overshot water wheel efficiency quotation

Utilizing of low renewable energy sources is an actual topic nowadays. This paper is focused on the locations with the low hydro-energy potential. It means locations with a head about 1m and flow rates about tens of litres per second. Hydro turbines for such parameters belong to the pico-turbines. It is not easy to design the hydro-turbine for such parameters with an acceptable efficiency. One of the possibilities is to use a water wheel. It is possible to find in a literature that the efficiency of overshot water wheels achieves 85%. This is the very good efficiency. It is not so easy to find some experimental data which proves this statement. Aims of this work are to design a simple manufactured overshot water wheel, measure the hydraulic efficiency of this wheel for wide range of parameters, finding an effect of the leading edge adjusting and the effect of the channel outflow edge position on the water wheel efficiency.

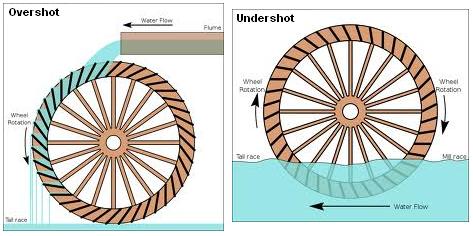

Each different type of water wheel has its advantages and disadvantages as well as features which make them suitable or unsuitable for different situations. In this article we will present a detailed mathematical analysis looking at the maximum possible efficiency of the overshot and undershot designs of water wheel. Many thanks to retired radio physics lecturer Bill for sharing this work with us.

The efficiencies of various types of water wheel are often quoted but it can be difficult to find a derivation. Only two types are discussed the overshot and the undershot. It is almost common sense to recognise that a greater efficiency will be realised when the wheel is overshot because we are using the weight of the water as well as the kinetic energy inherent in the water by virtue of its flow.

Water wheels have been with us some time and because of the spiralling cost of hydrocarbon fuels more people with the appropriate land and water are turning back to the water wheel for a cheap supply of power for heating and lighting.

This document looks albeit very superficially at water wheels and their efficiencies. There are a large number of variations of water wheels each with their own advantages and disadvantages. I have avoided the Pelton wheel which is far superior to a conventional water wheel – one of the reasons for this is because it extracts nearly all of the available energy by virtue of the reversal of momentum due to the shape of its cups.

Thanks to a new sensibility to renewable energy and to local and smart electricity production, traditional water wheels are regarded again as a clean and accessible way for pico-micro hydro electricity generation, especially in presence of very low heads and small flowrates. In particular, among the different kinds of water wheels, the overshot ones exploit the lowest flowrates with the highest efficiency (efficiency up to 85–90%).

Therefore, in order to determine the performance characteristics and to estimate the power losses and the output power for overshot water wheels, theoretical and experimental analyses are here developed. By a numerical optimization process, the power losses and the mechanical output power are theoretically quantified. A critical angular velocity is also identified (about 65% of the runaway speed). When the wheel rotation speed approaches the critical velocity, volumetric losses at the top of the wheel begin to increase linearly with the rotational velocity, while the other power losses start to decrease, due to the lower amount of water available to the wheel.

A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a wheel (usually constructed from wood or metal), with a number of blades or buckets arranged on the outside rim forming the driving car. Water wheels were still in commercial use well into the 20th century but they are no longer in common use. Uses included milling flour in gristmills, grinding wood into pulp for papermaking, hammering wrought iron, machining, ore crushing and pounding fibre for use in the manufacture of cloth.

Some water wheels are fed by water from a mill pond, which is formed when a flowing stream is dammed. A channel for the water flowing to or from a water wheel is called a mill race. The race bringing water from the mill pond to the water wheel is a headrace; the one carrying water after it has left the wheel is commonly referred to as a tailrace.

Waterwheels were used for various purposes from agriculture to metallurgy in ancient civilizations spanning the Hellenistic Greek world, Rome, China and India. Waterwheels saw continued use in the Post-classical age, like the Middle Ages of Europe and the Islamic Golden Age, but also elsewhere. In the mid to late 18th century John Smeaton"s scientific investigation of the water wheel led to significant increases in efficiency supplying much needed power for the Industrial Revolution.turbine, developed by Benoît Fourneyron, beginning with his first model in 1827.elevations, that exceed the capability of practical-sized waterwheels.

The main difficulty of water wheels is their dependence on flowing water, which limits where they can be located. Modern hydroelectric dams can be viewed as the descendants of the water wheel, as they too take advantage of the movement of water downhill.

Overshot and backshot water wheels are typically used where the available height difference is more than a couple of meters. Breastshot wheels are more suited to large flows with a moderate head. Undershot and stream wheel use large flows at little or no head.

There is often an associated millpond, a reservoir for storing water and hence energy until it is needed. Larger heads store more gravitational potential energy for the same amount of water so the reservoirs for overshot and backshot wheels tend to be smaller than for breast shot wheels.

Overshot and pitchback water wheels are suitable where there is a small stream with a height difference of more than 2 metres (6.5 ft), often in association with a small reservoir. Breastshot and undershot wheels can be used on rivers or high volume flows with large reservoirs.

Stream wheels are cheaper and simpler to build and have less of an environmental impact, than other types of wheels. They do not constitute a major change of the river. Their disadvantages are their low efficiency, which means that they generate less power and can only be used where the flow rate is sufficient. A typical flat board undershot wheel uses about 20 percent of the energy in the flow of water striking the wheel as measured by English civil engineer John Smeaton in the 18th century.

Stream wheels mounted on floating platforms are often referred to as hip wheels and the mill as a ship mill. They were sometimes mounted immediately downstream from bridges where the flow restriction of the bridge piers increased the speed of the current.

An undershot wheel is a vertically mounted water wheel with a horizontal axle that is rotated by the water from a low weir striking the wheel in the bottom quarter. Most of the energy gain is from the movement of the water and comparatively little from the head. They are similar in operation and design to stream wheels.

The word breastshot is used in a variety of ways. Some authors restrict the term to wheels where the water enters at about the 10 o’clock position, others 9 o’clock, and others for a range of heights.

The small clearance between the wheel and the masonry requires that a breastshot wheel has a good trash rack ("screen" in British English) to prevent debris from jamming between the wheel and the apron and potentially causing serious damage.

Breastshot wheels are less efficient than overshot and backshot wheels but they can handle high flow rates and consequently high power. They are preferred for steady, high-volume flows such as are found on the Fall Line of the North American East Coast. Breastshot wheels are the most common type in the United States of America

A vertically mounted water wheel that is rotated by water entering buckets just past the top of the wheel is said to be overshot. The term is sometimes, erroneously, applied to backshot wheels, where the water goes down behind the wheel.

