hydraulic power tong 40 000 price

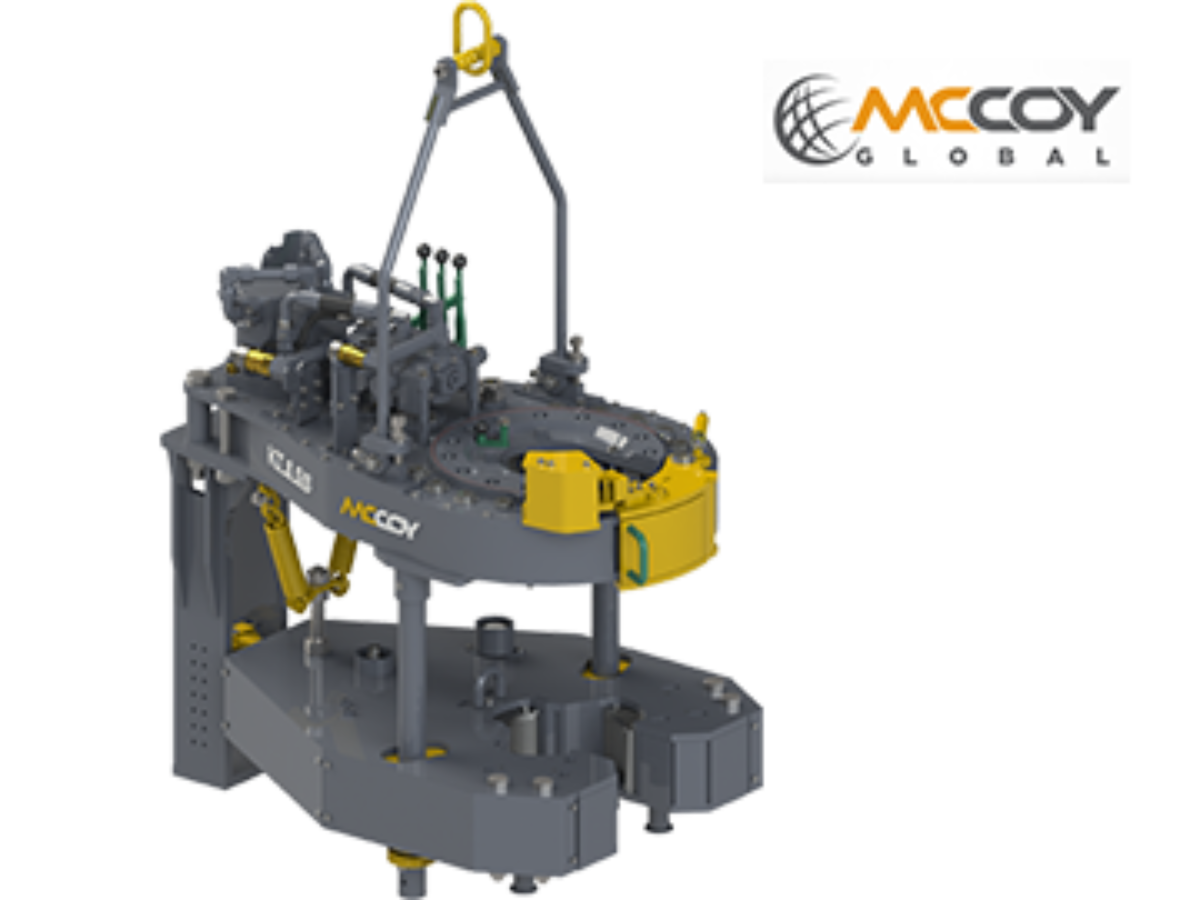

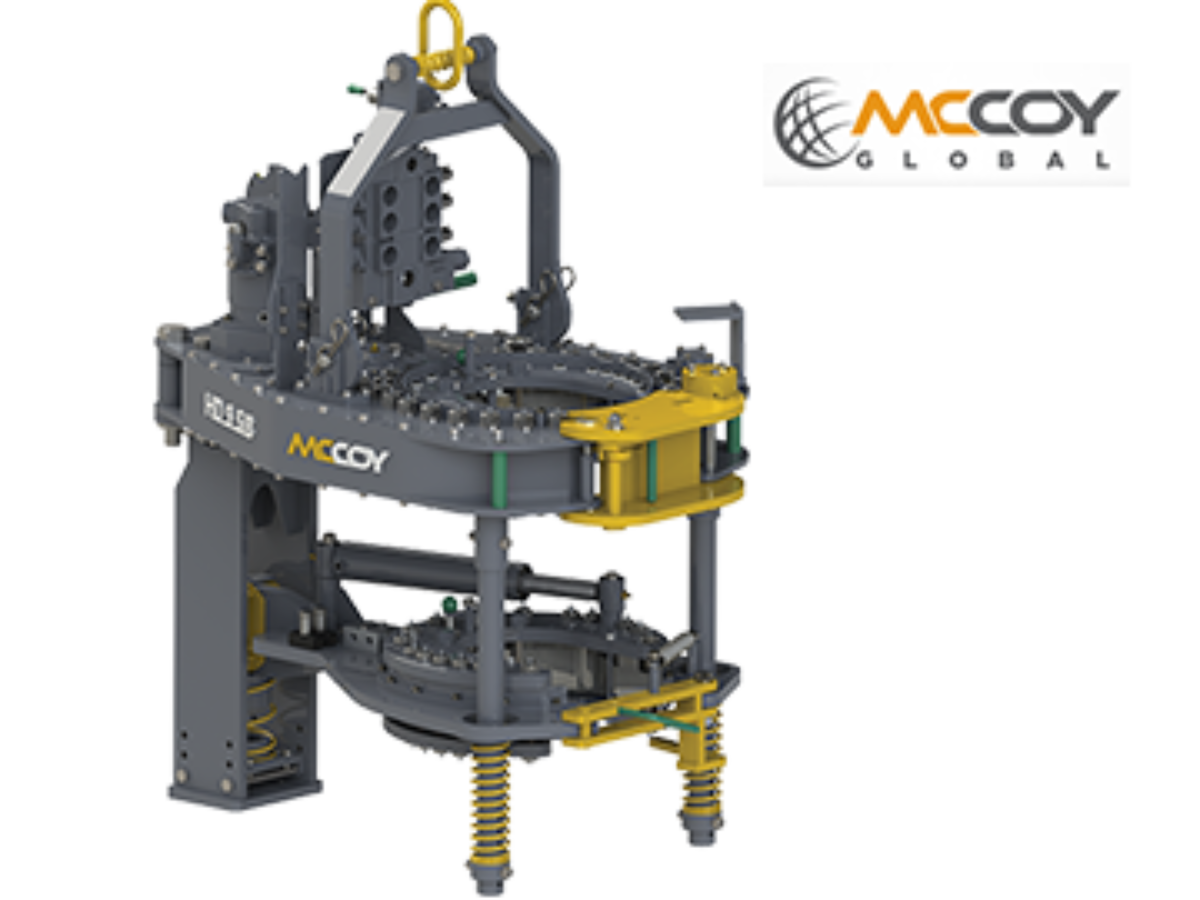

