overshot oil and gas quotation

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

Tianhe Oil Group Co. Ltd. is a global group. We are specialized in the production of drilling tools, including R&D, production, selling, leasing, maintenance and services. Tianhe has 5 main businesses spread across the globe in more than 50 countries in the world.

Tianhe Oil Group management prioritize its people, technology, continuous improvement and building brand awareness. Our mission is to continuously strive innovation and improvement and expand our business in the oilfield. We increased the investment in technology research and development, always looking to provide our global customers with the best technical products and services.

Tianhe Oil Group strongly believes and promotes Total Quality Management, implements the ISO quality management system, HSE management system and API standards. Our manufacturing facilities are well equipped with four automated induction heat treatment lines and dozens of other types of heat treatment ovens and well furnaces (Box type, well type, carburizing heat treatment furnace) to ensure full coverage of heat treatment required by the different products.

So far, Tianhe Oil Group has established strong business relationships with over 200 international oil & gas companies in supporting the top 50 oil producing countries. For example, we have partnered with Schlumberger, Halliburton, Baker Hughes, Weatherford, Shell, NOV, etc.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

You are viewing Bowen or Logan Overshots for sale by Pickett Oilfield, LLC. We have an extensive range of good used or rebuilt Overshots along with the accessories. Call us for your fishing tool needs. For more information contact us by phone at sales@pickettoilfield.com.

PickettOilfield.com offers prospective buyers an extensive selection of quality new, used, and refurbished Oilfield Equipment at competitive prices, including Overshots.

