hydraulic power tong 80000 torque for sale

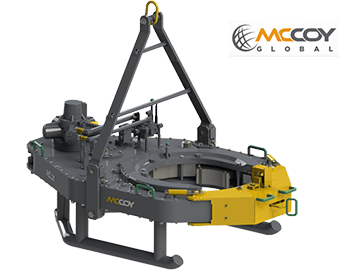

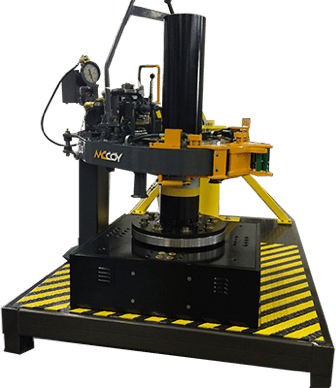

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for both Starr Power Tongs and McCoy Global hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

All of our power tongs are available with either the McCoy\\\\\\\\\\\\\\\"s patented WinCatt data acquisition software recently updated to the MTT systems or AllTorque\\\\\\\\\\\\\\\"s computer monitoring system for all the torque and turn control system needed in today\\\\\\\\\\\\\\\"s market for the making of tubular connections. Discover our wide selection of McCoy and Starr casing tongs, tubing tongs and power tongs for sale below!

Tongs - Power - BJ sucker rod tong adopts advanced sucker rod or tubing technology and has a compact structure, high reliability and is safe and convenient to operate.

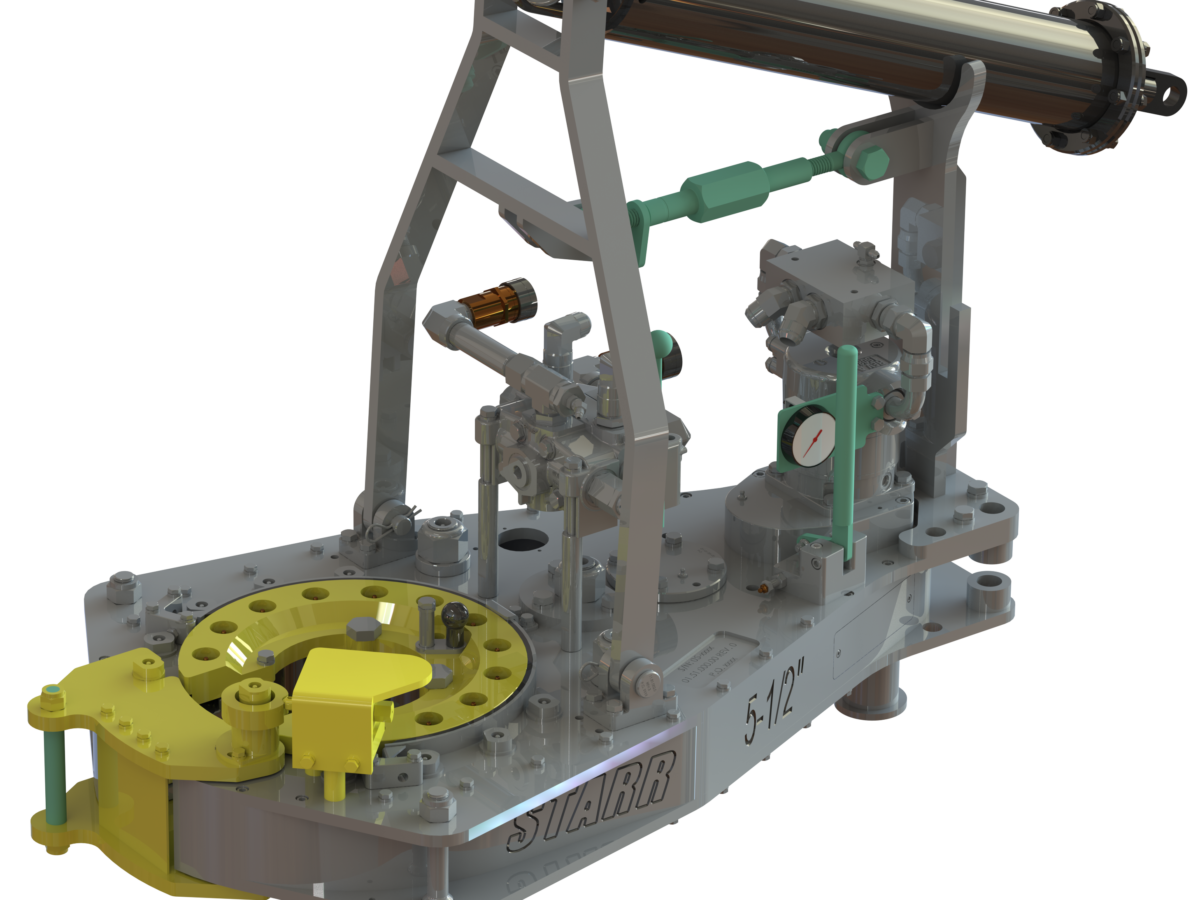

Tongs - Power - New Carter Tool Co. Inc., CT93R Hydraulic powered tubing tong. Complete with 2-3/8" to 3-1/2" jaw assemblies, standard motor, torque gauge assembly, pressure relief valve... More Info

