string to set the grapple.

To release from the fish, bump down, then simultaneously rotate to the right and slowly elevate the fishing string. It is best to have a clean fishing top before running the overshot.

Drilling tool fishing is probably every driller’s least favorite activity. But it happens. There are a huge number of tools available to fish almost anything out of the hole. For drill pipe and collars, there are overshots and spears — in many sizes for almost any job. But, when it comes to loose junk on the bottom of the hole, things get a little more interesting. It might be a loose bit, a wrench, a sledge hammer or tong dies. Anything that can fit in the hole will sooner or later end up on the bottom. I reckon it’s human nature, or Murphy’s law, but it happens.

Most commercial fishing tool companies have pretty sophisticated tools, such as reverse circulation junk baskets, and all kinds of well-engineered tools to do the job. But, sometimes, they are not quite what a customer needs. If the fish is large in relation to the hole size, such as a bit, a reverse basket will not pick it up because of the wall thickness. Something else is needed. Or, if the hole is just not worth the expense of using a commercial fishing company, a driller may opt to build his own fishing tool for the job.

This brings me to a tool that is often overlooked, but has been around forever and recovered a lot of junk in the hole: the poor-boy basket. Most fishing companies don’t push them because they are not fancy high-dollar tools that make great testimonials, but they work and can be built by the driller on location.

A poor-boy basket is basically a short piece of casing with fingers on the bottom that swallow the fish and close below it, making a successful recovery.

The layout and design of the fingers is very important to the operation of the tool and successful recovery of the fish. I have built these for years and pretty well have it down, so I thought I’d share with you how to lay out the leaves on a poor-boy basket for your best chance of recovery.

As I said, the diameter will be about as big as you think you can get into the hole. Measure the diameter of that casing, and make the basket about 25 percent longer than that number. It tapers into kind of a bullet shape. At one-third the length of the basket, it should taper to seven-eighths of the original diameter. At two-thirds the length of the basket, it should taper to one half of the original diameter. Cut the leaves so that they tend to close on right-hand rotation.

Once you’ve built your basket, here is the running procedure:Go in the hole at moderate speed, watching for ledges or doglegs. The basket is a delicate tool, and you need it intact when you get to the bottom.

Very slowly lower the string to drill over the fish. You should not see any weight loss on the indicator. The best way is to time drill. Lower the pipe about ½ inch every minute or two. Watch your pump pressure and torque.

If you are in soft formation, you will core into the formation, trapping the fish in the basket. In this case, you will see an increase in pump pressure when the leaves have passed the bottom of the hole, and torque will increase.

At this point, while still rotating, significantly increase the weight on the string, while watching your torque. This will close the leaves below the fish, and break any core you have cut.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

PARVEEN Overshot Expansion Joint (OEJ) Assembly is designed for applications where extreme tubing movements are expected due to stimulation or production of the well and when a tubing separation device is also required.The OEJ assembly is a one-trip system, which allows the well to be flanged up prior to setting the packer. The OEJ assembly incorporates a slick joint sub as well as housing – packing set including working seal units and a debris barrier above the working seals. The plain receptacle, housing – packing set and seals can be retrieved when the tubing string is recovered for maintenance or the entire completion can be retrieved by straight pull after ensuring that J-pin engaged with J-slot, thus allowing the packer to be retrieved.The OEJ assembly is available in varying lengths of up to 20 ft. stroke. Adjustable shear pins lock the inner & outer assembly together during run-in. Once the shear screw gets sheared by applying load, the outer assembly gets disengaged and it is free to move on the inner assembly, compensating for tubing movement.

The Series 10 Sucker Rod Overshot is a small, rugged tool designed for engaging and retrieving sucker rods, couplings, and other items from inside tubing strings.

Series 20 Short Catch Sucker Rod Overshots are designed for conditions when sucker rods, couplings, and other portions of a fish are too short for retrieval with a standard overshot.

The Hydraulic Release Overshot was designed to aid in the recovery of a stuck fish in a horizontal drilling application where normal rotation for release is not obtainable.

The Series 150 Releasing and Circulating Overshot consists of three main external parts: a Top Sub, a Bowl, and a Guide. Internal catch and pack-off parts are determined by the diameter of the fish. Each assembly is designed for a maximum catch diameter.

A Series 160 Side Door Overshot is recommended when fishing for cable tools or conductor lines in cased holes. The side door overshot is run in on tubing or drill pipe.

A Lead Impression Block is an effective tool used to determine dimensions, configuration, condition, and location of the top end of a fish in the hole.

Rotary Die Collars are the simplest external catch fishing tools designed for retrieving a fish from the hole. Die Collars are available in two types: Type A and Type B.

Full Circle Releasing Spears are used to internally engage and retrieve all sizes of tubing, drill pipe, and casing. It may be used with internal cutters for cut and pull operations.

Releasing Spears provide a positive means to engage and retrieve an internal fish from the well. The design of this rugged, dependable, and inexpensive internal catch fishing tool ensures positive engagement, easy release and re-engagement. It may be used with other equipment such as pack-off assemblies and internal cutters.

The segment-type spear grapple enhances the spear’s usefulness by providing an extended catching range beyond the maximum range of the standard one-piece grapple.

