oversized guide overshot pricelist

Series 150 Overshots General Description ................................................ 3 Use .......................................................................... 4 Construction ............................................................ 4 Gripping and Releasing Mechanism ................... 4 Pack-off Mechanism ............................................. 5 Operation ................................................................ 6 Precautions ............................................................. 6 Undersize Parts ....................................................... 7 Spiral Parts .............................................................. 7 Basket Parts ............................................................ 7I N D E X

Overshot Accessories ............................................. 7 Subsea Sheared Pipe Retrieval Method ................. 9 Specifications and Replacement Parts ......... 12 19 Overshot Accessories Tables ........................ 20 22 Calculated Strength Tables ........................... 23 24 Illustrations .............. 3, 5, 7, 8, 9, 10, 17, 19, 20 22

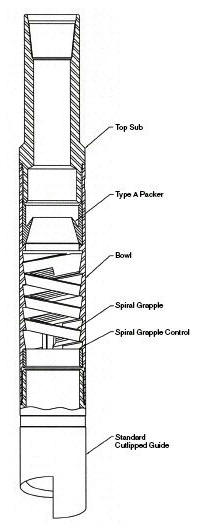

Series 150 Releasing and Circulating Overshot Series 150 Releasing and Circulating Overshot Dressed with Spiral Grapple and Parts Dressed with Basket Grapple and Parts

General DescriptionThe Bowen Series 150 Releasing The Bowen Series 150 Releasing and Bowen Overshots are continually devel-and Circulating Overshot provides the Circulating Overshot has gained world- oped to new standards of strength andstrongest tool available to externally wide acceptance for fishing by means efficiency and are expertly constructedengage, pack-off, and pull a fish. The of external engagement of a fish. Each of the highest quality material.basic simplicity and rugged construction Overshot is a carefully engineered unit. Each Bowen Series 150 Releasing andwith which it is designed have made In service, it takes a positive grip over a Circulating Overshot is a compact unitit the standard of all external catch large area of fish and is therefore capa- designed to engage, pack off and pull afishing tools. ble of withstanding extremely heavy pull- specific size of tubing, pipe, coupling, ing, torsional and jarring strains without tool joint, drill collar or smooth O.D. tool. damage or distortion to either the tool Through the installation of proper under- or the fish. size parts, they may be adapted to engage and pack off any smaller size.

3Bowen course thread Overshots are Construction Three types of Basket Grapples aredesigned for easier assembly and The Bowen Series 150 Releasing and available to meet the need for catchingmaintenance. The Bowen CT Overshot Circulating Overshot is composed of various types of fish:has a course ACME thread on the upper three outside parts: the Top Sub, Bowl, and Guide. The Basic Overshot may be The Plain Basket Grapple is standard,end of the Bowl where the Top Sub is dressed with either of two sets of internal and will always be furnished unlessattached and at lower end where the parts, depending on whether the fish to another type is specified. It is wickeredGuide is attached. See Supplemental be caught is near maximum catch size for its entire interior length. It is used toInstruction Manual 1150A for list. for the particular overshot. catch any plain single diameter fish.The course thread allows much easier If the fish diameter is near the maximum The Basket Grapple with Long Catchfield assembly and will stand more catch of the Overshot, a Spiral Grapple, Stop has an internal shoulder located atabuse than the fine series currently Spiral Grapple Control and Type A the upper end, to stop the fish in bestoffered. The internal parts are completely Packer are used. If the fish is a tubing catch position. It is designed to stop andinterchangeable with existing Bowen collar, a Type D Collar Packoff Assem- catch an upset, or box section of a toolOvershots. bly will replace the Type A Packer. joint, with sufficient length left below theCross over bushings can be provided Grapple to allow the joint or upset to befrom fine thread series to course thread If the fish diameter is considerably below packed off with a Basket Mill Controlseries, allowing full use of Bowls, Top maximum catch size (usually 12"), a Packer.Subs, and Guides currently in stock. Basket Grapple and a Mill Control Packer is used. The Basket Grapple with Short CatchAll sizes of Bowen Series 150 Releasing Stop has a double set of wickers, of twoand Circulating Overshot are available in Gripping and different internal diameters. It is used toFull Strength or Slim Hole Types. Despite Releasing Mechanism stop and catch a coupling with athe extremely small outside diameters The Bowl of the Overshot is designed ruptured piece of pipe engaged in itsof Full Strength Type Overshots, they with helically tapered spiral section in its upper end. The upper set of wickers willare engineered to withstand the pulling, inside diameter. The gripping member catch the ruptured pipe, and act as atorsional and jarring strains, which must (Spiral Grapple or Basket Grapple), is stop against the coupling, while thebe exerted by modern machinery, to fitted into this section. When an upward lower set of wickers will catch the coup-release and retrieve a lost fish. pull is exerted against a fish, an expan- ling. The coupling will be stopped in best sion strain is spread evenly over a long position to be packed off by the MillThe Slim Hole Type Overshots have section of the fish. No damage or distor- Control Packer.reduced outside diameters, as com- tion results to either the fish or the Over-pared to the Full Strength. They are used shot. This design permits a far stronger Grapple Controls are of two types: Spiralto perform pulling jobs in tight holes tool with a smaller outside diameter than Grapple Controls are used with Spiralwhere no other outside catch, releasing is possible with an overshot that employs Grapples; Mill Control Packers are usedfishing tool can be run. a single tapered section which supports with Basket Grapples. slips. Grapple Controls are used as a specialUseA Bowen Series 150 Releasing and A Spiral Grapple is formed as a left-hand key, to allow the Grapple to move up andCirculating Overshot is used to engage, helix with a tapered exterior to conform down during operation while simulta-pack off and retrieve twisted-off or lost with the helically tapered section in the neously transmitting full torque from thetubing, drill pipe, coupling, tool joint, Bowl. Its interior is wickered for engage- Grapple to the Bowl.casing or other similar fish. ment with the fish. Spiral Grapple Controls and Basket A Basket Grapple is an expansible cylin- Grapple Controls are plain. Mill Control der with a tapered exterior to conform to Packers include a packoff. See Pack-off the helically tapered section in the Bowl. Mechanism for a complete explanation. Its interior is wickered for engagement with the fish. In operation, the Overshot functions in the same manner, whether dressed with Spiral Grapple parts or Basket Grapple parts