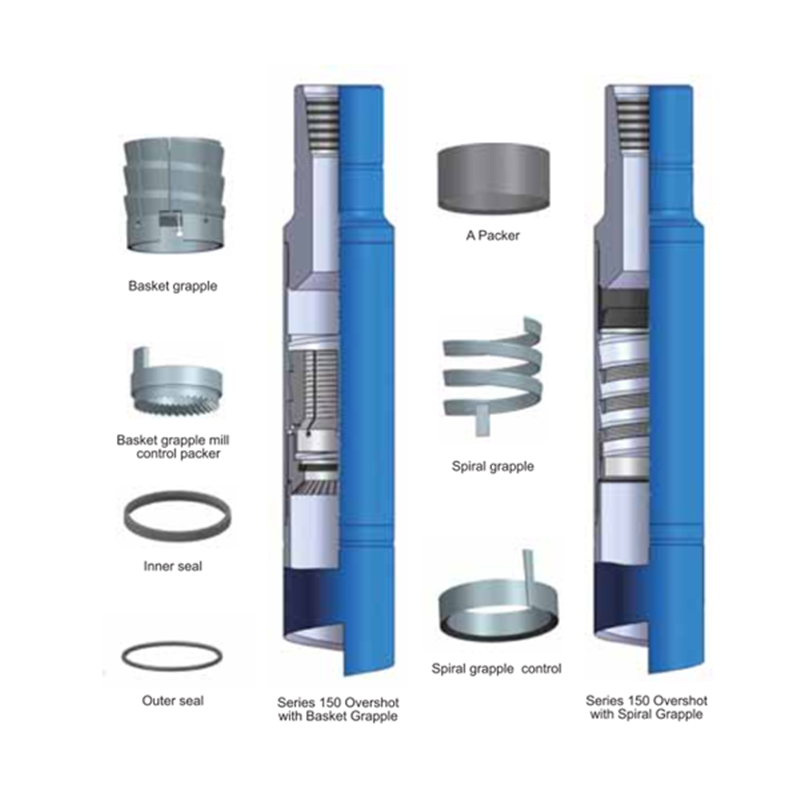

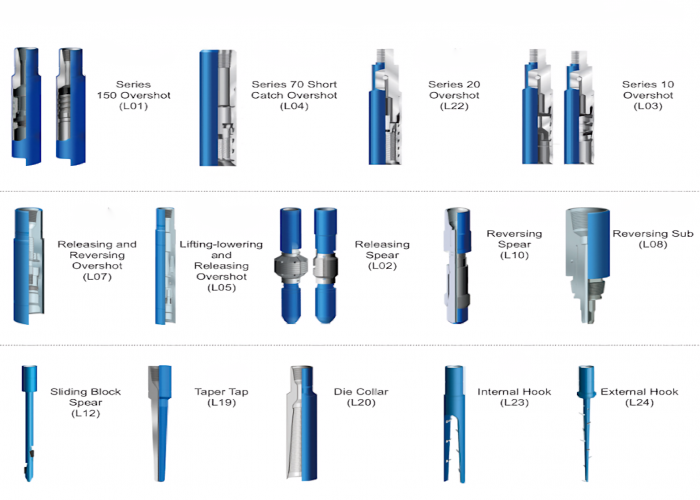

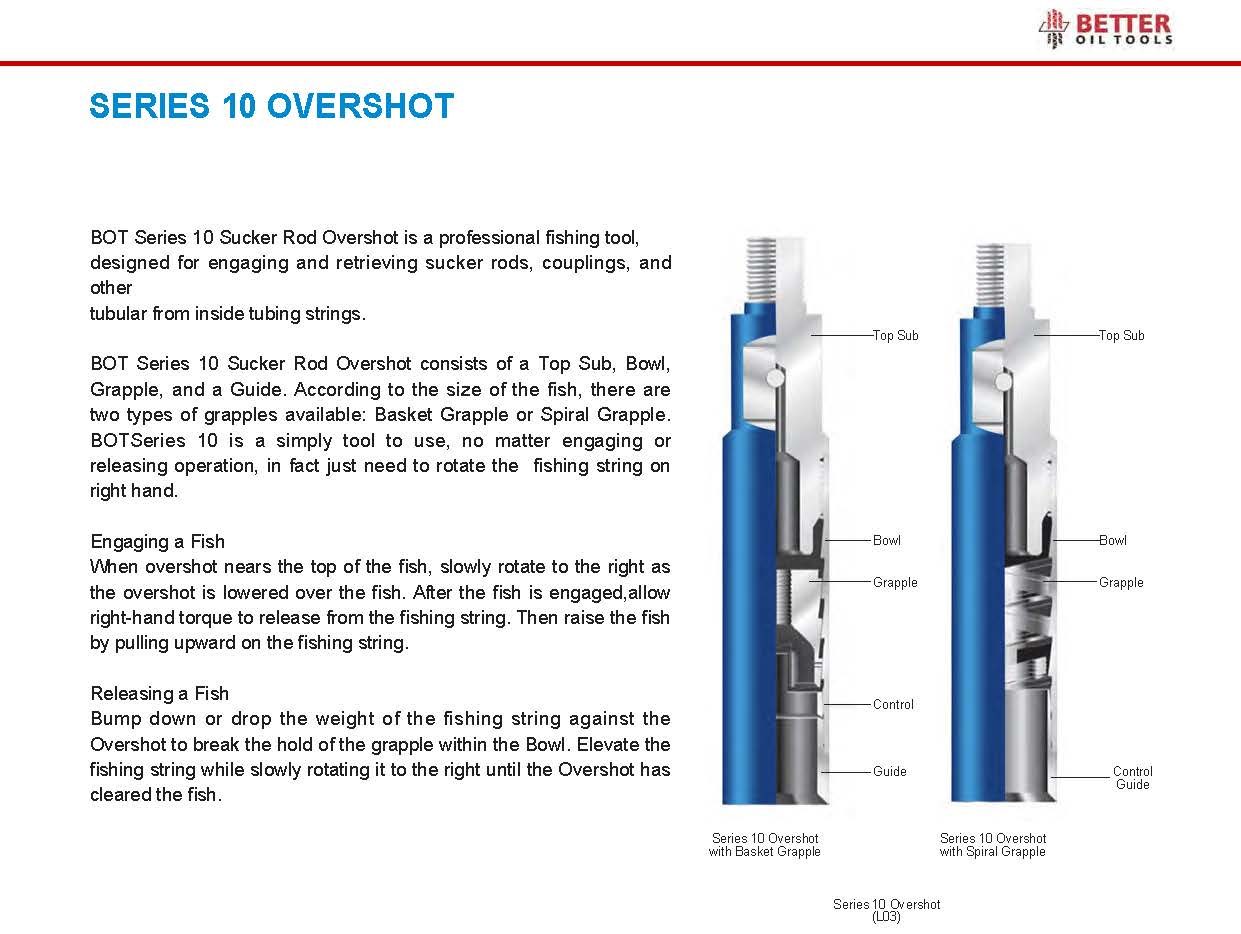

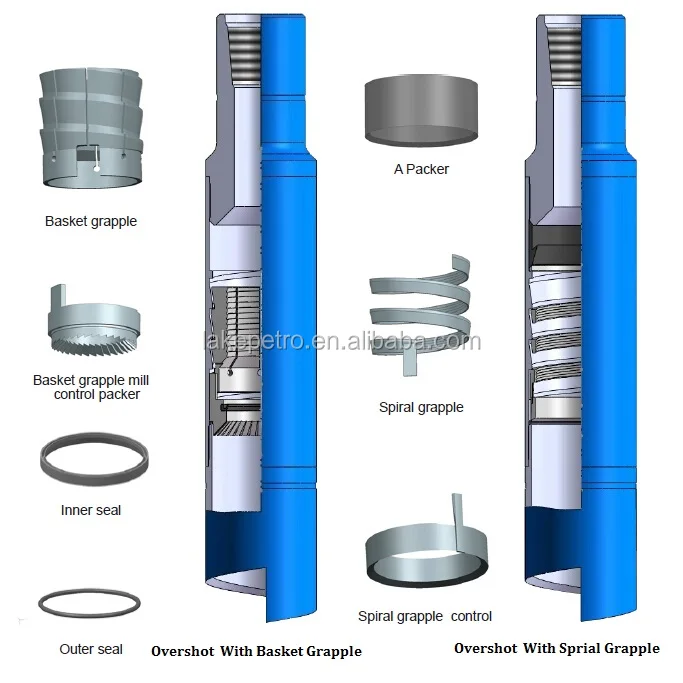

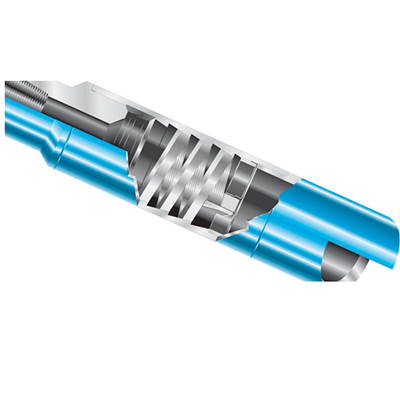

Overshots are a tool used on the downhole process during the fishing operations. It engages the tube or tool on the outside surface. A Grapple or other piece of equipment that is similar attaches onto the overshot and grabs the fish.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Oil and gas drilling and processing operations rely on the leak-free transfer of hydrocarbons, drilling muds, and other process fluids to optimize operating costs and minimize environmental impact. Drilling operators and service contractors require easy to use, adjust, and maintain process fluid transport piping systems as well as rapid erection, reliable drill through conductor, casing, and riser stacks.

Much of the complexity, time, and cost involved in the process ultimately comes down to the connections between piping and tubular assemblies. Mechanical Research & Design, Inc. offers several different rugged oilfield connector products that have been proven in the field over the last several decades to mitigate many of these concerns.

• Most of our connectors come in a variety of materials and meet H2S and API® 6A/16A/16F drill through and maritime riser requirements, API® 64 well control requirements, offshore drilling riser coating requirements, cold temperature drilling requirements, and can include Design Verification Reports from DNV®, ABS®, Lloyds®, or many other independent third-party certification bodies.

• Most drilling contractors prefer multiple seal configurations using our durable SEALFAST® inflatable or mechanical seals, which minimize down-time during drilling programs and minimize the chance of environmental spills (HNBR, NBR, and FKM elastomers available).

• Easy to change out and low maintenance – proprietary designs include removable inserts and plates for minimal service-time. Bolt-on and weld-on interface versions are available.

• Design pressure ratings vary from 10 PSIG for some bell nipple overshot seal housings, to 2000 PSIG for higher pressure-rated diverter overshot packers.

Primarily found on fixed base, jack-up, and other permanent offshore production oil platforms (particularly those with bell nipple systems), these single or multi-seal housings and connectors are typically de-actuated when running riser and conductor joints. The seals are then inflated/actuated once the stack is leveled and set to height. They are then used as mud containment seal housings. Due to the simplicity of the heavy profile inflatable seal cross-section, these housings offer quick height adjustments, eccentric stack-up allowance, and angular misalignment tolerance far exceeding most conventional connector systems.

