overshot titration manufacturer

A titration is a volumetric technique in which a solution of one reactant (the titrant) is added to a solution of a second reactant (the "analyte") until the equivalence point is reached. The equivalence point is the point at which titrant has been added in exactly the right quantity to react stoichiometrically with the analyten (when moles of titrant = moles of analyte). If either the titrant or analyte is colored, the equivalence point is evident from the disappearance of color as the reactants are consumed. Otherwise, an indicator may be added which has an "endpoint" (changes color) at the equivalence point, or the equivalence point may be determined from a titration curve. The amount of added titrant is determined from its concentration and volume:

A measured volume of the solution to be titrated, in this case, colorless aqueous acetic acid, CH3COOH(aq) is placed in a beaker. The colorless sodium hydroxide NaOH(aq), which is the titrant, is added carefully by means of a buret. The volume of titrant added can then be determined by reading the level of liquid in the buret before and after titration. This reading can usually be estimated to the nearest hundredth of a milliliter, so precise additions of titrant can be made rapidly.

Figure \(\PageIndex{1}\):The titration setup initially, before titrant (NaOH) has been added. NaOH is held in the burett, which is positioned above the beaker of acetic acid. Titrant (NaOH) is added until it neutralizes all of the analyte (acetic acid). This is called the equivalence point. Note: Unlike the picture, both substances are actually clear but are blue for visibility purposes in the picture.

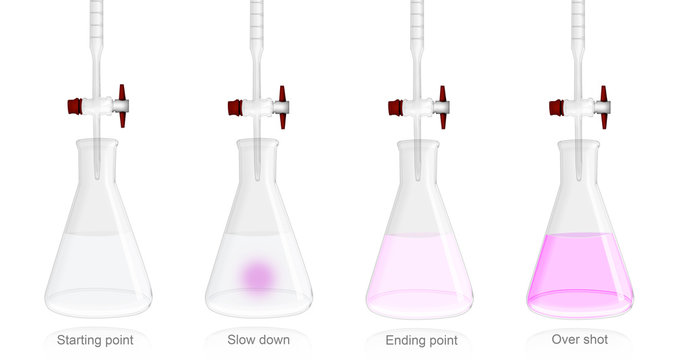

The added indicator changes to pink when the titration is complete, indicating that all of the aqueous acetic acid has been consumed by NaOH(aq). The reaction which occurs is

Eventually, all the acetic acid is consumed. Addition of even a fraction of a drop of titrant produces a lasting pink color due to unreacted NaOH in the flask. The color change that occurs at the endpoint of the indicator signals that all the acetic acid has been consumed, so we have reached the equivalence point of the titration. If slightly more NaOH solution were added, there would be an excess and the color of the solution in the flask would get much darker. The endpoint appears suddenly, and care must be taken not to overshoot the endpoint.

After the titration has reached the endpoint, a final volume is read from the buret. Using the initial and final reading, the volume added can be determined quite precisely:

Figure \(\PageIndex{2}\)The figure above shows a completed titration, where the equivalence point has been reached. NaOH (the titrant) has neutralized all of the Acetic Acid, leaving Acetate in the beaker. At this point, the moles of NaOH added is equivalent to the moles of acetic acid initially in the beaker.

The object of a titration is always to add just the amount of titrant needed to consume exactly the amount of substance being titrated. In the NaOH—CH3COOH reaction Eq. \(\ref{2}\), the equivalence point occurs when an equal molar amount of NaOH has been added from the graduated cylinder for every mole of CH3COOH originally in the titration flask. That is, at the equivalence point the ratio of the amount of NaOH, added to the amount of CH3COOH consumed must equal the stoichiometric ratio

Titration is often used to determine the concentration of a solution. In many cases it is not a simple matter to obtain a pure substance, weigh it accurately, and dissolve it in a volumetric flask as was done in Example 1 of Solution Concentrations. NaOH, for example, combines rapidly with H2O and CO2 from the air, and so even a freshly prepared sample of solid NaOH will not be pure. Its weight would change continuously as CO2(g) and H2O(g) were absorbed. Hydrogen chloride (HCl) is a gas at ordinary temperatures and pressures, making it very difficult to handle or weigh. Aqueous solutions of both of these substances must be standardized; that is, their concentrations must be determined by titration.

A sample of pure potassium hydrogen phthalate (KHC8H4O4) weighing 0.3421 g is dissolved in distilled water. Titration of the sample requires 27.03 ml NaOH(aq). The titration reaction is

By far the most common use of titrations is in determining unknowns, that is, in determining the concentration or amount of substance in a sample about which we initially knew nothing. The next example involves an unknown that many persons encounter every day.

