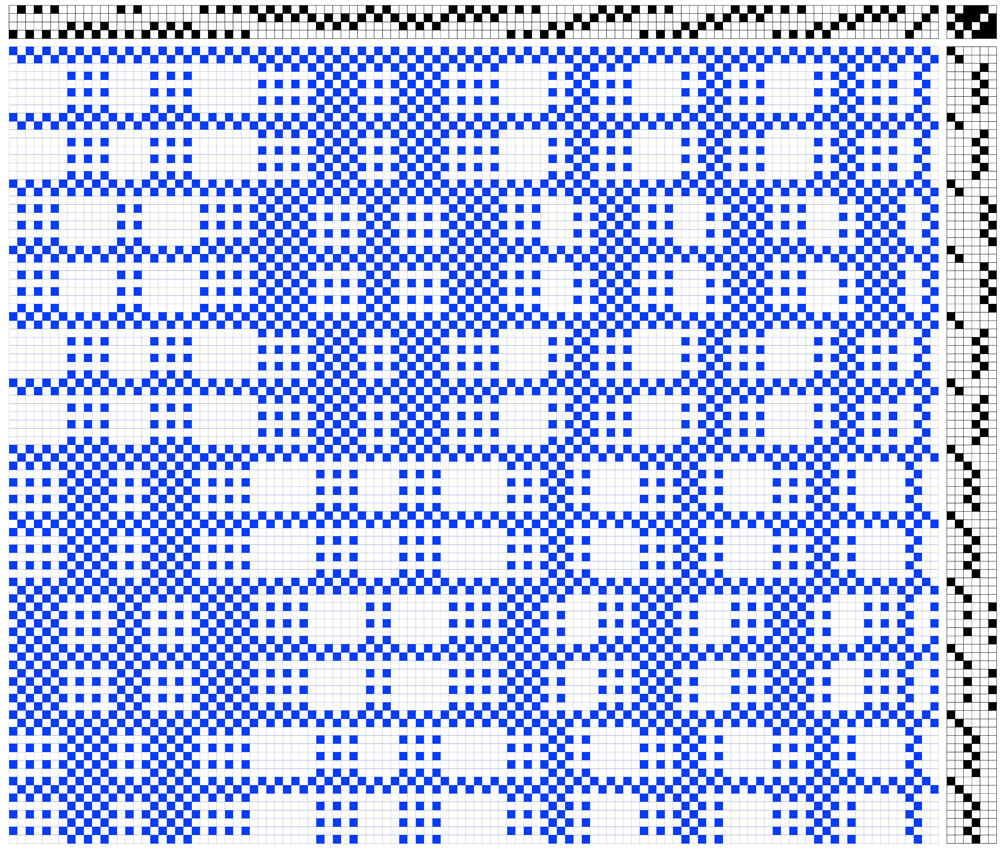

overshot patterns factory

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Double Cloth: Usually associated with professional weavers, double cloth is formed from two plain weave fabrics that swap places with one another, interlocking the textile and creating the pattern. Coverlet weavers initially used German, geometric, block-weaving patterns to create decorative coverlets and ingrain carpeting. These coverlets contain twice the yarn and are twice as heavy as other coverlets.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

Overshot: The earliest coverlets were woven using an overshot weave. There is a ground cloth of plain weave linen or cotton with a supplementary pattern weft, usually of dyed wool, added to create a geometric pattern based on simple combinations of blocks. The weaver creates the pattern by raising and lowering the pattern weft with treadles to create vibrant, reversible geometric patterns. Overshot coverlets could be woven domestically by men or women on simple four-shaft looms, and the craft persists to this day.

Summer-and-Winter: This structure is a type of overshot with strict rules about supplementary pattern weft float distances. The weft yarns float over no more than two warp yarns. This creates a denser fabric with a tighter weave. Summer-and-Winter is so named because one side of the coverlet features more wool than the other, thus giving the coverlet a summer side and a winter side. This structure may be an American invention. Its origins are somewhat mysterious, but it seems to have evolved out of a British weaving tradition.

Double Cloth: Usually associated with professional weavers, double cloth is formed from two plain weave fabrics that swap places with one another, interlocking the textile and creating the pattern. Coverlet weavers initially used German, geometric, block-weaving patterns to create decorative coverlets and ingrain carpeting. These coverlets contain twice the yarn and are twice as heavy as other coverlets.

Multi-harness/Star and Diamond: This group of coverlets is characterized not by the structure but by the intricacy of patterning. Usually executed in overshot, Beiderwand, or geometric double cloth, these coverlets were made almost all made in Eastern Pennsylvania by professional weavers on looms with between twelve and twenty-six shafts.

America’s earliest coverlets were woven in New England, usually in overshot patterns and by women working collectively to produce textiles for their own homes and for sale locally. Laurel Thatcher Ulrich’s book, Age of Homespun examines this pre-Revolutionary economy in which women shared labor, raw materials, and textile equipment to supplement family incomes. As the nineteenth century approached and textile mills emerged first in New England, new groups of European immigrant weavers would arrive in New England before moving westward to cheaper available land and spread industrialization to America’s rural interior.

Southern coverlets almost always tended to be woven in overshot patterns. Traditional hand-weaving also survived longest in the South. Southern Appalachian women were still weaving overshot coverlets at the turn of the twentieth century. These women and their coverlets helped in inspire a wave of Settlement Schools and mail-order cottage industries throughout the Southern Appalachian region, inspiring and contributing to Colonial Revival design and the Handicraft Revival. Before the Civil War, enslaved labor was often used in the production of Southern coverlets, both to grow and process the raw materials, and to transform those materials into a finished product.