These housings can be mounted under the drill floor or to under-deck structural beams, can integrate a full mud pan, as well as other process and flow lines necessary for managing mud elevations and quality during returns. These units are also ideal for use as weld or bolt-on adjustable low-pressure riser seal housings and diverter overshot seal housings. They allow rapid height adjustment during diverter change-out

• Bell Nipple Overshot Seal Housings: General drilling mud collection and containment housings with integral mud pan; bleed, fill, trip, flow, and swarf lines/nozzles available upon request.

• Diverter Overshot Packer Seal Housings: quick and easy installation and actuation for high-pressure applications – can have integral flow lines to act as a t-spool for diverter stacks.

• Telescoping LP Riser Seal Housings: Best for use with telescoping low-pressure riser systems that require flexible height adjustment and large angular make-up requirements. Often referred to as telescoping riser seal housings or packer seal housings.

These dynamic seal housings are often found on floating production oil rigs, barges, and on drillships. They are commonly paired up with our inflatable spherical packers on KFDS diverter systems or as conductor unions, allowing for the drilling stack to accommodate vertical displacement from standard wave and tidal action, as well as ocean swells. These units come with low-friction mandrels and specially formulated “wear rings” for maximum life.

Our inflatable and mechanical slip joint assemblies also come with all of the flexibility and adjustability that our static housings offer making them ideal for clients who want to set the drilling stack with ease and forget it.

Often used as an alternative to reducing mandrel spools in bell nipple systems, our SEALFAST® Inflatable and Mechanical drop-in reducers give clients another way to manage various riser and conductor sizes needed for the multiple diverters and BOP stacks needed in some drilling programs. These units are a flexible solution to quickly reduce conductor, and riser sizes while maintaining full drill-through capability. These units can be designed for full hang-off and nozzle loads for the drill stack and can be paired with a mud box or housing that interfaces to the rig floor or underfloor structure.

Available in a wide array of sizes and pressures, our housings can be used laterally, vertically, or on inclines. These units come with and without integral mechanical restraint for full nozzle load requirements. Our new, cutting edge, inflatable and spherical seal housing packers allow for the ultimate flexibility for your mud transport, drill through, or flow line requirements.

• Redundancy – Most of our connectors can be designed for single or multiple seals, offering redundancy for safety and environmental controls while minimizing downtime during drilling programs. Our most popular options are two and three seal housings, and some of our designs do not require a halt in production to replace seals!

• Adjustability – Save time with adjustable riser and conductor systems by using our SEALFAST® inflatable seal housings. These housings can be used for static linear adjustments in riser systems for up to several feet/meters make-up. Our seals are also often utilized as dynamic sealing solutions as conductor unions or slip joints on floating rigs.

• Flexibility – Allows for maximum angular misalignment and eccentricity in stack-ups in conductor casing and drilling risers due to stack-up or rig tilt.

• Reliability – We formulate special elastomer compounds engineered for use with highly corrosive drilling fluids, H2S environments, and industry-leading maximum temperatures, coupling them with rugged, heavy wall, low-stress design seal profiles.

• Ease of Maintenance – Save time and money changing over to a SEALFAST® seal and avoid costly and hard to source hydraulic components found in our competitor’s products. No special tools are required to change out our inflatable seals and have been perfected for maximum ease of removal with our proprietary designs.

In the modern era of oil & gas production, oil companies, drilling contractors, and drilling equipment providers have been focusing more than ever on optimizing drilling and production processes. Most of these improvements focus on cost efficiency, reduced process turnover time, safety, and meeting the ever-increasing levels of environmental controls mandated by statutory and regulatory bodies. Today’s tooling requires reliable operation in the harshest climates, seismic design, resistance to sour gas, as well as ever-increasing temperature and pressure ranges.

Mechanical Research & Design, Inc. specializes in a wide variety of oil & gas drilling and production tooling, from weld and bolt on seal housings to complete design-build drilling stack solutions. We specialize in pressure rated, industry certified, drill through and well control solutions as well as the ancillary structural equipment that supports these product solutions. Our products can be found on and offshore all around the globe supporting land-rigs, offshore platforms, and drill ships. We began by designing and manufacturing mud containment seal housings over 20 years ago and most of our equipment is still in operation, providing maximum flexibility, adjustability, and reliability for decades yet to come.

Mechanical Research & Design, Inc. prides itself on rapid engineering and manufacturing response from custom design adaptations to conventional drilling stacks and systems, and including rapid certification turn-around. Our staff is trained and experienced in the design and fabrication of many offshore drill plant solutions from the drill floor through down hole tooling. We provide an expansive array of drill through stacks and equipment utilizing our SEALFAST® Sealing Connectors; lifting and handling equipment; stack up and make-up platforms for dual purpose; well control equipment support structures; and a host of other customized tools you won’t find anywhere else in one location.

By utilizing our time-tested SEALFAST® inflatable and mechanical seals and packers, we are able to offer many flexible and configurable drilling stack solutions. Our products allow users to adjust for the height, angular alignment, and eccentricities in the drilling stack with unparalleled speed and efficiency. Our, fixed, telescoping, and spherical adjustment riser and mud flow line systems can be designed to accommodate down hole pressures from 5-2000 psig pressure ratings, with process mud temperatures of up to 300° F. Our active sealing technology continues to provide optimal sealing on mandrels and reducing faces, even if they corrode and wear over time, leading to lower maintenance costs

Mechanical Research & Design, Inc. designs and manufactures an assortment of fully certified Diverter and BOP support, restraint, lift, and storage equipment. Most units come certified for offshore portable equipment lifting and can include rated tie-down to deck structural steel for divert and upthrust events. Units can be adapted for integral nozzle load restraint for mud flow lines and safety rated work platforms. These frames are also used as make-up and load-rated hang-off platforms for surface drilling stacks.

Drilling riser and conductor make-up, hang-off, and stack-up support frames and modules are critical to drilling operations. We fabricate modular deck-slot frames rated to API® structural codes and for use in seismic zones, integrating to existing structural steel for weight and upthrust load transmission. Many of these frames can support dual operations such as lift/lower operations, conductor string cement verification, and manual to automated riser centralizer solutions. In addition to this, Mechanical Research & Design, Inc. provides hydraulic lifting and running tools, split handling clamps and spiders, and through bore access covers for safety. Most of these units can also carry Lloyd’s®, DNV®, or ABS® certifications.

We also design and manufacture an assortment of controls, enclosures, and hose management equipment solutions for offshore use. From ASME® certified pneumatic and hydraulic control panels to CSA®, UL®, and Atex® Hazloc Electrical Panels, we can provide most customized options for low and high pressure maintenance and monitoring for offshore portable or fixed location use. To support our panels, we provide manual and automated hose management systems and fire-rated umbilicals with API® certifications.

