fleet of power tong trucks manufacturer

GIANT Power Tongs was established in the summer of 2008 to serve northeastern BC and northern Alberta. We are members in good standing with ISNetworld, Complyworks and Secor. We run a fleet of 6 tong trucks based out of Fort St John. We can run all tubing and casing from 60.3mm to 339.7mm. Call us anytime for all your powertong, threadwashing, torque monitoring or thread inspection needs.

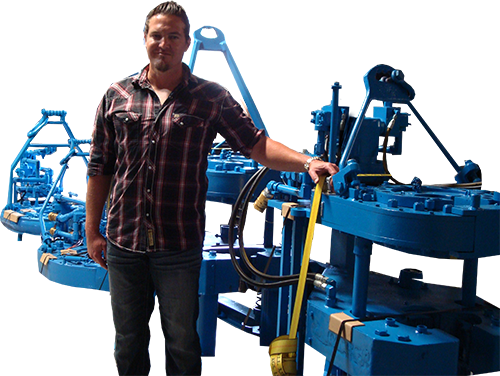

In your work you rely on having suppliers who use the best equipment to complete your jobs. Among the most important pieces of equipment required for oil drilling and completions are power tongs. Drifters Casing Service is a local provider of power tongs services in Grande Prairie and Whitecourt areas with a reputation for expertise and reliability.

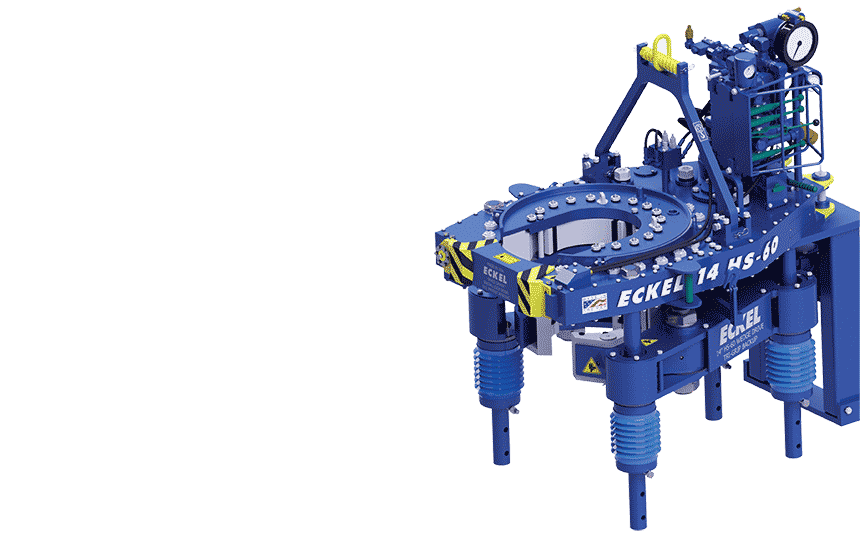

Eckel.Eckel is the one of the world’s leading power tong manufacturers. Each Eckel tong must pass a comprehensive compliance checklist so it’s ready to meet requirements in the field.

Universe. Since 1965, Universe Machine Corporation has supplied trustworthy steel products for the oilfield industry. Their quality standard system ensures that each power tong meets your application requirements.

We have many sizes of power tongs to fit the size of your pipe, from 2-3/8″ to 13- 3/8″. And our power tongs equipment offers a wide torque range to suit the job.

In addition to power tongs in Grande Prairie, we provide all other casing and tubing services you may need, including integral tubing tongs. You can also monitor your equipment with WinCatt Computer Torque Monitoring that we can provide and monitor on your behalf. All equipment can be used in drilling and completions work.

We’re your provider of oil field drilling and completions services that require power tongs and related oilfield equipment. Since 2000, our locally-owned and operated company has helped companies like yours get the work done right. Contact us for more information.

Today we operate a medium fleet of power tong and service trucks including a full line of casing and tubing running services from surface to production.

Safety performance is the #1 goal. We won’t do the work if we can’t do it safely. Doing is safe means that everyone goes home at the end of the day. This is our belief and our safety culture.

Dutch Casing Services has continually expanded our fleet of power tong equipment since our inception in 1999. We take great pride in consistently delivering a superior service experience to our clients. Attention to the details and regular maintenance in conjunction with proper training and certifications guarantees our equipment is operated in the safest manner on your jobsite.

Our experienced and skilled power tong technicians play a major role in the safety and efficiency of a casing run. This makes the selection of your power tong service company a key component of overall performance.

ProTorque attracts and employs some of the industry’s most talented and experienced casing running technicians. Every detail of a casing run must be considered when looking for cost savings and efficiency; particularly on long production strings where every second counts while maintaining a safe operation. When making-up hundreds of connections, filling on the fly and selecting the correct handling equipment (air or hydraulic powered slips); we save time and effort on long challenging casing runs. ProTorque can meet handling requirements of up to 500 tons of hoist capability.

