side door overshot in stock

When the cable cuts through mud cake, differential pressure sticking may occur. This is because one side of the cable is exposed to some degree of formation pressure, whereas the other is exposed to the hydrostatic mud column. Due to this significant difference in pressure, the cable will be pressed harshly into the formation, and friction against the formation stops the cable from moving any longer. Other reasons why sticking may occur include ledges, particularly severe doglegs, borehole caving, or the borehole becoming corkscrewed. As the length of the tool increases, as well as when there has been a long amount of time since the last conditioning trip, the chances of sticking will go up.

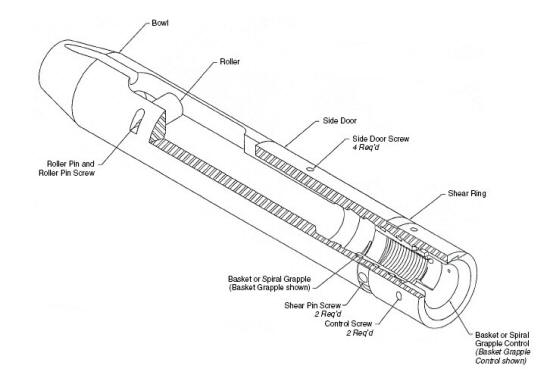

One option is a side-door overshot as shown in Figure 1. This method is similar to a regular overshot, except that it features a removable side door, so that the tool can be put together around the wireline at the well head itself. It is then possible to run the tool on some tubing or on the drillpipe, downhole alongside the wireline in order to make direct contact with the tool. This stops the wireline from being at risk of parting. It is not recommended that side-door overshots are used with deep open hole intervals. This is because it introduces the potential for keyseating, or differential sticking in the mud cake.

Throughout modern drilling, the most successful method to retrieve stuck logging tools is through the cut-and-thread method. This involves cutting the wireline at the surface, and then threading it through a pipe string while the pipe is lowered, until it engages with the logging tool. The line must be secured at the surface, and rope sockets need to be fitted to each end to form a spearhead both emerging from the top of the well, and a spearhead overshot at the logging end. A stand of pipe will then be hung in the derrick, allowing enough of an overshot at the bottom to catch the logging tool, or at least the wireline rope socket. When the upper end of the line is spooled down through the interior of the pipe until the overshot connects with the spearhead at the bottom, then the pipe will be run into the hole. This is repeated with additional stands until the bottom of the string is close enough to the fish. When this is achieved, the spearhead overshot can be disengaged and the overshot can be circulated clean, before it engages with the tool. When the fish has been grasped securely, the wireline will be pulled free from the rope socket, and then spooled out of the hole, and the tool itself recovered with the fishing string. Although the cut-and-thread method takes a lot of time, and comes with a certain amount of risk, it vastly improves the chances of recovering the wireline and tool fully, and is much quicker than trying to engage with the wireline in an open hole.

If it is not possible to use either a side-door overshot or a cut-and-thread, then an alternative is to break the weakpoint, and then recover the cable and use the drill pipe to fish for the logging tool. If tool recovery is not an option, then a last resort is to push it to the very bottom of the hole, and then plug it using cement.

Junk refers to any objects or debris which have been dropped into or lost in the hole. Junk can include all manner of things, from downhole tools and bottomhole assembly components, to bit cones, or even hand tools which have been accidentally dropped into the hole. In some cases, it may be clear what the junk is, such as when something has been visibly dropped down the hole. On the other hand, though, it may sometimes be unclear just what is causing the problem. While drilling is taking place, junk can be detected by an irregular torque, or by the drill being unable to move ahead when a new bit has been run. There are three main ways that junk can be dealt with; which method is chosen will depend on the size of the junk itself, and how hard the formation is. The junk can be recovered whole, split into smaller pieces so that these pieces can be recovered or that they are too small to cause any additional issues, or finally pushed into the side of a soft formation or the bottom of a formation with a large enough rathole. If none of these are possible and the junk continues to interfere with well operations, then the well made need to be sidetracked or abandoned.

There are multiple forms of junk baskets available, as shown in Figure 3 and Figure 4. These include core cutting junk baskets (Figure 3), and a combination junk/jet basket (Figure 4). These can be used to recover sidewall core bullets, bit cones, parts of cementing equipment, or other small pieces of debris.

The tools might penetrate the formation and cut a relatively short core, digging out debris from the bottom of the hole and then trapping it inside of an inner barrel.

