overshot wheel for sale

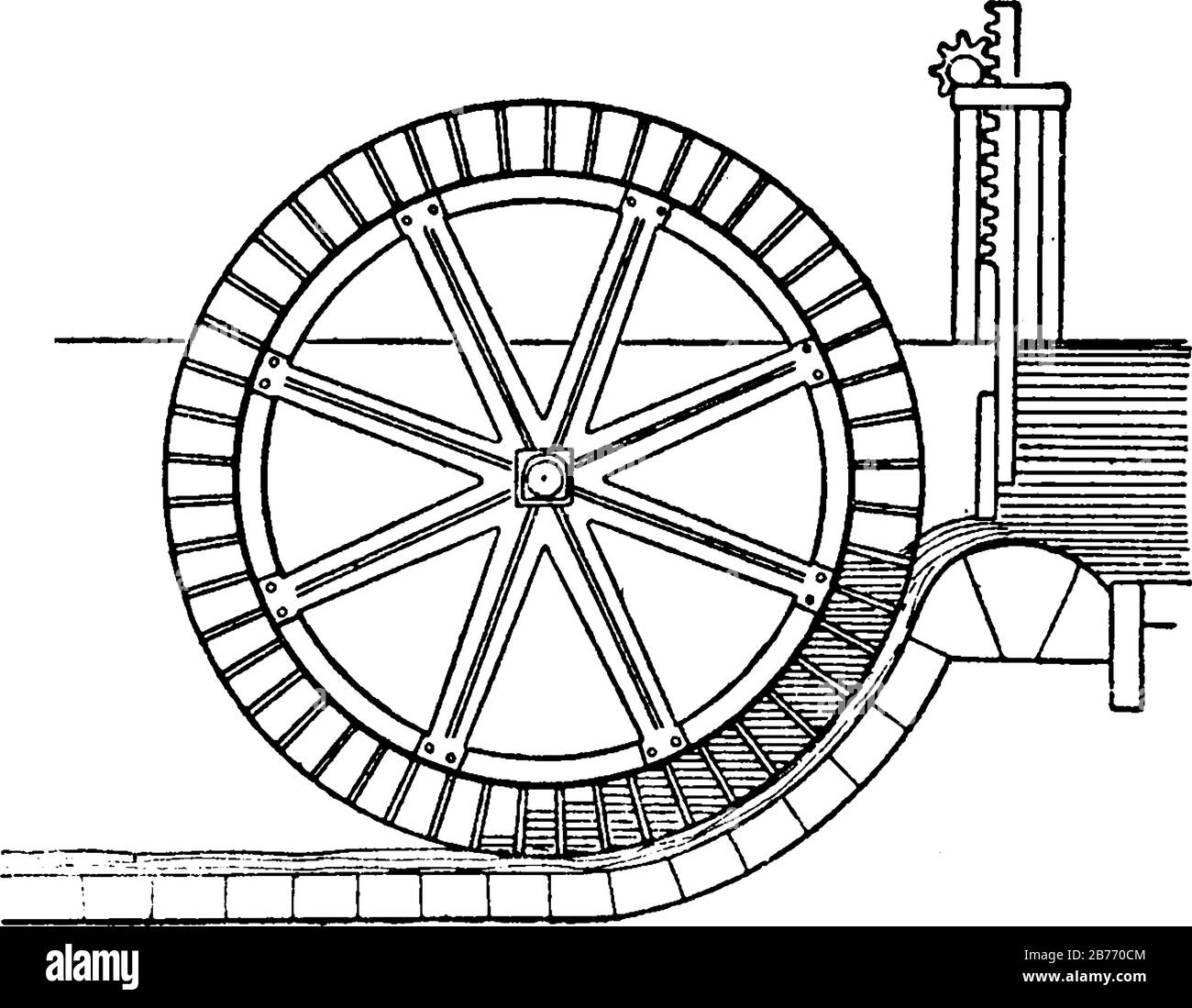

Overshot waterwheel A vertically-mounted wheel that is rotated by falling water striking paddles, blades or buckets near the top of the wheel is said to be overshot. In true overshot wheels the waters passes over the top of the wheel, but the term is sometimes applied to backshot or pitchback wheels where the water goes down behind the waterwheel.