4 be ordered to match each size BasketDuring the engaging operation, as the Grapple. Mill Control Packers whenOvershot is rotated to the right and used, replace a Plain Basket Control.lowered, the Grapple will expand when The Plain Basket Control is used withthe fish is engaged, allowing the fish to Type A Packer a Basket Grapple when no pack-off ofenter the Grapple. Thereafter with rota- the fish is required.tion ceased and upward pull exerted,the Grapple is contracted by the tapers Type D Packer assemblies are avail-in the Bowl and its deep wickers grip the Inner Seal able to pack off tubing collars in tubingfish firmly. size Series 150 Overshots. The Type D Packer assembly consists of a Packer,During the releasing operation, a sharp a Spring and an O-Ring. It is assembleddownward bump places the larger por- in the Bowl above the Grapple. Its uppertion of the Bowl tapers opposite the Mill Control end is sealed in a counter-bore in theGrapple smaller tapered portion, break- Packer Top Sub, by the O-Ring. In operation,ing the hold. Thereafter, when the Over- its lower end stops the collar in propershot is rotated to the right, and slowly catch position, while the integral moldedelevated, the wickers will screw the Outer Seal seal enters and packs off the collarGrapple off the fish, effecting release. threads at the top of the collar. TheseThe fact that Bowen Releasing and Cir- Type R Mill Control Packer Packers are listed on page 16.culating Overshots require right hand The Type D Collar Packer is designedrotation only, both during engaging and Type A Packer should be ordered for to be used with a Spiral Grapple, in placereleasing operation, is extremely impor- each catch size Spiral Grapple. of a Type A Packer, where the collartant. This feature eliminates the dangers being fished is too short to allow effectivethat are present when it is necessary to A Mill Control Packer is used when the catch and pack off length.rotate the string to the left. Overshot is dressed with a Basket Grap- ple. The Type R Mill Control Packer is used when a packoff is required. The unique double lip seal of the Mill Control Packer provides a positive seal of the fish. The Packer is self energized and is retained within the Mill Control by a lower second sealing lip and requires no ad- hesive for retaining the Packer. The Type Basket Grapple Basket Grapple R is most commonly used. It has a with Short Catch Stop with Long Catch Stop replaceable inner seal and a replaceable outer seal. The inner seal and the outerPack-off Mechanism seal may both be replaced in the fieldThe type of Pack-off used depends on when required. The Type R Mill Controlhow the Overshot is dressed, and the (with mill teeth) is available. Mill Controloperators choice. Packers are designed to remove small burrs and rough breaks only. Replace-When the Overshot is dressed with a ment inner and outer seals are listedSpiral Grapple, a Type A Packer is used. on page 20. Also see the special HighThe Type A Packer is a sleeve type. It Pressure Pack-off accessories on pageseats at its O.D. against the inside of the 19. Series 150 Overshot Type DBowl. It has an internal lip which seals with Type D Packer Packer Assemblyaround the fish. Each type A Packer is All Mill Control Packers are manufactured in Packed Off Positiondesigned to pack off a specific size. A to pack off a specific size. One should