The Core Type Junk Basket is an easy to use junk retrieval tool designed to effectively remove small objects such as bit cones, slips, hand tools, and tail chains from the hole.

The Full Flow Reverse Circulation Junk Basket is similar to the Reverse Circulation Junk Basket. The unique difference is the Full Flow Valve Assembly that enables continuous circulation through the center thereby keeping out shale and debris while running in the hole.

The alternately long and short fingers of the junk catcher assembly extend almost to the center of the basket to form a close-fitting receptacle that will retain small pieces of junk that may impede drilling progress or hold a core sample.

The Fishing Magnet is designed to retrieve small metal, oddly shaped objects such as mill shavings, bit cones, cutters, bearings, slips, tong pins and hand tools for the bottom of the well bore.

The EZ Clean™ Ditch Magnet with Rare Earth Elements is the most effective means available to trap and remove metal particles from drilling mud missed by the shale shaker. The ditch magnet will capture all magnezed metals. During milling operations, the magnet is parcularly valuable for the removal of mill cuttings and debris that cause wear on mud pumps and other equipment.

The Magna Fish™ Fishing Magnet is designed to retrieve small metal, oddly–shaped objects such as milling shavings, bit cones, cuers, bearings, slips, long pins, and hand tools from the boom of the wellbore. Typically, these objects are the result of bit failures, and accumula!on of mill cuttings, or simply accidental droppings of unmillable objects.

The Superior Hydraulic Jar is a straight pull, up only, jarring tool that utilizes a special valve section to meter oil from one side of the piston to the other side. This allows for controlled jarring action during stuck fish recovery.

The Z Type Hydraulic Jar is used for light drilling, fishing, coring, reaming, testing, side tracking, and washover operations. This straight-pull jar combines the principles of mechanics and hydraulics in a simple to assemble, easy to operate design.

The Surface Bumper Jar is installed in the drill string at the surface and is used whenever the downhole drilling, fishing, or washover running string becomes stuck and requires a heavy downward force to release it.

The Lubricated Fishing Bumper Sub is a dependable accessory that is suitable for all fishing operations, especially harsh, downhole applications and deep workover operations.

One of the most common tools used for any kind of fishing job is the bumper sub. The tool’s design allows full torque and unrestricted fluid circulation at all times.

The Drill Pipe Safety Joint is designed for the safe and dependable release from drilling, fishing, tubing, washover, or testing strings should they become stuck.

The Tubing Safety Joint is designed for the safe and dependable release from drilling, fishing, tubing, washover, or testing strings should they become stuck.

The Washover Safety Joint is designed for the safe and dependable release from drilling, fishing, tubing, washover, or testing strings should they become stuck.

The Type J Safety Joint provides a release option from tools such as taper taps or die collars that are normally non-releasable. It also provides a way to connect or disconnect fishing string and stuck fish.

The Bi-Directional Coiled Tubing Jar is designed to hit upward and downward blows. It can be dressed to only hit up or down. These tools’ small outside diameters and shorter lengths make them ideal for milling, drilling, workover, remedial, or completion operations, especially in vertical, deviated, and ultradeep wellbores.

The double-acting, Bi-Directional Coiled Tubing Energizer is an impact enhancement tool designed for slim holes (generally a well bore less than 6 inches in diameter). Its function is to supply intensified impact during the jarring operation by providing or enhancing jar impact from energy stored within its oil-filled compression chambers.

Junk Mills are hard-faced with sintered tungsten carbide particles that mill away stuck fish that can not be retrieved with conventional fishing methods. These tools are highly resistant to impact and their super rates of penetration result in fewer round trips. Their maximum useful life is enhanced by their self-sharpening feature.

The Internal Pressure Pipe Cutter utilizes pump pressure to actuate three carbide-coated knives to cut single and multiple strings of pipe from 4 inches O.D. to 36-inches O.D.

The Casing Roller repairs and restores dented, collapsed, or buckled tubing or casing of any size and weight to its original inside diameter and roundness.

High Pressure Type L Packer Type Casing Patches are designed to engage and seal off a properly prepared casing string. The Casing Patch design leaves the operator with a casing string that has a full-bore internal diameter.

High Pressure Type L Packer Type Casing Patches are designed to engage and seal off a properly prepared casing string. The Casing Patch design leaves the operator with a casing string that has a full-bore internal diameter.

The Lead Seal Cementing Casing Patch forms a permanent sealed connection between two strings of casing and cements them together in a single operation.

The dependable Hydraulic Wireline Jar utilizes a hydraulic system that permits controlled jarring in measuring line or stranded wireline operations when electrical continuity below the jar is not required.

This easy-to-service, hydraulic motor-driven 120-Ton Power Swivel provides smooth shock-free torque. It is rated to support tensile pipe loads of 120 tons at zero rpm and 65 tons dynamic load at 100 rpm. The compact swivel head design weighs only 2,000 lbs and fits many drilling or workover masts. A 2-3/4-inch bore gooseneck and washpipe assembly allows circulation through the 2-11/16-inch I.D. stem while rotating or in static mode.

The hydraulic motor-driven 85-Ton Power Swivel provides smooth shock-free torque. The compact swivel head design fits most drilling or workover masts and weighs only 1,163 lbs. It is rated to support tensile pipe loads of 85 tons at zero rpm and 45 tons dynamic load at 100 rpm. A 2-1/4-inch bore gooseneck and washpipe assembly allows circulation through the 2-inch I.D. stem while rotating or in static mode.

