wireline overshot in stock

The Hunting Releasable Overshot is designed to engage tools that have damaged or have no fish necks. The Overshot is designed to withstand high impacts associated with fishing operations.

Hunting Releasable Overshots are available in all common industry toolstring sizes and are manufactured with either sucker rod or integral quick connections as per customer requirements

Diamond core drilling tools is one of our key products, we specialized in design, production and sales of Q series including AQ, BQ, NQ, HQ, PQ etc sizes from 2009, currently our major products include diamond impregnated bits, surface set bits, PDC bits, reaming shell, core barrel, wireline drill rods, casing and casing shoe etc diamond core drilling consumables, which are applicable for mining, geotechnical exploration etc drilling jobs...

Overshots are lifting devices used commonly in wire-line drill jobs. The overshot is dropped using a cable into the inner tube assembly where it lifts up the drill rods from the drill holes. Doing so eliminates the need to couple or uncouple rod strings each time the core needs retrieval.

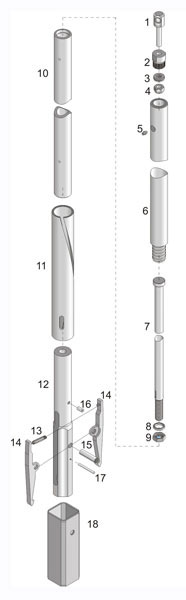

overshots include spare parts of eye bolt, cable swivel collar, thrust bearing, castle nut, cotter pin, grease fitting, cable swivel body, jar staff, jar tube, hex nut 3/4 UNC, washer, nord lock, cap, ezy lock O/shot, spring, ezy lock O/shot, sleeve, ezy lock O/shot, compression spring, ball 11/32”, ezy lock overshot head, lifting dog, plain pin 1/2”*2-1/8”, spring pin 1/4”*2”, locking pin, set screw, 3/8 UNF*3/4 nyloc, locking sleeve.

One variation of the overshots is the continuous tubing model. This type of overshot is fitted with a grapple system that turns 340 degrees and is ideal for catching slick-wall fish. The overshot also provides circulation back to the fish while pulling out the drill rods. Circulation is restored by using a highly pressurized pack-off which is fitted above the overshot.

The second type of overshots is the hydraulic release model. This one is a bit more advanced and uses set-down weight and differential pressure to activate it mechanically. The overshot pumps fluids into the fish and tools below before latching onto them and pulling. This prior fluid injection washes away debris and any other particles from the surface of the fish making latching easy and the grip tighter. The set-down weight and differential pressure mechanism makes this overshot perfect for horizontal fishing projects.

Another popular overshot in drilling projects is the 150 Release overshot. It uses a huge bore with wire-line tools for fishing out parted drill pipes and their collars. The 150 Release overshots come in different strength levels for varied applications in drill sites. On the other hand, the 70 type overshots are used where the 150 release overshot is not applicable. The 70 type overshot is more accurate in pulling out drill rods that are a bit too narrow to be latched with the 150 overshot.

Two other overshots currently in the market today are the Type 10 and Type 20 overshot. The type 10 overshot is specially designed to retrieve tubular fish 2 inches in diameter. This same overshot can also be used for retrieving 1 5/8 inch drill rods as well, but on a much smaller 2 3/8 tube. The type overshot evenly distributes loads on tool and fish thanks to the internal helix construction that is tapered to provide a 360 degree wall contact. For the 20 Type overshot, this one comes in handy when the fish" top is too short for the 10 Type overshot to pull. The 20 Type grapple fastens to the bottom of the tool thus makes this overshot successful for most projects that use short-neck drill rods.

Technology continues to see newer inventions of the overshots being released to perform even more specific jobs with unparalleled accuracy. Other kinds of overshots you will find in the market include the Chinese Standard Wire-line overshot, HQ overshot, WLP overshot, NQ overshot and the WLH overshot.

Overshot is a necessary device in wireline drilling. It"s dropped on a cable and directly couples onto and lift up the inner tube assembly, eliminating the need to couple and uncouple the rod string each time the core is retrieved.

Ezy Lock Overshot is a modified product based on compact overshot. It protects against accidental release of the core barrel. This is ideal for suface application when hoisting above ground. Q series overhshot are available in A, B, N, H and P size.

As a professional manufacturer of BQ NQ HQ PQ SQ series overshot assembly in China, we still provide customers worldwide with China overshot assembly, hoisting plug, foot clamp, circle wrench, etc.

1. Drill rod: BQ NQ HQ PQ SQ and AW, BW, NW, HW, BTW, NTWCasing tube: BW, NW, HW, HWT2. Core barrel: BQ NQ HQ PQ & head assembly and core barrel assembly3. BQ NQ HQ PQ , BTW, NTW, HTW etc. Diamond core bit, reaming shell & shoe bit (Imp. and surface-set, PDC) , oversize supplied4. Drill tool: hoisting plug, water swivel, overshot, outer tube & inner tube wrench, foot clamp,etc.