If titration of a dissolved vitamin C tablet requires 16.85 cm³ of 0.1038 M NaOH, how accurate is the claim on the label of the bottle that each tablet contains 300 mg of vitamin C?

Manual titrations are time consuming and can be inaccurate at times due to human error. Not to mention, important data can get easily lost due to improper tracking methods. The Thermo Scientific Orion Star T900 Series Automated Titrators are designed to make performing titrations easier, more reliable, and more reproducible than manual titrations.

These auto titrators expand the number of ions and compounds that can be measured beyond direct electrode analysis and offer dynamic process controls that adjust the titration to optimize analysis results.

Manual titration can be a time consuming and frustrating process. Watch how easy it is to find the endpoint, reproduce your workflow, and optimize your results. The auto-filling burette helps to minimize the handling of corrosive materials. Use of an auto titrator well help ensure a safer, more efficient lab.

A water treatment plant in the midwestern United States that ran up to 10,000 titrations each year improved their workflow. Learn how streamlining the workflow using an Orion Star Automated Titrator for low-level alkalinity titrations benefited the lab.

In this white paper, you’ll learn about the dispense accuracy and precision of the Orion Star T900 Series Automated Titrators. We’ll demonstrate that our auto titrators exceed well-established industry precision and accuracy specifications, providing users with greater confidence in their titration applications.

Streamline your manual titration workflows and increase efficiency and repeatability with an Orion Star T900 Series Automated Titrator. Review the applications chart below to find out if an auto titrator is for you.

We are currently unable to offer solutions for Karl Fischer, amperometric, stat, and dead stop titrations. For other questions please contact customer support to be connected to your local sales representative.

Get our top 10 tips for performing automated titrations, and methodologies for common uses of an auto titrator. Discover how to perform an acid/base titration for orange juice, water and petroleum in this ebook.

Performing manual titrations can be extremely tedious, requiring the operator to stand in one place, watching minuscule droplets drip into a sample container and diligently waiting for the color change or other endpoint indictor to occur before starting the process all over again, for possibly hours and hours of repeated sample titrations.

An automatic titrator allows you to start the titration and then walk away from the titrator to perform other tasks or tests while the titrator takes care of the titrant addition, endpoint detection and results calculations automatically without any involvement from the operator.

Manual titrations typically use a non-certified, Class B or Class A burette with stopcock to add doses of titrant to the sample. The operator uses the stopcock to start and stop the additions of titrant into the sample, often one drop at a time, until the endpoint is reached.

The precision of these additions, especially near the endpoint, is primarily determined by the operator’s skill level, experience and focus on the task at hand. All too commonly, an operator can allow too much titrant to flow out of the burette into the sample and overshoot the endpoint, requiring them to perform the entire titration all over again. Even highly skilled and experienced operators can be limited in the precision of their manual titration results by the last few drops of titrant, since each drop can vary in volume.

When using an automatic titrator, the titration is performed using a high-accuracy titrant delivery system that controls all titrant additions into the sample and will adjust the dose rate as it detects the endpoint approaching.

Once the endpoint is reached, the titrator uses the precisely measured volume of titrant added to the sample to automatically calculate the concentration results for the sample. The operator’s skill level, experience and focus on the task at hand is no longer a factor in the overall accuracy of the titration results and the possibility of missing the endpoint is greatly reduced.

Typically calculating titrations in the lab is done by calculating the sample concentration after the endpoint has been reached. There are many points in this calculation where human error can get in the way of consistent, reproducible results.

When using an auto titrator, it will automatically calculate the sample concentration from the entered parameters. Plus, on the automatic titrator, electrode, titrant and titration setup parameters can be saved as a method, so the exact same settings are used for each titration. These methods can be transferred between titrators for consistent procedures to be used on multiple titrators or multiple labs. This way you can save time with repeat titrations by running the exact same parameters each time without having to reenter any information.

Instead of manually logging the titration results in a notebook or scrap of paper, an auto titrator will automatically save the titration results in the data log with time and date stamp.

The endpoint of titration is overshot! Does this technique error result in an increase, a decrease, or have no effect on the reported percent acetic acid in the vinegar? Explain.

Titration is a quantitative analytical volumetric technique that permits the determination of the unknown concentration of an analyte with a known concentration of titrant. This is possible because the two react in a known stoichiometric manner allowing calculation of the unknown concentration.

To find the concentration of an analyte in a solution, scientists turn to titration. Once a drop-by-drop-by-drop method, this can now be handled automatically with a titrator, but getting an accurate answer still takes some skill. Part of the needed skill depends on what is being tested. Nonetheless, some general information applies to virtually any titration situation.