Typical overshot wheels has the water channeled to the wheels at the top and slightly to one side in the direction of rotation. The waters collects in the buckets on that side of the wheel, making it heavier than the other "empty" side. The weight turns the wheels, and the waters flows out into the tail-water when the wheels rotates enough to invert the buckets. The overshot design can use all of the waters flow for power (unless there is a leak) and does not require rapid flow.

Unlike undershot wheels, overshot wheels gain a double advantage from gravity. Not only is the force of the flowing water partially transferred to the wheel, the weight of the waters descending in the wheel"s buckets also imparts additional energy. The mechanical power derived from overshot wheels is determined by the wheel"s physical size and the available head, so they are ideally suited to hilly or mountainous country.

Overshot wheels demand exact engineering and significant head, which usually means significant investment in constructing a dam, millpond and waterways. Sometimes the final approach of the wat ers to the wheel is along a lengthy flume or penstock.http://en.wikipedia.org/wiki/Wikipedia:Text_of_the_GNU_Free_Documentation_License

Sullivan"s waterwheels , A small family business, located in the South Carolina Foothills! We want everyone to be able to own a beautiful relaxing millwheel of their own! Whether it be for your garden,pond,or as a beautiful addition to any landscaping, home and garden & yard large are small. We strive to bring you the best.

The overshot wheel is the most common wheel seen in North America. It is a gravity wheel. This means that it harnesses the force of gravity acting vertically on the water as it travels from the top to the bottom of the wheel. Properly designed for a particular site, and correctly timed, an overshot The overshot wheel is most effective when it turns as slowly as possible and can still handle the total flow of water available to it. The optimal rim speed should be only about 3 feet per second. The larger the wheel the slower it will need to turn. The incoming water must be traveling about three times the rim speed of the wheel so that it can fill the buckets effectively. This requires a foot or more of head above the wheel, usually controlled by a gate.

When the head, or fall of water was not sufficient for a large diameter overshot wheel, the breast wheel often is used. This is halfway between the overshot and undershot wheels. Water strikes the buckets of the breast wheel about midway between top and bottom, using the weight of the water for a 90 degree segment of arc. Their efficiency is far less than the overshot, which uses the weight of the water for a full 180 degrees.

This type of waterwheel relies on the flow of water, coming along the base flowing at a good rate of speed to push or thrust the waterwheel. This type of waterwheel is used on mills built on rivers or streams that do not have any height or (head). Undershot wheels are normally narrow and have to have the channel walls very close to the sides of the wheel to maximize the flow of water to pass through the wheels to generate power. This type of wheel is generally the least efficient type of wheel - usually in the 30-50% range. The exception to this is the Poncelet wheel that can get up to 80% efficiency if the channel is properly constructed and the buckets are designed right.

This type of waterwheel relies on the flow of water, generally in an open stream. This type of wheel is generally the least efficient type of wheel - usually in the 30-40% range. The exception to this is the Poncelet wheel that can get up to 80% efficiency if the channel is properly constructed and the buckets are designed right.

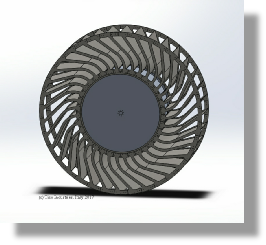

Many micro hydro electric generation strategies have evolved in recent years. Helical Ribbons, Under Water Blade Turbines, Tide and Wave action mechanical generators. Our approach is to simplify sustainable micro hydroelectric water wheel construction and improve the efficiency of energy generation. Our recent association with Ticho Industries in Italy has produced a new form of micro hydro waterwheels with a high efficiency electric generator mounted safely on the axle completely within the water wheel structure. This design simplifies micro hydro water wheel design for optimal water flow location mounting, system longevity, ease of maintenance and simplified electro mechanical connection. Our new design was created for city and rural stream based flows - including the outflows from major hydro electric dams, major navigation and irrigation dams, manufacturing and water treatment facilities.