Tongs - Power - New Carter Tool Co., Inc. 5-1/2" CTSX Hydraulic Tubing Tong with heavy case and cover; complete with rigid hanger assy., suspension spring assy., front end control assy.,... More Info

Tongs - Power - New Carter Tool Co. Inc. M-Series power sucker rod tongs, complete with spring hanger assy., gate assy., front end control assy., pressure gauge assy., two 90 degree XH s... More Info

Tongs - Power - New Carter Tool Co., Inc. 4-1/2" RSX Hydraulic Tubing Tong with heavy case and cover; complete with rigid hanger assy., suspension spring assy., front end control assy., ... More Info

Tongs - Power - D D 58-93-2-R Power Tubing Tong is smaller, lighter, and faster than the Foster 5893R. The D D 58-93-2-R Tong is capable of gripping tubulars from 1 5/16" to 7" o.d. More Info

Tongs - Power - FARR TONG MODEL KT 14,000 RINEER GA37 MOTOR, LIFT VALVE ASSEMBLY TORQUE CAPACITY: 50,000 FT/LB SIZE RANGE 4 1.2-14 WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN ... More Info

Tongs - Power - FARR TONG MODEL KT20,000 STAFFA 080 MOTOR, LIFT VALVE ASSEMBLY TORQUE CAPACITY: 50,000 FT/LB SIZE RANGE: 7-20 MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READ... More Info

Tongs - Power - FARR MODEL KT5500 HYDRAULIC TUBING TONG C/W 2 SPEED RINEER MOTOR, SIZE RANGE: 2-3/8 IN. - 5-1/2 IN. OD, TORQUE RTED: 18,700 FT/LB C/W SAFETY DOOR MOST SIZES OF FARR POWER... More Info

Tongs - Power - FARR TONG MODEL KT5500 TORQUE CAPACITY: 18000 FT/LB SIZE RANGE: 2 1/16-5 1/2 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIA... More Info

Tongs - Power - FARR TONG MODEL KT5500 5 1/2 IN. TONG TORQUE CAPACITY: 18,000 FT/LB SIZE RANGE: 2 1/16-5 1/2 IN. OD, RINEER 15-13 MOTOR, HIGH TORQUE CLINCHER BACKUP TRIPLE VALVE ASSEMBLY... More Info

Tongs - Power - FARR TONG MODEL KT7585 TORQUE CAPACITY: 25000 FT/LB SIZE RANGE: 2 1/16-8 5/8 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIA... More Info

Tongs - Power - FARR TONG MODEL KT7585 8 5/8 IN. TONG TORQUE CAPACITY 25,000 FT/LB SIZE RANGE: 2 1/16-8 5/8 IN. OD, RINEER 15-15 MOTOR CLINCHER BACKUP, TRIPLE VALVE MOST SIZES OF FARR PO... More Info

Tongs - Power - FARR TONG MODEL LW9625 TORQUE CAPACITY 12000 FT/LB SIZE RANGE 2 7/8 -9 5/8 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIATE... More Info

Tongs - Power - Farrs newest tubular connection tool offers a significantly reduced rig footprint, while continuing to deliver power & uncompromising reliability. The simple design drast... More Info

Tongs - Power - Farr Canada"s newest tubular connection tool offers a significantly reduced rig footprint, while continuing to deliver power and uncompromising reliability. The simple de... More Info