5Operation To Release from the Fish 5. Likewise, once the fish is in thisFirst determine that the Overshot is Bump down; then simultaneously rotate position, the circulation will sealproperly assembled, is dressed with the to the right and slowly elevate the fishing the Packoff Rubber around the fishproper size Grapple and that all its parts string until the Overshot is clear of the and prevent fluid passage downare in good working condition. Refer to fish; combined rotating and elevating is the outside. Thus, by building upSpecifications beginning on page 11. important. pressure with the pumps, the fluid To release from a recovered fish, follow can be forced down through the fish.Obviously, if the fish is smaller than themaximum outside diameter that the the same procedure while holding the Function of the OvershotOvershot was designed to engage, fish below the Overshot. when Releasinginstall undersize parts. The sharp downward bump places the Precautions largest portion of the Bowl tapers oppo-If the hole size is so much greater than Unless an upward strain is maintained, site the Grapple and breaks the hold.the fish size that it is possible for the never rotate the fishing string to the left Right-hand rotation expands the GrappleOvershot to pass alongside the fish, while the Overshot is engaged with the and by maintaining right-hand rotation,install either a Wallhook Guide or an fish. the Overshot may be withdrawn from theOversize Guide in place of the Standard Always bump the full weight of the fishing fish.Guide. (see page 18) string before starting releasing opera-If the top of the fish is a heavily burred Function of the Grapple tions.tool joint, replace the Standard Guide The mechanical conditions which causedwith the proper Milling Guide, Type A or Always shut off the circulating pumps the Grapple to expand and contract are:C. (see page 19) before lowering the Overshot over the 1. The Grapple is a left-hand helix. fish.If the fish has an unengageable upper 2. The lower end of the Grapple isend, install an Extension between the Function of the Overshot anchored in the Overshot Bowl.Top Sub and the Bowl (see illustration on in Engaging the Fish

page 7). After the Overshot has reached the top 3. The inside diameter of the Grapple of the fish, combined rotation and is smaller than the outside diameterUsing the Top Sub, connect the Overshot lowering results in the following: of the fish.to the fishing string and run it in the hole. 1. The guide will direct the fish into the As the Overshot is rotated to the rightTo Engage and Pull the Fish Overshot. and lowered over the fish, the drag ofAs the top of the fish is reached, slowly the fish against the grapple causes the 2. The Grapple will expand and the fishrotate the fishing string to the right and Grapple to unwind and expand suffi- will pass through it.gradually lower the Overshot over the ciently to allow the fish to enter.fish; combined rotating and lowering is 3. The fish will pass through the Pack- As the Overshot is rotated to the rightimportant. off Rubber and will be halted when it and withdrawn from the fish, the drag contacts the pin end of the Top Sub.Allow the right-hand twist to slack out of of the fish against the Grapple causes In the case where an external upsetthe fishing string and then pull on the fish the Grapple to unwind and expand section is being engaged by a Bas-by elevating the fishing string. sufficiently to allow the Overshot to be ket Grapple, the fish will be halted withdrawn.If the fish does not come, turn on the by the solid steel stop in the uppercirculating pumps and maintain an end of the Basket Grapple.upward strain while circulation is forced 4. The fish is now properly located inthrough the fish. the Overshot and thereafter when upward pull is exerted, the Grapple is contracted by the tapers in the Bowl and the hold will be secure.

6Undersize Parts Top Sub. The Rings also eliminate theUndersize parts are used when the fish weakening and hazardous practice ofto be caught is smaller than the maxi- welding a steel strap across the Bowlmum catch size of the Overshot. and Sub joint to hold them in place. Using excessive torque when making-upSpiral Parts these joints is also no longer necessaryUndersize Spiral parts: Spiral Grapple if the rings are used.and Type A Packer are used to catchsizes from Maximum Catch Spiral Bowen Lock Rings provide a positiveGrapple, down to Maximum Catch- and releasable means for lockingBasket Grapple, as specified in the straight-threaded shouldered joints sospecifications tables on pages 11 thru they will not back off.15 inclusive. Type SS Top Sub Type LS Top Sub (Short with Shoulder) (Elevator Type Extension SubsThese Spiral Grapples and Type A with Shoulder) If a twist-off has left a fishPacker should be changed for each whose upper end is unen- Overshot Accessoriesdifferent size fish. They will effectively gageable, an Extension Top Subscatch and pack off worn fish as much as Sub should be installed332" maximum undersize. The over-range Top Subs are available for Bowen between the Top Sub andof each grapple is approximately 132". Overshots in two types: SS, Short Sub the Bowl of the Overshot. with shoulder; and LS, Elevator Sub with This will permit lowering ofThere are exceptions, particularly in the shoulder. Type SS Top Subs are fur- the Overshot over the fishSlim Hole type Overshots. Some of these nished as part of the assembly, unless far enough to insure en-will effectively catch undersize or otherwise specified. gagement and a perfectoversize fish by no more than 116" Lock Rings pack off in the fishingmaximum. Bowen Lock Rings are available as operation. Extension SubsBasket Parts optional equipment to prevent the Top are listed on page 21.Undersize Basket parts are used to Sub and Bowl of Bowen Series 150catch sizes from Maximum Catch- Releasing and Circulating Overshots Extension SubBasket Grapple as specified in the from unthreading during backing-offspecification tables of pages 11 thru 15 operations. Use of Bowen Lock Ringsinclusive, down to any smaller size. eliminates the weakening practice ofBasket Grapples should be changed for drilling and tapping the Bowl to installeach size fish to be caught. a set screw for securing the Bowl to the

There are exceptions, particularly in theSlim Hole type Overshots. Some of these Knurlswill effectively catch undersize fish bymore than 132" maximum. Lock Rings