Note: *Cased Hole Only. The Chart above is a guide-line only and should be used as a rule of thumb; the final decision is that of the Customer; 4” Pin-up drill pipe is an option inside 7” casing, discuss

with Fishing Tool Manager for guidance. Consult with a EOFR Fishing Manager when requirements do not fall within the guide line shown; Bottom Hole Assemblies (BHA) also should be considered

* All pull loads listed are based on a magnet engaging a flat surface covering the entire face of the magnet. “Pick up” capability will be reduced considerably

RM2HJ4XE6–The wreckage of a fully-laden passenger Viscount aeroplane after it had overshot the runway at Rochford Airport and ended tail up on the railway line which runs alongside the airport. Firemen and emergency services clear the way for passengers to exit the plane. October 1960.

RM2M9A1Y0–Armstrong Whitworth A.W.41 Albemarle ST Mk.V V1823. The "Special Transport" Albemarles had provision for paratroops to load via large side doors and exit via a para-drop door in the floor. The photo clearly shows the guard rails fitted to keep parachute static lines from fouling the tail unit.

RM2HJ4T5P–The wreckage of a fully-laden passenger Viscount aeroplane after it had overshot the runway at Rochford Airport and ended tail up on the railway line which runs alongside the airport. Firemen and emergency services clear the way for passengers to exit the plane. October 1960.

RFRD20XK–HAMBURG, GERMANY - MAR 22, 2018: Defocused black and white of people entering EasyJet airplane early in the morning in Flughafen Hamburg through rear passenger door jetway stairs

RM2HJ52GB–The wreckage of a fully-laden passenger Viscount aeroplane after it had overshot the runway at Rochford Airport and ended tail up on the railway line which runs alongside the airport. Firemen and emergency services clear the way for passengers to exit the plane. October 1960.

RM2HJ5754–The wreckage of a fully-laden passenger Viscount aeroplane after it had overshot the runway at Rochford Airport and ended tail up on the railway line which runs alongside the airport. Firemen and emergency services clear the way for passengers to exit the plane. October 1960.

RM2HJ564R–The wreckage of a fully-laden passenger Viscount aeroplane after it had overshot the runway at Rochford Airport and ended tail up on the railway line which runs alongside the airport. Firemen and emergency services clear the way for passengers to exit the plane. October 1960.

RM2HJ52H8–The wreckage of a fully-laden passenger Viscount aeroplane after it had overshot the runway at Rochford Airport and ended tail up on the railway line which runs alongside the airport. Firemen and emergency services clear the way for passengers to exit the plane. October 1960.

Statement by H.E. Xi Jinping President of the People’s Republic of China at the General Debate of the 75th Session of the United Nations General Assembly (Ministry of Foreign Affairs, the People’s Republic of China, 2020); https://www.fmprc.gov.cn/mfa_eng/zxxx_662805/t1817098.shtml

Address by President Moon Jae-in at National Assembly to Propose Government Budget for 2021 (Office of the President, Republic of Korea, 2020); https://english1.president.go.kr/BriefingSpeeches/Speeches/898

Luderer, G. Economic mitigation challenges: how further delay closes the door for achieving climate targets. Environ. Res. Lett. https://doi.org/10.1088/1748-9326/8/3/034033 (2013).

Ohashi, H. et al. Biodiversity can benefit from climate stabilization despite adverse side effects of land-based mitigation. Nat. Commun. 10, 5240 (2019).

Additional Information:Forebay barns--often called Pennsylvania, Pomeranian, or Wisconsin porch barns--are a special type of bank or basement barn associated with German immigrants. In Wisconsin, examples cluster in Marathon, Lincoln, Ozaukee, and Green counties. Among basement barns, the forebay barn was distinctive. Its characteristic "forebay," or overshot, a second-floor extension, jutted out over the barnyard to protect the cattle doors below from snow drifts and to provide an open-air shelter for the cows. The forebay also allowed the farmer to pitch hay from the mow to the barnyard below without blocking the cattle doors. Usually constructed on the south or southeast face of the barn, the forebay also incorporated an early type of passive-solar design: in winter, it allowed the low sun to warm the stables, and yet it provided cooling shade when the summer sun was high overhead.

These forebay barns are often referred to as "Wisconsin porch barns." Each consists of a gable-roofed, two-story barn with a raised fieldstone basement and a haymow constructed of vertical wooden siding. Their deep forebays are framed independently from the rest of the structure and are supported by posts, unlike the cantilevered structures found in Pennsylvania and in Green County, Wisconsin. Almost all the barns also have at least one gabled wall-dormer on the forebay side, which allowed greater ventilation and sheltered the door through which the farmer pitched the hay.

8613371530291

8613371530291