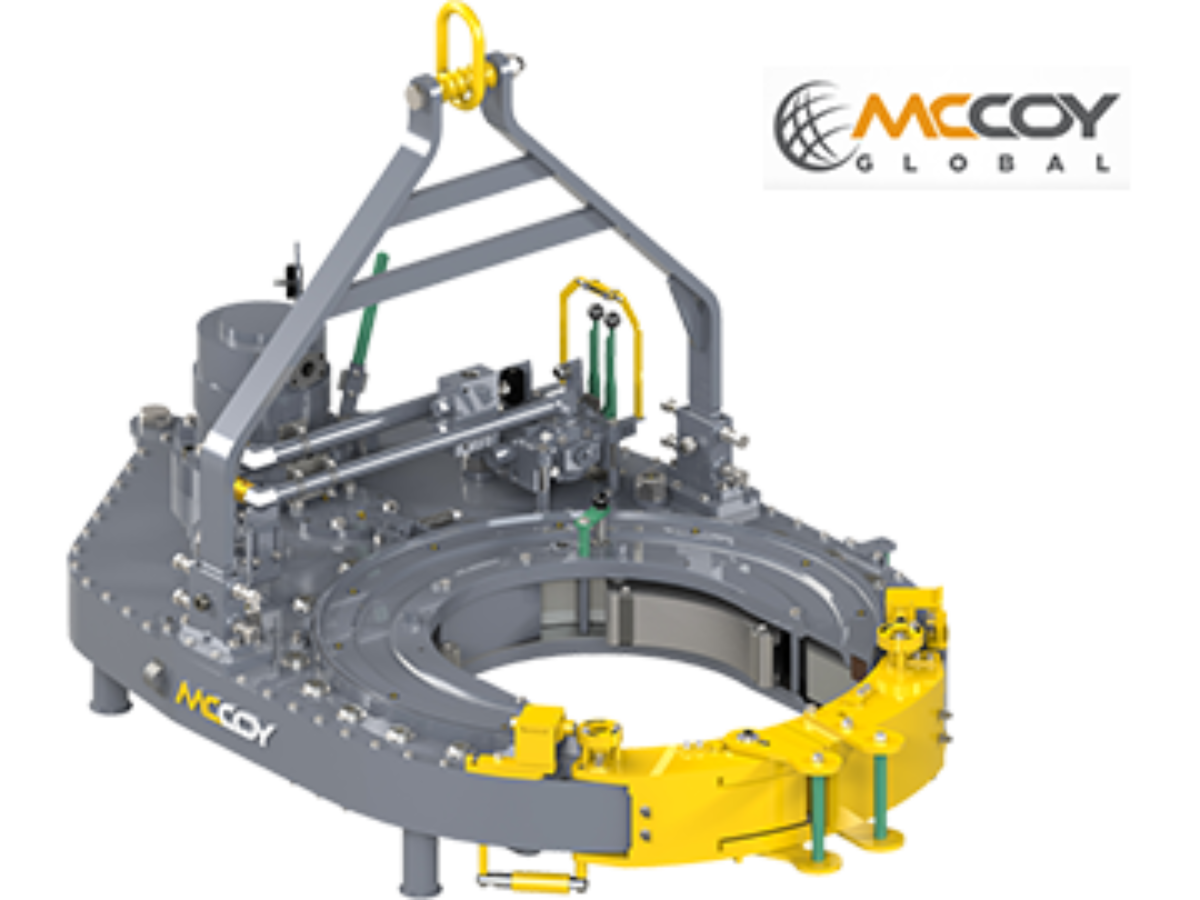

Casing Tongs provide make-up and break-out capabilities when running casing tubular in the drill hole to maintain well integrity. Casing tongs are available for various sizes from 5-1/2" to 36" and designed to handle high torque casing or lightweight casing. Available models: Standard, Hydra-Shift, High Torque, and Ultra High Torque with torques ranging from 15,000 ft-lbs up to 200,000 ft-lbs. Consistent operations between models reduce employee training.

The new 7.25 HS HT-80 for Drill Pipe and High Torque Casing Tong takes on the toughest job with make-up and break-out of drill pipe, drill collars, and high torque casing with a maximum torque of 80,000 ft-lbs. The 7.25 HS HT-80 is available with a two-speed Hydra-Shift® motor coupled with a two-speed gear train providing (4) torque levels and (4) RPM speeds. The variable speeds can slowly or quickly spin tubular 2⅜ through 7¼ inch as necessary. Having exceptional gripping capabilities with rig dies for drill pipe or wrap-around dies that securely encompass the tubular limit potential for damage. The 7.25 HS HT-80 is also available with Eckel Pyramid Fine Tooth dies, or True-Grit dies. The 7.25 HS HT-80 is another of our tongs models that exceed the competition in its class.

Scorpion Oil Tools, located in Houston, TX, manufactures and sells make up and break out hydraulic chain tongs for the resource drilling (oil drilling, gas drilling, mining, water well drilling, and others) and construction industries. Also called breakout machines, Scorpion tongs (which look like a Scorpion when in an open position) are safer than manual tongs and can be operated in both vertical and horizontal positions. We offer a wide range of tools that can fit any drilling application, including a bucking unit configuration (horizontal makeup / breakout machine), as well as portable breakout tongs. All Scorpion units can operate as torquing machines and breakout machines.