A typical overshot wheel has the water channeled to the wheel at the top and slightly beyond the axle. The water collects in the buckets on that side of the wheel, making it heavier than the other "empty" side. The weight turns the wheel, and the water flows out into the tail-water when the wheel rotates enough to invert the buckets. The overshot design is very efficient, it can achieve 90%,

Nearly all of the energy is gained from the weight of water lowered to the tailrace although a small contribution may be made by the kinetic energy of the water entering the wheel. They are suited to larger heads than the other type of wheel so they are ideally suited to hilly countries. However even the largest water wheel, the Laxey Wheel in the Isle of Man, only utilises a head of around 30 m (100 ft). The world"s largest head turbines, Bieudron Hydroelectric Power Station in Switzerland, utilise about 1,869 m (6,132 ft).

Overshot wheels require a large head compared to other types of wheel which usually means significant investment in constructing the headrace. Sometimes the final approach of the water to the wheel is along a flume or penstock, which can be lengthy.

A backshot wheel (also called pitchback) is a variety of overshot wheel where the water is introduced just before the summit of the wheel. In many situations, it has the advantage that the bottom of the wheel is moving in the same direction as the water in the tailrace which makes it more efficient. It also performs better than an overshot wheel in flood conditions when the water level may submerge the bottom of the wheel. It will continue to rotate until the water in the wheel pit rises quite high on the wheel. This makes the technique particularly suitable for streams that experience significant variations in flow and reduces the size, complexity, and hence cost of the tailrace.

The direction of rotation of a backshot wheel is the same as that of a breastshot wheel but in other respects, it is very similar to the overshot wheel. See below.

Some wheels are overshot at the top and backshot at the bottom thereby potentially combining the best features of both types. The photograph shows an example at Finch Foundry in Devon, UK. The head race is the overhead timber structure and a branch to the left supplies water to the wheel. The water exits from under the wheel back into the stream.

A special type of overshot/backshot wheel is the reversible water wheel. This has two sets of blades or buckets running in opposite directions so that it can turn in either direction depending on which side the water is directed. Reversible wheels were used in the mining industry in order to power various means of ore conveyance. By changing the direction of the wheel, barrels or baskets of ore could be lifted up or lowered down a shaft or inclined plane. There was usually a cable drum or a chain basket on the axle of the wheel. It is essential that the wheel have braking equipment to be able to stop the wheel (known as a braking wheel). The oldest known drawing of a reversible water wheel was by Georgius Agricola and dates to 1556.

The earliest waterwheel working like a lever was described by Zhuangzi in the late Warring States period (476-221 BC). It says that the waterwheel was invented by Zigong, a disciple of Confucius in the 5th century BC.Chinese of the Eastern Han Dynasty were using water wheels to crush grain in mills and to power the piston-bellows in forging iron ore into cast iron.

In the text known as the Xin Lun written by Huan Tan about 20 AD (during the usurpation of Wang Mang), it states that the legendary mythological king known as Fu Xi was the one responsible for the pestle and mortar, which evolved into the tilt-hammer and then trip hammer device (see trip hammer). Although the author speaks of the mythological Fu Xi, a passage of his writing gives hint that the water wheel was in widespread use by the 1st century AD in China (Wade-Giles spelling):

Fu Hsi invented the pestle and mortar, which is so useful, and later on it was cleverly improved in such a way that the whole weight of the body could be used for treading on the tilt-hammer (tui), thus increasing the efficiency ten times. Afterwards the power of animals—donkeys, mules, oxen, and horses—was applied by means of machinery, and water-power too used for pounding, so that the benefit was increased a hundredfold.

In the year 31 AD, the engineer and Prefect of Nanyang, Du Shi (d. 38), applied a complex use of the water wheel and machinery to power the bellows of the blast furnace to create cast iron. Du Shi is mentioned briefly in the Hou Han Shu) as follows (in Wade-Giles spelling):

In the seventh year of the Chien-Wu reign period (31 AD) Tu Shih was posted to be Prefect of Nanyang. He was a generous man and his policies were peaceful; he destroyed evil-doers and established the dignity (of his office). Good at planning, he loved the common people and wished to save their labor. He invented a water-power reciprocator (shui phai) for the casting of (iron) agricultural implements. Those who smelted and cast already had the push-bellows to blow up their charcoal fires, and now they were instructed to use the rushing of the water (chi shui) to operate it ... Thus the people got great benefit for little labor. They found the "water(-powered) bellows" convenient and adopted it widely.

Water wheels in China found practical uses such as this, as well as extraordinary use. The Chinese inventor Zhang Heng (78–139) was the first in history to apply motive power in rotating the astronomical instrument of an armillary sphere, by use of a water wheel.mechanical engineer Ma Jun (c. 200–265) from Cao Wei once used a water wheel to power and operate a large mechanical puppet theater for the Emperor Ming of Wei (r. 226–239).

The ancient Greeks invented the waterwheel independently and used it in nearly all of the forms and functions described above, including its application for watermilling.Hellenistic period between the 3rd and 1st century BC.

The compartmented water wheel comes in two basic forms, the wheel with compartmented body (Latin tympanum) and the wheel with compartmented rim or a rim with separate, attached containers.sakia gear.

The earliest literary reference to a water-driven, compartmented wheel appears in the technical treatise Pneumatica (chap. 61) of the Greek engineer Philo of Byzantium (ca. 280−220 BC).Parasceuastica (91.43−44), Philo advises the use of such wheels for submerging siege mines as a defensive measure against enemy sapping.dry docks in Alexandria under the reign of Ptolemy IV (221−205 BC).papyri of the 3rd to 2nd century BC mention the use of these wheels, but don"t give further details.Ancient Near East before Alexander"s conquest can be deduced from its pronounced absence from the otherwise rich oriental iconography on irrigation practices.

The earliest depiction of a compartmented wheel is from a tomb painting in Ptolemaic Egypt which dates to the 2nd century BC. It shows a pair of yoked oxen driving the wheel via a sakia gear, which is here for the first time attested, too.Museum of Alexandria, at the time the most active Greek research center, may have been involved in its invention.Alexandrian War in 48 BC tells of how Caesar"s enemies employed geared waterwheels to pour sea water from elevated places on the position of the trapped Romans.

Around 300 AD, the noria was finally introduced when the wooden compartments were replaced with inexpensive ceramic pots that were tied to the outside of an open-framed wheel.

