wireline overshot brands

Overshots are a key component of wireline coring systems. To retrieve the core sample, the overshot is lowered into the hole on a wire cable until it comes in contact with the spearhead point on the head assembly. Positive latching lifting dogs securely attach, and the inner tube assembly is pulled from the hole to retrieve the core. V-lock Overshots Hole Products" V-lock overshots are safe, reliable, fast, and easy to use. The automatic safety feature is designed to reduce the chance of an accidental release. When the inner tube assembly is attached and lifted, the lifting dogs automatically retract into position. No extra manual steps are required to activate the safety feature, thus reducing the potential for human error. Standard Overshots Hole Products" standard overshots feature a manual safety lock pin. Once the core filled inner tube is hoisted above the top of the drill rods the safety lock pin can be inserted through the overshot head and under the spearhead point. This will allow the operator to hoist and remove the core sample from the inner tube.

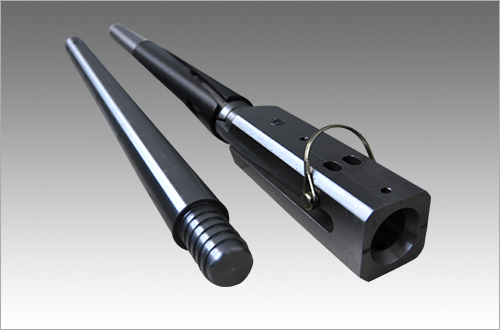

An OVERSHOT is attached to the end of a wireline and lowered into the outer tube. The Overshot then locks on to the Latch Head Assembly at the top of the core barrel.

The inner tube is then pulled to the surface with the core sample inside. Givens International offers an overshot for a spear point or quad latch head.

In today’s drilling operations, safety is not an option; it is a critical component of every successful drilling project. We have developed our Excore EX II Safety overshot with both safety and performance in mind.

As a result, drillers are confident and have a peace of mind with one less process to worry about. This overshot simplifies the process and maximizes the speed of each over cycle resulting in increased productivity levels.

Overshot is a necessary device in wireline drilling. It"s dropped on a cable and directly couples onto and lift up the inner tube assembly, eliminating the need to couple and uncouple the rod string each time the core is retrieved.

Ezy Lock Overshot is a modified product based on compact overshot. It protects against accidental release of the core barrel. This is ideal for suface application when hoisting above ground.

Overshot is a key component of wire-line coring systems. To retrieve the core sample, the overshot is lowered into the hole on a wire cable until it comes in contact with the spearhead point on the head assembly. Positive latching lifting dogs securely attach, and the inner tube assembly is pulled from the hole to retrieve the core.

Shop for nq hq overshot on Alibaba.com to find a variety for every season. Place small orders for individual use or large shipments to sell as a brand. Look for nq hq overshot that are designed for long-lasting comfort and trendy style. Each one pairs well with a wide range of other clothes and accessories to make versatile outfits for any occasion. Find different suppliers to help you get just the right price.

Most nq hq overshot have short sleeves that make them ideal for keeping cool in warmer weather. Some are designed to have a fashionable appearance, while others are made for athletic wear. Look for garments made of woven fabrics such as cotton when you need something comfortable. Fabrics such as spandex or bamboo allow for flexibility and stretchiness for a better fit.

Most manufacturers of nq hq overshot on Alibaba.com allow for a wide array of customization options. Order a shipment with just the right colors and sizes for your needs. Packaging and graphics can be made to order as well, ensuring your clothing will look just the way you want. Some suppliers offer sample shipments to try the product out before placing a full-sized order in the future.

Look for nq hq overshot on Alibaba.com to get as many as you need while keeping within your budget. A wide selection of fashionable and athletic versions are available. Whether you need them for yourself or your customers, nq hq overshot can be found with the features and styles to suit your tastes.

Since Boart Longyear introduced the Q Wireline system in 1966, retrieving the inner tube from the core barrel has been handled the same way: an overshot with lifting dogs (spring loaded hooked ‘fingers’) is lowered or pumped into the hole until it snaps over a pivoting spearhead mechanism affixed to the inner tube assembly. Once the head assembly has been removed from the hole, the driller uses the pivoting spearhead to position the head assembly on their workspace and squeezes the back of the lifting dogs to release.