To do this you will need to know two things, the quantity of water and the height of the water fall. From this you can determine the Horsepower at the axle of the waterwheel.

To get electricity out of a waterwheel you will have to gear the RPMs of the waterwheel (generally from 5-10 rpm”s up t0 500 - 1700 rpm’s) and then run it through a generator or a DC motor to charge a battery bank. This will generally cut your power at the axle HP by almost 1/3 to 1/2. A waterwheel is really designed to do mechanical work.

Here"s the famous Fitz Metal wheel that claimed 90% efficiency with curved paddles. Used on the majority of mills and other businesses powered by water. 24 paddles, brass bushing with 6" solid brass axle and assembled with 32 sets of brass screws and bolts. Wheel is laser cut from .060 whie styrene.Spokes set off from wheel.Wheel matches all 2" sluices.

This 2" wide wheel is wider than our previous resin cast. Has the detail of wooden wheel construction - 30 paddles in laser cut white styrene plastic.

Kit includes all the sluice details: Flow Control, Side Spill, sluice squares plus 4 sets of brass bolts/nuts for flow control. Side spill can be "either side". There"s a customizable end "square" to be drilled to insert you water source tubing. Feautres engraved sides with wooden board design.Fits 2" wide wheels.

Kit includes Styrene Sluice #4041 (above) PLUS 2 Bent-trestle with cross member in styrene. Sluice is removable (not attached) for easy cleaning of algae without removing mill or raceway/wheelposts.The bents fit into an "in stream" simplified raceway with smaller wheel post design (complete drawings included).

PLANS for 3-Story Waterwheel Mill are shown in 3 full pages sized 24" x 36" showing 1:24 scale CAD drawings at actual size.For Larger Click on Picture (right)

There are many wheel configurations, vane/blade shapes and water-flow patterns. Undershot wheels and horizontal wheels were the most common choices for tide mills. Since the height of the impoundment area was the height of high tide, the head of water was probably not high enough to power an overshot wheel.

Probably the most important of the early engines which utilized water power was the vertical waterwheel. Its two basic forms are the undershot and the overshot. The undershot vertical wheel rotated in the vertical plane and had a horizontal axis. It normally had flat radial blades attached to its periphery and derived its motion from the impact of water flowing under the wheel and against these blades. While capable of working on any convenient stream without mill races (narrow artificial water channels, it worked most effectively in a race and with a stable volume of water running at a fairly high velocity. [Stronger than a Hundred Men: A History of the Vertical Water Wheel by Terry S. Reynolds Baltimore: The Johns Hopkins University Press, 1983.]

The Undershot Wheel worked in a running stream and could turn in shallow water. It was often built by the first settlers since it was relatively simple to set up … They were common in the early days when a dam could be built to compensate for dry periods … . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The tub wheel could only work where the water flowed regularly throughout the year, and needed at least an eight-foot fall. The tub wheel was horizontal and was described as acted upon by percussion of water. The shaft is vertical, running the stone of top of it, and serves as a spindle. The water is shot on the upper side of the wheel in the direction of a tangent fitted with blades. It revolves in a sturdy tub, projecting far enough above the wheel to prevent the water from shooting over it, and whirls above it until it strikes the buckets. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The overshot vertical wheel was a much more efficient device. Water was fed at the top of the overshot wheel into “buckets” or containers built into the wheel’s circumference, and the weight of the impounded water, rather than its impact, turned the wheel. Each “bucket” discharged its water into the tail race at the lower portion of its revolution and ascended empty to repeat the process. The overshot wheel was usually more expensive than the undershot, since a dam and an elevated head race were normally required to build up a large fall of water and to lead the water to the wheel’s summit. It was suitable mainly to low water volumes and moderately high falls.