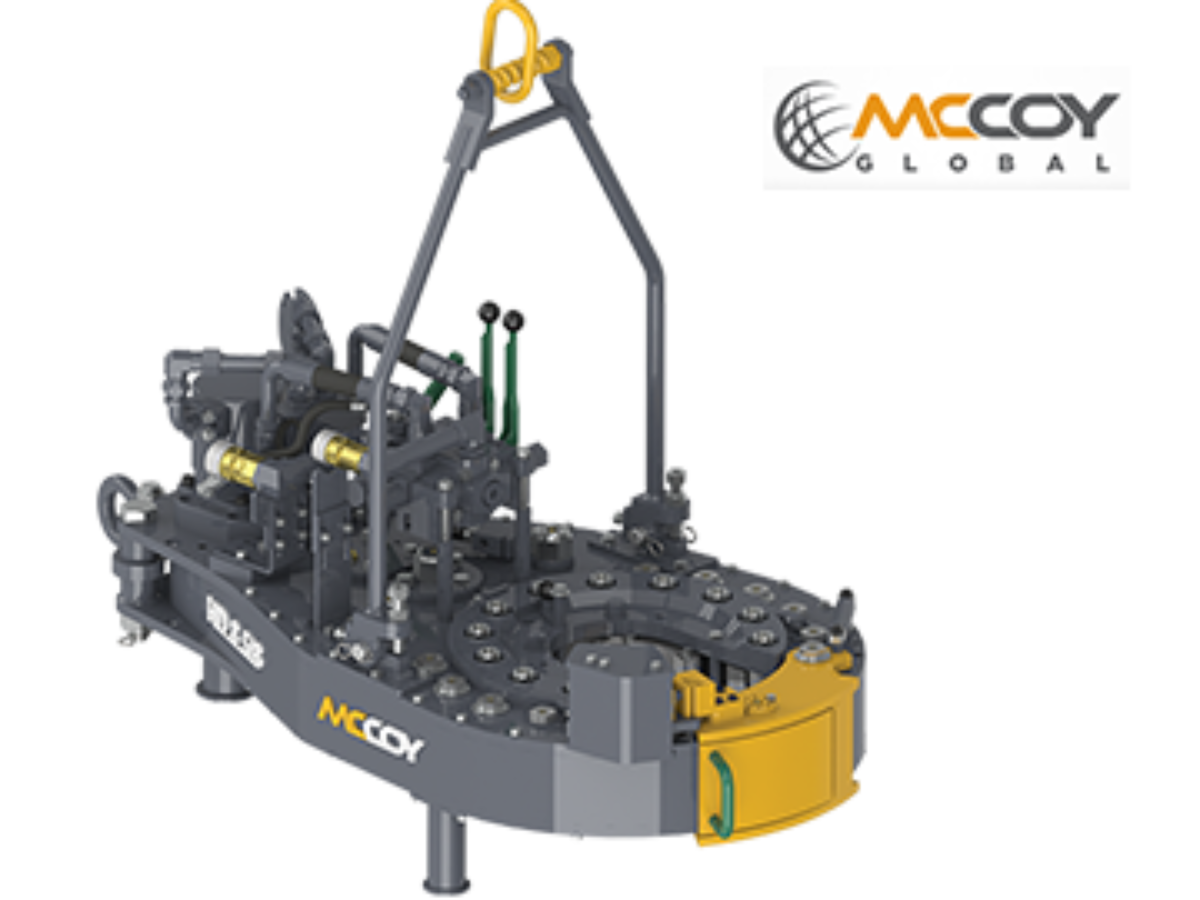

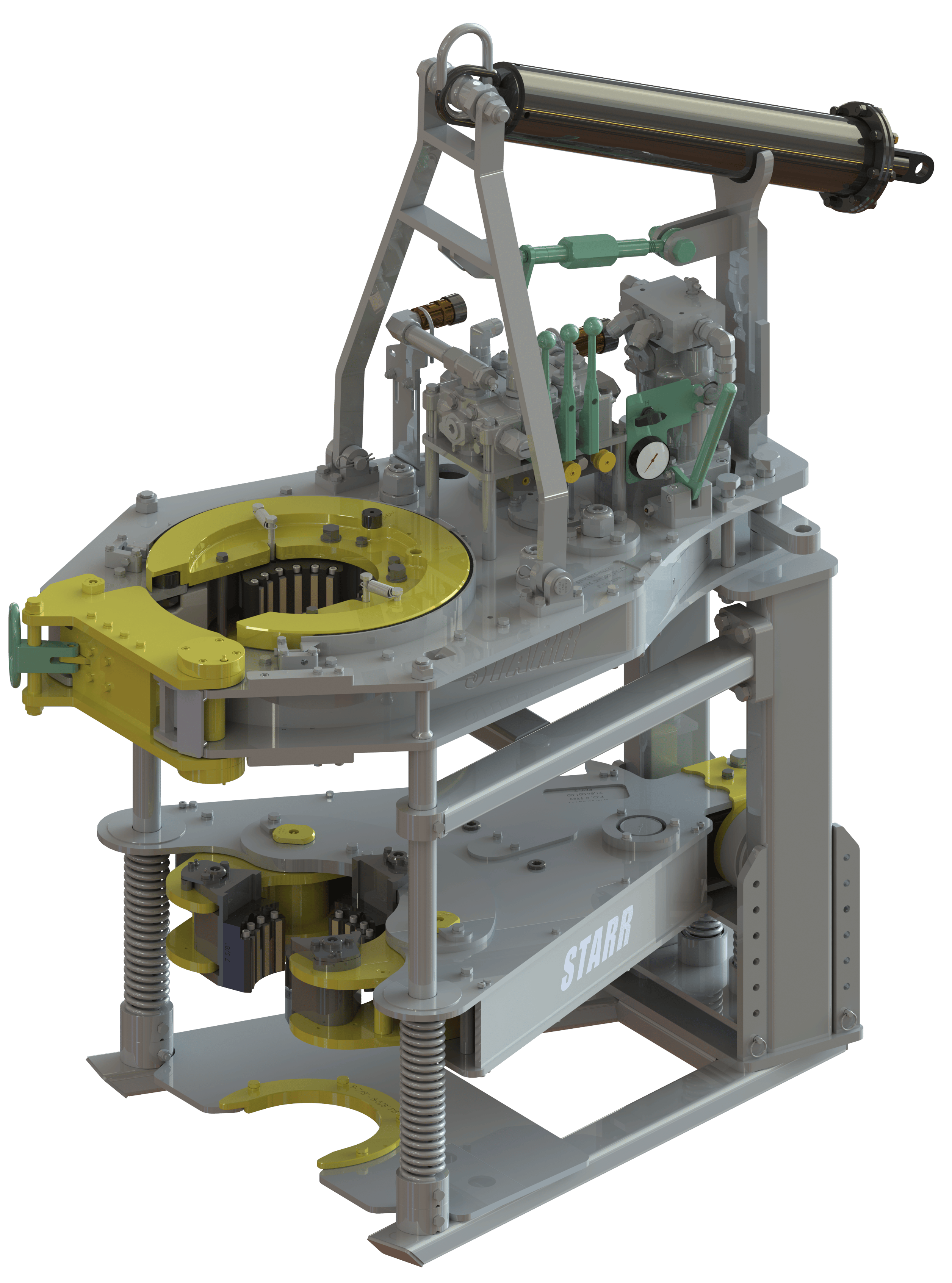

The 9-5/8” power tong with Rineer GA15-13 two-speed hydraulic motor, motor valve, lift cylinder valve, rigid sling, FARR® hydraulic backup, configured for compression load cell.