Inner tube handling: When hoisting the inner tube assembly, elastic action of the wireline cable or accidental impact during handling can un-load cable tension and overcome spring loads which allows the hooked lifting dogs to accidentally release the spearhead. The surface ‘Ezy-Lock’ overshot includes a twist-sleeve that locks onto the spearhead even without cable tension, whereas competing overshots require cable tension to maintain a lock

Boart Longyear currently provides a secondary safety pin that clips through the overshot, passing just under the spearhead tip. This adds an extra layer of protection in case the lifting dogs are excessively worn or deformed. However, spearheads are loaded cyclically and often loaded ‘off-pivot’, which deforms the components over time, to the point of disassembly. While the more recent MKII™ version of the spearhead assembly is much more robust, in the case of spearhead failure, the head assembly will release from the overshot regardless of lifting dog or safety pin use or condition.

Enter Boart Longyear’s new Roller Latch™ Overshot. This patent-pending overshot leverages previous experience with Roller Latch head assemblies to create a more reliable and longer lasting system that eliminates spearheads and lifting dogs entirely. The spearhead assembly is replaced by a one-piece socket receptacle (spearhead adapter) that accepts the overshot itself, which has rollers that latch into an internal groove in the spearhead adapter.

The increased toughness and hardness of the bearing quality latch rollers have a proven history of outlasting traditional pivoting latches for wear life. The new overshot will also feature the same Nitreg-ONC surface treatment as Roller Latch head assemblies that drastically improves corrosion resistance (Nitreg is a trademark of Nitrex Inc.).

Safety pin integration in the new underground Quick Pump-In overshot now pulls double duty of both locking the overshot from accidentally releasing while hoisting, as well as holding the head assembly and overshot together in case of component failure due to excessive wear. Also, the socket and rollers are not affected by side loading and ‘off-pivot’ loading during tube handling outside the hole, eliminating gradual deformation or disassembly. The new surface overshot will also include a one-hand twist-lock sleeve to maintain a locked position while hoisting outside the hole, even with a loss of wireline cable tension.

It’s also easy to use. Instead of pushing the backs of the lifting dogs together, the driller pushes the two halves of the assembly together, retracting the rollers and releasing the head assembly. This operation takes about the same amount of force as the current overshot, so drillers won’t miss a beat.

Additional benefits have been included apart from the elimination of the spearhead and lifting dogs. While the current design uses a solid pivot pin that is peened into place (making it difficult to re-build), the Roller Latch Overshot has no pins whatsoever. Everything is held in place by simple threaded connections for easy maintenance.

The Quick Pump-In (Q/P, underground) assembly further addresses two issues specific to pump-in applications. First, in the event of a stuck tube, the driller needs to disengage and retrieve wireline cable in order to pull rods. Today, that is done by overloading and breaking a shear pin placed just underneath the cable swivel. In theory this pin breaks at under half the wireline cable’s max load capacity, but in practice its strength is highly variable because shear pins are inherently weak and ductile. Many operators remove the shear pin, which removes release capability and may result in excessive wireline cable replacement.

The Roller Latch Overshot features a brand new pump-in cable release system, originally conceptualized and prototyped by one of our expert underground drillers in Canada. A slotted sleeve and pumping seal assembly is placed over the wireline and pumped up to the overshot. The sleeve engages a quick-release mechanism and releases the wireline. This system has proven to be much more reliable, and may be the feature drillers are most thrilled to have going forward. Reports of fewer broken wirelines have been received from several sites testing the pump-in cable release system.

To combat this and make Q/P Roller Latch easier to use while maintaining its safety features, a ‘brake release spring’ was created. This spring assembles quickly inside of the spearhead adapter on the head assembly. While tripping on its own, the head assembly brake works normally, but when the overshot latches into it this spring is compressed, disengaging the brake. This feature has also been received very positively by drillers in the field.

A surface-style overshot is also in development in B/N/H sizes. In addition to many of the features outlined in this article, the aim is to add more innovations, including:

An improved lock sleeve to disable accidental head assembly release and stop drillers from accidentally sending the overshot down the hole while locked

Excitement is high as testing continues. Drillers are noting the various positive developments: it’s easier to use, saves on wireline, and makes working with Q/P Roller Latch head assemblies much easier in difficult conditions. We’re looking forward to further field success as testing begins on the surface design.

The Wireline Releasable Overshot is a slip type overshot used to retrieve a fish lost in the well bore that does not have a conventional fishing neck.

Once latched onto a fish the overshot can be released by jarring downwards provided the overshot has a solid footing upon which the core can be driven against.

The Wireline Releasable Overshot is composed of the top sub, cylinder, nut, main spring, mandrel, auxiliary spring, adapter sleeve, slips etc., simple structure,easy to use.