The Romans used waterwheels extensively in mining projects, with enormous Roman-era waterwheels found in places like modern-day Spain. They were reverse overshot water-wheels designed for dewatering deep underground mines.Vitruvius, including the reverse overshot water-wheel and the Archimedean screw. Many were found during modern mining at the copper mines at Rio Tinto in Spain, one system involving 16 such wheels stacked above one another so as to lift water about 80 feet from the mine sump. Part of such a wheel was found at Dolaucothi, a Roman gold mine in south Wales in the 1930s when the mine was briefly re-opened. It was found about 160 feet below the surface, so must have been part of a similar sequence as that discovered at Rio Tinto. It has recently been carbon dated to about 90 AD, and since the wood from which it was made is much older than the deep mine, it is likely that the deep workings were in operation perhaps 30–50 years after. It is clear from these examples of drainage wheels found in sealed underground galleries in widely separated locations that building water wheels was well within their capabilities, and such verticals water wheels commonly used for industrial purposes.

Taking indirect evidence into account from the work of the Greek technician Apollonius of Perge, the British historian of technology M.J.T. Lewis dates the appearance of the vertical-axle watermill to the early 3rd century BC, and the horizontal-axle watermill to around 240 BC, with Byzantium and Alexandria as the assigned places of invention.Strabon (ca. 64 BC–AD 24) to have existed sometime before 71 BC in the palace of the Pontian king Mithradates VI Eupator, but its exact construction cannot be gleaned from the text (XII, 3, 30 C 556).

The first clear description of a geared watermill offers the late 1st century BC Roman architect Vitruvius who tells of the sakia gearing system as being applied to a watermill.

About the same time, the overshot wheel appears for the first time in a poem by Antipater of Thessalonica, which praises it as a labour-saving device (IX, 418.4–6).Lucretius (ca. 99–55 BC) who likens the rotation of the waterwheel to the motion of the stars on the firmament (V 516).central Gaul.Barbegal watermill complex a series of sixteen overshot wheels was fed by an artificial aqueduct, a proto-industrial grain factory which has been referred to as "the greatest known concentration of mechanical power in the ancient world".

In Roman North Africa, several installations from around 300 AD were found where vertical-axle waterwheels fitted with angled blades were installed at the bottom of a water-filled, circular shaft. The water from the mill-race which entered tangentially the pit created a swirling water column that made the fully submerged wheel act like true water turbines, the earliest known to date.

Apart from its use in milling and water-raising, ancient engineers applied the paddled waterwheel for automatons and in navigation. Vitruvius (X 9.5–7) describes multi-geared paddle wheels working as a ship odometer, the earliest of its kind. The first mention of paddle wheels as a means of propulsion comes from the 4th–5th century military treatise

Ancient water-wheel technology continued unabated in the early medieval period where the appearance of new documentary genres such as legal codes, monastic charters, but also hagiography was accompanied with a sharp increase in references to watermills and wheels.

The earliest excavated water wheel driven by tidal power was the Nendrum Monastery mill in Northern Ireland which has been dated to 787, although a possible earlier mill dates to 619. Tide mills became common in estuaries with a good tidal range in both Europe and America generally using undershot wheels.

Cistercian monasteries, in particular, made extensive use of water wheels to power watermills of many kinds. An early example of a very large water wheel is the still extant wheel at the early 13th century Real Monasterio de Nuestra Senora de Rueda, a Cistercian monastery in the Aragon region of Spain. Grist mills (for corn) were undoubtedly the most common, but there were also sawmills, fulling mills and mills to fulfil many other labour-intensive tasks. The water wheel remained competitive with the steam engine well into the Industrial Revolution. At around the 8th to 10th century, a number of irrigation technologies were brought into Spain and thus introduced to Europe. One of those technologies is the Noria, which is basically a wheel fitted with buckets on the peripherals for lifting water. It is similar to the undershot water wheel mentioned later in this article. It allowed peasants to power watermills more efficiently. According to Thomas Glick"s book, Irrigation and Society in Medieval Valencia, the Noria probably originated from somewhere in Persia. It has been used for centuries before the technology was brought into Spain by Arabs who had adopted it from the Romans. Thus the distribution of the Noria in the Iberian peninsula "conforms to the area of stabilized Islamic settlement".Spaniards, the technology spread to the New World in Mexico and South America following Spanish expansion

The type of water wheel selected was dependent upon the location. Generally if only small volumes of water and high waterfalls were available a millwright would choose to use an overshot wheel. The decision was influenced by the fact that the buckets could catch and use even a small volume of water.

Harnessing water-power enabled gains in agricultural productivity, food surpluses and the large scale urbanization starting in the 11th century. The usefulness of water power motivated European experiments with other power sources, such as wind and tidal mills.canals, put Europe on a hydraulically focused path, for instance water supply and irrigation technology was combined to modify supply power of the wheel.feudal state.

The water mill was used for grinding grain, producing flour for bread, malt for beer, or coarse meal for porridge.fulling mill, which was used for cloth making. The trip hammer was also used for making wrought iron and for working iron into useful shapes, an activity that was otherwise labour-intensive. The water wheel was also used in papermaking, beating material to a pulp. In the 13th century water mills used for hammering throughout Europe improved the productivity of early steel manufacturing. Along with the mastery of gunpowder, waterpower provided European countries worldwide military leadership from the 15th century.

Millwrights distinguished between the two forces, impulse and weight, at work in water wheels long before 18th-century Europe. Fitzherbert, a 16th-century agricultural writer, wrote "druieth the wheel as well as with the weight of the water as with strengthe [impulse]".Leonardo da Vinci also discussed water power, noting "the blow [of the water] is not weight, but excites a power of weight, almost equal to its own power".laws of force. Evangelista Torricelli"s work on water wheels used an analysis of Galileo"s work on falling bodies, that the velocity of a water sprouting from an orifice under its head was exactly equivalent to the velocity a drop of water acquired in falling freely from the same height.

The water wheel was a driving force behind the earliest stages of industrialization in Britain. Water-powered reciprocating devices were used in trip hammers and blast furnace bellows. Richard Arkwright"s water frame was powered by a water wheel.

The most powerful water wheel built in the United Kingdom was the 100 hp Quarry Bank Mill water wheel near Manchester. A high breastshot design, it was retired in 1904 and replaced with several turbines. It has now been restored and is a museum open to the public.

The biggest working water wheel in mainland Britain has a diameter of 15.4 m (51 ft) and was built by the De Winton company of Caernarfon. It is located within the Dinorwic workshops of the National Slate Museum in Llanberis, North Wales.