It is likely that the [emergence of undershot and overshot wheels] was at least partially influenced by several more primitive devices which tap the power of falling water – the water lever, the noria, and the primitive horizontal watermill. [Stronger than a Hundred Men: A History of the Vertical Water Wheel by Terry S. Reynolds Baltimore: The Johns Hopkins University Press, 1983.]

The overshot wheel required a dam above it so that the weight of water falling on it would make it turn. After one-third of a revolution, the water was spilled from the wheel. The water first striking the wheel gave it momentum, but the weight of the water in its buckets kept it turning. [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The difference between the pitch-back and the overshot wheels is that the trough stops shorter here and pours the water onto the wheel before the top of the wheel, or ‘on the near side’ as the millwrights used to say. The result therefore is that the wheel revolves in the opposite direction from the overshot, i.e. towards the flume or head-race. The buckets face in the opposite direction and the water therefore falls off at the same side as that on which it was received. [British Water-Mills by Leslie Syson. London, 1965]

The breast wheel, like the undershot wheel, turned in the opposite direction to the overshot wheel and received water above its center shaft at the nearest point of the water supply, and revolved easily because it was less loaded with water. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The flutter wheel was used when there was a large supply of water. It was small, low and wide—about three feet in diameter and up to eight feet wide. It got its attractive name from the sound it made. As the wheel went around, the blades cut through the entering water, making a noise like the fluttering wings of a bird. It was used almost entirely to power early sawmills. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

The turbine with its curved blades, eventually replaced the waterwheel [in the mid-nineteenth century]. … Roy S. Hubbs pointed out that older undershot waterwheels presented a flat blade for the incoming water to impact, allowing half of the velocity to pass through unchecked. The Poncelet design [and the later resulting turbine] presented a curved blade with its lip angled tangentially to the incoming water … Benoit Fourneyron turned the wheel on its side and dropped the water into its center, allowing the water to flow simultaneously out of all the passages between the blades. … Since the turbine used all the openings between its blades simultaneously, it could be made much smaller. It turned much faster than the larger wheels. . [Mill: The History and Future of Naturally Powered Buildings by David Larkin. New York, 2000.]

Operating on the seesaw principle, the water lever utilized the power of falling water, but without the continuous rotary motion of water wheels. One end of a pivoted beam was equipped with a spoon-shaped bucket. On the other end was a hammerlike counterweight used for pounding or crushing. Water was directed into the bucket from a falling stream; the bucket filled, overweighed the hammer, and lifted it. The ascent of the bucket caused the water to spill; the hammer than overbalanced the bucket and fell. The cycle was then repeated to produce a steady pounding action.

The noria used for raising water, was form of undershot water wheel, but it activated no machinery (such as gears or millstones) beyond itself. It was simply a large vertically situated wheel, sometimes as much at 50-80 feet in diameter, equipped with radial blades which rotated the apparatus as they were impacted by the flowing water in which the lower portion of the wheel was immersed. Buckets of wood, bamboo, or pottery were attached to the rim of the wheel. As the device rotated, they were filed with water at the bottom of the wheel; the water was carried upwards in the buckets and emptied near the top of the wheel into a trough. The buckets were the returned empty to the bottom of the wheel to repeat the process.

Through all of antiquity and on into the early Middle Ages almost the only work to which the force of falling water was applied was grinding wheat. This was always to be one of its more important functions. But by the tenth century, European technicians had begun to adapt the vertical water wheel to other tasks. By the sixteenth century, in addition to flour mills, there were hydropowered mills for smelting, forging, sharpening , rolling slitting, polishing, grinding, , and shaping metals. Water wheels were available for hoisting materials and for crushing ores. There were mills for making beer, olive oil, poppy oil, mustard, coins, and wire. Water wheels were used in the preparation of pigment, paper, hemp, and tanning bark, and for fulling, sawing wood, boring pipes, and ventilating mines.

Years ago, in response to a customer"s request, I went looking for a reliable source of waterwheels for ornamental ponds and streams. You"ll love what I found!