“Titration issues are typically either systematic or random,” says Matthew Eby, application and technical support manager for the Mettler-Toledo NA division in Columbus, Ohio. “Systematic errors generate the same results, although incorrect, every time; random errors generate no results or various incorrect results without consistency.” Since systematic errors generate the same problems every time, they are the easiest to figure out. To see whether a problem is systematic, says Eby, “It is always advised before troubleshooting to run the sample or method with the issue multiple times to look for trends and to see the repeatability of the issue before attempting to address the problem.”

Scientists in research and industry use titration in so many ways that variety alone creates a challenge. “Depending on the type of reaction, whether it’s an acid-based, a redox, a complexometric, or a nonaqueous titration, using the right electrode can make all the difference,” says Lori Carey, product manager for titration at Metrohm USA in Riverview, Florida. “Metrohm has fine-tuned the electrode design for even the most difficult samples, and referencing our Metrohm titration monograph is very helpful as an overview for many titrations.”

The goal of titration is finding the end point, but that can be elusive. “There are many different reasons why an end point may not be obvious,” Carey says. “There are a few simple questions you can ask yourself to identify the cause.”

The questions, says Carey, include, is the correct titrant at the proper concentration being used? Is the electrode fully submerged in the sample? Is the sample completely dissolved, and is the analyte of interest available for titration? Are the increments in the titration method set properly? And did the titration just stop too soon?

Other experts also see users struggling at times with the titration end point. According to Alicia Guardado, technical adviser at Hach Company in Loveland, Colorado, “For titrations in which the user is looking for a visual end point, the most common issue is probably going to be overshooting the end point.” She adds, “This is usually caused by not completely mixing in each drop of titrant or dispensing drops that are too large.” Even for titrations that require a pH-change end point, Guardado points out, it can easily be overshot if the pH probe being used does not have a fast enough response.

Also, when titration runs into trouble, history impacts the troubleshooting. “If a titration method and procedure have been used for some time with success,” Eby says, “then that is the last thing one would want to modify; the fluctuations are most likely due to hardware, reagent, or sample inconsistencies.”

Even the sample can contribute to the problem. “With sample fluctuations, users should try to pretreat samples in a way that minimizes effects of interference, temperature, pH, etc., so that the results are consistent,” Guardado says. “Things like pH adjustment to a specified pH, dilution, and filtration are common pretreatment steps, and these will vary largely depending on the type of titration being performed.”

“The best way to deal with any fluctuations in system performance or sample results is to make sure you are taking care of your titration system,” Carey says. “Making sure the electrode is stored in the correct solution and calibrated properly will help reduce fluctuations.” In addition, she says, “Making sure that your dosing burettes are properly vented to the molecular sieve or ascarite will help protect the titrant concentration from degrading.”

To keep your automated titration running smoothly and accurately, Carey offers some valuable advice. “It’s always good to refresh your mind with how the electrode system works, because understanding the key functioning areas of an electrode will often lead you to the proper troubleshooting techniques,” she says. “Additionally, review the different modes of titration and how changes in titration parameters affect the shape of your titration curve.” To develop new titration knowledge or refresh it, Metrohm hosts several Titration Bootcamp courses. Carey says, “I would always recommend [these courses] to anyone working in the field of titration, regardless of their years of experience.”

So keeping up titration knowledge and the condition of the equipment go a long way toward preventing problems. Even an automated titrator needs care and skill to ensure ongoing accuracy in the results. The level of skill needed, however, depends on the task at hand.

In this webinar, learn how you can evaluate the quality of titrations in your lab and uncover potential financial and productivity improvements. http://www.labmanager.com/titrationsspotlight

A drift of zero can be a sign that the cell might be over-titrated. In combination with the mV signal (lower than end-point criteria) and the color of the working medium (darker yellow than usual), it is a clear indicator for over-titration. However, volumetric titrations sometimes exhibit a zero drift for a short time without being over-titrated.

If you have a real excess of iodine in the titration cell, the result of the next determination will most likely be erroneous. Therefore, over-titration should be avoided. There are various possible reasons for over-titration, like the sample itself (e.g., oxidizing agents which generate iodine from the working medium), the electrode (coating or invisible depositions on the Pt pins/rings), the reagent, and method parameters (e.g., the titration is rate too high), to name just a few.

Different factors can cause over-titration, however, the reagent is not always the reason behind this issue. The indicator electrode can also be the reason for overshooting the endpoint. In this case, regular cleaning of the electrode can prevent over-titration (see also questions 7 to 9 from Part 1 in this series on cleaning).