7Construction The Breakout Clamp consists of two screw handle is then tightened whichBowen Lock Rings are used in pairs keys that fit into the Lock Ring grooves, a forces the slightly tapered keys into theconsisting of two identical rings. The lower key seat, and an extended pin flat Lock ring breakout grooves, holds therings have cam-teeth on one face, knurls link chain attached at one end to a cam-teeth together, and permits theon the other, and two breakout grooves bracket which has a guide for another shoulders to back away from the knurledon the edges. They are precision made (movable) key seat attached to a screw faces when the joint is broken. Lockfrom alloy steel, stress relieved, and heat handle. Rings are listed of page 21.treated. To position the Breakout Clamp, theAssembly screw handle is backed-up as far as itOne Lock Ring is inverted and placed on will to, the other end of the chain is putthe other so the cam-teeth intermesh through a hole in the lower key seat, andand the breakout grooves are aligned, the keys are placed in the ring groovesand then they are placed on the Top Sub. opposite each other. The chain is thenThe Bowl is threaded on, and as the joint pulled around the rings so that all slackis made-up, the knurled faces opposite is removed and the nearest pin is slippedto the cam-teeth dig in and grip the into the pin slot on the bracket. Theshoulders. The pitch on the cam-teeth isgreater than the thread pitch, so ifreverse rotation is applied, the cam-teethbegin to ride up on each other. Thisproduces a wedging action which Itcoloy Mill Extensioneffectively locks the Top Sub to the Bowl. Screw HandleThe joints are properly made up when Bracket with Guide Itcoloy Mill Extensionreverse torque has been applied and a Itcoloy Mill Extensions are used to millslight separation in the cam-teeth Movable Key Seat away flared or jagged metal from the topshoulders is observed. Heavy make-up of the fish so that the fish will pass easily Pintorque is not required. Slot into the Overshot Bowl. For ordinaryWhen the Overshot is dressed with a work, they are installed between the Bowlspiral grapple and type A Packer, a and the standard, oversize or wall hookSpacer is required between the Packer guides.and Top Sub. Please refer to Lock RingTable on page 21. The purpose of the The Itcoloy Mill Extension is also usedSpacer is to fill the space produced by in the Bowen Subsea Sheared Pipethe extra standoff of the Top Sub when Retrieval Method (see page 9). In this Keysused with the Lock Rings. No Spacer is case it is installed between the Overshotrequired when A Packer is not used. Bowl and the special guides. They may be ordered by giving the OvershotDisassembly number and specifying Itcoloy MillWhen unthreading is desired, a special Extension Type and fish size. PricesBowen Lock Ring Breakout Clamp is available on request.required. Slight right-hand torque mayhave to be applied for lining-up the Ringbreakout grooves to receive the Clamp. Lower Key Seat Chain

8 Itcoloy Mill Guide The BOP being used must have at least Itcoloy Mill Guides are used to mill two sets of rams: lower pipe rams and away jagged metal form the top of the shear rams above them. Before shear- fish so that the fish will pass easily into ing, it is necessary to land the nearest the Overshot Bowl. tool joint on the pipe rams and close them to suspend and pack off the string. They may be ordered, using the stan- The shearing then produces flattened dard Guide number, and specifying, flare-ends with protruding ears. Itcoloy Mill Guide Type C and fish size. When the rig returns, the string must be Subsea Sheared retrieved, the end brought to the surface Pipe Retrieval and the sheared piece removed. In the During operations from a floating rig, past, sheared pipe retrieval has been dif- there is often many hundred feet of drill- ficult, costly and time-consuming. Often ing sting string extending from the rig to large parts of the BOP stack must be the sea floor, through the wellhead blow- brought to the surface to effect retrieval. out preventer (BOP) stack, and down into the well. If occurrences like a blow- The Bowen method of sheared pipe out, a loss of anchor and the rig drifts, retrieval can be achieved in a simple, a dangerous storm is approaching, etc., time-saving and economical manner. it is sometimes necessary for the rig to It requires only two easy steps using hurriedly move from the well-site. This the Series 150 Circulating and Releasing is done by temporarily severing the drill Overshot equipped with a few special sting inside the BOP and only tripping- accessories Oversize Guide Wallhook Guide out the upper end.GuidesIf the hole size is so much greater than Blowout Preventer Stackthe fish size that it is possible for theOvershot to pass alongside the fish, anOversize Guide or a Wallhook Guidemust be installed in place of the Stan-dard Guide to insure alignment of thefish with the Overshot. These are listedon page 18. Type A Mill Guide

Twist-offs in tool joints are not alwaysimmediately revealed at the surface andas a result drilling is not halted at once.In such cases the top of the fish is usu-ally a badly burred tool joint, or drill pipe, Shear Ramsand a Type A Mill Guide must be installedon the Overshot to trim the burr off thefish so that it can enter the Overshot.Itcoloy Mill Guides perform the sameservice on undersize tool joints and arealso used when the top of the fish is an Pipe Ramsunusually jagged section of pipe. Moreinformation on these is shown on page19. Itcoloy Mill Guide

