overshot packer made in china

Fishing tool is a special fishing drilling tool used to retrieve fallen objects from the borehole. At any stage of the operation, the drill rig operator will encounter unexpected situations, such as falling drill string, stuck pipe, missing drill bit, etc. The equipment that falls into the well is called "fish" or "trash", and the tools used to remove the equipment are called "fishing tools." Sometimes it may be necessary to use "fishing tools" to retrieve older wellbore equipment, such as packers, liners, tubing, or any stuck objects in the well. The drilling tools for fishing must be retrieved from the borehole in order to continue drilling operations.

Overshot is a very common fishing tool. The main fishing object is a smooth tube fish, which belongs to the external fishing type (i.e. catching the external surface of the fish).

Taper tap and die collar are common fishing tools for fishing the inner hole of the string. They are used for fishing the inner hole with holes such as tubing, drill pipe, casing milling pipe, packer, water distributor, etc. It is made of high-quality alloy steel and especially heats treated. It has the advantages of high strength, high toughness, and simple buckle making.

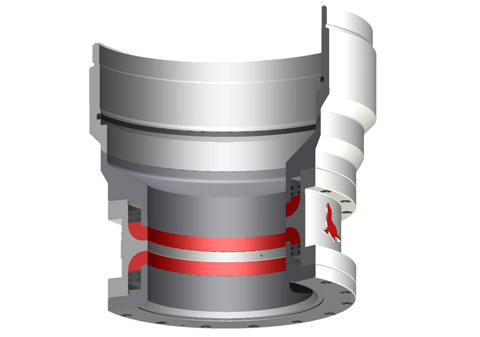

The RedSeal Dual Overshot Packer has been developed to provide a dual seal barrier in surface drilling systems used on jack-up and platform applications.

The RedSeal Dual Overshot Packer has been developed to provide a dual seal barrier in surface drilling systems used on jack-up and platform application. The system provides the operator with a primary and secondary seal system to mitigate potential environmental spills.

The system has been developed with a similar design philosophy to the RedSeal Packer system developed for drilling riser telescopic joints but does not include a facility for refill of the packer online as the seal element is a static seal and not subject to the dynamic motion associated to the RedSeal Packer system. Physically the RedSeal Dual Overshot Packer is shorter than traditional single packer systems allowing the system to be utilised in riser systems where stack-up heights are critical.

RedSeal Dual Overshot Packer can be supplied with a dedicated control system to monitor seal actuating pressure and (upon actuating pressure loss to primary seal element) switch automatically to the secondary seal, thereby minimising any environmental impact.

The Retrievable Bridge Plug(RBP) is a high-pressure packer style bridge plug used for multiple selective zone treating and testing operations. The RBP is designed to set in tension or compression, which makes it ideal for shallow applications to test wellhead for deep, high-pressure applications. The plug is designed with a large internal by-pass to prevent swabbing when running and retrieving. The by-pass closes during the setting of the plug and opens prior to releasing the upper slips to equalize pressure when unsetting.

Oil well completion tools include: Subsurface safety valve, wireline retrievable subsurface safety valve, single string production packer, dual strings production packer, ESP packer, mechanical set packer, permanent packer, compensation device, bridge plug, sliding sleeve, nipples etc.

Parveen is specialized in design and supply of Completion tools like Production packers Bridge plugs and their accessories by using the well established quality management system that meets API and ISO standards.

Packer is a mechanical device with a packing element installed in a designed receptacle, used for blocking fluid (liquid or gas) communication through the annular space between conduits by sealing off the space between them”.

A Packer is usually set just above the producing zone to isolate the producing interval from the casing annulus or from producing zones elsewhere in the wellbore.

Parveen offers a complete line of production packers and accessories — from standard packers to specialized designs for the most hostile environments. Our packers are designed as per API 11 D1 Validation Grade V6-V0 and Quality Control Grade Q3-Q1.

In addition to providing a seal between the tubing and casing, other functions of a packer are as follows:Prevent downhole movement of the tubing string, generating considerable axial tension or compression loads on the tubing string.