A low stirring speed also increases the risk of over-titration, so make sure the solution is well mixed. Depending on the type of reagent, the parameters of the titration need to be adjusted. Especially if you use two-component reagents, I recommend decreasing the speed of the titrant addition to avoid over-titration. Over-titration has an influence on the result, especially if the degree of over-titration changes from one determination to the next. So over-titration should always be avoided to guarantee correct results.

I recommend using the drift correction in coulometric KF titration only. You can also use it in volumetric titration, but here the drift level is normally not as stable as for coulometric titrations. This can result in variations in the results. A stabilization time can reduce such an effect. However, compared to the absolute water amounts in volumetry, the influence of drift is usually negligible.

If possible, use a larger sample size to increase the amount of water added to the titration cell with the sample. Furthermore, you should try to reduce the drift value in general. Perhaps the molecular sieve or the septum need to be replaced. You can also use a stabilizing time to make sure the drift is stable before analyzing the sample.

The sample is weighed in a headspace vial and closed with a septum cap. Then the vial is placed in the oven and heated to a predefined temperature, leading the sample to release its water. At the same time, a double hollow needle pierces through the septum. A dry carrier gas, usually nitrogen or dried air, flows into the sample vial. Taking the water of the sample with it, the carrier gas flows into the titration cell where the water content determination takes place.

Very often, the oven is used in combination with a coulometric titrator. The coulometric titration cell used in an oven system is filled with 150 mL of reagent. Theoretically, this amount of reagent allows for the determination of 1500 mg of water. However, this amount is too high to be determined in one titration and it would lead to very long titration times and negative effects on the results. We recommend that the water content of a single sample (in a vial) should not be higher than 10 mg, ideally around 1000–2000 µg water. For samples with water contents in the higher percentage range, you should consider the combination with a volumetric titrator.

Post written by Michael Margreth, Sr. Product Specialist Titration (Karl Fischer Titration)at Metrohm International Headquarters, Herisau, Switzerland.

Using a color indicator for manual titrations can be fast and simple, but there is a trade-off between time and accuracy. Color indicators are chemical dyes that change color based on the properties of a solution.

These color indicators are often used during manual titrations as an indicator of the consumption of a certain chemical, or the presence of a chemical in excess. The color change correlates to the titration endpoint.

In a potentiometric measuring system, a titration endpoint is determined based on a change in potential in the solution. A meter and sensor accurately determine the millivolt (mV) potential of the sample solution. The sensor, such as a pH, ORP, or ion selective electrode, behaves according to the Nernst equation.

The type of sensor used will determine which ion(s) in the solution are measured. The inner reference potential of the electrode’s cell is compared to the outer membrane potential. During a titration, the activity of the ion being titrated changes as the titration progresses. The titration endpoint can be detected by determining the point where the maximum potential change occurs.

A nickel titration can be determined potentiometrically. However, nickel is a special case in that a sensor to directly detect ion activity is not commercially available. Instead, the nickel concentration can be determined in a titration by monitoring the displacement of copper by nickel with a cupric ion selective electrode (ISE).

We then titrate with EDTA. As the titration progresses, EDTA first binds the nickel ions in solution. Once all the nickel is bound, the EDTA then react with the free copper ions in solution. When this happens, the activity of the copper ion drastically decreases, which is detected by the cupric ISE. This signals the titrator to detect the endpoint.

With potentiometry, we are monitoring the actual activity of the ion we are trying to measure rather than looking at a color change with our eyes. Tracking the titration this way allows the reaction to be monitored in a consistent manner that eliminates subjectivity and increases accuracy and consistency between analysts.

Titrations by hand are tedious and the endpoint can easily be overshot. A manual burette stopcock can only dispense one drop (~50 µL) at a time, and it takes skill to do so. This is not the case with automatic titration. An automatic titrator can dose down to 5 µL per dose with a standard 25 mL burette installed, ensuring that the endpoint is precisely detected every time.

Automation also helps increase accuracy and repeatability without wasting time. By utilizing customizable and flexible dosing options offered by many automatic titrators, the titrator looks at the rate of mV change throughout the titration to determine the dosing speed and size.

By doing this, larger volumes will be dosed more frequently at the beginning of the titration since the potential change is small. As the reaction approaches the endpoint, the mV potential starts to change more dramatically per dose. As a result, the titrator proportionally scales down the dose size and increases the time between doses.

Dosing a larger volume of titrant in the beginning of the titration, and less at the end, keeps the speed of each titration to a minimum while ensuring high resolution around the endpoint. Automating the dosing and endpoint detection allows analysts to perform other lab duties.

Since they used a color indicator, their titration results were open to interpretation between many different technicians. The lab manager noticed that they were obtaining inconsistent results across shifts, and this resulted in inconsistencies in their finished products.