No matter your specific application within the oil and gas industry, Mechanical Research & Design, Inc. can meet your needs with a combination of specialized product lines and specialized applications of standard products. We feature a wide range of standard products ideal for use both on and offshore, such as our weld testing and isolation repair solutions. In addition to the oil and gas sector, our solutions can be found in nearly any industry that requires sealing, pressure testing, isolation, packaging, or part handling. We can customize most of our standard solutions to fit any unique need.

6 Claims. (Cl. 294-102) This invention relates to iishing tools for oil wells and more particularly, but not by way of limitation, to a mechanically operated overshot for retrieving lost objects in drilled wells or the like.

Various apparatuses are being used throughout the oil industry for recovering lost fish, such as broken off drill pipe, sticker rods, drilling tools and other objects that may he dropped in the drilled well which must be removed before the drilling operation can proceed. However, none of the present devices, as far as is known, can release and re-engage the overshot with the ish by continneus movement in a right hand rotation without pulling the overshot tool and the fishing string from the Well bore. Furthermore, it is apparent that certain present day overshot devices can engage and release from a fish, but then must be pulled from the well if it is desired to re-engage the overshot with the lost fish.

The present invention provides an overshot for retrieving lost fish in a well bore which is always turned in a right hand motion either for releasing or reengaging the lost fish. The right hand rotation is desirable because the iishing string or drill pipe is joined together with right hand threads and any operation requiring a left hand rotation may have sufficient torque to provide for an unthreading of the tool joint connections of the drill pipe fishing string, whereupon the lower portion Would fall into the well bore and necessitate a further fishing job therefor.

The present invention provides a combination overshot having a control head maintained in operating position by a coil spring wherein the control head is designed so that any rotation of the overshot in a right hand motion will continuously provide for successive engagement of slip members carried by the control head and disengagement by release of the slip members with a further rotation. The rotation of the overshot to provide the successive engagement and release of the slip members with the fish is provided by applying a prenited States atent O determined weight on the overshot at the top of the Well.

A certain amount of pre-determined weight is applied to the overshot string to cause a disengagement of the biting Contact of the slips against the lost fish, and with a onequarter right hand rotation thereof maintains the slips in a released condition. An application of predetermined weight of lesser amount permits a continued right hand rotation of the control lugs in the control head slots to a position to effect a re-engagement of the slips with the lost fish. It will thus be seen that the release of the slips and the re-engagement thereof is with a con tinuous right hand rotation of the control lugs with respect to the control head in the overshot. This is very effective in the case of accidental release of the slips from the fish, the driller can take a right hand rotation on the fishing string and the overshot to bring the overshot back ly rotated in a right hand direction to eiect a milling operation of the top jagged edges of the fish or to straighten the fish up in the body of the overshot.

it is an important object of this invention to provide an overshot shing tool which may engage a lost sh in the drilled well, yet be released from the lost fish, and caused to re-engage it by a continuous right hand motion of the overshot.

A further object of this invention is to provide an overshot lishing tool for the drilling of oil wells which has an easy and positive connection for release and reengagement with the lost fish in the well bore.

An additional object of this invention is to provide an overshot fishing tool for oil well bores having Working parts which are not likely to be damaged and are so arranged and constructed as to provide positive contact with the fish, as well as positive release thereof and positive re-engagement.

And still another object of this invention is to provide an overshot fishing tool for oil well bores which is etiiciently packed oil below the slips and which also provides for milling off the top of the fish and prevent injury or damage to the packer, thereby eliminating an extra trip into the well bore to replace the working parts of the overshot.

And still another object of this invention is to provide an overshot fishing tool which is simple and efiicient in operation and particularly provides for easy engagement and release of the slips with the fish and yet prevents any possibility of unjointing the threaded connections of the drill pipe string supporting the overshot in the well bore.

Other objects and advantages of the invention will be evident from the following detailed description, read in conjunction with the accompanying drawings, which illustrate my invention.

Referring to the drawings in detail, reference character 2, designates the overshot apparatus generally which provides an upper head member 3 secured to the shing string of drill pipe in any suitable manner, preferably threaded. The head is provided with a cylindrical exension member 5 threaded at 6 to a lower cylindrical body or bowl member "7 acting as a main housing for the over shot proper. A control head d is disposed within the body "7 and has the upper portion thereof extending into the sleeve for purposes as will be hereinafter set forth. The lower end of the sleeve 5 acts as shoulders for anchoring one end of a helical spring 9 encircling the control head, wherein the opposite lower end of the spring 9 is anchored on shoulders itl provided by the circular fiange portion of the control head ti. The lower portion of the control head al is provided with a recessed portion il forming a lower shoulder l2 for the reception of a circular fiange portion i3 acting as a lug on each of the plurality of slips i4 (preferably three or four) held in ICC p suspension thereby on the control head. 8.

The slips are provided with serrated teeth for purposes as will be hereinafter set forth. Furthermore, the lowerrnost portion of the outer circumference of the slips is provided with a downwardly extending tapered portion 16 adapted to cooperate with a tapered portion 17 provided on the inner periphery of the body member 7 as is clearly shown in Figs. l, 2 and 3. Immediately below the tapered portion- 17 an inner projecting shoulder portion 128 is provided in the bowl 7. A rubber packing ring is disposed below the shoulder 18, which acts to restrict any vertical upward movement of the packingy ring 1"9 therein. A retaining ring 20 for the packer 1"9 isV held in position in the bowl 7 by a mill holder body member 21 threadedly secured at 22 to the lower portion of the bowl 7. The top of the mill body 21 restricts any downward movement of the packer ring 20. The -millbody 21 is threadedly engaged at 23 with the lower" guide member 24 of the overshot.

The mill body s provided with a cut-away portion 25 providing shoulders 26. A mill insert 27 is disposed in the cut-away 25 and restricted in its upward movement by the shoulders 26. The lower guide member 24 is provided with shoulders 29 restricting downward movement *of the mill insert 27. The lower portion of the guide 24 is cut away at 30 to provide for easy access of the fish 31 in-to the overshot, as will be hereinafter set forth.