This project was really popular when I posted it on Instagram, so I thought I would share it here also. It is a simple overshot pattern - with a twist. Also a great way to show off some special yarn. The yarn I used for my pattern was a skein of hand spun camel/silk blend. I wove the fabric on my Jack loom but you could also use your four or eight shaft loom.

Overshot is a weave structure where the weft threads jump over several warp threads at once, a supplementary weft creating patterns over a plain weave base. Overshot gained popularity in the turn of the 19th century (although its origins are a few hundred years earlier than that!). Coverlets (bed covers) were woven in Overshot with a cotton (or linen) plain weave base and a wool supplementary weft for the pattern. The plain weave base gave structure and durability and the woollen pattern thread gave warmth and colour/design. Designs were basic geometric designs that were handed down in families and as it was woven on a four shaft loom the Overshot patterns were accessible to many. In theory if you removed all the pattern threads form your Overshot you would have a structurally sound piece of plain weave fabric.

I was first drawn to Overshot many years ago when I saw what looked to me like "fragments" of Overshot in Sharon Aldermans "Mastering Weave Structures".

I wanted to use my handspun - but I only had a 100gms skein, I wanted to maximise the amount of fabric I could get using the 100gms. I thought about all the drafts I could use that would show off the weft and settled on overshot because this showcases the pattern yarn very nicely. I decided to weave it “fragmented” so I could make my handspun yarn go further. I chose a honeysuckle draft.

Burel Factory Part 3 - warping and weaving. Image 1: making the warp Image 3: these old looms require a fulltime attendant to change the spindles in the shuttles and to make sure that the loom is functioning correctly. You can see the attendant change the spindle in one of the shuttles (2 are in play) and then restart the loom Image 4: the overshot pattern is controlled by this chain of keys that control the treadling of the harnesses, each of which has been threaded according to the chart.

Woven by Rachel SnackWeave two overshot patterns with the same threading using this downloadable weave draft to guide you. This pattern features the original draft along with one pattern variation. Some yarns shown in the draft are available to purchase in our shop: 8/2 cotton, wool singles, 8/4 cotton (comparable to the 8/4 linen shown).

please note: this .pdf does not explain how to read a weaving draft, how to interpret the draft onto the loom, or the nuances of the overshot structure.

Fine-toothed nylon ratchets provide precise tension control. The conveniently located heddle blocks on the sides of the loom hold the rigid heddle in the up, down, or neutral position. The heddle, available in 5, 8, 10 and 12 dents per inch, is made of durable ABS plastic, with large eyes and slots. Flip is ideal for plain weaves and pick-up patterns.

Place an overshot card on top of the shot charge just before crimping to improve overall crimp quality and seal in small shot and/or buffer. Excellent for use with BPI Roll Crimpers.

Our testing lab has proven that poor crimps can alter the performance of an otherwise good load. Overshot cards always produce better, more consistent crimps and this consistency is demonstrated in the standard deviation of loads in our lab. Our ballistic lab recommends overshot cards for better crimps in all loads.

Clear Overshot Disks(either plain or printed with shot size) are also offered for great roll crimping options. See pictures in Additional Images or click on this link.

Shotshell size selection:Use the same size gauge as your hull. Smaller diameter cards also work if your particular size is out of stock. For example, a 20ga overshot card works in a 16-gauge shotshell and so on.

RM2DN1783–Coverlet fragment, Medium: wool, cotton Technique: plain compound cloth (overshot), Traditional, geometric design showing combinations of small triangles in dark blue on a white, undyed cotton ground. Reversible., USA, early 19th century, woven textiles, Coverlet fragment

RM2DMGFPC–Coverlet, Medium: wool, cotton Technique: plain compound weave (overshot), Traditional geometric design in bands of black and tan wool pattern wefts on undyed cotton ground. One plain edge continuous with field. Reversible., USA, 19th century, woven textiles, Coverlet

RM2DMEEY0–Coverlet fragment, Medium: cotton, wool Technique: overshot, Small section of coverlet showing traditional geometric design in brown wool pattern weft on undyed cotton ground. May be walnut dye. Possibly made in Pennsylvania., USA, mid-18th–early 19th century, woven textiles, Coverlet fragment

RM2DM8YKP–Coverlet fragment, Medium: wool, cotton Technique: plain compound weave (overshot), Fragment showing traditional design of combinations of various triangles and diamonds, slightly curving, in bands of rust red and two shades of blue wool on undyed cotton ground. Reversible., USA, 19th century, woven textiles, Coverlet fragment

RM2DMJ9CG–Coverlet fragment, Medium: wool, linen or cotton Technique: plain weave with supplementary weft patterning (overshot), Traditional coverlet design with blocks of geometric pattern and a deep chevron border, in dark blue, indigo-dyed wool with undyed linen (or cotton)., Pennsylvania, USA, early 19th century, woven textiles, Coverlet fragment

RM2DMTTRC–Coverlet fragment, Medium: cotton, wool Technique: plain compound cloth (overshot), Traditional geometrical decoration with squares in broad framework with various fillings. In deep blue, bright rust, and blue-green wool pattern wefts used in bands of these colors on undyed cotton ground., probably Pennsylvania, USA, early 19th century, woven textiles, Coverlet fragment

8613371530291

8613371530291