Mandrel is a main component of a packer that contains the end connections and provides a conduit through the packer. It is subjected to direct exposure to flowing fluid hence its material selection is a very vital decision. Primarily used materials are L80 Type 1, 9CR, 13CR, 9CR1Mo. For more corrosive and sour services Duplex, Super Duplex, Inconel are also used as per the requirement.

The slip is a wedge-shaped device with wickers (or teeth) on its face, which penetrate and grip the casing wall when the packer is set. There are different types of slips designs are available in packers like dovetail slips, rocker type slips bidirectional slips depending upon packer assembly requirements.

The cone is beveled to match the back of the slip and forms a ramp that drives the slip outward and into the casing wall when setting force is applied to the packer.

Packing element is the most important part of any packer and it provides the primary sealing purpose. Once the slips have anchored into the casing wall, additional applied setting force energizes the packing-element system and creates a seal between the packer body and the inside diameter of the casing. The primarily used element materials are NBR, HNBR or HSN, Viton, AFLAS, EPDM etc. Most popular element system are permanent single element system with expansion ring, three piece element system with spacer ring, ECNER element system, Spring loaded element system, Fold back ring element system.

Lock ring play a vital role in packer’s function. The purpose of a lock ring is to transmit axial loads and allow unidirectional motion of packer components. The lock ring is installed into the lock ring housing and both move together over the lock ring mandrel. All setting force generated due to tubing pressure is locked into packer by lock ring.

As the name implies Permanent Packers cannot be retrieved, but can be destructively removed (i.e. milling).The permanent packer is fairly simple and generally offers higher performance in both temperature and pressure ratings. In most instances, it has a smaller outside diameter (OD), offering greater running clearance inside the casing string than do retrievable packers. The smaller OD and the compact design of the permanent packer help the tool negotiate through tight spots and deviations in the wellbore. The permanent packer also offers the largest inside diameter (ID) to make it compatible with larger-diameter tubing strings and monobore completions.

PARVEEN Model D Production Packers provide excellent clearance for run-in while the PARVEEN Model “F” Production Packers offer a larger seal bore. The two models carry different pressure ratings noted later in this document. PARVEEN Packers are designed for differential pressures up to 10,000 PSI.

PARVEEN Model DB Hydraulic-Set Dual Bore Permanent Production Packers are the hydraulically set one-trip completion packers, ideal for high volume production in high angle, extremely deviated well. These packers feature the largest possible bore through combined packer and seal accessory. The packer is run on the hydro-set anchor latch seal unit which is made up in the top of the packer via the left-hand threads on the latch and is set by applied tubing pressure. The DB packer requires some type of temporary plugging device such as a shear out plug or wire line blanking plug located close to the end of the tubing. PARVEEN Packers are designed for differential pressures up to 10,000 PSI.

Retrievable Packer has a design feature that enables its removal from the well posts operation or whenever required. This packer can be retrieve with tension in tubing or with retrieving tool. Parveen has wide variety of Retrievable packers that suits different well conditions and operating parameters.

The PARVEEN MODEL RHP-DB Retrievable Packer delivers high performance with simplicity of design and desirable economics. The dual bore packer allows for a large ID through the packer by sealing in an upper seal bore. No tubing rotation required to fully set the packer. It has one-piece, self energizing packing element and features bidirectional slips below the packing element for maximum protection from debris fouling. This location protects the slips from being lost during retrieval or milling. A retrieving tool is required to retrieve these packers. PARVEEN Packers are designed for differential pressures up to 7,500 PSI.

The PARVEEN MODEL RHP-SPR Packer is a hydraulic set single-string retrievable packer and may be used in virtually any production application. Tubing pump pressure is used to set the packer and the setting force is locked into the packer by a body lock ring. A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set, and opens during the releasing process to allow pressure equalization. Shear screws are used to control the packer release. The shear release value is adjustable by adding or removing screws from the shear housing or by use of steel screws. PARVEEN Packers are designed for differential pressures up to 10,000 PSI.