Hand-crafted in Pennsylvania by a local Amish carpenter, these wooden waterwheels come complete with sealed wheel bearings and a cold-rolled steel axle. Screws and fasteners are yellow zinc coated. Yesteryear will come alive in your pond or stream when you find a creative way to include one of these beautiful turning waterwheels.

Please note that all of our Amish-made water wheels are overshoot wheels (the water is meant to flow into the wheel from the top just past the center point.) We do not have any undershot wheels, designed for the water to turn the wheel as it flows beneath them. We feel that an overshot wheel is more showy and traditional and are that for which the majority of our customers are looking.

Because of the inherent characteristics of wood, these waterwheels may include knots and other natural blemishes. Includes natural variations such that no two waterwheels will be identical.

The waterwheels rotate freely around a stationary axle, and as such are configured for decoration only, not for driving equipment. We recommend using with a 100gph pump for the best display. Wheel bearings are sealed and we do not recommend greasing, especially where they will be in contact with fish or other wildlife.

To establish if your site is suitable for generating electricity from a Poncelet Wheel you need to have flowing water and you need to know the three key components, which are WATER VELOCITY (in metres per second), AREA (in square metres) and HEAD (in metres).

Power wheels, the overshot in particular, benefits from several often overlooked design features. Operational reliability and ruggedness are very high in a practical installation, the overshot tolerates heavily silted waters, flood debris, rocks, rubbish and outright vandalism. The high rotational inertia and increased static torque create a self cleaning mechanism that breaks tangled fishing lines and carrier bags. Fish and all aquatic life are completely unaffected and water quality may be slightly improved.

The overshot and midshot wheels are very much more efficient than often stated, indeed the overshotis the most efficient energy extractor for limited applications. We make hese to any size; Our Ultra Ultra low head midshots operate in impossibly low head situations finding great favour with utilities and agencies for continuous small or transient high power demands.

Water wheel design has evolved over time with some water wheels oriented vertically, some horizontally and some with elaborate pulleys and gears attached, but they are all designed to do the same function and that is too, “convert the linear motion of the moving water into a rotary motion which can be used to drive any piece of machinery connected to it via a rotating shaft”.

Early Waterwheel Design were quite primitive and simple machines consisting of a vertical wooden wheel with wooden blades or buckets fixed equally around their circumference all supported on a horizontal shaft with the force of the water flowing underneath it pushing the wheel in a tangential direction against the blades.

These vertical waterwheels were vastly superior to the earlier horizontal waterwheel design by the ancient Greeks and Egyptians, because they could operate more efficiently translating the hydrokinetic energy of the moving water into mechanical power. Pulleys and gearing was then attached to the waterwheel which allowed a change in direction of a rotating shaft from horizontal to vertical in order to operate millstones, saw wood, crush ore, stamping and cutting etc.

Most Waterwheels also known as Watermills or simply Water Wheels, are vertically mounted wheels rotating about a horizontal axle, and these types of waterwheels are classified by the way in which the water is applied to the wheel, relative to the wheel’s axle. As you may expect, waterwheels are relatively large machines which rotate at low angular speeds, and have a low efficiency, due to losses by friction and the incomplete filling of the buckets, etc.

The action of the water pushing against the wheels buckets or paddles develops torque on the axle but by directing the water at these paddles and buckets from different positions on the wheel the speed of rotation and its efficiency can be improved. The two most common types of waterwheel design is the “undershot waterwheel” and the “overshot waterwheel”.

The Undershot Water Wheel Design, also known as a “stream wheel” was the most commonly used type of waterwheel designed by the ancient Greeks and Romans as it is the simplest, cheapest and easiest type of wheel to construct.

In this type of waterwheel design, the wheel is simply placed directly into a fast flowing river and supported from above. The motion of the water below creates a pushing action against the submerged paddles on the lower part of the wheel allowing it to rotate in one direction only relative to the direction of the flow of the water.

This type of waterwheel design is generally used in flat areas with no natural slope of the land or where the flow of water is sufficiently fast moving. Compared with the other waterwheel designs, this type of design is very inefficient, with as little as 20% of the waters potential energy being used to actually rotate the wheel. Also the waters energy is used only once to rotate the wheel, after which it flows away with the rest of the water.