The largest working water wheel in the world is the Laxey Wheel (also known as Lady Isabella) in the village of Laxey, Isle of Man. It is 72 feet 6 inches (22.10 m) in diameter and 6 feet (1.83 m) wide and is maintained by Manx National Heritage.

During the Industrial Revolution, in the first half of the 19th century engineers started to design better wheels. In 1823 Jean-Victor Poncelet invented a very efficient undershot wheel design that could work on very low heads, which was commercialized and became popular by late 1830s. Other designs, as the Sagebien wheel, followed later. At the same time Claude Burdin was working on a radically different machine which he called turbine, and his pupil Benoît Fourneyron designed the first commercial one in the 1830s.

Development of water turbines led to decreased popularity of water wheels. The main advantage of turbines is that its ability to harness head is much greater than the diameter of the turbine, whereas a water wheel cannot effectively harness head greater than its diameter. The migration from water wheels to modern turbines took about one hundred years.

Water wheels were used to power sawmills, grist mills and for other purposes during development of the United States. The 40 feet (12 m) diameter water wheel at McCoy, Colorado, built in 1922, is a surviving one out of many which lifted water for irrigation out of the Colorado River.

Two early improvements were suspension wheels and rim gearing. Suspension wheels are constructed in the same manner as a bicycle wheel, the rim being supported under tension from the hub- this led to larger lighter wheels than the former design where the heavy spokes were under compression. Rim-gearing entailed adding a notched wheel to the rim or shroud of the wheel. A stub gear engaged the rim-gear and took the power into the mill using an independent line shaft. This removed the rotative stress from the axle which could thus be lighter, and also allowed more flexibility in the location of the power train. The shaft rotation was geared up from that of the wheel which led to less power loss. An example of this design pioneered by Thomas Hewes and refined by William Armstrong Fairburn can be seen at the 1849 restored wheel at the Portland Basin Canal Warehouse.

Australia has a relatively dry climate, nonetheless, where suitable water resources were available, water wheels were constructed in 19th-century Australia. These were used to power sawmills, flour mills, and stamper batteries used to crush gold-bearing ore. Notable examples of water wheels used in gold recovery operations were the large Garfield water wheel near Chewton—one of at least seven water wheels in the surrounding area—and the two water wheels at Adelong Falls; some remnants exist at both sites.Walhalla once had at least two water wheels, one of which was rolled to its site from Port Albert, on its rim using a novel trolley arrangement, taking nearly 90 days.water wheel at Jindabyne, constructed in 1847, was the first machine used to extract energy—for flour milling—from the Snowy River.

The early history of the watermill in India is obscure. Ancient Indian texts dating back to the 4th century BC refer to the term cakkavattaka (turning wheel), which commentaries explain as arahatta-ghati-yanta (machine with wheel-pots attached). On this basis, Joseph Needham suggested that the machine was a noria. Terry S. Reynolds, however, argues that the "term used in Indian texts is ambiguous and does not clearly indicate a water-powered device." Thorkild Schiøler argued that it is "more likely that these passages refer to some type of tread- or hand-operated water-lifting device, instead of a water-powered water-lifting wheel."

According to Greek historical tradition, India received water-mills from the Roman Empire in the early 4th century AD when a certain Metrodoros introduced "water-mills and baths, unknown among them [the Brahmans] till then".ancient India, predating, according to Pacey, its use in the later Roman Empire or China,

Around 1150, the astronomer Bhaskara Achārya observed water-raising wheels and imagined such a wheel lifting enough water to replenish the stream driving it, effectively, a perpetual motion machine.Arabic and Persian works. During medieval times, the diffusion of Indian and Persian irrigation technologies gave rise to an advanced irrigation system which bought about economic growth and also helped in the growth of material culture.

After the spread of Islam engineers of the Islamic world continued the water technologies of the ancient Near East; as evident in the excavation of a canal in the Basra region with remains of a water wheel dating from the 7th century. Hama in Syria still preserves some of its large wheels, on the river Orontes, although they are no longer in use.Murcia in Spain, La Nora, and although the original wheel has been replaced by a steel one, the Moorish system during al-Andalus is otherwise virtually unchanged. Some medieval Islamic compartmented water wheels could lift water as high as 30 metres (100 ft).Muhammad ibn Zakariya al-Razi"s Kitab al-Hawi in the 10th century described a noria in Iraq that could lift as much as 153,000 litres per hour (34,000 imp gal/h), or 2,550 litres per minute (560 imp gal/min). This is comparable to the output of modern norias in East Asia, which can lift up to 288,000 litres per hour (63,000 imp gal/h), or 4,800 litres per minute (1,100 imp gal/min).

The industrial uses of watermills in the Islamic world date back to the 7th century, while horizontal-wheeled and vertical-wheeled water mills were both in widespread use by the 9th century. A variety of industrial watermills were used in the Islamic world, including gristmills, hullers, sawmills, shipmills, stamp mills, steel mills, sugar mills, and tide mills. By the 11th century, every province throughout the Islamic world had these industrial watermills in operation, from al-Andalus and North Africa to the Middle East and Central Asia.crankshafts and water turbines, gears in watermills and water-raising machines, and dams as a source of water, used to provide additional power to watermills and water-raising machines.factory complexes built in al-Andalus between the 11th and 13th centuries.

The engineers of the Islamic world developed several solutions to achieve the maximum output from a water wheel. One solution was to mount them to piers of bridges to take advantage of the increased flow. Another solution was the shipmill, a type of water mill powered by water wheels mounted on the sides of ships moored in midstream. This technique was employed along the Tigris and Euphrates rivers in 10th-century Iraq, where large shipmills made of teak and iron could produce 10 tons of flour from corn every day for the granary in Baghdad.flywheel mechanism, which is used to smooth out the delivery of power from a driving device to a driven machine, was invented by Ibn Bassal (fl. 1038–1075) of Al-Andalus; he pioneered the use of the flywheel in the saqiya (chain pump) and noria.Al-Jazari in the 13th century and Taqi al-Din in the 16th century described many inventive water-raising machines in their technological treatises. They also employed water wheels to power a variety of devices, including various water clocks and automata.

A recent development of the breastshot wheel is a hydraulic wheel which effectively incorporates automatic regulation systems. The Aqualienne is one example. It generates between 37 kW and 200 kW of electricity from a 20 m3 (710 cu ft) waterflow with a head of 1 to 3.5 m (3 to 11 ft).

Overshot (and particularly backshot) wheels are the most efficient type; a backshot steel wheel can be more efficient (about 60%) than all but the most advanced and well-constructed turbines. In some situations an overshot wheel is preferable to a turbine.