PARVEEN Model ERD Retrievable Hydraulic Seal Bore Packer is a Retrievable Packer. Hydraulically set by pressure in the tubing. It is run with Hydraulic Setting Tool & retrieving is done independently from the Tubing, using a Retrieving Tool manipulated on a work string. This packer is ideally suited for highly deviated well both onshore & offshore. Model ERD Retrievable Hydraulic Seal Bore Packer can be use in oil production wells or in water or gas injection wells. PARVEEN Packers are designed for differential pressures up to 7500 PSI.

The PARVEEN MODEL RHP-SPR FEED THRU Packer is a hydraulic set retrievable packer and may be used in virtually any production application. Tubing pump pressure is used to set the packer and the setting force is locked into the packer by a body lock ring. A large internal by-pass reduces swabbing when running and retrieving. The by-pass closes when the packer is set, and opens during the releasing process to allow pressure equalization. Shear screws are used to control the packer release. The shear release value is adjustable by adding or removing screws from the shear housing or by use of steel screws.

PARVEEN FEED THRU packer can be used for smart completion, chemical injection and electrical submersible pump application. Packers are designed for differential pressures up to 7,500 PSI.

PARVEEN Hydroset II-A Packer is a hydraulic set, mechanically held dual string production packer normally run above a single string hydraulic set or wire-line set seal bore packer. Because no tubing manipulation is required to set this packer, the well head can be installed and flanged up before setting. This packer is available with short string or long string setting capabilities and a variety of tubing connections. This packer is also adaptable for electrical submersible pump applications. This packer features a sequential upper slip release system designed to release each slip individually to reduce the pull required to release the packer. The angles on the upper slips and upper slip body result in the slips releasing smoothly from the casing.

PARVEEN Model-R Single-Grip Mechanical Production Packer is a retrievable packer set by compression that isolates the annulus from the production conduit in most production, stimulation and testing operations. The field-proven design includes rocker slips and a three-element packing system that helps to ensure correct setting and pack off. These packers can be used for cementing, fracture stimulation, zone isolation and testing & production. PARVEEN Packers are designed for differential pressures up to 5000 PSI.

PARVEEN Model-R Double-Grip Mechanical Production Packer is a retrievable packer set by compression that isolates the annulus from the production conduit in most production, stimulation, and testing operations. The field-proven design includes rocker slips and a three-element packing system that helps to ensure correct setting and pack off. A hydraulic hold down controls differential pressure from below. These packers can be used for Injection, pumping, zone isolation and testing & production. PARVEEN Packers are designed for differential pressures up to 5000 PSI.

The PARVEEN MODEL TST-3 Retrievable Packer is a heavy duty service packer ideally suited for all types of squeeze cementing, formation fracturing, high pressure acidizing, etc. It is a large opening compression set packer with hydraulic button-type hold down. It withstands high pressure from above or below and uses a three-element packing system, J-slot, and a drag block mechanism for easy setting. The tool features a proven three element packing system and hydraulically controlled balance sleeve designed to keep the by-pass valve closed when set. PARVEEN Packers are designed for differential pressures up to 10,000 PSI.

The PARVEEN MODEL AD-1 Tension Packer is a retrievable, single grip tension set packer, used in water flood, oil production or treating applications. This compact, economical packer is used for shallow wells where sufficient set down weight is not available to utilize a set down packer. It is set by left hand rotation and has three release methods.

releasable slip overshot is the most effective tool through fishing outer diameter of pipe, used for catch the fish with smooth external diameter. The sizes of the overshot are designed in accordance with the o.d of drill collar, drill pipe, oil tube as well as collars of them and have formed a complete series for fishing. According to different application, it may be equipped with some accessories, such as extension sub, wall hook, oversize guide , etc.

Due to its complete function, compact structure, it is safe and reliable in use. Its sealing structure may effect high-pressure mud circulation after a fish is gripped. If the gripped fish was stuck, it could be released easily. The overshot comes with a wide range of available accessories and has been proven to be the most versatile and reliable in the field.

8613371530291

8613371530291