Another disadvantage of the undershot water wheel is that it requires large quantities of water moving at speed. Therefore, undershot waterwheels are usually situated on the banks of rivers as smaller streams or brooks do not have enough potential energy in the moving water.

One way of improving the efficiency slightly of an undershot waterwheel is to divert a percentage off the water in the river along a narrow channel or duct so that 100% of the diverted water is used to rotate the wheel. In order to achieve this the undershot wheel has to be narrow and fit very accurately within the channel to prevent the water from escaping around the sides or by increasing either the number or size of the paddles.

The Overshot Water Wheel Design is the most common type of waterwheel design. The overshot waterwheel is more complicated in its construction and design than the previous undershot waterwheel as it uses buckets or small compartments to both catch and hold the water.

These buckets fill with water flowing onto the wheel through a penstock design above. The gravitational weight of the water in the full buckets causes the wheel to rotate around its central axis as the empty buckets on the other side of the wheel become lighter.

This type of water wheel uses gravity to improve output as well as the water itself, thus overshot waterwheels are much more efficient than undershot designs as almost all of the water and its weight is being used to produce output power. However as before, the waters energy is used only once to rotate the wheel, after which it flows away with the rest of the water.

Overshot waterwheels are suspended above a river or stream and are generally built on the sides of hills providing a water supply from above with a low head (the vertical distance between the water at the top and the river or stream below) of between 5-to-20 metres. A small dam or weir can be constructed and used to both channel and increase the speed of the water to the top of the wheel giving it more energy but it is the volume of water rather than its speed which helps rotate the wheel.

Generally, overshot waterwheels are built as large as possible to give the greatest possible head distance for the gravitational weight of the water to rotate the wheel. However, large diameter waterwheels are more complicated and expensive to construct due to the weight of the wheel and water.

When the individual buckets are filled with water, the gravitational weight of the water causes the wheel to rotate in the direction of the flow of water. As the angle of rotation gets nearer to the bottom of the wheel, the water inside the bucket empties out into the river or stream below, but the weight of the buckets rotating behind it causes the wheel to continue with its rotational speed.

Once the bucket is empty of water it continues around the rotating wheel until it gets back up to the top again ready to be filled with more water and the cycle repeats. One of the disadvantages of an overshot waterwheel design is that the water is only used once as it flows over the wheel.

The Pitchback Water Wheel Design is a variation on the previous overshot waterwheel as it also uses the gravitational weight of the water to help rotate the wheel, but it also uses the flow of the waste water below it to give an extra push. This type of waterwheel design uses a low head infeed system which provides the water near to the top of the wheel from a pentrough above.

Unlike the overshot waterwheel which channelled the water directly over the wheel causing it to rotate in the direction of the flow of the water, the pitchback waterwheel feeds the water vertically downwards through a funnel and into the bucket below causing the wheel to rotate in the opposite direction to the flow of the water above.

Just like the previous overshot waterwheel, the gravitational weight of the water in the buckets causes the wheel to rotate but in an anti-clockwise direction. As the angle of rotation nears the bottom of the wheel, the water trapped inside the buckets empties out below. As the empty bucket is attached to the wheel, it continues rotating with the wheel as before until it gets back up to the top again ready to be filled with more water and the cycle repeats.

The difference this time is that the waste water emptied out of the rotating bucket flows away in the direction of the rotating wheel (as it has nowhere else to go), similar to the undershot waterwheel principal. Thus the main advantage of the pitchback waterwheel is that it uses the energy of the water twice, once from above and once from below to rotate the wheel around its central axis.

The result is that the efficiency of the waterwheel design is greatly increased to over 80% of the waters energy as it is driven by both the gravitaional weight of the incoming water and by the force or pressure of water directed into the buckets from above, as well as the flow of the waste water below pushing against the buckets. The disadvantage though of an pitchback waterwheel is that it needs a slightly more complex water supply arrangement directly above the wheel with chutes and pentroughs.