Arctic Weather 85-Ton and 120-Ton Power Swivels are enclosed in insulated, 20-foot metal containers. The containers have adjustable louvers to allow operation in warmer temperatures. Two bi-fold doors on one side and double doors at the back permit complete access.

The engine is equipped with an oil pan, coolant heaters, and an ambient air temperature sensor. The battery is enclosed in a lockable box and is equipped with a battery warmer.

The arctic weather package also features deicer injector to prevent them from icing. Fuel and hydraulic tank heaters, and a hydraulic powered hose reel. One of the back doors features a hose window for routing hoses out of the container. To retain heat, the hose window is fitted with rubber flaps and a metal door on separate skid that is pulled in and out of the container by a dual drum hydraulic winch.

6 Claims. (Cl. 294-102) This invention relates to iishing tools for oil wells and more particularly, but not by way of limitation, to a mechanically operated overshot for retrieving lost objects in drilled wells or the like.

Various apparatuses are being used throughout the oil industry for recovering lost fish, such as broken off drill pipe, sticker rods, drilling tools and other objects that may he dropped in the drilled well which must be removed before the drilling operation can proceed. However, none of the present devices, as far as is known, can release and re-engage the overshot with the ish by continneus movement in a right hand rotation without pulling the overshot tool and the fishing string from the Well bore. Furthermore, it is apparent that certain present day overshot devices can engage and release from a fish, but then must be pulled from the well if it is desired to re-engage the overshot with the lost fish.

The present invention provides an overshot for retrieving lost fish in a well bore which is always turned in a right hand motion either for releasing or reengaging the lost fish. The right hand rotation is desirable because the iishing string or drill pipe is joined together with right hand threads and any operation requiring a left hand rotation may have sufficient torque to provide for an unthreading of the tool joint connections of the drill pipe fishing string, whereupon the lower portion Would fall into the well bore and necessitate a further fishing job therefor.

The present invention provides a combination overshot having a control head maintained in operating position by a coil spring wherein the control head is designed so that any rotation of the overshot in a right hand motion will continuously provide for successive engagement of slip members carried by the control head and disengagement by release of the slip members with a further rotation. The rotation of the overshot to provide the successive engagement and release of the slip members with the fish is provided by applying a prenited States atent O determined weight on the overshot at the top of the Well.

A certain amount of pre-determined weight is applied to the overshot string to cause a disengagement of the biting Contact of the slips against the lost fish, and with a onequarter right hand rotation thereof maintains the slips in a released condition. An application of predetermined weight of lesser amount permits a continued right hand rotation of the control lugs in the control head slots to a position to effect a re-engagement of the slips with the lost fish. It will thus be seen that the release of the slips and the re-engagement thereof is with a con tinuous right hand rotation of the control lugs with respect to the control head in the overshot. This is very effective in the case of accidental release of the slips from the fish, the driller can take a right hand rotation on the fishing string and the overshot to bring the overshot back ly rotated in a right hand direction to eiect a milling operation of the top jagged edges of the fish or to straighten the fish up in the body of the overshot.

it is an important object of this invention to provide an overshot shing tool which may engage a lost sh in the drilled well, yet be released from the lost fish, and caused to re-engage it by a continuous right hand motion of the overshot.

A further object of this invention is to provide an overshot lishing tool for the drilling of oil wells which has an easy and positive connection for release and reengagement with the lost fish in the well bore.

An additional object of this invention is to provide an overshot fishing tool for oil well bores having Working parts which are not likely to be damaged and are so arranged and constructed as to provide positive contact with the fish, as well as positive release thereof and positive re-engagement.

And still another object of this invention is to provide an overshot fishing tool for oil well bores which is etiiciently packed oil below the slips and which also provides for milling off the top of the fish and prevent injury or damage to the packer, thereby eliminating an extra trip into the well bore to replace the working parts of the overshot.

And still another object of this invention is to provide an overshot fishing tool which is simple and efiicient in operation and particularly provides for easy engagement and release of the slips with the fish and yet prevents any possibility of unjointing the threaded connections of the drill pipe string supporting the overshot in the well bore.

Other objects and advantages of the invention will be evident from the following detailed description, read in conjunction with the accompanying drawings, which illustrate my invention.

Referring to the drawings in detail, reference character 2, designates the overshot apparatus generally which provides an upper head member 3 secured to the shing string of drill pipe in any suitable manner, preferably threaded. The head is provided with a cylindrical exension member 5 threaded at 6 to a lower cylindrical body or bowl member "7 acting as a main housing for the over shot proper. A control head d is disposed within the body "7 and has the upper portion thereof extending into the sleeve for purposes as will be hereinafter set forth. The lower end of the sleeve 5 acts as shoulders for anchoring one end of a helical spring 9 encircling the control head, wherein the opposite lower end of the spring 9 is anchored on shoulders itl provided by the circular fiange portion of the control head ti. The lower portion of the control head al is provided with a recessed portion il forming a lower shoulder l2 for the reception of a circular fiange portion i3 acting as a lug on each of the plurality of slips i4 (preferably three or four) held in ICC p suspension thereby on the control head. 8.