Hanna Instruments worked with the manufacturer to automate their manual titrations using our Automatic Potentiometric Titrator HI932. Once the titrations were automated, results became consistent across shifts and the analysts were able to perform other tasks while a titration was running.

The Automatic Titrator Nickel Package HI932 offers everything you need to accomplish a smooth transition from manual titrations to automated titrations. Our HI932 package includes:

It is a time-saving approach that reduces the likelihood of human error during the titration process along with helping to prevent any overshooting of the endpoint.

Titration is a sensitive analytical method that lets you determine an unknown concentration of a chemical in solution by introducing a known concentration of another chemical. Several factors can cause errors in titration findings, including misreading volumes, mistaken concentration values or faulty technique. Care must be taken as the solution of the known concentration is introduced into a specific volume of the unknown through laboratory glassware such as a burette or pipette. Indicators are used to determine when a reaction has come to an end.

The end point of a titration is when the reaction between the two solutions has stopped. Indicators, which change color to indicate when the reaction has stopped, do not change instantly. In the case of acid-base titration, the indicator may first lighten in color before changing completely. Also, each individual perceives color slightly differently, which affects the outcome of the experiment. If the color has changed slightly, too much of the titrant, which comes from the burette, can be introduced into the solution, overshooting results.

The accuracy of titration requires precise measurement of the volume of materials in use. But markings on a burette can be easily misread. One way to misread the volume is by looking at the measurement on an angle. From above, it can seem like the volume is lower, while from below, the apparent volume looks higher. Another source of measurement error is looking at the wrong spot. A solution forms a concave curve and the bottom of the curve is used to measure the volume. If the reading is taken from the higher sections of the curve, the volume measurement will be in error.

Other human or equipment errors can also creep in. Human error includes using selecting the wrong reagents or using the wrong amount of indicator. Equipment error typically is in the burette, which can develop leaks over time. Even a small loss of fluid will affect the results of the titration.

This invention generally relates to the quantitative chemical analysis of liquids by means of volumetric titration, more specifically it provides a device that is more compact, rugged, and easier to use than the presently available apparatus, while maintaining accuracy of measurement.

The analysis of fluids for a specific chemical constituent is often accomplished by a procedure known as titration, in which a standard solution is mixed in increments with a sample to which has been added a color-forming indicator so that a marked color change occurs at the point where the amount of standard solution just neutralizes all of the constituent present in the sample. At this endpoint, the amount of the unknown constituent in the sample may be ascertained from the amount of standard solution used.

The prior art basic apparatus used for titration has hardly changed since the beginning, and remains cumbersome and difficult to use. The unknown is delivered to a titration flask with a pipette, then standard is added by means of a burette until the endpoint is reached. Specifically, it suffers from the following disadvantages:

a) The apparatus is of multiple pieces. At a minimum, six pieces are required: a pipette, a burette, a burette stand, a burette clamp, a titration flask, and a funnel.

f) The burette must be rinses before use with the standard. This takes time and wastes standard. Also, standard remaining in the burette at the end of a series of titrations must be discarded.

i) A small amount of unknown or standard may be splashed on the side of the titration flask. The titration must be paused to wash down this deposit, or a titration error will occur.

j) Any partial droplet on the tip of the burette is shown by burette reading as having been delivered, but has not been delivered to the titration flask. For best accuracy, it must be washed off into the titration flask.

l) The operator must add precisely the right amount of standard to achieve the endpoint. One must proceed cautiously or too much standard will be added, overshooting the end point. A good deal of time may be consumed doing a titration because of fear of overshooting the end point. This is especially true for an inexperienced operator. If the end point is overshot, the operator must then repeat the titration, or live with a less than optimum result.

n) The apparatus is most accurate when a substantial portion of the contents of the burette is used for a titration. Therefore, to attain the required accuracy, it may be necessary to repeat the titration using a different amount of unknown, either by using a different pipette or by quantitatively diluting the unknown; or it may be necessary to use a standard of greater or lesser strength.

o) It is sometimes advantageous or necessary to perform reverse titrations, where the standard is titrated with the unknown. It is very inconvenient to do a series of reverse titrations, as the burette must be drained and filled with each new unknown.

Improvements have been made by the invention upon the basic apparatus. The glassware may be replaced by plastic. The burette can be arranged so that it is automatically filled. The burette may be replaced by a dispenser with digital readout. Stirring may be done with a magnetic stirrer and stir bar. However, the basic manipulations remain the same, with the result that performing a titration remains a complex and time consuming matter. Simpler methods using drip counting have been described and are used, however, they are of limited accuracy.