Step 1: Flare Mill-Down Step 2: Engage and Pull Bowen sheared Pipe Retrieval OvershotThe standard guide, grapple and packer After the milling step is completed, the assemblies are available for all sizes ofhave been removed from a Bowen Bowen Overshot is brought back to the drill pipe and BOPs. Prices will beOvershot and it is then dressed with a surface, dressed with a special flat- quoted on request.Mill Extension and special flat-bottom bottom Short Guide, Extension Sub andLong Guide, and installed on the drill a Basket Grapple and Mill Control Packer How to Orderstring. The Mill Extension has tapered sized to engage the joint. (The Short Specify:milling ribs of Bowen Itcoloy (sintered Guide also has a soft metal end to (1) Make and working bore sizetungsten carbide) facing on its I.D. The prevent ram damage.) The Overshot is of BOPOvershot is lowered into the BOP and lowered again and as it enters the BOP, (2) The distance between the counterover the end of the drill pipe, and then the milled-down flare-end passes lines of the BOP pipe rams androtation takes place to mill down the through the Grapple and Mill Control shear ramsflared ears of the sheared pipe. The end Packer, and is housed in the Extension (3) Drill pipe body O.D. and tool jointof the Long Guide is faced with soft Sub while the Grapple engages and O.D. and lengthmetal so that if inadvertently it contacts packs off the tool joint. A pull is exertedthe BOP pipe rams, it does not damage on the Overshot to make certain ofthem. The Guide is also of a length engagement and then the BOP pipewhich prevents the Mill Extension from rams are retracted, and the string iscontacting and damaging the tool joint in raised to the rig floor where the severedthe BOP. This is important because this joint is removed and replaced, allowingjoint O.D. is where engagement of the normal operations to resume.string will take place.

10Assembly ListsThe lists of assemblies and accessoriesin this Instruction manual have beenreduced to the most popular Overshotsand parts worldwide. This has been doneto make it easier for the customer toquickly find the information they requireand also for the ease of transmitting theelectronic version of the file.

The Bowen Series 150 Overshot productline consists of many different sizes andtypes of assemblies and items. A listof over 225 of these is in SupplementalInstruction Manual 1150A. If a locallypopular assembly is not listed in Manual1150 it will most probably be listed inManual 1150A. However, this is still nota complete list. There are additionalassemblies not listed.

The standard Series 150 Overshot is aright-hand operation tool with right-handthreads. But there are many specialsoffered. Some of the other tools madeare right-hand tools with left-handthreads, left-hand tools with left-handthreads, left-hand tools with right-handthreads, tools for H2S service, toolsfor CO2 service, tools for H2S and CO2service, very high strength tools, verythin wall tools, and with sizes rangingfrom 25/16" OD to above 32" OD.

11SpecificationsMaximum Catch Size (Spiral) 2 2-1/8 2-3/8 2-1/2 2-1/2 2-7/8 3-1/16 3-1/16 3-1/8Maximum Catch Size (Basket) 1-13/16* 1-3/4 2 2 2 2-19/32 2-11/16 2-19/32 2-5/8Overshot O.D. 2-5/16 2-21/32 3-1/8 3/3/8 3-5/8 3-5/8 3-3/4 3-15/16 3-7/8Standard Box Connection Per Customer OrderType SH SH XSH SH FS XSH SH SH SHComplete Assembly Part No. B-8919 C-10199 9305 C-4623 C-5080 9270 37585 C-5101 C-1835(Dressed with Spiral Parts) Weight 13 28 42 46 55 51 50 60 56

Replacement PartsTop Sub Part No. A-8920 A-10200 9311 A-5083 A-5081 9276 37586 A-5102 A-1842 Weight 7 13 20 22 25 26 25 30 28Bowl Part No. B-8921 B-10201 9306 B-5088 B-5082 9271 37587 B-5103 B-1836 Weight 2-1/2 6 9 10 13 11 11 14 16Packer Part No. 9407 B-10202 9309 B-5089 B-3395 8550 37588 B-3594 B-1839 Weight 1/8 1/8 1/8 1/8 1/8 1/4 3/8 3/8 3/8Packer Seat Ring Part No. A-8922 A-10203 9310 A-5090 A-5084 9274 37589 A-3595 A-1840 Weight 1/32 1/16 1/8 1/8 1/8 1/8 1/8 1/8 1/8Spiral Grapple Part No. 9403 B-10204 9307 B-5091 B-5085 9272 37590 B-3596 B-1837 Weight 5/8 3/4 3/4 3/4 3/4 1-1/8 1-1/4 1-1/2 1-1/2Spiral Grapple Control Part No. 9405 A-10205 9308 A-5092 A-5086 9273 37591 B-3597 A-1838 Weight 1/8 1/2 3/4 3/4 3/4 3/4 3/4 7/8 1Standard Guide Part No. 9404 A-10206 9312 A-5093 A-5087 9275 37592 A-3598 A-1841 Weight 1-1/2 7 11 12 15 11 11 13 16