The slips are provided with serrated teeth for purposes as will be hereinafter set forth. Furthermore, the lowerrnost portion of the outer circumference of the slips is provided with a downwardly extending tapered portion 16 adapted to cooperate with a tapered portion 17 provided on the inner periphery of the body member 7 as is clearly shown in Figs. l, 2 and 3. Immediately below the tapered portion- 17 an inner projecting shoulder portion 128 is provided in the bowl 7. A rubber packing ring is disposed below the shoulder 18, which acts to restrict any vertical upward movement of the packingy ring 1"9 therein. A retaining ring 20 for the packer 1"9 isV held in position in the bowl 7 by a mill holder body member 21 threadedly secured at 22 to the lower portion of the bowl 7. The top of the mill body 21 restricts any downward movement of the packer ring 20. The -millbody 21 is threadedly engaged at 23 with the lower" guide member 24 of the overshot.

The mill body s provided with a cut-away portion 25 providing shoulders 26. A mill insert 27 is disposed in the cut-away 25 and restricted in its upward movement by the shoulders 26. The lower guide member 24 is provided with shoulders 29 restricting downward movement *of the mill insert 27. The lower portion of the guide 24 is cut away at 30 to provide for easy access of the fish 31 in-to the overshot, as will be hereinafter set forth.

Control head Referring to Figs. 4, 5 and 6 specifically setting forth the. structure of the control head, it will be apparent that this comprises a cylindrical member 8 having a pair of diametrically vertically disposed slot or .groove portions 34 extending substantially through half of the length of the control member 8. A horizontally disposed slot portion 35 connects with one side of one of the vertical slots 34- "(Fig. 6), while a second horizontal slot portion 36 connects with the other vertical slot 3.4 at the opposite side thereof, as is clearly shown in Fig. 6. The slots 35 `and 36 are interconnected by the groove 37 (Fig. 5) for purposes as Will be hereinafter set forth.. The passage- *way- 38--of the cylindrical. control head 8 is of sutiicient fdiarneter at 39.1totpermit entry of the iish 31 in a manner as will be hereinafter set forth.

The-extension sleeve 5 is provided with a pair of kiixed "diametri"callyopposedi lug members 40 normally adapted Operation In Operation, the overshot is lowered into the well bore (not shown) on the drill pipe string 4 until it makes a contact with the lost"iish 31 in the well bore, such as a broken off drill pipe or the like, and the fish 31 is directed through the guide"24 into the body of the overshot. As the overshot makes a contact it is rotated in a right hand direction so that the cut away portion 30 will assist the entry of the iish 31 into the overshot. As the overshot 2 moves vertically downward over the iish 31, the jagged edges 42 of the broken off top portion will contact the mill teeth 43 of the mill. insert 27, which with rotation of the overshot 2` mill off the jagged edges thereof, and thereby prevent any damage or injury to the rubber packing ring, which would necessitate replacement thereof.

Continued lowering of the overshot 2 over the iish 31 will bring the top thereof vinto contact with the slips 14, and since the control head 8 is free to movevertically a limited` distance within the body member 7, the slips and control head are moved upwardly by the force of the contacted fish, thereby disengagingV the outer taper 16 from seating relation with the taper 17 `of the body. This upward movement will cause expansion of the slips outwardly so that the fish 31 might enter therein and pass upwardly in the body 7 until it makes Contact with the upper mill teeth 44 provided in the passageway 39 of the control head 8. Lower teeth 45 are provided at the lowermost portion of the control head 8 (Fig. 2) to assist the upper teeth in holding the iish against rotation by contacting the upper "edge thereof.

As the fish 31 makes contact with the mill teeth 44, the force of this contact is felt by the operator at the surface of the well, whereupon the overshot is raised upward to bring the taper 17 simultaneously upward into contact with the outer taper 16 of the slips 14 causing the slips to move inwardly into biting engagement with the fish in the position shown in Fig. 2.

It will be apparent that during the upward movement of the overshot 2 that the helical spring 9 maintains a downward thrust on the control head 8 and engagement of they mill teeth 44 against the top of the iish 31 so that any" simultaneous downward movement of the control head is precluded, and the taper 17 upon contacting the taper 16 will move the teeth 15 of the slips 14 into biting engagement with the outer periphery of the sh 31. In this operation the lugs 40 on the extension sleeve 5l are disposed in the vertical slots 34 permitting the. upward telescoping movement of the body 7 relative. to` the control head 8. With the slips 14 in biting engagement with the fish: 31, any continued upward movement of the overshot will carry the fish 31 therewith unless the fish is stuck sufficiently in the bore to resist removal thereof. In such an instance, it may be desired to release the overshot from the fish 31 in order to take another bite at it.