Automated analyzers have been developed, however they are expensive and are best used for the analysis of many similar samples. Such analyzers are not suited for field or educational use, or the analysis of a small number of samples. U.S. Pat. No. 5,817,954 issued to Kahng et. al. on Oct. 6, 1998, shows how the apparatus for automatic titration can be simplified, using some of the same ideas as the present patent.

l) There is very good indication of the nearness to the endpoint, and the adjustment to the endpoint is rapid and easily done. Therefore, the time required to do titration is much reduced.

q) The apparatus is easily customized or programmed so that the results of titrations of a given sort can be directly read form the scale or digital display, with no computation required. Other objects and advantages will become apparent from the specifications, drawings, and description.

A syringe barrel 22 is constructed of material resistant to the chemicals used during the titration. Glass and various plastics are suitable. A needle 30 is attached to the syringe barrel 22 by a fitting, or it may be cemented in place. The needle is generally of stainless steel, but small bore plastic tubing may also be used. The inside bore of the needle should be as small in bore as possible without unduly restricting the uptake and discharge of the standard and unknown. The syringe barrel 22 may also have an opening for attachment of a sensor 44 located at the base of the syringe barrel 22 near the syringe inlet. Placement of the sensor near the inlet is important because when placed there, it can give information about the approach of the endpoint. The sensor is most commonly a pH electrode. Sensor 42 is connected to a meter for sensor 46 which may be an integral part of the titration apparatus. A vernier scale 24 imprinted upon barrel 22 is used in conjunction with a scale 28 imprinted on the plunger 26 to read the volumes used. For less accurate work a vernier is not necessary, and a single mark on the barrel will suffice. Because it is the proportion of unknown to standard that is of interest, the divisions of the scale need not correspond to any standard unit of volume. Rather, they are chosen for maximum readability. Division into centimeters and subdivision into millimeters is a good choice. A displacement sensor 50 connected to volume display 52 may also be used to measure the volumes of unknown and standard. These sensors are in common use, the most basic application being a calipers with digital readout.

A microprocessor with controls and display 58 may be electrically connected to displacement sensor 50. The microprocessor may be used to record the volume information, the strength of the standard, and to calculate the strength of the unknown. A holder 54 may be used to store the apparatus between uses, to charge the battery between uses, and to hold the apparatus in a fixed relationship to the unknown or standard in a beaker 56 during the titration.

The apparatus is first rinsed with water or other suitable liquid and the syringe plunger is positioned at or near the bottom. The small amount of liquid remaining in the syringe will not interfere with the titration. The beginning position is read. The needle tip is then wiped free of any adhering liquid. The syringe is held in a generally horizontal position, and the tip of the needle placed in a sample of the unknown. If the endpoint is to be detected by means of a color change, the addition of a small amount of an indicator to either the standard or unknown is generally necessary. A volume of the unknown is drawn into the syringe. The needle is withdrawn, wiped clean of unknown, and the volume read from the scale and vernier. The stirrer is then turned on. The needle is then placed in a sample of the standard and the standard is drawn up until the endpoint is reached. The rate of stirring is such that mixing is sufficiently slow so the nearness of the endpoint can be easily ascertained, either by a change in color in the region near the inlet or by a change in the sensor readout, the sensor being placed near the inlet. The importance of a proper rate of mixing and how this makes it easy to rapidly adjust to the endpoint cannot be overemphasized. It the mixing rate is too rapid, there will be little notice of the approach of the endpoint. If the mixing rate is too slow, excessive time is spent waiting for mixing to become complete. The small movements necessary to get exactly to the endpoint are more easily made if a thumb wheel or other means is used. At the end of the titration, the amount of standard is read. A calculation using the amount of unknown, the amount of standard, and the strength of the standard is done to give the strength of the unknown. For the most accurate work, a correction for the amount of standard left in the syringe is made. All liquid is expelled from the syringe and the apparatus is ready for the next titration.

If a series of titrations of a given type is planned and a standard of consistent strength is available, a scale may be selected that has a mark showing the amount of unknown to be drawn up, and that will directly read the concentration of the unknown at the end of the titration, making a calculation unnecessary. For example the apparatus can be used to determine the titratable acidity of a wine, or the grape juice or other juice from which a wine is to be made. The syringe is equipped with a mark indicating the amount of unknown to be drawn up. The titration is done with a standard base solution until the endpoint is reached. Marks of the syringe plunger show directly the titratable acidity in any desired units. Thus a series of removable scales can be used with the same plunger to perform different standardized titration.

Thus the reader will see that the titration apparatus of the invention provides a highly compact and easy to use device with many advantages over existing apparatus.

The apparatus is suitable for almost any type of volumetric titration, with the exception of those which evolve a gas, or form a precipitate which would clog the needle. The apparatus as described titrates a liquid with a liquid. A solid can be titrated if it is dissolved and drawn up in its entirety. The apparatus could also find use in the compounding of solutions, especially those that require a titration.