A municipal utility partnered with Volta and Palfinger on aerial truck with an all-electric auxilliary power system that cut 70%+ of vehicle emissions. The truck will reach ROI in under two years from fuel and maintenace savings.

Pathmaker is an expanding Tubular Running Service company developed by Industry professionals with remarkable TRS experience and expertise. We are family owned and operated and have been proudly serving Alberta and British Columbia Oil & Gas Industry for over 36 years.

The interests of our customers are valued so that we can grow as partners sharing a mutual goal of providing excellence, reducing risk, and reducing non-productive time to increase overall operation efficiency. We continue to expand our services, equipment and team to serve the needs of our growing clientele.

Our elevated standards for field running procedures means our customers are ensured quality and consistency every time. With one of the most extensive employee assessment and training programs, its easy to see why we continually exceed industry recommended standards.

Pathmaker has continually expanded our fleet of power tong equipment since 1981. We take pride in consistently delivering a superior service to our customers. Attention to details and regular maintenance in conjunction with proper training and certifications guarantees our equipment is operated in the safest manner on your job site

Educated in API Visual Inspection, receipt of product, investigative failure procedures, assembly and de assembly, storage, shipping, classification and identification of API tubular.

It is our goal to be able to offer safe and quality work with both integrity and efficiency. We operate, following the rules and guidelines in our OH&S handbook, along with COR, ISNET, and HSE requirements. We believe that safety and productivity of our company is directly related to those working for us and therefore our policies regarding drug and alcohol are strictly enforced to ensure the safety of all those involved. Improving safety is an ongoing commitment, with constant evaluation of policies and procedures and implementation of improvements.

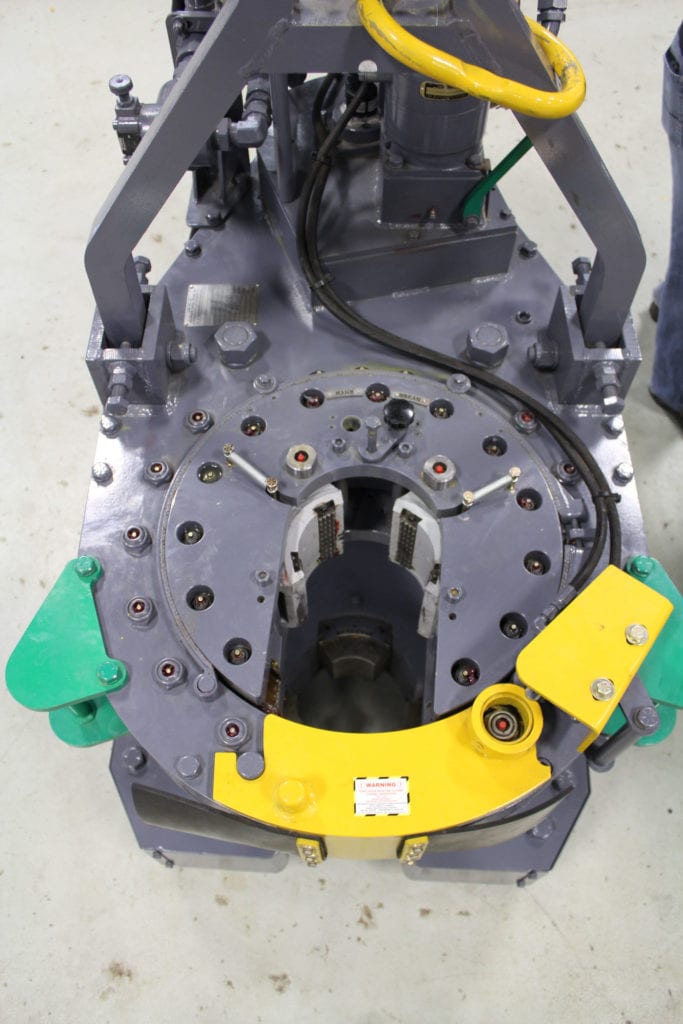

Pathmaker combines experienced crews with the latest power tong equipment. We offer Integral, Conventional, and High Torque Power Tong services.Power Tong services include:Handling equipment, including rotary slips, spiders, and single joint elevators

Pathmaker Services Power Tong fleet consists of top of the line outfitted units available. Proper maintenance ensures that our customers are receiving reliable and maintained equipped units every time.

Pathmaker uses WinCatt software for our Computer Torque Monitoring services. WinCatt interacts with Pathmaker"s control hardware, providing real-time monitoring and control of tubular connection power tong make-up to ensure your connections are completed to the exact manufacturer"s specification for premium connections, shouldering time, delta torque, delta slope, and delta turns. Pathmaker also uses WinnCatt to provide a summary report of your make up results to prepare torque graphs for each joint.

Provide the customers with a detalied report of the make-up of each tubular connection, including rejected reports, scatter charts, histograms, and pie charts.