In order to prevent any retrograde or left hand rotation of the overshot proper for the release action, thereby subjecting the drill" pipe string to possible unthreading at any of the tool joint sections, the release action of the slips from the fish 31 is provided by a continued right hand motion of the overshot. This is done by application of a pre-determined weight on the overshot string which causes the diametrically opposite lugs 4"0 to move vertically downward in the diametrically opposed, slots 34 until `brought into contact with the bottom wall-47" (Figs. 1 and" 6) this downward movement of overshot 2 causes the tension from the spring `9 to act against the control head to force the teeth 44 into biting engagement with the topof the iish 31. The teeth 44 in contact with the fish 31 preclude a rotating movement by they controlV head 8, so that when a quarter right yhand turnv motion is made with the overshot 2, the lugs 40 are permittedy to move into the groove 36 of the stationary control head 8. In this position, a slight upward movement of the overshot will allow the lugs to move vertically upward Ainto the groove 37" and abut against the top wall 48 of the slots 35"and 37 (Fig. 5), thereby the overshot is in a released condition and can be removed from the well if desired".

`In the event that the slips 14V are desired to be reengaged` with the sh 31 from this position, a predetermined weight of lesser amount than the original pre-determined weight is applied to the fishing string thereby movingthe lugs 40- away from contact with the top wall-48 of the slots 3S, 37, and" in this position the tension of the spring 9 causes the teeth 44 to engage the topof the sh 31 preventing rotation of the control head 8 whereuponv a further one-quarter right hand `turn will move Ithe lugs l40 .into .the second diametrically opposed slot 34 whereupon the lugs 40 are permitted to move Avertically upward therein to cause engagement of the slips through4 seating of the tapers 17 and 16 of the bowl 7 and siips.1"4 respectively. The amount of weight necessary to eiect the last operation is only enough to overcome the ftictional resistance due to the engagement of the ylugs .40 with the. topY wall 48 of the control "head slot "37; It will be apparent that the considerable weight of the fishing string and the overshot apparatus is bearing against the lugs to provide considerable frictional resistance, and in order to efficiently effect a right hand rotation of the body 7, this pre-determined weight is placed on the overshot string to overcome the frictional resistance and move the lugs 40 away from contact with the top wall 48.

lt will be apparent that vertical movement of the lugs 40 in the various slots, such as the operating slots 34 for engagement of the slips, or the releasing slots and 36 permitting disengagement of the slips, provides variable conditions on the helical spring 9 due to the anchoring of the extension sleeve S against the upper end thereof. However, the control head 8 is in substantially rigid position relative to the fish 31 and is maintained there by the tension of the helical spring 9 which is always bearing against the flanges l@ of the control head to eect this condition. The amount of spring tension may be variable relative to the position of the sleeve 5, nevertheless tension is always present to provide this downward thrust on the control head.

lt will thus be apparent that in case of accidental release ot` the slips from the fish, the driller can take a right hand turn on the fishing string, raise up very slowly until a pre-determined weight is indicated on the weight indicator (not shown) at the top of the well to position the lugs back into the slots 34 for re-engagement ot" the slips with the fish. Furthermore, during the milling operation of the top jagged edges of the fish, the overshot string is rotated in a right hand direction, and sometimes these jagged edges are quickly removed, and this factor plus the weight of the overshot and fishing string will cause the overshot to be released, particularly if during the rotation the lugs di) are positioned in the slots 34. However, it will be apparent that whether the overshot is purposely or accidentally released, it can be easily re-engaged with the fish by a continued right hand motion without any danger of unthreading the fishing string.

The packer ring i9 provides a seal around the outer periphery of the fish 3l when mud is pumped through the overshot by forcing the inside diameter of the ring i9 to close around and against the fish, thereby sealing ofi" any openings and assuring that all wasliings will be through the inner passageway of the cylindrical fish 3i and out through the bottom to provide a washing action directed at the bottom of the fish and thereby assist a stuck fish in becoming free.

From the foregoing, it is apparent that the present invention contemplates an overshot fishing tool for use in recovering lost fish elements in a well bore which may be easily engaged and disengaged with the fish and that the engagement and disengagement are both accomplished by a subsequent turning in a right hand direction in or ler to prevent any possibility of retrograde rotation of the fishing string and unthreading of any portions thereof. Furthermore, it will be apparent that the overshot fishing tool is provided with a novel control head permitting the uniform rotation of the overshot body to provide for the engagement or disengagement of lthe attaching members of the overshot from the lost fish without any retrograde movement whatsoever.

Changes may be made in the combination and arrangement of parts as heretofore set forth in the specification and shown in the drawings, it being understood that any modification in the precise embodiment of the invention may be made within the scope of the following claims without departing from the spirit of the invention.

l. ln an overshot fishing tool for retrieving broken ofi drill pipe and the like in a well bore comprising a sectional cylindrical body member adapted to be lowered over the pipe, a control head carried in the body member, a plurality of serrated slips carried thereby, a tapered portion provided in the body member cooperatping engagement of the slips with the broken drill pipe, a helical spring anchored between a shoulder of the control head and the body member for urging the control member into substantially rigid contact with the broken drill pipe disposed therein, a plurality of diametrically opposed lugs provided in the body, a plurality of diametrically opposed vertical slots provided in the control head, for telescopic reception of the lugs, a peripheral slot provided in the control head and communicating with the diametrically opposed vertical slots to provide for movement of the lugs therethrough and facilitate engagement and release of the overshot tool with the broken pipe by a continuous rotation in the same direction.

