overshot titration factory

Electrogravimetry is a method used to separate and quantify ions of a substance, usually a metal. Quantification of these ions primarily depends on the rate of movement of charged species (ions) in an electric field. This article details the various types of electrometric titrations, namely, conductometric titration, oscillometric (high frequency) titration, potentiometric titration, amperometric titration, biamperometric titration, bipotentiometric titration, and coulometric titration. It also provides a brief outline of the applications of electrometric titrations.

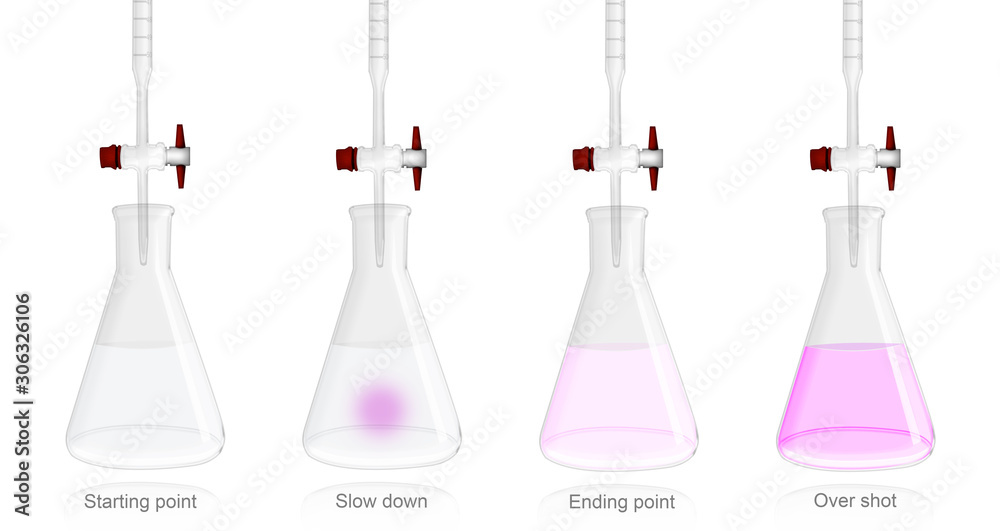

During your titration, you overshot your endpoint and your solution was too pink. Would this lead to a final pKa that was too high or too low? Explain why using chemical reasoning.

The pKa will not be affected since pKa values are obtained before the endpoint of the titration. In a titration curve, it is found in the region where...

Process analyzers have been specially developed for use in harsh and aggressive industrial environments. The IP66protected housing is divided into two parts, and consists of separate wet and electronic parts. The electronics part contains all components relevant to control and operate the process analyzer. Modular components like burettes, valves, pumps, sampling systems, titration vessels, and electrodes can be found in the analyzer wet part. Representative samples can thus be taken from the process measuring point several meters away. The analysis procedure, the methods to be used, and method calculations are freely programmable.

Potential dangers for the entire system can be caused by incorrect measurement results. In order to minimize the risk, a detector is used to notify the system of the presence of sample in the vessel. The testing of the initial potential of the analysis or titration curves / color development in photometric measurements are diagnostic data that are continuously recorded and interpreted. Results can be verified by reference analysis or their plausibility can be clarified using standard and check solutions.

The Romans were known to use waterwheels extensively in mining projects, with enormous Roman-era waterwheels found in places like modern-day Spain. They were reverse overshot water-wheels designed for dewatering mines. A series of overshot mills existed at Barbegal near Arles in southern France where corn was milled for the production of bread. The Roman poet Ausonius mentions a mill for cutting marble on the Moselle. Floating mills were also known from the later Empire, where a wheel was attached to a boat moored in a fast flowing river.

Most water wheels in the United Kingdom and the United States are (or were) vertical wheels rotating about a horizontal axle, but in the Scottish highlands and parts of southern Europe mills often had a horizontal wheel (with a vertical axle). Water wheels are classified by the way in which water is applied to the wheel, relative to the wheel"s axle. Overshot & pitchback waterwheels are suitable where there is a small stream with a height difference of more than 2 meters, often in association with a small reservoir. Breastshot and undershot wheels can be used on rivers or high volume flows with large reservoirs.