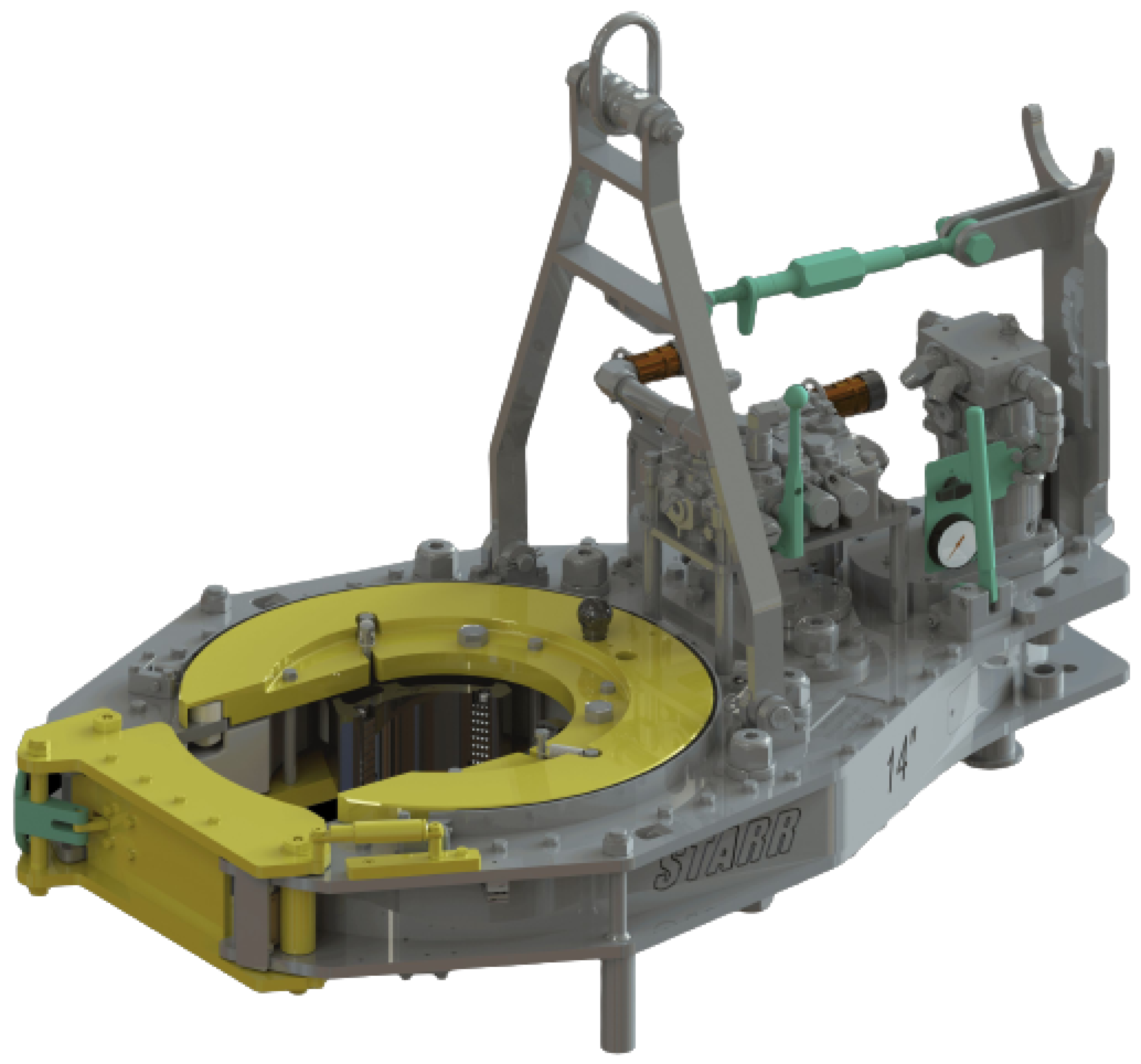

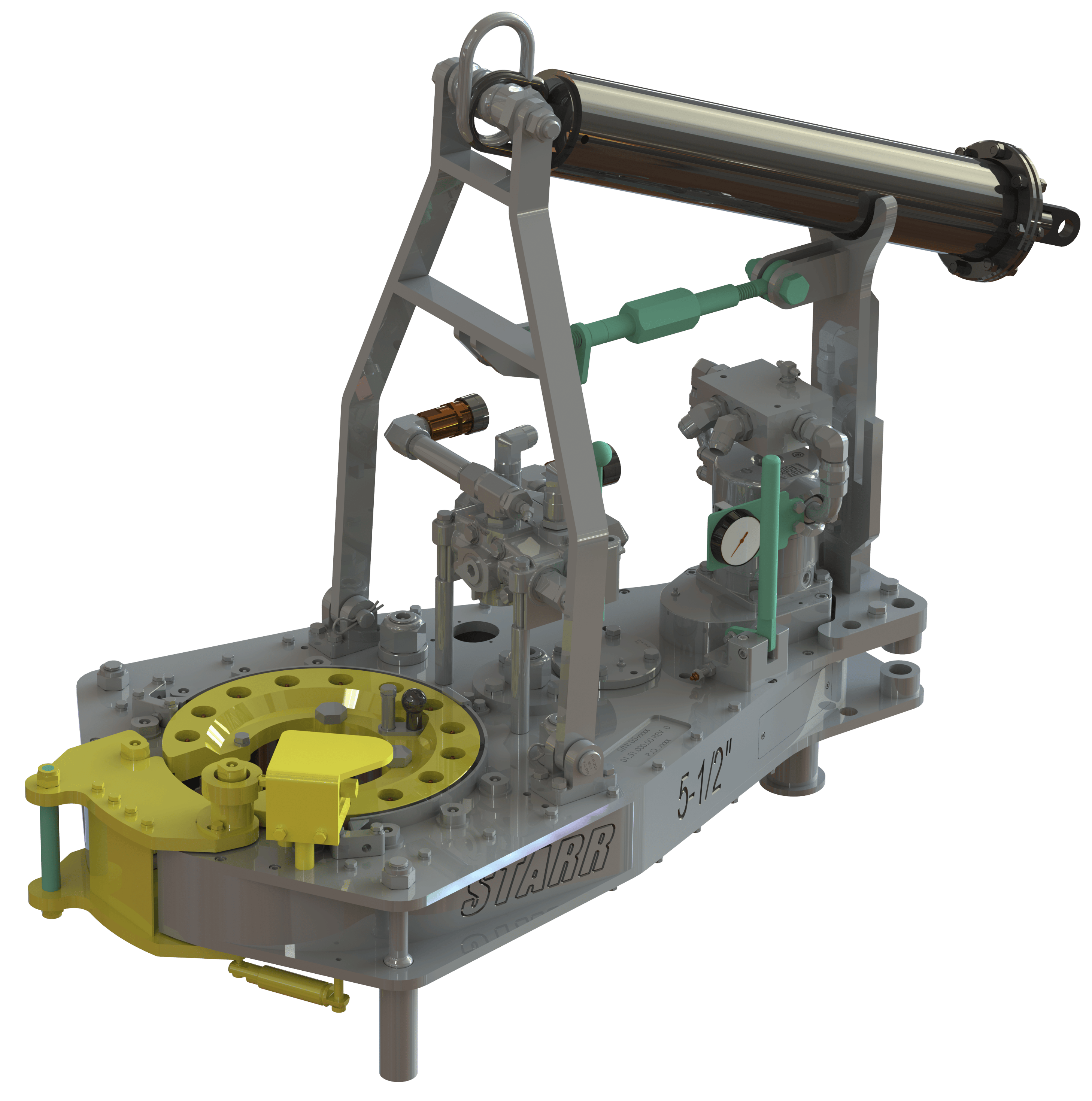

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for both Starr Power Tongs and McCoy Global hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

All of our power tongs are available with either the McCoy\\\\\\\\\\\\\\\"s patented WinCatt data acquisition software recently updated to the MTT systems or AllTorque\\\\\\\\\\\\\\\"s computer monitoring system for all the torque and turn control system needed in today\\\\\\\\\\\\\\\"s market for the making of tubular connections. Discover our wide selection of McCoy and Starr casing tongs, tubing tongs and power tongs for sale below!

We offer modular spring hangers, which attach to the tong bridle and act as a hanger for the tong. In-turn, providing thread compensation to limit stresses during makeup. Give us a call today for pricing and shipping details.

Our power tongs are built to last. With 2 motor options for the 9-7/8” hydraulic power tong, you crew can reach rated torque at 2,500 psi. Which means, the tools can reach 40,000 ft-lb or 60,000 ft-lb of torque on every single joint, every day.