2. ln an overshot iishing tool for removing broken off drill pipe and the like from oil well bores comprising a cylindrical body adapted to be lowered over the pipe, a control head disposed in the body, a plurality" of serrated slips carried by the control head, cooperating taper means between the slips and the body to eiect a gripping engagement of the slips with the drill pipe, a plurality of longitudinal groves provided in the control head, a plurality of lugs provided in the body and cooperating with the grooves to provide longitudinal movement between the body and the control head, said lugs responsive to a pre-determined weight for movement in the grooves to disengage the tapering means and release the slips from the pipe, a horizontal groove provided in the control head and disposed conterminous with the bottom of the vertical grooves and responsive to a right hand rotation of the body relative to the control head to move the lugs from the vertical groove into the lowermost horizontal groove for maintaining a release of the slips with the pipe.

3. in an overshot iishing tool for removing broken oft" drill pipe and the like from oil well bores comprising a cylindrical body adapted to be lowered over the pipe, a control head disposed in the body, a plurality of serrated slips carried by the control head, cooperating taper means between the slips and the body to effect a gripping engagement of the slips with the drill pipe, a plurality ot longitudinal slots provided in the control head, a plurality of lugs provided in the body and cooperating with the slots to provide longitudinal movement between the body and the control head, said lugs responsive to a pre-determined weight for movement in the slots to disengage the tapering means and release the slips from the pipe, means in the control head cooperating with the lugs to provide a continuous right hand rotation ot the body relative to the control head for rca-engagement of the slips with the pipe, said means being a horizontal slot provided in the control head and disposed conterminous with the bottom of the vertical siot to move the lugs from the vertical slot into the lowermost horizontal slot for maintaining a release of the slips with the pipe, a second horizontal slot in the control head disposed above the first mentioned horizontal slot and communicating therewith, said lugs responsive to a decrease in the pre-determined weight to be moved vertically upward from the first .mentioned holizontal slot to the top of the second mentioned horizontal slot to provide for continuous right hand rotation of the body relative to the head for effecting 1re-engagement of the slips with the pipe.

4. ln a combination release overshot and control head utilized for retrieving lost fish in a well bore including a cylindrical body disposed over the fish, a control head movably disposed in the upper portion of the body, a helical spring anchored between the body and a shoulder of the control head for urging the control head constantly in one direction, a plurality of slip members carried by the head, taper means provided between the body member and the slips for moving the slips in one direction to provide engagement of the slips with the ing with a tapered portion on the slips to elect a gripdrill pipe, a plurality of diametrically opposed grooves provided in lthe head, a pair of diametrically opposed lugs provided in the body cooperating with the grooves to provide longitudinal movement between the body and the headfsaidtapering means responsive to one position of the vlugs in the grooves to cause engagement of the slips with the lost fish, and in another position of the lugs in the grooves to provide for release of the slips with the fish, a pair of vertically spaced connecting horizontally .disposed slots provided in the head between the opposed grooves, said horizontal slots providing for disposition .of `the lugs from the grooves into the slots after release of the slips from the lish, said lugs so disposed in the slots responsive to a right hand rotation of the body member for movement through the slots for reinsertion into the grooves.

5. In an overshot fishing tool for removing broken drill pipe and the like. from oil well bores comprising a cylindrical body to be lowered over the pipe, a control heady disposed in the body, a plurality of serrated slips carried by the control head, cooperating taper means between the slips and the body to effect a gripping engagement ofA the slips with the drill pipe, a plurality of longitudin-al slots provided. in the control head, a plurality of lugs provided in the body and cooperating with the slots to provide longitudinal movement between the body and the control head, a peripheral slot provided in the control head having portions thereof disposed at spaced vertical planes, said peripheral slot communicating with the longitudinal slots, said lugs responsive to a predetermined weight for movement into the peripheral slot providing disengagement of the slips from the pipe, and

6, in an overshot fishing tool for removing broken drill pipe and the like from oil well bores comprising a cylindrical body to be lowered over the pipe, a movable control head disposed in the body, gripping means carried by the control head, taper means between the gripping means and the body to provide for engagement of the gripping means with the pipe, a pair of diametrically opposed lugs provided on the body and cooperating with the slots to provide longitudinal movement between the body and the control head, said lugs in one position of the slots providing for seating the taper means causing engagement of the gripping means with the drill pipe, and responsive to a predetermined weight moving the lugs to a lower position in the slots to disengage the taper means and release the gripping means from the pipe, and a peripheral slot disposed in the control head and having portions thereof disposed at spaced vertical planes and cooperating with the first mentioned longitudinal slots in response to a right hand rotation of the body member in relation to the control head to move the lugs therethrough.

Tianhe Oil Group Co. Ltd. is a global group. We are specialized in the production of drilling tools, including R&D, production, selling, leasing, maintenance and services. Tianhe has 5 main businesses spread across the globe in more than 50 countries in the world.

Tianhe Oil Group management prioritize its people, technology, continuous improvement and building brand awareness. Our mission is to continuously strive innovation and improvement and expand our business in the oilfield. We increased the investment in technology research and development, always looking to provide our global customers with the best technical products and services.

Tianhe Oil Group strongly believes and promotes Total Quality Management, implements the ISO quality management system, HSE management system and API standards. Our manufacturing facilities are well equipped with four automated induction heat treatment lines and dozens of other types of heat treatment ovens and well furnaces (Box type, well type, carburizing heat treatment furnace) to ensure full coverage of heat treatment required by the different products.