Breastshot wheels are less efficient than overshot wheels (see below), more efficient than undershot wheels, and are not backshot (see below). The individual blades of a breastshot wheel are actually buckets, as are those of most overshot wheels, and not simple paddles like those of most undershot wheels. A breastshot wheel requires a good trash rake and typically has a masonry "apron" closely conforming to the wheel face, which helps contain the water in the buckets as they progress downwards. Breastshot wheels are preferred for steady, high-volume flows such as are found on the fall line of the North American East Coast.

A vertically-mounted water wheel that is rotated by falling water striking paddles, blades or buckets near the top of the wheel is said to be overshot. In true overshot wheels the water passes over the top of the wheel, but the term is sometimes applied to backshot or pitchback wheels where the water goes down behind the waterwheel.

A typical overshot wheel has the water channeled to the wheel at the top and slightly beyond the axle. The water collects in the buckets on that side of the wheel, making it heavier than the other "empty" side. The weight turns the wheel, and the water flows out into the tail-water when the wheel rotates enough to invert the buckets. The overshot design can use all of the water flow for power (unless there is a leak) and does not require rapid flow.

Unlike undershot wheels, overshot wheels gain a double advantage from gravity. Not only is the force of the flowing water partially transferred to the wheel, the weight of the water descending in the wheel"s buckets also imparts additional energy. The mechanical power derived from an overshot wheel is determined by the wheel"s physical size and the available head, so they are ideally suited to hilly or mountainous country. On average, the undershot wheel uses 22 percent of the energy in the flow of water, while an overshot wheel uses 63 percent, as calculated by English civil engineer John Smeaton in the 18th century.

Overshot wheels demand exact engineering and significant head, which usually means significant investment in constructing a dam, millpond and waterways. Sometimes the final approach of the water to the wheel is along a lengthy flume or penstock.

A backshot wheel (also called pitchback) is a variety of overshot wheel where the water is introduced just behind the summit of the wheel. It combines the advantages from breastshot and overshot systems, since the full amount of the potential energy released by the falling water is harnessed as the water descends the back of the wheel.

A backshot wheel continues to function until the water in the wheel pit rises well above the height of the axle, when any other overshot wheel will be stopped or even destroyed. This makes the technique particularly suitable for streams that experience extreme seasonal variations in flow, and reduces the need for complex sluice and tail race configurations. A backshot wheel may also gain power from the water"s current past the bottom of the wheel, and not just the weight of the water falling in the wheel"s buckets.

Overshot (and particularly backshot) wheels are the most efficient type; a backshot steel wheel can be more efficient (about 60%) than all but the most advanced and well-constructed turbines. Nevertheless, in some situations an overshot wheel is preferable to a turbine.

Traditionally water wheels have been made mostly from wood. Steel in overshot (and pitchback) wheels allows higher speeds. A wooden wheel with a wooden axle cannot necessarily sustain high speed needed for hydroelectric power generation.

The pulse amplitude is another key variable for targeting as it controls the volume of neural tissue directly activated by the induced electric field. Reducing ECT pulse amplitude, in conjunction with an appropriate electrode configuration, can enable focusing of the neural stimulation to particular brain regions salient to therapeutic effect, while minimizing the electric field strength in areas that could result in undesirable side effects. Furthermore, individual amplitude adjustment appears to be the most appropriate approach to compensate for anatomical variability across patients, as it could provide comparable electric field magnitude in the brains of all patients. For these reasons, the pulse amplitude is a central dosing parameter in other brain stimulation therapies such as rTMS and DBS. Some older ECT studies have used amplitude titration for individual dosing, yielding current amplitudes significantly below presently used values (800/900 mA). However, there has not been significant effort to explore this parameter in recent studies, which could be explained in part by the non-existent or limited amplitude control features of common ECT devices. Amplitude titration could also reduce adverse side effects associated with seizure threshold titration procedures, since it employs a gradual increase of the volume of activated neural tissue until a seizure is elicited, thus avoiding excessive stimulation of large portions of the brain that would occur at conventional current amplitudes. The potential clinical value of lowering pulse amplitude and of amplitude titration to individualize dosage should be examined.

8613371530291

8613371530291