Control head Referring to Figs. 4, 5 and 6 specifically setting forth the. structure of the control head, it will be apparent that this comprises a cylindrical member 8 having a pair of diametrically vertically disposed slot or .groove portions 34 extending substantially through half of the length of the control member 8. A horizontally disposed slot portion 35 connects with one side of one of the vertical slots 34- "(Fig. 6), while a second horizontal slot portion 36 connects with the other vertical slot 3.4 at the opposite side thereof, as is clearly shown in Fig. 6. The slots 35 `and 36 are interconnected by the groove 37 (Fig. 5) for purposes as Will be hereinafter set forth.. The passage- *way- 38--of the cylindrical. control head 8 is of sutiicient fdiarneter at 39.1totpermit entry of the iish 31 in a manner as will be hereinafter set forth.

The-extension sleeve 5 is provided with a pair of kiixed "diametri"callyopposedi lug members 40 normally adapted Operation In Operation, the overshot is lowered into the well bore (not shown) on the drill pipe string 4 until it makes a contact with the lost"iish 31 in the well bore, such as a broken off drill pipe or the like, and the fish 31 is directed through the guide"24 into the body of the overshot. As the overshot makes a contact it is rotated in a right hand direction so that the cut away portion 30 will assist the entry of the iish 31 into the overshot. As the overshot 2 moves vertically downward over the iish 31, the jagged edges 42 of the broken off top portion will contact the mill teeth 43 of the mill. insert 27, which with rotation of the overshot 2` mill off the jagged edges thereof, and thereby prevent any damage or injury to the rubber packing ring, which would necessitate replacement thereof.

Continued lowering of the overshot 2 over the iish 31 will bring the top thereof vinto contact with the slips 14, and since the control head 8 is free to movevertically a limited` distance within the body member 7, the slips and control head are moved upwardly by the force of the contacted fish, thereby disengagingV the outer taper 16 from seating relation with the taper 17 `of the body. This upward movement will cause expansion of the slips outwardly so that the fish 31 might enter therein and pass upwardly in the body 7 until it makes Contact with the upper mill teeth 44 provided in the passageway 39 of the control head 8. Lower teeth 45 are provided at the lowermost portion of the control head 8 (Fig. 2) to assist the upper teeth in holding the iish against rotation by contacting the upper "edge thereof.

As the fish 31 makes contact with the mill teeth 44, the force of this contact is felt by the operator at the surface of the well, whereupon the overshot is raised upward to bring the taper 17 simultaneously upward into contact with the outer taper 16 of the slips 14 causing the slips to move inwardly into biting engagement with the fish in the position shown in Fig. 2.

It will be apparent that during the upward movement of the overshot 2 that the helical spring 9 maintains a downward thrust on the control head 8 and engagement of they mill teeth 44 against the top of the iish 31 so that any" simultaneous downward movement of the control head is precluded, and the taper 17 upon contacting the taper 16 will move the teeth 15 of the slips 14 into biting engagement with the outer periphery of the sh 31. In this operation the lugs 40 on the extension sleeve 5l are disposed in the vertical slots 34 permitting the. upward telescoping movement of the body 7 relative. to` the control head 8. With the slips 14 in biting engagement with the fish: 31, any continued upward movement of the overshot will carry the fish 31 therewith unless the fish is stuck sufficiently in the bore to resist removal thereof. In such an instance, it may be desired to release the overshot from the fish 31 in order to take another bite at it.

In order to prevent any retrograde or left hand rotation of the overshot proper for the release action, thereby subjecting the drill" pipe string to possible unthreading at any of the tool joint sections, the release action of the slips from the fish 31 is provided by a continued right hand motion of the overshot. This is done by application of a pre-determined weight on the overshot string which causes the diametrically opposite lugs 4"0 to move vertically downward in the diametrically opposed, slots 34 until `brought into contact with the bottom wall-47" (Figs. 1 and" 6) this downward movement of overshot 2 causes the tension from the spring `9 to act against the control head to force the teeth 44 into biting engagement with the topof the iish 31. The teeth 44 in contact with the fish 31 preclude a rotating movement by they controlV head 8, so that when a quarter right yhand turnv motion is made with the overshot 2, the lugs 40 are permittedy to move into the groove 36 of the stationary control head 8. In this position, a slight upward movement of the overshot will allow the lugs to move vertically upward Ainto the groove 37" and abut against the top wall 48 of the slots 35"and 37 (Fig. 5), thereby the overshot is in a released condition and can be removed from the well if desired".

`In the event that the slips 14V are desired to be reengaged` with the sh 31 from this position, a predetermined weight of lesser amount than the original pre-determined weight is applied to the fishing string thereby movingthe lugs 40- away from contact with the top wall-48 of the slots 3S, 37, and" in this position the tension of the spring 9 causes the teeth 44 to engage the topof the sh 31 preventing rotation of the control head 8 whereuponv a further one-quarter right hand `turn will move Ithe lugs l40 .into .the second diametrically opposed slot 34 whereupon the lugs 40 are permitted to move Avertically upward therein to cause engagement of the slips through4 seating of the tapers 17 and 16 of the bowl 7 and siips.1"4 respectively. The amount of weight necessary to eiect the last operation is only enough to overcome the ftictional resistance due to the engagement of the ylugs .40 with the. topY wall 48 of the control "head slot "37; It will be apparent that the considerable weight of the fishing string and the overshot apparatus is bearing against the lugs to provide considerable frictional resistance, and in order to efficiently effect a right hand rotation of the body 7, this pre-determined weight is placed on the overshot string to overcome the frictional resistance and move the lugs 40 away from contact with the top wall 48.

lt will be apparent that vertical movement of the lugs 40 in the various slots, such as the operating slots 34 for engagement of the slips, or the releasing slots and 36 permitting disengagement of the slips, provides variable conditions on the helical spring 9 due to the anchoring of the extension sleeve S against the upper end thereof. However, the control head 8 is in substantially rigid position relative to the fish 31 and is maintained there by the tension of the helical spring 9 which is always bearing against the flanges l@ of the control head to eect this condition. The amount of spring tension may be variable relative to the position of the sleeve 5, nevertheless tension is always present to provide this downward thrust on the control head.

lt will thus be apparent that in case of accidental release ot` the slips from the fish, the driller can take a right hand turn on the fishing string, raise up very slowly until a pre-determined weight is indicated on the weight indicator (not shown) at the top of the well to position the lugs back into the slots 34 for re-engagement ot" the slips with the fish. Furthermore, during the milling operation of the top jagged edges of the fish, the overshot string is rotated in a right hand direction, and sometimes these jagged edges are quickly removed, and this factor plus the weight of the overshot and fishing string will cause the overshot to be released, particularly if during the rotation the lugs di) are positioned in the slots 34. However, it will be apparent that whether the overshot is purposely or accidentally released, it can be easily re-engaged with the fish by a continued right hand motion without any danger of unthreading the fishing string.