So far, Tianhe Oil Group has established strong business relationships with over 200 international oil & gas companies in supporting the top 50 oil producing countries. For example, we have partnered with Schlumberger, Halliburton, Baker Hughes, Weatherford, Shell, NOV, etc.

Dropping stuff into a well, or worse, a person or animal falling into a well is a problem as old as mankind and wells.[See Luke 14:5 and Matthew 12:11.]

And I know about this "Honey I dropped the Pump" problem too, and haven"t added a full article on retrieving stuff from water wells at InspectAPedia because of lack of photos of the array of in-well-stuff grabbing tools, and also because I don"t think most homeowners will have much luck retrieving stuff that has fallen into their well on their own.

First off, it sounds like a horrible problem when a well pipe breaks and we drop stuff into the well. But don"t panic. You have to figure that you"re not the first people to have such bad luck - and it happens most often to well drillers not homeowners.

Because it does happen, just about every well driller and most plumbers who work on wells have a collection of grabbing devices, some of them home made, that can be lowered into the well to grapple around and grab on to the upper end of what now sits deep down in the well casing. It may take a few trials, but eventually they get stuff out by that method.

In that case the rigger brings in a truck or a portable winch system that includes a powered well pipe pulling mechanism that can handle the weight.

Certainly that device is used when, during the well pipe and pump pulling process, the operator has to stop to remove vertical lengths of well piping. Otherwise we"d have many feet of pipe sticking up in the air - creating another problem.

Then, trusting the clamp, the upper length of well piping is removed, the winch pulling connection is made to the newly exposed top of well piping just above the clamp, and the process continues.

You can infer from all of this, that in your case the bottom line is you"ll need to call your local well driller/well installer who should have the winch equipment as well as a clamping system to both grab and retrieve the top of the broken well piping as well as to pull it out without further catastrophes.

Magnets or junk magnets, are sometimes used to retrieve smaller metal objects that have fallen into a well; it"s doubtful that a magnet could pull a steel well pipe however. In the oil and gas industry junk magnets are run into a well ahead of a diamond drilling tool in order to remove metal junk that can damage the drilling bit.

Overshoots or Overshots are fishing devices that fit over the exterior of the well pipe and then grab onto the well pipe exterior to enable lifting the pipe.

Logan Oil Tools calls these "external catch" devices. [12] The overshot may be a metal mesh device, or a spiral device, one or more round or oval loops, or similar devices that grab on to the pipe exterior. The overshot was invented by Bowen in 1935.

Reamers: are devices used to ream out collapsed well casings in the oil and gas industry; [11] and those clever folks also use an impression block to figure out the shape of whatever it is that has fallen into the well if they don"t already know. [12]

Spears or releasing spears for well fishing are fishing devices that are inserted into the interior bore of a well pipe and then grab onto the interior sides of the pipe.

Logan Oil Tools calls devices of this sort "internal catch" devices.[12] Releasing spears include design features that can when appropriate release the "caught" pipe or component. Spearing tools are used to retrieve piping from a well when it cannot be grasped with an external catch tool.

See WELL FISH TOOL & CAMERA SOURCES at the end of this article for manufacturers of well retrieval tools, well pipe retrievers, well pump retrievers, specialty well repair tools, and for patented designs that suggest home made well pipe retrieval tools.

Boot baskets are used in oil and gas drilling to catch debris below the bit that are too heavy to be circulated out of the bore hole during the drilling procedure.

Cameras, Well-Bore Inspection - a well bore inspection camera can be lowered into the well to give a better understanding of exactly where your dropped obstruction lies and how to grapple-it.

Well bore inspection cameras can give a down view or side view or both simultaneously to identify and help retrieve obstructions, as well as to inspect the condition of the well bore and well casing.

Die Collars - used to retrieve a lost well pipe, the die collar is a coupling lowered over the lost pipe; the gas or oil version may not be easily workable for a plastic water well pipe; see our "double bite metal loop" pipe retriever discussed below.

Grinders: in the oil and gas industry a "junk mill" is sent into the well to try to grind up smaller junk that has fallen into the well. The Junk mill works with a boot basket to retrieve the ground up stuff - if it works. This probably won"t help with water well troubles.[11]

Spears - are expanding devices inserted into the interior of the lost pipe. Pulling on a line attached to the spear (along with mechanical design of the spear) or turning it expand the spear inside the lost pipe.

Junk Mill Bits - also referred to as bladed junk mills, cement mills, taper mills, pilot mills, and similar but more heavy-duty conebuster mills, are used in the oil and gas industry to literally drill-through plugs, packers, cement, or stuff dropped into a well

Store bought or home made single or double bite metal loop well pipe retriever: some well pipes can be successfully retrieved by fabricating a flexible pair of metal rings with squared or sharp edges connected and hinged to a rod that is in turn connected to the bottom of a working pipe long enough to reach down to the top of your well pipe in the well. When the pair of metal rings slip over the exposed upper end of the well pipe, push the assembly a few feet further down over the pipe.

If you"ve got your design right (test it above ground first) when you pull up on the assembly the rings will hinge to an angle that will "bite" onto the vertical pipe in the well and allow you to pull the assembly back out.