The development of the hydraulic turbine wheels with their improved efficiency (>67%) opened up an alternative path for the installation of water wheels in existing mills, or redevelopment of abandoned mills.

The kinetic energy can be accounted for by converting it into an equivalent head, the velocity head, and adding it to the actual head. For still water the velocity head is zero, and to a good approximation it is negligible for slowly moving water, and can be ignored. The velocity in the tail race is not taken into account because for a perfect wheel the water would leave with zero energy which requires zero velocity. That is impossible, the water has to move away from the wheel, and represents an unavoidable cause of inefficiency.

The power is how fast that energy is delivered which is determined by the flow rate. It has been estimated that the ancient donkey or slave-powered quern of Rome made about one-half of a horsepower, the horizontal waterwheel creating slightly more than one-half of a horsepower, the undershot vertical waterwheel produced about three horsepower, and the medieval overshot waterwheel produced up to forty to sixty horsepower.

From the cross sectional area and the velocity. They must be measured at the same place but that can be anywhere in the head or tail races. It must have the same amount of water going through it as the wheel.

A parallel development is the hydraulic wheel/part reaction turbine that also incorporates a weir into the centre of the wheel but uses blades angled to the water flow.

The University of Southampton School of Civil Engineering and the Environment in the UK has investigated both types of Hydraulic wheel machines and has estimated their hydraulic efficiency and suggested improvements, i.e. The Rotary Hydraulic Pressure Machine. (Estimated maximum efficiency 85%).

These type of water wheels have high efficiency at part loads / variable flows and can operate at very low heads, < 1 m (3 ft 3 in). Combined with direct drive Axial Flux Permanent Magnet Alternators and power electronics they offer a viable alternative for low head hydroelectric power generation.

The Editors of Encyclopædia Britannica. "Waterwheel". Britannica.com. Encyclopædia Britannica, Inc. Retrieved 19 January 2018. |last1= has generic name (help)

Müller, G.; Wolter, C. (2004). "The breastshot waterwheel: design and model tests" (PDF). Proceedings of the Institution of Civil Engineers - Engineering Sustainability. 157 (4): 203–211. doi:10.1680/ensu.2004.157.4.203. ISSN 1478-4629 – via Semantic Scholar.

Wikander 2000, p. 395; Oleson 2000, p. 229It is no surprise that all the water-lifting devices that depend on subdivided wheels or cylinders originate in the sophisticated, scientifically advanced Hellenistic period, ...

Oleson 2000, pp. 235: The sudden appearance of literary and archaological evidence for the compartmented wheel in the third century B.C. stand in marked contrast to the complete absence of earlier testimony, suggesting that the device was invented not long before.

An isolated passage in the Hebrew Deuteronomy (11.10−11) about Egypt as a country where you sowed your seed and watered it with your feet is interpreted as an metaphor referring to the digging of irrigation channels rather than treading a waterwheel (Oleson 2000, pp. 234).

As for a Mesopotamian connection: Schioler 1973, p. 165−167: References to water-wheels in ancient Mesopotamia, found in handbooks and popular accounts, are for the most part based on the false assumption that the Akkadian equivalent of the logogram GIS.APIN was nartabu and denotes an instrument for watering ("instrument for making moist").As a result of his investigations, Laessoe writes as follows on the question of the saqiya: "I consider it unlikely that any reference to the saqiya will appear in ancient Mesopotamian sources." In his opinion, we should turn our attention to Alexandria, "where it seems plausible to assume that the saqiya was invented."

Adriana de Miranda (2007), Water architecture in the lands of Syria: the water-wheels, L"Erma di Bretschneider, pp. 48f, ISBN 978-8882654337 concludes that the Akkadian passages "are counched in terms too general too allow any conclusion as to the excat structure" of the irrigation apparatus, and states that "the latest official Chicago Assyrian Dictionary reports meanings not related to types of irrigation system".

Terry S, Reynolds, Stronger than a Hundred Men; A History of the Vertical Water Wheel. Baltimore; Johns Hopkins University Press, 1983. Robert, Friedel, A Culture of Improvement. MIT Press. Cambridge, Massachusetts. London, England. (2007). p. 33.

Smeaton, "An Experimental Inquiry Concerning the Natural Powers of Water and Wind to Turn Mills, and Other Machines, depending on Circular Motion," Royal Society, Philosophical Transactions of the Royal Society of London 51 (1759); 124–125

Davies, Peter; Lawrence, Susan (2013). "The Garfield water wheel: hydraulic power on the Victorian goldfields" (PDF). Australasian Historical Archaeology. 31: 25–32.

Wikander 2000, p. 400: This is also the period when water-mills started to spread outside the former Empire. According to Cedrenus (Historiarum compendium), a certain Metrodoros who went to India in c. A.D. 325 "constructed water-mills and baths, unknown among them [the Brahmans] till then".

Gies, Frances; Gies, Joseph (1994). Cathedral, Forge, and Waterwheel: Technology and Invention in the Middle Ages. HarperCollins Publishers. p. 115. ISBN 0060165901.

Donners, K.; Waelkens, M.; Deckers, J. (2002), "Water Mills in the Area of Sagalassos: A Disappearing Ancient Technology", Anatolian Studies, Anatolian Studies, Vol. 52, vol. 52, pp. 1–17, doi:10.2307/3643076, JSTOR 3643076, S2CID 163811541

Murphy, Donald (2005), Excavations of a Mill at Killoteran, Co. Waterford as Part of the N-25 Waterford By-Pass Project (PDF), Estuarine/ Alluvial Archaeology in Ireland. Towards Best Practice, University College Dublin and National Roads Authority

Oleson, John Peter (1984), Greek and Roman Mechanical Water-Lifting Devices: The History of a Technology, University of Toronto Press, ISBN 978-90-277-1693-4

Quaranta Emanuele, Revelli Roberto (2015), "Performance characteristics, power losses and mechanical power estimation for a breastshot water wheel", Energy, Energy, Elsevier, 87: 315–325, doi:10.1016/j.energy.2015.04.079

Oleson, John Peter (2000), "Water-Lifting", in Wikander, Örjan (ed.), Handbook of Ancient Water Technology, Technology and Change in History, vol. 2, Leiden: Brill, pp. 217–302, ISBN 978-90-04-11123-3

Reynolds, T.S. (1983) Stronger Than a Hundred Men: A History of the Vertical Water Wheel, Johns Hopkins studies in the history of technology: New Series 7, Baltimore: Johns Hopkins University Press, ISBN 0-8018-2554-7

Siddiqui, Iqtidar Husain (1986). "Water Works and Irrigation System in India during Pre-Mughal Times". Journal of the Economic and Social History of the Orient. 29 (1): 52–77. doi:10.1163/156852086X00036.