The packer ring i9 provides a seal around the outer periphery of the fish 3l when mud is pumped through the overshot by forcing the inside diameter of the ring i9 to close around and against the fish, thereby sealing ofi" any openings and assuring that all wasliings will be through the inner passageway of the cylindrical fish 3i and out through the bottom to provide a washing action directed at the bottom of the fish and thereby assist a stuck fish in becoming free.

From the foregoing, it is apparent that the present invention contemplates an overshot fishing tool for use in recovering lost fish elements in a well bore which may be easily engaged and disengaged with the fish and that the engagement and disengagement are both accomplished by a subsequent turning in a right hand direction in or ler to prevent any possibility of retrograde rotation of the fishing string and unthreading of any portions thereof. Furthermore, it will be apparent that the overshot fishing tool is provided with a novel control head permitting the uniform rotation of the overshot body to provide for the engagement or disengagement of lthe attaching members of the overshot from the lost fish without any retrograde movement whatsoever.

Changes may be made in the combination and arrangement of parts as heretofore set forth in the specification and shown in the drawings, it being understood that any modification in the precise embodiment of the invention may be made within the scope of the following claims without departing from the spirit of the invention.

l. ln an overshot fishing tool for retrieving broken ofi drill pipe and the like in a well bore comprising a sectional cylindrical body member adapted to be lowered over the pipe, a control head carried in the body member, a plurality of serrated slips carried thereby, a tapered portion provided in the body member cooperatping engagement of the slips with the broken drill pipe, a helical spring anchored between a shoulder of the control head and the body member for urging the control member into substantially rigid contact with the broken drill pipe disposed therein, a plurality of diametrically opposed lugs provided in the body, a plurality of diametrically opposed vertical slots provided in the control head, for telescopic reception of the lugs, a peripheral slot provided in the control head and communicating with the diametrically opposed vertical slots to provide for movement of the lugs therethrough and facilitate engagement and release of the overshot tool with the broken pipe by a continuous rotation in the same direction.

2. ln an overshot iishing tool for removing broken off drill pipe and the like from oil well bores comprising a cylindrical body adapted to be lowered over the pipe, a control head disposed in the body, a plurality" of serrated slips carried by the control head, cooperating taper means between the slips and the body to eiect a gripping engagement of the slips with the drill pipe, a plurality of longitudinal groves provided in the control head, a plurality of lugs provided in the body and cooperating with the grooves to provide longitudinal movement between the body and the control head, said lugs responsive to a pre-determined weight for movement in the grooves to disengage the tapering means and release the slips from the pipe, a horizontal groove provided in the control head and disposed conterminous with the bottom of the vertical grooves and responsive to a right hand rotation of the body relative to the control head to move the lugs from the vertical groove into the lowermost horizontal groove for maintaining a release of the slips with the pipe.

3. in an overshot iishing tool for removing broken oft" drill pipe and the like from oil well bores comprising a cylindrical body adapted to be lowered over the pipe, a control head disposed in the body, a plurality of serrated slips carried by the control head, cooperating taper means between the slips and the body to effect a gripping engagement of the slips with the drill pipe, a plurality ot longitudinal slots provided in the control head, a plurality of lugs provided in the body and cooperating with the slots to provide longitudinal movement between the body and the control head, said lugs responsive to a pre-determined weight for movement in the slots to disengage the tapering means and release the slips from the pipe, means in the control head cooperating with the lugs to provide a continuous right hand rotation ot the body relative to the control head for rca-engagement of the slips with the pipe, said means being a horizontal slot provided in the control head and disposed conterminous with the bottom of the vertical siot to move the lugs from the vertical slot into the lowermost horizontal slot for maintaining a release of the slips with the pipe, a second horizontal slot in the control head disposed above the first mentioned horizontal slot and communicating therewith, said lugs responsive to a decrease in the pre-determined weight to be moved vertically upward from the first .mentioned holizontal slot to the top of the second mentioned horizontal slot to provide for continuous right hand rotation of the body relative to the head for effecting 1re-engagement of the slips with the pipe.

4. ln a combination release overshot and control head utilized for retrieving lost fish in a well bore including a cylindrical body disposed over the fish, a control head movably disposed in the upper portion of the body, a helical spring anchored between the body and a shoulder of the control head for urging the control head constantly in one direction, a plurality of slip members carried by the head, taper means provided between the body member and the slips for moving the slips in one direction to provide engagement of the slips with the ing with a tapered portion on the slips to elect a gripdrill pipe, a plurality of diametrically opposed grooves provided in lthe head, a pair of diametrically opposed lugs provided in the body cooperating with the grooves to provide longitudinal movement between the body and the headfsaidtapering means responsive to one position of the vlugs in the grooves to cause engagement of the slips with the lost fish, and in another position of the lugs in the grooves to provide for release of the slips with the fish, a pair of vertically spaced connecting horizontally .disposed slots provided in the head between the opposed grooves, said horizontal slots providing for disposition .of `the lugs from the grooves into the slots after release of the slips from the lish, said lugs so disposed in the slots responsive to a right hand rotation of the body member for movement through the slots for reinsertion into the grooves.

5. In an overshot fishing tool for removing broken drill pipe and the like. from oil well bores comprising a cylindrical body to be lowered over the pipe, a control heady disposed in the body, a plurality of serrated slips carried by the control head, cooperating taper means between the slips and the body to effect a gripping engagement ofA the slips with the drill pipe, a plurality of longitudin-al slots provided. in the control head, a plurality of lugs provided in the body and cooperating with the slots to provide longitudinal movement between the body and the control head, a peripheral slot provided in the control head having portions thereof disposed at spaced vertical planes, said peripheral slot communicating with the longitudinal slots, said lugs responsive to a predetermined weight for movement into the peripheral slot providing disengagement of the slips from the pipe, and

6, in an overshot fishing tool for removing broken drill pipe and the like from oil well bores comprising a cylindrical body to be lowered over the pipe, a movable control head disposed in the body, gripping means carried by the control head, taper means between the gripping means and the body to provide for engagement of the gripping means with the pipe, a pair of diametrically opposed lugs provided on the body and cooperating with the slots to provide longitudinal movement between the body and the control head, said lugs in one position of the slots providing for seating the taper means causing engagement of the gripping means with the drill pipe, and responsive to a predetermined weight moving the lugs to a lower position in the slots to disengage the taper means and release the gripping means from the pipe, and a peripheral slot disposed in the control head and having portions thereof disposed at spaced vertical planes and cooperating with the first mentioned longitudinal slots in response to a right hand rotation of the body member in relation to the control head to move the lugs therethrough.