A rope with a large sharp edged "washer" or any other round object that can be dropped over the well pipe can do this same job. Some technicians call this assembly a cam cleat but more often that"s a nautical device for halyards and one that doesn"t work in this application.

Box Tap / Die Collar, used to retrieve tubular fish tools that can"t be rotated. This is a special type of overshoot used to connect to the top of tubing or piing. See Overshoots below. Produced by Schlaumberger and others.

I"m doubtful this tool is able to grab a round well pipe (the maximum length is about six feet and the end looks like suction cups) but the company may have tool ends that can be adapted for that purpose.

Elevators: Well pipe grapplers, well pipe elevators, or well pipe grabbers that will grab onto plastic pipe or iron pipe down inside of a well casing are sometimes home made based on designs such as the items listed above. Shown above are a pair of (green) well pipe elevators, and below, a pair (red) casing lifters provided by Hole Products.

The Hole Products company explains that standard duty SD pipe elevators are used for lifting threaded or coupled pipe: the lifter slides against the bottom side of a pipe coupling, while the company"s HD pipe elevators are used for well casing installation, setting well screens and pulling pump columns.

Expanding rubber plug pipe retriever: a home-made stack of rubber plugs placed over a threaded rod can, if your well pipe is not too deep in the well, be pushed into the top end of the pipe in the well.

The down-end of your threaded rod is locked onto a washer and nut and rubber plug just small enough to force into the upper end of the pipe in the well.

If you can stab that plug into the well pipe you then tighten the upper end of the treaded rod (a nut and washer will do) until you"ve expanded the rubber plug enough to grab onto and lift the in-well pipe.

Pipes in oil and gas drilling become stuck in wells differently from what happens in a drilled water-well or borehole well, but some of the tools developed for the oil and gas industry may also benefit the water well drilling and well retrival tool industry.

Well pipes that fall into a water well borehole may become mechanically stuck, or corrosion in some cases may cause separation of metal well pipe sections or the dropping of a pump and pipe section down into the well. On occasion, a section of steel well casing itself may corrode and fall into the well as may a poorly-installed well casing repair sleeve.

After obtaining an estimate of the free point by using the pipe stretch estimate technique, the traditional freepoint tool is run in the hole to 1000 feet above the estimated stuck point. The tool is anchored in place. Stretch and or torque is then applied to the pipe.

The tool is then run roughly 500 feet past the estimated stuck point. Stretch and torque are applied, and readings are taken. If the tool indicates that the pipe is stuck at that point the tool is pulled uphole and readings are taken again.

The tool is then pulled uphole logging the entire string. The tool will detect differences in the magnetization of the pipe, thereby indicating free and stuck sections of pipe. - Wikipedia, retrieved 2016/05/31, original source: https://en.wikipedia.org/wiki/Pipe_recovery_operations

Hooking onto existing fittings on the well pipe in the well: if the length of pipe that fell into the well includes couplings or a pitless adapter fitting, often any small grappling hook and line can grab onto the edge of that protrusion and pull the assembly out of the well.

Pull slowly and smoothly and as soon as you can mechanically grab the end of the lost pipe as it emerges from the well, do so. The pipe tongs shown below, provided by Hole Products (cited below) are used to grip pipe for hoisting; this tool will automatically release the pipe when tension is released on the lift line.

Magnets for use in a well bore: Hole Products and other well service companies produce powerful magnets that can be lowered into a well to retrieve tools or metal pieces of irregular shape that have fallen into a well and that can"t be grabbed by other tools shown here.

I"m a little nervous about this approach because if the attempt fails and you leave the hook and a section of line in the well you"ve added to the mess that needs to be pulled out of the well.

Overshot mesh well pipe or item retrievers for fishing stuff out of a well: the most effective tools we know about for pulling lost well pipes out of a drilled well are various versions of overshots. Overshots, an "overshoot" type tool, are a bit easier to get over the outside of a well pipe than spear type tools are to get into the well pipe, unless the upper end of the pipe is near the top of the well.

Some supplies use the term "recovery bell" for overshots. The overshot is a cylindrical or conical shaped (bell shaped) device lowered over the upper end of a pipe to be retrieved from a well. Some companies (Schlumberger) produce a releasing overshot or overshots used for jarring or stuck material backoff operations.

The overshot is lowered over the end of the pipe in the well. If there is enough friction around the object the braided sleeve will contract and grab the object when the line is pulled up - like that braided rush "chinese finger trap" trick we played with as kids.

The overshot is attached to the end of a drilling rod or in the water well industry to the end of a section of well piping that is lowerd into the bore hole.

Some overshots include hardened self-cutting threads that will grab onto the upper end of a well pipe that has been dropped into the well borehole, thus allowing the pipe to be retrieved.

Pin Tap / Screw-In Sub taps are used to retrieve a tubular fishing tool or pipe from a well when it is cannot be rotated. Basically this is similar to a "screw extractor" that is reverse-threaded to be turned into a seized bolt, screw, or in this case pipe or fishing tubular tool that cannot be turned or rotated in its normal direction. Produced by Schlumberger and perhaps others. Also see Taper Tap.

PVC glue-on well pipe retrieval: some report success by lowering a new section of PVC pipe down into the well onto the lower end of which has been cemen

8613371530291

8613371530291