Pathmaker offers Thread Supervision services to ensure that manufactures running procedures are diligently followed and that every connection is inspected prior to make-up as a list physical and visual check. Our Thread Supervisors follow an ongoing training program and stay currently with the connection manufacturers guidelines. Our Thread Supervisors are trained in field repair and connection theory. If you get a damaged joint on location, we can provide you with information on the connection and see if the connection will possibly fail due to damage. We have experience with 8 round premium casing and tubing such as API, Tenaris, Voestalpine, US Steel, VAM Hydrill, IPSCO, and EVRAZ.

One die size will fit all weights of that size of casing. If you are running multiple weights or have a different weight landing joint, you may just have to change it.

Pathmaker is an expanding Tubular Running Service company developed by Industry professionals with remarkable TRS experience and expertise. We are family owned and operated and have been proudly serving Alberta and British Columbia Oil & Gas Industry for over 36 years.

The interests of our customers are valued so that we can grow as partners sharing a mutual goal of providing excellence, reducing risk, and reducing non-productive time to increase overall operation efficiency. We continue to expand our services, equipment and team to serve the needs of our growing clientele.

Our elevated standards for field running procedures means our customers are ensured quality and consistency every time. With one of the most extensive employee assessment and training programs, its easy to see why we continually exceed industry recommended standards.

Pathmaker has continually expanded our fleet of power tong equipment since 1981. We take pride in consistently delivering a superior service to our customers. Attention to details and regular maintenance in conjunction with proper training and certifications guarantees our equipment is operated in the safest manner on your job site

Educated in API Visual Inspection, receipt of product, investigative failure procedures, assembly and de assembly, storage, shipping, classification and identification of API tubular.

It is our goal to be able to offer safe and quality work with both integrity and efficiency. We operate, following the rules and guidelines in our OH&S handbook, along with COR, ISNET, and HSE requirements. We believe that safety and productivity of our company is directly related to those working for us and therefore our policies regarding drug and alcohol are strictly enforced to ensure the safety of all those involved. Improving safety is an ongoing commitment, with constant evaluation of policies and procedures and implementation of improvements.

Pathmaker combines experienced crews with the latest power tong equipment. We offer Integral, Conventional, and High Torque Power Tong services.Power Tong services include:Handling equipment, including rotary slips, spiders, and single joint elevators

Pathmaker Services Power Tong fleet consists of top of the line outfitted units available. Proper maintenance ensures that our customers are receiving reliable and maintained equipped units every time.

Pathmaker uses WinCatt software for our Computer Torque Monitoring services. WinCatt interacts with Pathmaker"s control hardware, providing real-time monitoring and control of tubular connection power tong make-up to ensure your connections are completed to the exact manufacturer"s specification for premium connections, shouldering time, delta torque, delta slope, and delta turns. Pathmaker also uses WinnCatt to provide a summary report of your make up results to prepare torque graphs for each joint.

Provide the customers with a detalied report of the make-up of each tubular connection, including rejected reports, scatter charts, histograms, and pie charts.

Pathmaker offers Thread Supervision services to ensure that manufactures running procedures are diligently followed and that every connection is inspected prior to make-up as a list physical and visual check. Our Thread Supervisors follow an ongoing training program and stay currently with the connection manufacturers guidelines. Our Thread Supervisors are trained in field repair and connection theory. If you get a damaged joint on location, we can provide you with information on the connection and see if the connection will possibly fail due to damage. We have experience with 8 round premium casing and tubing such as API, Tenaris, Voestalpine, US Steel, VAM Hydrill, IPSCO, and EVRAZ.

One die size will fit all weights of that size of casing. If you are running multiple weights or have a different weight landing joint, you may just have to change it.

Offshore Energy Services, Inc. (OES), answering to the ever-changing tubular connection design, has continued to meet the market demand by upgrading our Hydraulic Power Tong fleet.

We have multiple size and torque ranges available. The tubular size ranges we are capable of handling are 36" through 4-1/2" with torques up to 150,000 ft./lbs.

DC Power Tong continues to set the standard in the casing and tubing service industry by offering superior service & innovative casing technology. To exceed our customersʼ expectations, DC Power Tong also provides hydro test trucks, pressure test units, and equipment and pipe wrangler rentals to ensure your project is completed safely and efficiently. At DC Power Tong, we treat your project as if it is our very own, and thatʼs what weʼre all about.

Bitz Power Tongs Ltd. is a Canadian owned and locally operated company, with a fleet of power tong trucks and pipe laydown units. Bitz Power Tongs opened its doors in Edson, Alberta in 1994. The company began with one truck and Lloyd Bitz; owner, as the only tong operator. With Lloyd"s vastknowledge, work ethic and years of experience working in all areas of the oilfield, the company flourished, requiring additional staff and equipment.

8613371530291

8613371530291