David L. Farley ATTORNEY United Statesv Patent O RELEASING OVERSHOT David L. Farley, Duncan, Okla., assigner to Halliburton Company, a corporation of Delaware Filed Mar. 14, 1958, Ser. No. 721,500

1 Claim. (Cl. 294-4102) This invention relates to an oil well device and more particularly to what is known as an overshot for removing objects Ifrom oil wells in a fishing operation.

Overshots are well-known devices for retrieving objects from oil wells. Ordinarily, such overshots are lowered into an oil well on either a wire line or on tubing or drill pipe and surround and latch on to the object or fish to be removed, the grapple having spring fingers of some sort to assist in making the coupling.

The overshot `of the present invention has similar mechanisms, but it is especially designed to release from the fish when desired, as in the case where the fish is stuck and cannot be removed and it is necessary to remove the overshot fro-rn the well without pulling the fish.

The overshot of the present invention is composed basically of a locking spring and a releasing mechanism. The locking spring consists of a cylindrical part split into several sections which act as fingers. When the fingers are spread over the neck of the fish, the inner shoulders of the fingers normally hook below the top of the fishing neck so that when upward force is exerted on the overshot, this force is transferred to the fish. The overshot can be released by jarring downwardly upon the locking spring and the housing which contains it. Within the housing there is la releasing sleeve held in inactive position `during normal operation of the tool, and provided with a snap ring and two shear pins. Downward jarring shears these pinsso that the housing can then slide downwardly and cause the snap ring to secure the releasing sleeve in -a higher position in the housing. Then, when an upward yforce is exerted on the overshot, the releasing sleeve comes in contact with the lower end of the locking spring, thus, spreadingy the fingers and allo-wing the overshot to pull off from the fishing neck.

It will -thus be seen that an object of the invention is to provide a releasing overshot which can be lowered into a .well in such a condition that it will serve as a grapple and impart upward pull or upward jarring action upon a fish but which may be caused to releasefrom the fish upon downward jar being delivered to it.

Other objects and advantages reside in certain novel features of the arrangement and construction of parts, Vas will be apparent from the following description taken in connection with the accompanying drawing in which:

Figure 2 is a view in vertical quarter cross section of the releasing overshot of Figure l, the view illustrating the position of the parts when the overshot is first brought into grapple posit-ion with a fish; v

Figure 4 is a view in vertical `cross section of the retrievable overshot similarto that of Figures 2 and 3 but illustrating the position of the parts after a downward ICC jarring blow has been delivered to shear the pins but before the fingers of the locking spring have been disengaged from the leek of the fish; and

Figure 5 is a view of the releasing overshot in vertical quarter cross section similar to Figures 2, 3, and 4 but illustrating the positionvof `the parts after the overshot is released from the neck of the fish.

Referring to the drawing in detail and first to the general assembly of Figure 1it will be seen that a cable 10 is there illustrated as supporting a conventional twoway jar 11 which is, in turn, connected to a releasing overshot 12 connected to a fishing neck L13 of a fish 14.

The novelty of the present invention resides in the general assembly illustrated and more particularly in the details of construction of the releasing overshot which is contained within the housing 12.

Figures 2, 3, 4, and 5 are all similar and illustrate the sequence of operation of the releasing overshot as well as the details of construction of the various parts.

As shown in Figures 2, 3, 4, and 5, the housing 12 is provided with a threaded coupling 16, at its upper end. The housing 12 is a hollow cylinder but is provided with a number of -grooves and lands on its interior. Near its upper end it is provided with a land 15 of circular shape which serves as a guide for the locking spring 23. Some distance below the land 15, there is a second circular land 17 which also serves as a guide, and beneath this land 17 there is a groove y18, the purpose of which will be apparent :from the description hereinafter.

There are two shear pins 19 employed in the overshot, these "being fitted into suitable sockets in the housing 12, as illustrated in Figures 2 and 3, and arranged 180 degrees apart. For purposes of assembly, the sockets for the pins 19 may be provided with externally removable caps, -but these have not been illustrated in the drawing for reasons of clarity.

There is also provided in the overshot assembly a split snap ring 20. This is mounted in a groove on the releasing sleeve 26 and serves to lock the sleeve in its upper position in the housing 12, as described hereinafter, once the pins 19 have sheared. As shown in Figures 2 and 3, this snap ring 20 is held compressed by the lower portion of the housing 12. When it is raised sufiiciently within the housing 12, it snaps outwardly into the groove 18, as illustrated in Figures 4 and 5.

For normal operation in making connection with the head 21, there is a locking spring consisting of a cylinder of spring steel having a ring portion 23 and depending fingers 24 terminating at the lower end in catches 25. Thus, when the overshot "is lowered into the well, the

fingers 24 move outwardly radially and then inwardly to" clasp the fish beneath the head 21. l" The locking spring is so mounted as to have a certain amount of play within the cylinder 12 in that it can slide upward-ly and downwardly between the top of the housing 1-2 and the upper land 15. This locking spring is more or less of conventional design and need not be described furtherl here.

The important -feature of the invention resides in the provision of mechanism for spreading the fingers 24 outwardly and holding them in an outwardly or expanded position should it be desired to release the overshot from the fish. To this end a releasing sleeve 26 is mounted in the lower portion of the housing 12 and held in place therein by the shear pins 19. So long as the pins 19 are not sheared, the releasing sleeve is held stationary with respect to the sleeve 12 and occupies the inactive posit-ionv shown in Figures 2 and3 with respect thereto. When the "pins 19 are sheared,.the sleeve 26 can then move upwardly with respect to the housing 12 and occupy thepositions of Figures 4 and 5, the split ring 2t) serving to limit the amount of travel of the sleeve 26 with respect to the housing 12 as the ring 20 enters the groove 1S.

The upper surface of the sleeve 26 is provided with a tapered cam surface 27. The purpose of this surface 27 is to engage the lower edges of the catches 25 and force them outwardly when pulling upwardly on `the cable and housing 12.

With the above mechanism, it will be clear that the overshot mechanism, consisting of the housing 12 and the parts mounted in it, may be lowered into a well until the locking spring engages and grapples a suitable shing neck, such as illustrated in Figure 2. In normal operation an upward pull may then be taken on housing 12, and the upward pull may be transmitted by the land 15 to the locking ring and iish. Any number of upward jar blows can then be delivered by the jar 11 to the fish through the spring lingers 24 and catches 25.