12SpecificationsMaximum Catch Size (Spiral) 3-1/8 3-3/8 3-1/2 3-21/32 3-21/32 3-3/4 3-3/4 4 4-1/4 4-5/8 4-5/8Maximum Catch Size (Basket) 2-5/8 2-7/8 2-7/8 3-1/8 3.220 3-7/32 3-1/4 3-1/2 3-11/16 4-1/8 4-1/8Overshot O.D. 4-1/8 3-7/8 4-3/8 4-9/16 4-11/16 4-5/8 4-11/16 4-7/8 5-9/16 5-1/2 5-5/8Standard Box Connection Per Customer OrderType FS XSH SH SH FS SH SFS SH FS SH FSComplete Assembly Part No. 9105 21300 C-4619 C-5151 9109 C-5129 9120 C-5154 5896 C-4969 5698(Dressed with Spiral Parts) Weight 70 70 72 77 83 82 83 95 130 120 130

Replacement PartsTop Sub Part No. 9106 21301 A-4620 A-5152 9110 A-5130 9110 A-5155 5897 A-4970 5699 Weight 33 33 36 38 40 42 40 48 61 60 65Bowl Part No. 9107 21302 B-4621 B-5153 9111 B-5131 9121 B-5156 5898 B-4971 5700 Weight 18 18 18 19 21 20 21 24 34 30 33Packer Part No. 809 21303 6515 L-6665 6665 B-5538 9122 B-5157 169 L-1140 1140 Weight 3/8 3/8 3/8 1/2 1/2 1/2 1/2 1/2 5/8 5/8 5/8Packer Seat Ring Part No. 1748 21304 A-3358 A-4338 43496 A-5132 6666 A-5158 172 L-1136 1136 Weight 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8Spiral Grapple Part No. 1741 21305 B-3607 B-4339 6662 B-5133 9123 B-5159 165 M-1135 1135 Weight 1-1/2 1-1/2 1-1/2 1-3/4 1-3/4 1-3/4 2 2 2-1/2 2-1/4 2-1/4Spiral Grapple Control Part No. 1747 21306 B-3608 B-4340 6674 A-5134 9124 B-5160 186 M-1137 1137 Weight 1 1 1-1/8 1-1/4 1-1/4 1-1/4 1-1/2 1-1/2 2 1-1/2 1-1/2Standard Guide Part No. 1746 21307 A-4622 A-4341 6667 A-5135 9125 A-5161 187 M-1138 1143 Weight 17 17 15 16 18 16 18 19 30 25 27

13SpecificationsMaximum Catch Size (Spiral) 4-3/4 4-3/4 5 5 5-1/8 5-1/4 5-3/8 5-1/2 6-1/4 6-1/4 6-1/4Maximum Catch Size (Basket) 4-1/4 4-1/4 4-1/2 4-3/8 4-5/8 4-5/8 4-3/4 4-7/8 5-5/8 5-9/16 5-1/2Overshot O.D. 5-5/8 5-3/4 5-29/32 6-1/8 5-3/4 6-3/8 6-1/2 6-5/8 7-3/8 7-5/8 7-7/8Standard Box Connection Per Customer OrderType SH FS SH SFS SH SH SH SH SH SFS FSComplete Assembly Part No. C-5168 8975 C-5171 7787 C-11823 6655 4773 8625 9692 8741 C-2108(Dressed with Spiral Parts) Weight 133 138 140 157 160 176 182 185 216 241 261

Replacement PartsTop Sub Part No. A-5169 8976 A-5172 7789 A-11824 6656 4774 8626 9693 8742 B-2106 Weight 62 64 65 69 69 78 79 78 87 99 105Bowl Part No. B-5170 8977 B-5173 7788 B-11825 4503 9205 8617 9694 1641 B-2109 Weight 32 33 34 40 33 52 53 54 62 69 76Packer Part No. B-2199 6114 L-5950 5950 B-11826 94505 9209 8618 9689 1642 L-1680 Weight 3/4 3/4 3/4 3/4 3/4 33/4 7/8 3/4 1-1/8 1-1/8 1-1/8Packer Seat Ring Part No. A-2200 6120 A-4368 5945 LA-11827 4510 9210 8622 9690 1643 A-2072 Weight 1/8 1/8 1/8 1/4 1/8 3/8 3/8 3/8 1/4 3/8 3/8Spiral Grapple Part No. B-2021 6112 B-4369 5942 B-11828 4498 9207 8619 9687 1644 B-2073 Weight 2-1/2 2-3/4 2-1/2 2-1/2 2-1/2 33 3 4 5 5-1/4 5-3/4Spiral Grapple Control Part No. B-2202 6113 B-4370 5944 A-11829 4499 9208 8620 9688 1645 A-2074 Weight 2 2-1/4 2 2-1/4 2 2-1/2 2-1/2 2-1/2 3 3-1/4 3-1/2Standard Guide Part No. B-2203 6121 B-4371 5946 A-11830 4504 4775 8621 9691 5525 A-2075 Weight 33 34 34 42 33 39 43 45 58 63 69