Wikander, Örjan (2000), "The Water-Mill", in Wikander, Örjan (ed.), Handbook of Ancient Water Technology, Technology and Change in History, vol. 2, Leiden: Brill, pp. 371–400, ISBN 978-90-04-11123-3

Wilson, Andrew (1995), "Water-Power in North Africa and the Development of the Horizontal Water-Wheel", Journal of Roman Archaeology, vol. 8, pp. 499–510

This page appears to have been repeatedly edited by people with no direct knowledge of the subject. I can still see a few vestiges of information I put in (I live in a former mill and have direct personal experience handling three different waterwheels and several francis turbines) but grammatical and factual errors have been introduced into my text.

I will edit this page back into some form of useability ASAP. I"ll need to split out noria (which are fundamentally different from all other wheels) all the turbines (which are *not* waterwheels although they are derived from Poncelet"s wheel) and the undershot/backshot/etc information in order to create a source of information that does more than simply mislead and misinform; I apologize in advance for my inability to create a unified page with all that together but it"s better than being FLAT OUT WRONG.

The language of the lead paragraph needs a little cleaning-up. I can"t edit it, who can? I refer to (specifically) these items: "Water wheels and hydropower was widely used". "Were" needs to be substituded for "was". "Hydropower" needs replaced by "hydro-power".

Charlie: I am no expert, although I am an engineer and familiar with mechanical power . I added some info. on Smeaton and water turbines which I didn"t see but thought worth mentioning. One other thing I noted was no mention of the suspended wheel. Perhaps you can add something. Thanks.Phmoreno (talk) 19:25, 27 November 2011 (UTC)

Derrick: An overshot steel wheel (wheels aren"t really "typically wooden" as the text states; I crawled inside an overshot steel Fitz at the Casho Mill just last week) is more efficient than any other type given the same conditions of head, flow, volume, and operator expertise, because it gains power from both the forward impetus of the water and the weight of the water descending. However, the conditions under which an overshot wheel may be used are more restrictive than for any other type, and will usually (not "always" as in the text) require a dam and/or a long flume. A backshot overshot will spin until floodwater in the tail race rises past the wheel axle; without backshooting, an overshot wheel will stop when the water level passes the bottom bucket, which makes it nearly as flood-tolerant as a breastshot or boat-mounted undershot while producing significantly more power during non-flood conditions. I"ll try to find some references to the studies of wheel efficiency that were done at the turn of the 20th century.

This article seems to lump together all the terms for various types of water wheels. In particular, I was under the impression a noria is a specific type of water wheel with buckets on its rim. The article should distinguish them better. Deco 28 June 2005 21:11 (UTC)

Although the person who made the suggestion has not made a case, I think that is reasonable to merge the articles (for the time being). I think it is possible that there may come a time when the articles for (note different titles) overshot water wheel and undershot water wheel may be split out, but that time is not yet. Noisy | Talk 10:34, 15 April 2006 (UTC)

Support. The article water mill also needs to be merged, or this one merged to that. Alternatively the explanation of the different kinds of whater wheel should be removed from water mill and replaced by a short cross-referred paragraph. Peterkingiron 22:23, 9 May 2006 (UTC)

Undershot, Overshot, Backshot and Breastshot have all been merged as requested. Watermill has been de-tagged for merging as, though it contains a waterwheel, it is not in itself a waterwheel. SilkTork 18:27, 30 May 2006 (UTC)

Smeaton performed experiments in 1754 that conclusively demonstrated the superiority of the overshot system: Brindley was Smeaton"s pupil, and one of his water wheels can be seen at the Brindley Mill in Leek, Staffordshire, England.

In this diff, Moerou toukon added the following text:Joseph Needham dated the early uses of water wheel can be dated to 4th century BC India. Joseph Needham noted in 1965 that certain ancient Indian texts from around 350 BC mentioned a cakkavattaka (turning wheel) and a further elaboration of a revolving machine.

Joseph Needham noted in 1965 that certain ancient Indian texts dating from around 350 BC mentioned a chakkacattaka (machine with wheel posts attached). On this basis he suggested that the machine in question was a noria and that it was the first water powered prime mover.

Not knowing much about water wheels I don"t want to change this, but the ordering of the "Types" looks wrong to me. "Backshot" starts by saying "An overshot wheel is backshot...", but Overshot wheels are not described until the following section. At the very least, surely the order of these two sections should be reversed?

A pitchback/backshot waterwheel is actually a variation of undershot/low breast/breastshot/high breast waterwheel. An overshot waterwheel will revolve in the opposite direction to the others. Mjroots (talk) 19:26, 20 January 2008 (UTC)

Vocabulary is a minefield with different reputable authorities using different definitions. The energy conversion in backshot is the same as for overshot so it should be considered a variant of overshot. However, by some dictionary definitions, eg Collins, a backshot weel is also an undershot wheel!

This page is still confusing on the question of whether a backshot wheel is a sub-type of over-shot wheel. The overshot section says "The term is sometimes, erroneously, applied to backshot wheels", implying that backshot wheels are NOT a variety of overshot wheels, and that this usage is incorrect. Then, in the very next subsection, it says "A backshot wheel is a variety of overshot wheel". This needs fixing; if it"s a matter of varying usage this needs to be addressed directly, but the article still needs editing to remove the contradiction. Casper Gutman (talk • contributions) 13:52, 9 March 2021 (UTC)

Really, there is no engineering / technical literature on water wheels in English. Reynold"s book e.g. is excellent, but focuses on history. Books by Fairbairn, Bjoerling etc. only give some hints at the design / the performance. I find Nuernbergks" book somehwat overly long. The Wiki-article on water wheels is incomplete and in parts erroneous (most water wheels in the 19th Century were not built of wood but of steel or steel and wooden planks since steel (or rather wrought iron) was mucy stronger, allowed for larger wheels, enabled designers to choose hydraulically more effcieint geometries, and did not deteriorate).