The accuracy attainable is limited principally by the quality of construction and the readability of the volumes. The apparatus will be most accurate when the full volume of the syringe is used, and the amounts of unknown and standard are equal. For example, with a vernier scale and a syringe travel of 70 millimeters, the unknown and the standard could each be read to 0.1 of 35 millimeters, leading to a potential accuracy of about 0.5% for the titration. If the amount of unknown is 10% of the amount of standard, or the reverse, the liquid drawn up in lesser amount could be read to 0.1 of 7 millimeters, leading to a potential accuracy of about 1.4%. Thus, a large range of unknowns can be analyzed with a given standard without great loss of accuracy. If a displacement sensor with digital readout is fitted, the accuracy of reading is increased, as these sensors can detect a change in position of as little as 0.01 millimeter.

This invention relates to the quantitative chemical analysis of liquids by means of volumetric titration, and aims to provide a device that is more compact, rugged, and easier to use than the presently available apparatus, while maintaining accuracy of measurement.

The analysis of fluids for a specific chemical constituent is often accomplished by a procedure known as titration, in which a standard solution is mixed in increments with a sample to which has been added a color-forming indicator so that a marked color change occurs at the point where the amount of standard solution just neutralizes all of the constituent present in the sample. At this endpoint, the amount of the unknown constituent in the sample may be ascertained from the amount of standard solution used.

The basic apparatus used for titrations has hardly changed since the beginning, and remains cumbersome and difficult to use. The unknown is delivered to a titration flask with a pipette, then standard is added by means of a burette until the endpoint is reached. Specifically, it suffers from the following disadvantages:

a) The apparatus is of multiple pieces. At a minimum, six pieces are required: a pipette, a burette, a burette stand, a burette clamp, a titration flask, and a funnel.

f) The burette must be rinsed before use with the standard. This takes time and wastes standard. Also, standard remaining in the burette at the end of a series of titrations must be discarded.

i) A small amount of unknown or standard may be splashed on the side of the titration flask. The titration must be paused to wash down this deposit, or a titration error will occur.

j) Any partial droplet on the tip of the burette is shown by burette reading as having been delivered, but has not been delivered to the titration flask. For best accuracy, it must be washed off into the titration flask.

l) The operator must add precisely the right of amount of standard to achieve the endpoint. One must proceed cautiously or too much standard will be added, overshooting the endpoint. A good deal of time may be consumed doing a titration because of fear of overshooting the endpoint. This is especially true for an inexperienced operator. If the end point is overshot, the operator must then repeat the titration, or live with a less than optimum result.

n) The apparatus is most accurate when a substantial portion of the contents of the burette is used for a titration. Therefore, to attain the required accuracy, it may be necessary to repeat the titration using a different amount of unknown, either by using a different pipette or by quantitatively diluting the unknown; or it may be necessary to use a standard of greater or lesser strength.

o) It is sometimes advantageous or necessary to perform reverse titrations, where the standard is titrated with the unknown. It is very inconvenient to do a series of reverse titrations, as the buret must be drained and filled with each new unknown.

Improvements have been made upon the basic apparatus. The glassware may be replaced by plastic. The burette can be arranged so that it is automatically filled. The burette may be replace by a dispenser with digital readout. Stirring may be done with a magnetic stirrer and stir bar. However, the basic manipulations remain the same, with the result that performing a titration remains a complex and time consuming matter. Simpler methods using drop counting have been described and are used, however they are of limited accuracy.

Automated analyzers have been developed, however they are expensive and are best used for the analysis of many similar samples. They are not suited for field or educational use, or the analysis of a small number of samples. U.S. Pat. No. 5,817,954 issued to Kahng et. al. on Oct. 6, 1998, shows how the apparatus for automatic titration can be simplified, using some of the same ideas as the present patent.

It is the object of this invention to provide an apparatus and technique for titration that is superior to the existing apparatus. Specifically, some advantages are:

l) There is very good indication of the nearness to the endpoint, and the adjustment to the endpoint is rapid and easily done. Therefore, the time required to do a titration is much reduced.

q) The apparatus is easily customized or programed so that the results of titrations of a given sort can be directly read from the scale or digital display, with no computation required.