14SpecificationsMaximum Catch Size (Spiral) 6-1/2 6-1/2 6-5/8 6-5/8 6-3/4 7 7-1/4 8 8-3/8 8-1/2 9Maximum Catch Size (Basket) 5-7/8 5-3/4 6 5-7/8 6-1/8 6-3/8 6-5/8 7-1/4 7-3/4 7-3/4 8-1/4Overshot O.D. 7-5/8 8-1/8 7-3/4 8-1/4 8-1/8 8-1/8 8-3/8 9-5/8 9-1/2 10-1/8 10-5/8Standard Box Connection Per Customer OrderType SH FS SH FS SH SH SH FS SH FS FSComplete Assembly Part No. 9860 C-5342 4785 C-3032 C-5222 9217 C-5354 264 4834 8960 C-5321(Dressed with Spiral Parts) Weight 220 274 235 280 243 251 260 337 314 358 401

Replacement PartsTop Sub Part No. 9861 A-5343 9133 A-3033 A-5223 9218 A-5355 265 9063 8961 A-5322 Weight 87 115 100 120 102 107 114 158 153 165 178Bowl Part No. 9862 B-3711 9134 B-3034 B-5224 9219 B-5356 266 9062 8962 B-5323 Weight 64 67 78 69 69 71 84 77 87 97Packer Part No. 9865 2372 9136 A-1814 B-5225 9224 B-5357 235 9055 8956 B-5324 Weight 1-1/8 1-1/8 1-1/8 1-1/8 1-1/8 1-1/4 1-1/4 1-1/2 1-1/2 1-5/8 2Packer Seat Ring Part No. 9866 A-2373 9135 A-1815 A-5226 9225 A-5358 241 9056 8953 A-5325 Weight 3/8 3/8 1/2 1/2 1/2 1/2 1/2 1/2 1/2 3/4 3/4Spiral Grapple Part No. 9863 B-2374 9137 N-84 B-5227 9222 B-5359 238 9057 8957 B-5326 Weight 5-1/2 5-3/4 5-1/2 6 5-3/4 5-3/4 6 7-3/8 6-1/2 9 10Spiral Grapple Control Part No. 9864 B-2375 9138 M-89 A-5228 9223 B-5360 239 9058 8958 B-5327 Weight 3-1/2 3-1/2 3 3 3 3-1/2 3 4 3-1/2 4-3/4 5Standard Guide Part No. 9867 A-2376 9139 A-1818 A-5229 9226 A-5361 240 9059 8959 A-5328 Weight 60 71 60 72 62 62 64 81 70 90 108

15SpecificationsMaximum Catch Size (Spiral) 9-5/8 10-1/8 11-1/4 12 14 14-3/4Maximum Catch Size (Basket) 8-7/8 9-3/8 10-1/2 11-1/4 13-1/4 14Overshot O.D. 11-1/4 11-3/4 12-3/4 13-3/4 16 16-3/4Standard Box Connection Per Customer OrderType FS FS Complete Assembly Part No. C-12822 5329 15800 33006 68028 64553(Dressed with Spiral Parts) Weight 520 642 948 975

REPLACEMENT PARTSTop Sub Part No. A-12823 5330 15801 33007 68029 64554 Weight 218 375 500 500 Bowl Part No. B-12824 5331 15802 33008 68030 64555 Weight 125 115 116 115 Packer Part No. B-12825 5332 15805 33011 68031 64556 Weight 2-1/4 2-1/2 2-5/8 3 Packer Seat Ring Part No. A-12826 5333 Weight 3/4 3/4 Spiral Grapple Part No. B-12827 5334 15803 33009 68033 64558 Weight 12 12 17 16 Spiral Grapple Control Part No. B-12828 5335 15804 33010 68034 64559 Weight 6 7 11 6 25Standard Guide Part No. A-12829 5336 15806 33012 68035 64560 Weight 130 130 200 110

16Bowen Type D Collar Packer Assemblies for Tubing OvershotsUse with Overshot No. 9305 C-4623 C-5080 9270 C-51010vershot Maximum Catch 2-3/8 2-1/2 2-1/2 2-7/8 3-1/16Maximum Size to Pack-off: 1.660 1.990 1.990 2-3/8 OD 2-3/8 ODTubing Collar O.D. EUE EUE EUE UPSET UPSETComplete Assembly Part No. 39380 39382 39383 39384 24046 Weight 2-5/8 2-7/8 2-7/8 3-3/16 3-5/8

Bowen Type D Collar Packer Assemblies for Tubing OvershotsUse with Overshot No. 9105 C-4619 9109 C-5151Overshot Maximum Catch 3-1/8 3-1/2 3-21/32 3-21/32Maximum Size to Pack-off 2-3/8 OD 2-7/8 OD 2-7/8 OD 2-7/8 ODTubing Collar EUE NON EUE EUE UPSETComplete Assembly Part No. 9095 39393 6653 6653 Type D Collar Packer Assembly Weight 4-5/8 5-3/4 4-5/8 4-5/8