For an overview of water wheel technology see “Performance characteristics of water wheels”, Müller G. & Kauppert K., 2004, IAHR Journ. Hydr. Res., Vol. 42, No. 5. There, the main types of water wheels are presented with efficiency figures from measurements (76% for breast shot wheels, 85% for overshot wheels, and an overview over the literature is give. Gerald, 26.02.2008 —Preceding unsigned comment added by 152.78.178.181 (talk) 14:09, 27 February 2008 (UTC)

Please do not include turbines (save as a cross-reference), as they are not waterwheels. Otherwise if you have relaible information with citable sources, please add it. However, please do not alter the basic terminology, as the usual Englihs terms are used. Peterkingiron (talk) 21:40, 28 February 2008 (UTC)

This article describes the waterwheel solely as a "machine for converting the energy of flowing water to useful work" This is somehow incorrect, as the waterwheel can also be used for different jobs such as pumping, ... see http://www.fao.org/docrep/010/ah810e/AH810E06.htm (see the paddle wheel image which is type of waterwheel

Water wheels can be used in systems to convert the energy of flowing or falling water into mechanical power or electricity (if a electricity generator is added), or they can be used for moving the water (eg for pumping or marine propulsion). In the latter case, no flowing water needs to be present, and instead, another energy source (eg electricity, ...) is used to propel the wheel.

In the Middle Ages, waterwheels were used as tools to power factories throughout different counties. The alternatives were the windmill and human and animal power. The most common use of the water wheel was to mill flour in gristmills, but other uses included foundry work and machining, and pounding linen for use in the manufacture of paper.

A water wheel consists of a large wooden or metal wheel, with a number of blades or buckets arranged on the outside rim forming the driving surface. Most commonly, the wheel is mounted vertically on a horizontal axle, but the tub or Norse wheel is mounted horizontally on a vertical shaft. Vertical wheels can transmit power either through the axle or via a ring gear and typically drive belts or gears; horizontal wheels usually directly drive their load.

A mill pond is formed when a flowing stream is dammed to feed a waterwheel. A channel for the water flowing to or from a water wheel is called a mill race (also spelled millrace) or simply a "race", and is customarily divided into sections. The race bringing water from the mill pond to the water wheel is a headrace; the one carrying water after it has left the wheel is commonly referred to as a tailrace.[1]

The rotation for the backshot wheel appears wrong - how can the weight of water on the right side of the wheel cause it to rotate counter-clockwise? --Wtshymanski (talk) 16:35, 30 September 2009 (UTC)

I think the blades or buckets are facing the wrong way, because as shown they will scoop up water on the up side of the wheel and will not benefit from the tail race flow described in the text.

The reason why I replaced the definition to being a bladed rotor for hydro energy conversion systems, also incorporated the notion that a waterwheel can also be used for pumping, ...

As part of a HECS, this is possible as then, the process is simply reversed; instead of generating energy from moving water, energy is put into the device and water is moved instead.

The complete water technology of the Muslim was adopted from the Greeks and the local Near Eastern populace. When the Muslims came out of the desert, they were little more advanced than the Germanic tribes were. The section seems to be written under the premise that as soon as Muslim engineers began to employ the same methods, it became Muslim technology - which sounds odd for such an early date in time. Gun Powder Ma (talk) 03:52, 24 March 2010 (UTC)

Do you really mean "steel". Steel was a very expensive material until Henry Bessemer"s innovation. I would have expected cast or wrought iron to be used. I do not know about America, but in UK, cast iron was much used in the structure of water wheels from the early 19th century. Wrought iron mihgt be used for the buckets, but not much elsewhere. Peterkingiron (talk) 22:39, 12 March 2010 (UTC)

Though I don"t have any specialist knowledge of waterwheels, the last sentence of this section seems to me to be simply wrong. I can"t believe there is any _inherent_ reason why a horizontally-axled wheel would need gearing and a vertically-axled wheel wouldn"t; it will surely depend on the required speed and orientation of whatever machinery is to be driven by the wheel. Perhaps whoever wrote this was thinking just of flour mills (for which the sentence may well be true). I have deleted the sentence. 132.244.72.5 (talk) 14:52, 9 June 2011 (UTC)

I"m sure all sorts of wheels were constructed and used both with and without gearing, in many places and times, so I support your edit. However, I personally do not know of any examples of a tub wheel that were geared. Norse mills have a straight shaft running from a wheel in the basement to a millstone on the first floor; the speed and weight of the stones that can be driven is determined by the available water. This is an extremely simple design that I could build by myself in the course of a single growing season. It may well have been invented before gears! It"s possible that any miller willing to go to the trouble of building a gear train (even lantern gears are non-trivial engineering) would have built a more powerful and complex horizontal axle wheel system rather than an inefficient vertical axle tub wheel. Keep in mind that in a Norse mill, if a heavy stone is stopped independently of the wheel, or the wheel is suddenly stopped or accelerated, the axle will shatter (hopefully) or else the blades will snap off. In either case repairs are straightforward. In a geared mill, failure points must be engineered into the gear train - in the USA, this is often done by using a huge iron gear fitted with apple-wood teeth - because the gearing will necessarily be the point of failure when eleventy-some tons of stone are already in motion and a drifting log sneaks past the trash rake, stopping the wheel. This does happen - I have seen the result! - and without engineered failure points the entire system can be almost instantly reduced to a pile of mangled scrap, putting workers in considerable danger from flying shards of metal and wood. — Preceding unsigned comment added by 205.153.180.229 (talk) 17:54, 24 August 2011 (UTC)

The wiki page that I will be critiquing is the page for the water wheel. This page is very long so I will not be critiquing the whole thing I will only focus on the introduction and the section that describes the different types of water wheels, a word count of roughly 1500 words.

It is an unwritten rule in the academic world that you cannot use Wikipedia as a valid source to cite in any professional writing piece. Having said that, there is still so much to learn from this wonderful search engine. When we were given our first discussion board assignment the first thing I searched for was information on the water wheel in Wikipedia so that I could easily find a smaller subtopic to search for within a real academic journal. Although I did not do this, I believe I could have easily used the Wikipedia page for the assignment. Not only did I find a description of every type of waterwheel there was, I found the origins of the wheel, its various uses, different countries and how they used it differently from one another, how it was made, and various pictures that gave great descriptions of what each part does. But when it comes down to it we still need to remember that it is Wikipedia and it is far from perfect.

I’ll start my critique with the positives and negatives I found from the introduction to the water wheel Wikipedia page. Every good introduction must tell the reader the five W’s, who, what, where, when, and why. So based on that definition of an introduction this introduction is not a very good one. It starts off well by explaining to the reader what a water is what it does, so you can cross the “what” off that checklist. It then starts to answer the “when” question, but does so in an incomplete fashion. It states when the typical water wheel was taken out of commercial use, which was around the 20th century. It could have completely answered the “when” question if it had explained when it was first invented, or when it was used most commonly. The introduction does a good job of explaining the “why” aspect. It explains why water mills are needed, and the answer is to generate some type of power.