A syringe barrel 22 is constructed of material resistant to the chemicals used during the titration. Glass and various plastics are suitable. A needle 30 is attached to the syringe barrel 22 by a fitting, or it may be cemented in place. The needle is generally of stainless steel, but small bore plastic tubing may also be used. The inside bore of the needle should be as small in bore as possible without unduly restricting the uptake and discharge of the standard and unknown. The syringe barrel 22 may also have an opening for attachment of a sensor 44, located at the base of the barrel 22 near the syringe inlet. Placement of the sensor near the inlet is important because when placed there, it can give information about the approach of the endpoint. The sensor is most commonly a pH electrode. Sensor 42 is connected to a meter for sensor 46 which may be an integral part of the titration apparatus, A vernier scale 24 imprinted upon barrel 22 is used in conjunction with a scale 28 imprinted on the plunger 26 to read the volumes used. For less accurate work, a vernier is not necessary, and a single mark on the barrel will suffice. Because it is the proportion of unknown to standard that is of interest, the divisions of the scale need not correspond to any standard unit of volume. Rather, they are chosen for maximum readability. Division into centimeters and subdivision into millimeters is a good choice. A displacement sensor 50 connected to volume display 52 may also be used to measure the volumes of unknown and standard. These sensors are in common use, the most basic application being a calipers with digital readout.

A microprocessor with controls and display 58 may be electrically connected to displacement sensor 50. The microprocessor may be used to record the volume information, the strength of the standard, and to calculate the strength of the unknown. A holder 54 may be used to store the apparatus between uses, to charge the battery between uses, and to hold the apparatus in a fixed relationship to the unknown or standard in a beaker 56 during the titration.

The apparatus is first rinsed with water or other suitable liquid and the syringe plunger is positioned at or near the bottom. The small amount of liquid remaining in the syringe will not interfere with the titration. The beginning position is read. The needle tip is then wiped free of any adhering liquid. The syringe is held in a generally horizontal position, and the tip of the needle placed in a sample of the unknown. If the endpoint is to be detected by means of a color change, the addition of a small amount of an indicator to either the standard or unknown is generally necessary. A volume of the unknown is drawn into the syringe. The needle is withdrawn, wiped clean of unknown, and the volume read from the scale and vernier. The stirrer is then turned on. The needle is then placed in a sample of the standard and the standard is drawn up until the endpoint is reached. The rate of stirring is such that mixing is sufficiently slow so the the nearness of the endpoint can be easily ascertained, either by a change in color in the region near the inlet. or by a change in the sensor readout, the sensor being placed near the inlet. The importance of a proper rate of mixing and how this makes it easy to rapidly adjust to the endpoint cannot be overemphasized. If the mixing rate is too rapid, there will be little notice of the approach of the endpoint. If the mixing rate is too slow, excessive time is spent waiting for mixing to become complete. The small movements necessary to get exactly to the endpoint are more easily made if a thumb wheel or other means is used. At the end of the titration, the amount of standard is read. A calculation using the amount of unknown, the amount of standard, and the strength of the standard is done to give the strength of the unknown. For the most accurate work, a correction for the amount of standard left in the syringe is made. All liquid is expelled from the syringe and the apparatus is ready for the next titration.

If a series of titrations of a a given type is planned and a standard of consistent strength is available, a scale may be selected that has a mark showing the amount of unknown to be drawn up, and that will directly read the concentration of the unknown at the end of the titration, making a calculation unnecessary. For example the apparatus can be used to determine the titratable acidity of a wine, or the grape juice or other juice from which a wine is to be made. The syringe is equipped with a mark indicating the amount of unknown to be drawn up. The titration is done with a standard base solution until the endpoint is reached. Marks on the syringe plunger show directly the titratable acidity in any desired units. Thus a series of removable scales can be used with the same plunger to perform different standardized titrations.

Thus the reader will see that the titration apparatus of the invention provides a highly compact and easy to use device with many advantages over existing apparatus.

The apparatus is suitable for almost any type of volumetric titration, with the exception of those which evolve a gas, or form a precipitate which would clog the needle. The apparatus as described titrates a liquid with a liquid. A solid can be titrated if it is dissolved and drawn up in its entirety. The apparatus could also find use in the compounding of solutions, especially those that require a titration.

The accuracy attainable is limited principally by the quality of construction and the readability of the volumes. The apparatus will be most accurate when the full volume of the syringe is used, and the amounts of unknown and standard are equal. For example, with a vernier scale and a syringe travel of 70 millimeters, the unknown and the standard could each be read to 0.1 of 35 millimeters, leading to a potential accuracy of about 0.5% for the titration. If the amount of unknown is 10% of the amount of the standard, or the reverse, the liquid drawn up in lesser amount could be read to 0.1 of 7 millimeters, leading to a potential accuracy of about 1.4%. Thus, a large range of unknowns can be analyzed with a given standard without great loss of accuracy. If a displacement sensor with digital readout is fitted, the accuracy of reading is increased, as these sensors can detect a change in position of as little as 0.01 millimeter.

8613371530291

8613371530291