The Breastshot Water Wheel Design is another vertically-mounted waterwheel design where the water enters the buckets about half way up at axle height, or just above it, and then flows out at the bottom in the direction of the wheels rotation. Generally, the breastshot waterwheel is used in situations were the head of water is insufficient to power an overshot or pitchback waterwheel design from above.

The disadvantage here is that the gravitational weight of the water is only used for about one quarter of the rotation unlike previously which was for half the rotation. To overcome this low head height, the waterwheels buckets are made wider to extract the required amount of potential energy from the water.

Breastshot waterwheels use about the same gravitational weight of the water to rotate the wheel but as the head height of the water is around half that of a typical overshot waterwheel, the buckets are a lot wider than previous waterwheel designs to increase the volume of the water caught in the buckets.

The disadvantage of this type of design is an increase in the width and weight of the water being carried by each bucket. As with the pitchback design, the breastshot wheel uses the energy of the water twice as the waterwheel is designed to sit in the water allowing the waste water to help in the rotation of the wheel as it flows away down stream.

Historically water wheels have been used for milling flour, cereals and other such mechanical tasks. But water wheels can also be used for the generation of electricity, called a Hydro Power system.

By connecting an electrical generator to the waterwheels rotating shaft, either directly or indirectly using drive belts and pulleys, waterwheels can be used to generate power continuously 24 hours a day unlike solar energy. If the waterwheel is designed correctly, a small or “micro” hydroelectric system can produce enough electricity to power lighting and/or electrical appliances in an average home.

Look for Water wheel Generators designed to produce its optimum output at relatively low speeds. For small projects, a small DC motor can be used as a low-speed generator or an automotive alternator but these are designed to work at much higher speeds so some form of gearing may be required. A wind turbine generator makes an ideal waterwheel generator as it is designed for low speed, high output operation.

If there is a fairly fast flowing river or stream near to your home or garden which you can use, then a small scale hydro power system may be a better alternative to other forms of renewable energy sources such as “Wind Energy” or “Solar Energy” as it has a lot less visual impact. Also just like wind and solar energy, with a grid-connected small scale waterwheel designed generating system connected to the local utility grid, any electricity you generate but don’t use can be sold back to the electricity company.

In the next tutorial about Hydro Energy, we will look at the different types of turbines available which we could attach to our waterwheel design for hydro power generation. For more information about Waterwheel Design and how to generate your own electricity using the power of water, or obtain more hydro energy information about the various waterwheel designs available, or to explore the advantages and disadvantages of hydro energy, then Click Here to order your copy from Amazon today about the principles and construction of waterwheels which can be used for generating electricity.

Gravity devices are those where any kinetic energy present at the entry of the device is either minimal or lost in turbulence and does nor contribute measurably to the output of the device. Such devices include most waterwheel types, Archimedes screws (where the outer case rotates with the flutes); Hydrodynamic screws (as used for sewage pumping and now being used in reverse as low-head prime-movers); Norias (more commonly used for raising water) and consist of a string of buckets like an overshot waterwheel attached to form a chain, and positive displacement devices or hydraulic engines.

Impulse turbines are those where the potential energy in a ‘head of water’ is largely converted into kinetic energy at a nozzle or spout. The simplest of such devices is the Gharat or Norse Wheel (where the conversion to kinetic energy takes place in an open flume). The more conventional devices harness the potential energy in a pipeline or penstock that terminates in a nozzle. The flow path through the turbine is usually used to describe the specific device, namely, tangential-flow, radial-flow, cross-flow, axial-flow or mixed-flow. Specific turbine designers have been associated with most of these devices, though confusion can result because they often designed several different types of device (The Pelton Waterwheel Company also made cased reaction turbines, Herschel pre dates Jonval’s patent that was the precursor of the Turgo Impulse wheel, a single nozzle version developed by Gilkes. Donat Banki, a Hungarian was also making cross-flow turbines many years before Mitchell and Ossburger came on the scene.