With an investment like this, you don’t want one malfunctioning part to be the reason why your equipment isn’t performing. That’s why we build our tongs to be serviceable, high in quality. By using an ISO 9001:2015 quality system, we maintain a close eye on our products.

Tongs - Power - STARR 9-7/8 TONGS 40K AND 60K MODELS AVAILABLE, WITH OR WITHOUT INTEGRAL BACKUP. TOOLS ARE SOLD WITH ONE YEAR WARRANTY. ACCESSORIES ARE AVAILABLE IN STOCK ON REQUEST. C... More Info

The all new Eckel 9⅞ HS-40 and HS-55 is the result of months of engineering and extensive stress analysis that insures higher performance, reliability, and long life. Eckel 9⅞ HS-40 provides world class performance with up to 40,000 ft-lbs while the Eckel 9⅞ HS-55 has 55,000 ft-lbs maximum torque. The tong features our new patent pending CASE STIFFENER technology that enhances overall torque output. Having a high full 360� rotational torque and speed-shifting capability insures the tong can makeup special torque-turn connections that require continuous rotation. A two-speed Hydra-Shift motor is coupled with a two-speed gear train to provide (4) torque levels and (4) RPM speeds allowing the operator remarkable control of the connection.

PuYang Baolitong Petro, a professional manufacturer of varous oilfield equipment, including oil drilling and service equipment ,Oil production equipment ,OCTG products, wellhead & downhole tools and spare part. Our design and products are restrictly under API SPEC 5CT/ 7K/8C/6A.

PuYang Baolitong Petro Co has built an excellent global distribution network and the capability of providing value added services to end users.We welcome potential buyers to contact us

Quality tongs improve the efficiency and safety of drill floor operations. These large-capacity, self-locking wrenches apply torque where needed when making up or breaking out tubing. Just like a plumber using opposing pipe wrenches, rig tongs are always used in opposing pairs. One set of tongs is tied off with a cable or chain to the derrick, and the other is pulled with mechanical catheads.