Wireline series: Geobor S, WLA, WLB, WLN, WLH, WLP, WLB3, WLN3, WLH3, WLP3, WLN2, AQ, BQ, NQ, HQ, PQ, SQ, PQ3, HQ3, NQ3, BQ3, NQ2, WL-56, WL-66, WL-76

Overshots are a key component of wireline coring systems. To retrieve the core sample, the overshot is lowered into the hole on a wire cable until it comes in contact with the spearhead point on the head assembly. Positive latching lifting dogs securely attach, and the inner tube assembly is pulled from the hole to retrieve the core. V-lock Overshots Hole Products" V-lock overshots are safe, reliable, fast, and easy to use. The automatic safety feature is designed to reduce the chance of an accidental release. When the inner tube assembly is attached and lifted, the lifting dogs automatically retract into position. No extra manual steps are required to activate the safety feature, thus reducing the potential for human error. Standard Overshots Hole Products" standard overshots feature a manual safety lock pin. Once the core filled inner tube is hoisted above the top of the drill rods the safety lock pin can be inserted through the overshot head and under the spearhead point. This will allow the operator to hoist and remove the core sample from the inner tube.

That’s exactly what National EWP was looking for when it put the new Epiroc DiscovOre wireline coring system and Arrow 3S overshot to the test in a side-by-side field trial at a customer’s Arizona property. Both systems were run on the job’s Christensen CS14.

The site superintendent explains that a key focus area for almost all wireline core drilling is reducing “hit time,” or the time it takes for an overshot to lock onto the coring assembly after falling hundreds or thousands of feet through drilling mud. “Shortening the hit time when you’re coring 5- and 10-foot lengths can make a huge difference over a shift. When you can consistently shorten the tube-to-tube cycle, you get more feet drilled in a day.”

Greg Leavitt, Epiroc sales specialist in tooling exploration, visited the site to help with the timings. Leavitt says that while faster hit times were definitely the focus of comparison, safety is National EWP’s top priority. “It’s important not only to National, but their mining customers. Their customers only permit safe operators on their projects. When they choose National EWP, they know they’re guaranteed that. That’s why National is interested in the DiscovOre system and Arrow 3S overshot. They never stop looking for safety improvements.”

The National crew was completing the final hole of a five-hole survey in an especially problematic, highly fractured formation. Blockages frequently limited core lengths to just 5 feet or less. “Every extra minute waiting for the overshot to hit and lock onto the tube is multiplied by the number of trips out of the hole over each 12-hour shift,” Leavitt says. “It’s a significant amount of lost coring time.”

The system range covers all exploration tool sizes and works with common makes of exploration drill pipe, tubes and bits. Holes ranged from 300 to 2,100 feet with HO-size tooling set up for 10-foot-long, 2.4-inch-diameter triple-tube coring. The crew alternated every other sample between the DiscovOre system and their unmodified, traditional head and overshot system, as another of the system’s advantages is that it is compatible with exploration tooling the company already has.

The DiscovOre system design addresses several design weaknesses of older style wireline systems, according to the company. It completely eliminates the spearpoint, and there are no roll pins in the tube head to fail. The streamlined design decreases overall weight for greater ease and safety in handling. The Arrow 3S overshot locks into the coring assembly automatically and hits faster.

“The customer National is working for now, for instance, requires a three-fold redundancy in safety mechanisms.” One of those, Leavitt explains, is the helper’s ability to manually twist-lock the overshot in place. “What their customer likes about the DiscovOre system is that it has an automatic latch. It doesn’t need a twist lock. You don’t have to touch it, and that’s the ultimate in safety.”

Growth in the ‘50s fueled new technology, and in 1953, Longyear applied for a patent on the first wireline core retrieval system, the Q™ Wireline. Tom Shenosky, Epiroc product manager of Exploration Rock Drilling Tools, says many wireline tooling systems produced by various manufacturers over the years have, for the most part, simply continued the original system’s design based on spearhead, roll pins and open bearing assembly.

That changes with the DiscovOre. The overshot and tube head are key focus points for improving both efficiency and safety. The system has no spearhead and no roll pin in the head assembly, with sealed bearings and a sleek design, reducing its mass by about 10 pounds.

The DiscovOre and Arrow 3S design “flips” the locking system. Instead of a spearpoint that plunges into an overshot assembly, the Arrow 3S latching takes places within the head assembly. The company says the design isn’t just safer on the string. A common safety practice for other systems is to fold a spearpoint down when it is on the rack waiting for reuse. But spearpoint roll pins commonly jam up after they have been in use for some time. When handlers can no longer fold them to the side, they are left extended straight out from the body, presenting a risk of injury to workers moving around them.

The roll pin and the spearhead are the sole points of support, core after core, all shift long, day after day. That makes them critical wear points and common cause of premature failure. When they fail inside a hole, exploration drillers waste production time trying to fetch the tube out. Failing outside of the hole results in heavy tubes dangerously bouncing around a helper and driller in a confined work space. The company says DiscovOre eliminates the spearhead and the roll pins in the tube head altogether, providing not only safer, but more reliable and more efficient solution for wireline systems.

Using a wireline system, core is recovered quickly by retrieving the inner tube directly through the drill string. The rods remin in the hole until the bit needs to be replaced. This has big cost advantages when drilling deep holes for mineral exploration.

Overshot is a necessary device in wireline drilling. It"s dropped on a cable and directly couples onto and lift up the inner tube assembly, eliminating the need to couple and uncouple the rod string each time the core is retrieved.

Ezy Lock Overshot is a modified product based on compact overshot. It protects against accidental release of the core barrel. This is ideal for suface application when hoisting above ground. Q series overhshot are available in A, B, N, H and P size.

8613371530291

8613371530291