Free-stream devices encompass large slow running wheels and turbines, some of which are being tried out for marine energy applications. Like wind turbines, the power delivered increases as a cube of the velocity, such that a doubling of the velocity gives an eight fold increase in power output. The devices themselves are very large and slow running and only have very specialised applications for extracting small amounts of power from bank-side locations on very large rivers.

One of the most successful high head turbines was developed in California during the gold rush from a device referred to as a ‘hurdy gurdy’ that was basically a cartwheel with buckets around the periphery. A carpenter by the name of Lester Pelton came up with the now familiar double bucket shape and went on to found ‘The Pelton Watewheel Company’ of San Francisco. The bucket design was later improved by Doble who joined the company as an engineer in 1899. Doble’s improvement is the central cut-out in the bucket that prevents the water jet from first striking the back of the bucket and wasting energy. www.oldpelton.net. Today, similar machines are operating from over 1000 metres of fall and generating up to 100MW of power.

The waterwheels that were used on these sites in the U.K. are usually of the Roman or horizontal shaft type, though the vertical shaft type is much more common in Mediterranean and Asian countries. Depending on the fall of water available, the horizontal wheels are classified into ‘Overshot’, ‘Breast-shot’, ‘Back-shot’ and ‘Under-shot’. With the exception of projects to restore a mill to its original design, or where the visual appearance is important to maintain, only the overshot wheel is suitable for a new power generation projects.

Overshot waterwheels are the most fish-friendly and able to handle leaves and sticks. A similar device is the Noria or chain wheel, which has the disadvantage of potential more maintenance, but it runs faster, is more efficient and easier to install than an overshot waterwheel.

The power available is a function of the head and flow so building a large wheel will only increase the cost and reduce the shaft speed but not increase the power. Major components in the cost are the primary gearbox and the material required in the construction of the wheel itself. We are happy to build any type of waterwheel, but the cost is likely to be significantly greater than that of an equivalent turbine, when you take the gearing and installation costs into consideration. There are no short cuts with waterwheels and the engineering has to be good, on account of the high torque in the low speed drive.

Mills with ponds are seldom suitable for redevelopment for anything other than a few kilowatts because the water flow is obviously too little to sustain the mill on a continuous basis, and it is much too expensive to install a wheel or turbine that can only be operated for a few hours a day. In some cases the ponds were only used in the summer months when the water was low, but today we are looking to the higher winter flow for the bulk of the power that can be used for heating. There is always a loss of head into and out of the pond, but this may be recoverable with a turbine installation.

Mills on weirs or with short wide diversion channels present the most difficult challenge for the developer. The available head may only be a metre or so and the flow required to generate useful amounts of power will be several cubic metres of water per second. The undershot waterwheels that were originally used at these sites are totally redundant on account of their high cost and low efficiency. The exact layout of the site becomes increasingly important with the lower falls, because access for excavators and to install the large items of equipment is more difficult.

Tubular turbines of the propeller type can be used for mill sites with a higher head, typically those that originally employed ‘Overshot’ waterwheels. Many different arrangements are possible to suite existing civil works but the main compromise arises from their inflexible performance. If the mill is only extracting a small percentage of the available water from the main river, then there is no problem. If however the water flow reduces below that which is required to supply the turbine, either water storage, another smaller turbine or a change in turbine speed will be required.

Low cost open impulse turbineshave been developed by us, primarily for projects in the Developing World. Installed outside the mill house like a waterwheel, it is an economic alternative for smaller domestic sites here in the U.K. They cannot be used with a draft tube since the runner is open to the atmosphere but the installation and maintenance is much simpler. The valve control shaft is extended through the mill house wall to an operating lever on the ,inside or a simple open shoot conveys the water directly to the runner in the manner of the old ‘flutter wheels’ used in the USA in the 19c. Installation work is usually kept to a minimum and may be in an old waterwheel pit or even behind an existing wheel under the launder. A vertical shaft version like the Indian Gharat can produce considerably more power by increasing the entry area, whilst maintaining its self-cleaning characteristics.

8613371530291

8613371530291