17Bowen Type D Collar Packer Assemblies for Tubing OvershotsUse with Overshot No. 5148 C-5129 C-4686 C-5139 C-5154 C-5142 C-5428 C-5425 9515 58960vershot Maximum Catch 3-21/32 3-3/4 3-3/4 3-7/8 4 4 4-1/8 4-1/8 4-1/4 4-1/4Maximum Size to Pack-off 2-7/8 OD 2-7/8 OD 2-7/8 OD 2-7/8 OD 2-7/8 OD 2-7/8 OD 2-7/8 OD 2-7/8 OD 3-1/2 OD 3-1/2 OD Tubing Collar EUE EUE EUE EUE EUE EUE EUE EUE NON NON UPSET UPSETComplete Assembly Part No. 39225 39397 39398 39399 39401 39402 39403 39404 9538 5895 Weight 4-5/8 4-3/4 7-1/4 8-1/8 8-3/8 8-3/8 7-3/8 7-3/8 5-7/8 8-1/2

Bowen Type D Collar Packer Assemblies for Tubing OvershotsUse with Overshot No. 5162 8975 C-5165 C-4814 5737 5698 C-5168 C-4829 C-7096 C-7093 4825Overshot Maximum Catch 4-1/4 4-1/2 4-1/2 4-1/2 4-5/8 4-5/8 4-3/4 4-3/4 4-7/8 4-7/8 5Maximum Size to Pack-off 3-1/2 OD 3-1/2 OD 3-1/2 OD 3-1/2 OD 3-1/2 OD 3-1/2 OD 4 OD 4 OD 4 OD 4 OD 4 OD Tubing Collar NON EUE EUE EUE EUE EUE NON NON NON NON EUE UPSET UPSET UPSET UPSET UPSETComplete Assembly Part No. 35696 6104 B-13548 39405 39406 18661 39407 39408 39409 39410 39226 Weight 8-3/8 7-1/2 9 8 8 9 8-1/2 8-1/2 5-1/2 12-1/2 10-1/2

18Overshot Guides and Wallhook GuidesIf the hole size is so much greater than the fish size that it is possible for the Overshot to pass alongside the fish,an Oversize Guide or a Wallhook Guide must be installed to insure alignment of the fish with the Overshot.

Oversize Guides Wallhook GuidesFor Overshot Guides with Outside DiameterOver To Weight (Lbs.) Length of Guide 30" 36" 42" 48" 4-1/2 Over 5" to 5-1/2" O.D. Wt. Lbs. 81 94 110 4-1/2 5 23 Over 5-1/2" to 6" O.D. Wt. Lbs. 87 102 117 5 5-1/2 27 Over 6" to 6-1/2" O.D. Wt. Lbs. 93 110 126 5-1/2 6 30 Over 6-1/2" to 7" O.D. Wt. Lbs. 100 117 134 Oversize Guide6 6-1/2 34 Over 7" to 7-1/2" O.D. Wt. Lbs. 108 126 144 6-1/2 7 49 Over 7-1/2" to 8" O.D. Wt. Lbs. 115 135 155 7 7-1/2 65 Over 8" to 8-1/2" O.D. Wt. Lbs. 123 145 166 1887-1/2 8 75 Over 8-1/2" to 9" O.D. Wt. Lbs. 132 155 177 1988 8-1/2 85 Over 9" to 9-1/2" O.D. Wt. Lbs. 191 2138-1/2 9 87 Over 9-1/2" to 10" O.D. Wt. Lbs. 204 2289 9-1/2 90 Over 10" to 10-1/2" O.D. Wt. Lbs. 244 2739-1/2 10 110 Over 10-1/2" to 11" O.D. Wt. Lbs. 285 31810 10-1/2 131 Over 11" to 11-1/2" O.D. Wt. Lbs. 299 33310-1/2 11 137 Over 11-1/2" to 12" O.D. Wt. Lbs. 312 34811 11-1/2 143 Over 12" to 12-1/2" O.D. Wt. Lbs. 327 36611-1/2 12 159 Over 12-1/2" to 13" O.D. Wt. Lbs. 343 38312 12-1/2 175 Over 13" to 13-1/2" O.D. Wt. Lbs. 360 40212-1/2 13 183 Over 13-1/2" to 14" O.D. Wt. Lbs. 377 42113 13-1/2 190 Over 14" to 14-1/2" O.D. Wt. Lbs. 391 43613-1/2 14 197 Over 14-1/2" to 15" O.D. Wt. Lbs. 404 45114 14-1/2 205 Over 15" to 15-1/2" O.D. Wt. Lbs. 419 46714-1/2 15 223 Over 15-1/2" to 16" O.D. Wt. Lbs. 433 48315 15-1/2 242 Over 16" to 16-1/2" O.D. Wt. Lbs. 448 50015-1/2 16 250 Over 16-1/2" to 17" O.D. Wt. Lbs. 462 51616 16-1/2 257 Over 17" to 17-1/2" O.D Wt. Lbs. 479 53516-1/2 17 267 Over 17-1/2" to 18" O.D Wt. Lbs. 496 55417 17-1/2 27817-1/2 18 30018 18-1/2 32118-1/2 19 32719 19-1/2 33419-1/2 20 34420 20-1/2 35320-1/2 21 362

Milling Guides, Type A and Type C (Fluted and Itcoloy)In cases where the top of the fish is a badly burred tool joint or drill pipe, a Type A MillingGuide should be installedon the Ov

8613371530291

8613371530291