Tongs used during makeup (tightening) operations are called makeup tongs; the ones used during breakout (the process of unscrewing drill string components) are called breakout tongs. Depending on the specific application, there are also riser tongs, chisel tongs, rotary tongs and manual tongs.

During makeup operations, the “lead tongs” (pronounced “leed”) are the pipe tongs suspended in the derrick or mast and operated by a chain or a wire rope connected to the makeup cathead or the breakout cathead.

The tong pull line is a length of wire rope with one end connected to the end of the tongs and the other to the cathead on the drawworks. When the driller actuates the cathead, it takes in the tong line and exerts force on the tong to either make up or break out drill pipe.

The lead-tong hand is the crew member operating the lead tongs when drill pipe and drill collars are being handled and pipe is going into the hole. For breakout operations, breakout tongs are used to start unscrew sections of pipe from one another, primarily drill pipe coming out of the hole.

Tong dies play a key part in helping power tongs or manual tongs grip tool joints. Running in or pulling out tubular at oil rigs, the tool joints are adjusted with power tongs or manual tongs.

Dies are pieces of serrated steel installed in the tongs that grip the tool joint of drill pipe when the tongs are latched onto the pipe. Tong dies are made of alloy steel, and their hardened surfaces resist wear. The inner ductile core minimizes the shock of impact and torque.

During makeup, how much force should be applied to the tongs to get the torque needed? The formula to determine torque value when you use the rig tong to make-up the connection is this:

Keystone’s K-Series tubing tongs are pull-tested and complete documentation is available with each purchase. Designed for heavy-duty service of tubing 1.050 to 3.875-inch OD, they offer a wraparound design with approximately a 300-degree die contact to prevent crushing of thin wall tubing.

MOT"s Hydraulic Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells. MOT’s

Our TEDA Style power tongs apply correct, uniform torque, reducing costly rod and tubing failures, delivering ample power to make up and break out rods and tubulars from 5/8” rod to 5-1/2” casing. Our series of XQ power tongs come with Bi-Directional jaw systems that save time and enhance safety, and go from make to break with the flip of a knob.

Tongs offer a variety of upgrades from our standard XQ series of TEDA Style models featuring Eaton hydraulic motors for extra torque and reliability, two or three spool directional control valves for more efficient hydraulic operations, and modified structures for higher strength, durability and adaptability to specific job requirements.

Are available from 5-1/2” to 20” pipe and are able to handle both API Standard and PREMIUM (Proprietary Steel Grade) casing connections which require higher torque. Available in a variety of models with hydraulic back-up tongs optional: “KMA", “KHT”, “TQ", “KJD”, “KD” and SE 16-25 with torques ranging from 15,000 ft-lbs up to 55,000 ft-lbs.

The S30,000 basic rig, consists of a 40′ telescoping mast and 140′ per minute line speed at 30,000 lbs. single line. Also, as standard equipment is a 100 gallon oil reservoir, 6,000 lbs. tail out winch, tandem hydro pump, 275′ of 3/4″ XIPS main line cable, 15 ton swivel safety bearing hook, fail safe brake, hydro control & variable speed engine control. Painted Standard SEMCO White. SEE OPTION LIST.

Special applications and tough requirements demanded that we respond with a new tong designed and built with today"s pipe handling challenges in mind, the 8⅝ Hydra-Shift® HT. By utilizing a two-speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor, the operator has a more flexible choice of torque/RPM"s to work with during make-up or break-out. At the beginning of the job, the operator will choose a tong gear ratio that is most appropriate for the current tubular connection and shift the variable speed motor handle into high or low as required. This tong also offers sliding heads with wrap-around dies, which provides evenly applied pressure to the pipe and a greater pipe gripping coverage, which reduces tubular damage. This tong not only offers the operator the speed options down to the slow speed parameter now demanded by the pipe manufacturers and oil companies, but it also has the option of speeds of 100 RPM"s when required. Available torque: 40,000 ft-lb

The Tri-Grip® Backup is the industry standard for reliable make-up and break-out of tubular connections that are optionally supplied with Eckel tongs. Utilizing two hydraulic cylinders and a three head arrangement ensures a slip-free operation. The backup is suspended at an adjustable level below the power tong employing three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for the connection"s thread travel. The Tri-Grip® uses two pivoting heads and one stationary. The Eckel Tri-Grip® Backup has exceptional gripping capabilities with Rig Die

8613371530291

8613371530291