The biggest issues with the introduction however, are that it does not answer the “where” or the “who”. The editors of this page could easily add a sentence or two for each, explaining that the first water wheel was invented by the ancient Greeks and Romans somewhere between the third and first century BC.

Overall I think this is a very effective introduction to the water wheel, it gives the reader enough background knowledge without overwhelming them with facts.

In my opinion, the section of the water wheel’s Wikipedia page that describes the different types of wheels is extremely helpful and full of information, but there are still a few flaws that can be found.

First, I"ll start off by explaining what I like about this section. Not everyone can just read a sentence and completely comprehend what is being talked about, that is why I think the pictures involved in this page are extremely helpful. They not only show you what each type of wheel looks like but also give some type of description as to how it works and the science behind it.

Another thing I like about it is that it not only describes how each wheel works but it describes the pros and cons to each wheel and says how each wheel is different from one another just in case the reader is confused at all. For example, when describing the breastshot wheel it states that “breastshot wheels are less efficient than overshot wheels, more efficient than undershot wheels, and are not backshot wheels”.

This section of the Wiki page does have a few downfalls though. One thing I do not like about this section is that it assumes that everyone reading it is an expert in the field of water wheels. What I mean by this is that the language that is used is pretty complex there is a lot of terminology that I was not familiar with. For example, it uses a lot of physics phrases like “potential energy”, and handy-man phrases like “flume” and “penstock”. I am sure the average reader, who is searching Wikipedia for a reason, does not understand this lingo.

In conclusion, the water wheel Wikipedia page is extremely useful for someone who needs a quick background check or reminder of what this piece of technology entails. Some of the strong attributes to this page are the very clearly outlined sections, in this case the different types of wheels which describe each type perfectly. The pictures and diagrams included are extremely helpful for the understanding of how each type of wheel works. Another positive aspect is the overall layout of the page, it is the most efficient and organized way the editors could have created it. But the most impressive and most powerful strength to this page is the Reference section, all the information is coming from some of the top schools in the world so you know it is trustworthy. One major downfall to the page is the diction they used though, which probably comes from the sources used. To an average person searching what a water wheel was, the page is too intelligent. If someone is using Wikipedia to search something, they most likely do not know too much on the subject and they should be able to clearly find all their answers on Wiki. However, this is not the case with this page so if I could make some changes to the page I would dumb it down a bit. Overall, the water wheel page in Wikipedia is one of the most developed, well organized pages I have ever used and if the only criticism I have for it is that it is too smart, than I think it is a staple in the Wikipedia community. — Preceding unsigned comment added by HIST406-11jlorber (talk • contribs) 22:56, 2 October 2011 (UTC)

What excellent material on water raisng wheels. Burying it in history may have been a good idea at the time but now the lead and and all other section were about power wheels- and the history about irrigation. I have done a surgical operation, (not a single comma was erased in the process) to reestablish a structure- and will attempt to clean it up further quite soon- particular to add the compartmented wheel to the types of wheel section. --ClemRutter (talk) 10:35, 15 January 2013 (UTC)

Can I explain that Wikipedia has a policy WP:UNDUE that prevents an article being swamped with fascination but off focus facts. For instance it is there to prevent an article on a form of motive power becoming an erudite article on Hellenistic scholarship. All that needs to be replaced by a brief synopsis, and the detailed material be transfered to a new more specific article. We have reached that stage now. I suggest History of water wheels in the classical world or Water wheels in the classical world but many other titles may be more political acceptable or appropriate.--

This site was helpful for me to analyze a 1925 photograph I have of an undershot waterwheel in Weston, Massachusetts. I happened to notice that the diagram for the breastshot waterwheel is mixed up. The water flow is pointing from the tail race towards the wheel, exactly the opposite of how the term tail race was defined. I hope someone can fix it.

Terry S, Reynolds, Stronger than a Hundred Men; A History of the Vertical Water Wheel. Baltimore; Johns Hopkins University Press, 1983. Robert, Friedel, A Culture of Improvement. MIT Press. Cambridge, Massachusetts. London, England. (2007). p. 33., has been challenged as an notable reference.

Put is straight- this style of writing is not one I aspire to, but in the context of flowery prose it is consistent. The problem is that it does reflect the facts, and the cradle of the early industrial revolution was Shropshire and the European waterwheel did enable iron to be processed in a way that it wasn"t in Asia or Africa. The technology was soon exported to the European settlers in New England. Yes, I agree it is chauvanist- and verging on racist and could profitably be rewritten- but it is too easy to just delete it without replacing it with something more subtle. --

Although the Laxey Wheel is the largest working water wheel in existence, is it thought to be the largest ever (either non-working or demolished)? PhilUK (talk) 21:22, 17 May 2015 (UTC)

The angelfire web site (written by Theodore R. Hazen & Pond Lily Mill Restorations) states " The "Lady Isabella" is claimed to be the largest water wheel in Europe: and the largest metal water wheel in the world."

However, on the same site the page on Noria states "This type of water wheel includes the largest water wheel in the world, being 90 feet in diameter". I can find not other reference to it.

The World’s Largest Working Water Wheel The title implies that it is not the largest of all time. In the text it states "The wheel is quite huge; 22.2 meters in diameter with a width of 1.83 meters and enjoys being the only largest survivor of its kind in the world."

I started drafting a rewrite of the mathematical part and came to the conclusion that it couldn"t be done adequately in isolation. I am preparing a reorganisation and partial rewrite of the page offline and I have started transferring that work to Draft:Water wheel

In the current article this is stated: "The overshot design is very efficient, it can achieve 90%,[17] and does not require rapid flow." I cannot find that number (90% efficiency) in the quoted source. — Preceding unsigned comment added by Pastej (talk • contribs) 01:05, 2 December 2021 (UTC)

Electricity is used to operate many electrical appliances and devices. The most basic power can be transmitted to remote distance just with a power cable. This makes a lot of countries including Indonesia looking for many ways to harvest energy to increase the electricity supply to meet human needs. Besides, relying on fossil fuel which is very limited and would probably finished in a short time, one of the applications that are geared towards the use of renewable energy, such as water energy…Expand

The water wheel is an ancient device that uses flowing or falling water to create power by means of paddles mounted around a wheel. The force of the water moves the paddles, and the consequent rotation of the wheel is transmitted to machinery via the shaft of the wheel.

The first reference to a water wheel dates back to around 4000 BCE. Vitruvius, an engineer who died in 14 CE, has been credited with creating and using a vertical water wheel during Roman times. The wheels were used for crop irrigation and grinding grains, as well as to supply drinking water to villages. In

8613371530291

8613371530291