Assume, however, that the fish cannot be moved or that for any other reason it is desired to release the overshot from the fish, the upward pull is discontinued and a downward jar blow is delivered b v the jar 11 to the housing 12. Such downward blow will cause the parts to take the position shown in Figure 4. 1n this position, the sleeve 26 is resting upon the sh and the downward stress of the jar blows has been taken by the jar pins 19 so that they have sheared. As soon as the pins 19 shear, there can be relative movement between the housing 12 and the sleeve 26 so that the ring 2G snaps into the groove 18 and holds the sleeve 26 in its upper position in the housing 12. After this has happened, upward pull upon the overshot will cause the cam surface 27 to engage the catches and spread the spring iingers 25a outwardly so that the catches 25 can be moved upwardly past the head 21 and the overshot removed from the ,well without engagement with the tish 13.

While only one embodiment of the invention has been shown and described herein, it is obvious that various changes may be made in the arrangementand construction of the parts yWithout departing from the spirit of the invention or the scope of the annexed claim.

A releasing overshot for use in removing a fish from a well or the like, comprising a cylindrical housing, a locking spring within said housing and having a sh engaging catch depending therefrom, a releasing sleeve Within said housing beneath said catch, said catch and said releasing sleeve having opposed surfaces eifective to positively cam said catch to a fish releasing position upon movement of said releasing sleeve relatively toward said catch, releasable retaining means for holding said releasing sleeve in a lower inoperative position in said housing and out ot" engagement with said catch, said retaining means being releasable upon forcible downward movement of said housing relative to said releasing sleeve to position said releasing sleeve in an upper operative position in said housing, and a latch between said releasing sleeve and said housing for holding said releasing sleeve in said upper position in said housing after said forcible upward movement therein, said opposed surfaces engaging in said upper position of said releasing sleeve to positively cam said catch to a sh releasing position whereby the overshot maybe removed from the well without the tish.

To recap, in the first half of 2014, oil prices spent most of the time bouncing between $100/bbl and $105/bbl. But the shale boom had put millions of new barrels of oil into the markets over the course of several years, and by mid-2014 the market was approaching an over-supply situation. The price of oil started to decline, but then in the second half of the year OPEC embarked upon a price war to win back market share that had been lost to the American shale boom.

The result was that the bottom fell out of the oil market. By the end of 2014, the price had declined to $53/bbl. The price remained depressed for all of 2015, and by early 2016 WTI fell below $30/bbl.

At the time, I called this episodeOPEC’s Trillion Dollar Miscalculation. I don’t believe that if OPEC knew how far oil prices would fall — and knew that their efforts wouldn’t actually derail the U.S. shale boom — that the cartel would have embarked upon that strategy.

The question now is whether the current situation is more like the first half of 2014, or whether it is more like 2011, when prices rose above $100/bbl and largely stayed there for the next three years.

I would argue that we are somewhere in between. In 2011, the markets weren’t oversupplied, but that’s where they were ultimately headed. U.S. oil production has increased by 600,000 barrels per day (bpd) year-over-year, but we are still 1.5 million bpd below the levels just before the Covid-19 pandemic hit the U.S. Thus, with demand largely recovered to pre-pandemic levels, we are still undersupplied relative to two years ago.

Last month OPEC and its allies said they would increase oil production by a total of 400,000 bpd in February. However, the cartel has been undershooting its production targets. That helps keep oil prices high, especially in light of the slow ramp-up of U.S. oil production.

When I made myenergy sector predictionslast month, I noted that “OPEC is always the wildcard.” They want the highest oil prices the market can bear, but that is always tempered by non-OPEC oil production. There are also demand factors that OPEC has to consider. High oil prices create incentives for alternatives, like faster adoption of electric vehicles.

So, how will it all shake out? I still believe the U.S. will significantly increase oil production this year, and that will help temper oil prices. It’s not at all clear to me that the 17% price increase in WTI that we saw in January is justified based on the fundamentals.

But oil prices overshoot the fundamentals all the time. WTI at $145/bbl in 2008 overshot the fundamentals, and the oil price plunge deep into negative territory in 2020 overshot the fundamentals. And when the correction toward the fundamentals happens, it can be swift.

Still, with oil just 8% away from that $100/bbl mark, and momentum continuing from January, it seems more likely than not that WTI will reach that level. But how long can it stay there, and where is the top of this current bull market in oil? I will be among those surprised if it’s still at that level in the second half of the year.

Despite failing miserably in their prior $8/MMBtu gas price predictions for this summer and fall (see Daily GPI, June 29), analysts at Raymond James & Associates said in their “Stat of the Week” that once the weather returns to normal, bullish gas market fundamentals will again push prices sharply higher. As a result, the analysts have raised their gas price forecast for 2005 yet again to $6.65 from $6.25. They also bumped up their crude oil price forecast for the fourth quarter to $40/bbl from $36.

“We believe that the current bearish sentiment in the natural gas market will reverse by the end of the year and year-over-year weather comparisons become more favorable and surplus gas currently available shrinks as a result of continuing declines in supply,” said Raymond James analysts J. Marshall Adkins and Wayne Andrews. “The weather has briefly interrupted an extremely bullish U.S. natural gas price move, but as the weather factor fades gas should resume its strong upward move.

“Assuming traditional BTU parity of 6:1 and our new 2005 oil forecast ($40), fair value for natural gas in 2005 should be between $6.50 and $7,” they added.

The new $6.65 forecast is $1.30 more than the current Wall Street consensus and 50 cents more than the 2005 strip of futures prices on the New York Mercantile Exchange as of Friday’s close. Current near-month futures are well below $5.

However, the Raymond James analysts said they are still considering the possibility that gas prices could be pushed even higher than their extremely bullish projections in the short term to more than $7/MMBtu because of a strong economy, favorable fuel switching ratios and declining domestic supply.

Over the longer term, Adkins and Andrews also have raised their price forecasts mainly due to the ongoing tight supply situation in gas and oil. Their new gas price forecast is $6, up from $5.50. “[A]ssuming only a 2% annual long-term decline in domestic production (versus the 3-4% decline we project in 2004) and an average 2% growth in domestic gas demand we belive there could be a 4-5 Bcf/d supply shortfall (about 6-8% of demand) in 2007 — despite an estimated 250% increase in LNG imports over this time fame. This gap could potentially widen further to 9-10 Bcf/d by 2010 under the same assumptions.” Their long-term crude oil forecast is $35/bbl, up from $30.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291