That’s exactly what National EWP was looking for when it put the new Epiroc DiscovOre wireline coring system and Arrow 3S overshot to the test in a side-by-side field trial at a customer’s Arizona property. Both systems were run on the job’s Christensen CS14.

The site superintendent explains that a key focus area for almost all wireline core drilling is reducing “hit time,” or the time it takes for an overshot to lock onto the coring assembly after falling hundreds or thousands of feet through drilling mud. “Shortening the hit time when you’re coring 5- and 10-foot lengths can make a huge difference over a shift. When you can consistently shorten the tube-to-tube cycle, you get more feet drilled in a day.”

Greg Leavitt, Epiroc sales specialist in tooling exploration, visited the site to help with the timings. Leavitt says that while faster hit times were definitely the focus of comparison, safety is National EWP’s top priority. “It’s important not only to National, but their mining customers. Their customers only permit safe operators on their projects. When they choose National EWP, they know they’re guaranteed that. That’s why National is interested in the DiscovOre system and Arrow 3S overshot. They never stop looking for safety improvements.”

The National crew was completing the final hole of a five-hole survey in an especially problematic, highly fractured formation. Blockages frequently limited core lengths to just 5 feet or less. “Every extra minute waiting for the overshot to hit and lock onto the tube is multiplied by the number of trips out of the hole over each 12-hour shift,” Leavitt says. “It’s a significant amount of lost coring time.”

The system range covers all exploration tool sizes and works with common makes of exploration drill pipe, tubes and bits. Holes ranged from 300 to 2,100 feet with HO-size tooling set up for 10-foot-long, 2.4-inch-diameter triple-tube coring. The crew alternated every other sample between the DiscovOre system and their unmodified, traditional head and overshot system, as another of the system’s advantages is that it is compatible with exploration tooling the company already has.

The DiscovOre system design addresses several design weaknesses of older style wireline systems, according to the company. It completely eliminates the spearpoint, and there are no roll pins in the tube head to fail. The streamlined design decreases overall weight for greater ease and safety in handling. The Arrow 3S overshot locks into the coring assembly automatically and hits faster.

“The customer National is working for now, for instance, requires a three-fold redundancy in safety mechanisms.” One of those, Leavitt explains, is the helper’s ability to manually twist-lock the overshot in place. “What their customer likes about the DiscovOre system is that it has an automatic latch. It doesn’t need a twist lock. You don’t have to touch it, and that’s the ultimate in safety.”

Growth in the ‘50s fueled new technology, and in 1953, Longyear applied for a patent on the first wireline core retrieval system, the Q™ Wireline. Tom Shenosky, Epiroc product manager of Exploration Rock Drilling Tools, says many wireline tooling systems produced by various manufacturers over the years have, for the most part, simply continued the original system’s design based on spearhead, roll pins and open bearing assembly.

That changes with the DiscovOre. The overshot and tube head are key focus points for improving both efficiency and safety. The system has no spearhead and no roll pin in the head assembly, with sealed bearings and a sleek design, reducing its mass by about 10 pounds.

The DiscovOre and Arrow 3S design “flips” the locking system. Instead of a spearpoint that plunges into an overshot assembly, the Arrow 3S latching takes places within the head assembly. The company says the design isn’t just safer on the string. A common safety practice for other systems is to fold a spearpoint down when it is on the rack waiting for reuse. But spearpoint roll pins commonly jam up after they have been in use for some time. When handlers can no longer fold them to the side, they are left extended straight out from the body, presenting a risk of injury to workers moving around them.

The roll pin and the spearhead are the sole points of support, core after core, all shift long, day after day. That makes them critical wear points and common cause of premature failure. When they fail inside a hole, exploration drillers waste production time trying to fetch the tube out. Failing outside of the hole results in heavy tubes dangerously bouncing around a helper and driller in a confined work space. The company says DiscovOre eliminates the spearhead and the roll pins in the tube head altogether, providing not only safer, but more reliable and more efficient solution for wireline systems.

Overshot is a necessary device in wireline drilling. It is dropped on a cable and directly couples onto and lifts up the inner tube assembly, eliminating the need to couple and uncouple the rod string each time the core is retrieved.

SPS Mining Supplies Ltd. offers spare and complete overshot products in BC and the Yukon for use in coring. From our location in Smithers, we can have tools delivered straight to your jobsite the very same day. When your productivity and profitability matter, you can count on SPS Mining Supplies Ltd. — give us a call today! We carry parts from brands such as:

8613371530291

8613371530291