A trailer-mounted coiled tubing rig utilizing a truck equipped with hydraulic wet kit. The trailer rig includes a mast with integral work floor, drawworks, travelling block, storage reel with level wind, injector, and necessary equipment to accommodate an optional top drive. The truck is fitted with a transfer case allowing the truck engine to power the hydraulic system. The rig is designed for drilling applications and includes means for drilling with either coil tubing or jointed pipe in addition to running casing tubulars. The injector is fixed at a set height within the mast. Drilling with jointed pipe or running of casing can be achieved without moving the rig by sliding the injector forward allowing the travelling block and or top drive assembly to pass clear of the injector. All drilling functions can be controlled via the remote control console that is designed for mounting at a remote location. Secondary controls located on the drill unit itself can also be used to operate the drilling functions. Sets up functions are only achieved through controls mounted on the rig trailer.

The mast is a steel fabricated twin tube design with raising/lowering from two multi-stage hydraulic cylinders. The mast supports both means of hoisting induced by the injector and casing winch. The mast supports the injector at a fixed height. The injector is attached to a slide mechanism which hydraulically moves the injector to provide clearance for the traveling block and or top drive while hoisting of jointed pipe. The mast also supports a 3-sheave crown block assembly strung with 7/8 inch drill line.

straightner assembly. A 2 section goose neck folds hydraulically for transport mode. Hydraulic cylinder used to fold gooseneck acts as strut to stabilize and support gooseneck while in

operating mode. Cylinder has provision to provided optional warning of critical out hole tension of storage reel. Hold down rollers (qty. 3) are hydraulically operated. Gooseneck supplied with 3 1/2” roller kit. 2 7/8” roller kit shipped loose. The gooseneck is mounted to a slewing ring that allows the gooseneck to pivot for optimum alignment of coiled tubing to the storage reel. A hydraulic cylinder is used to lock the gooseneck for transport.

Drive group Single hydraulic motor with planetary gear reduction designed to hold tension on drum regardless of direction of travel or injector speed. Integral to hydraulic motor drive assembly, fail-safe in line brake (hydraulic pressure required to release brake).

Internal reel plumbing Consisting of ridged 3” – 3000 psi maximum working pressure steel plumbing and hydraulically actuated plug valve. Plumbing is connected from the coiled tubing terminating outside the reel via a blast joint that passes through the reel axle to a point outside the reel, which permits the connection of the drilling fluid/air system. All connections are 1502 style hammer unions.

The rig is equipped with the necessary hydraulic power source, controls, plumbing and attaching hardware to accommodate a Foremost RC 240 hydraulic top drive assembly. What is not included is the top drive itself consisting of hydraulic motors, gearbox, control valve, mud swivel, carriage, break out tong/guide, bales, elevators and kelly hose.

Note: speed maybe more or less depending on the available HP of the truck engine or other hydraulic requirements. Hydraulic system is designed to accommodate a Foremost model RC 240 top drive, installation of any other model will need to be reviewed and approved by Foremost. Failure to due so will result in termination of any warranties.

The drawworks winch is hydraulically driven with a closed loop piston motor circuit through a planetary reduction. Dynamic braking is provided by the hydraulic system.

The tong wrench system is mounted to the trailer deck directly behind the substructure floor. The system utilizes two independent hydraulic cylinders with cables necessary to operate manual pipe tongs used in the makeup and breakout of threaded connections. Counterweights are provided to assist in the lifting and lowering of both the makeup and breakout tong wrenches.

All drilling and casing operations are achieved through remote electrical over hydraulic controls referred to as the Primary System. A redundant Secondary System featuring a combination of electric over hydraulic and manual controls is also provided. The Primary System is designed for remote mounting in the customer supplied control room. The Secondary System is located entirely on the drill rig. A third manual only control system is also supplied and is limited to set up functions such as outriggers, mast raise, gooseneck and hold down rollers and are mounted on the drill rig. A complete set of instrumentation for monitoring rig performance and function such as hydraulic pressures and engine system are included.

Display for top drive torque is supplied under the original specification. A pressure transducer mounted at the forward rotation hydraulic line produces an electronic signal to an analog style gauge. The gauge is calibrated to foot-pounds.

A manifold system is provided as a means of connecting the customer supplied air/fluid circulation system to either the coiled tubing storage reel or top drive assembly. A hammer union connection point is provided at the trailer so the remote air/fluid system can be connected. A single gate valve is used to stop the flow two the top drive and a hydraulically actuated plug valve used to stop the flow to the coiled tubing. In general the system will be using air and water as the main drilling fluid and is rated at the following pressures

BOP plumbing consisting of quick connectors, hoses and steel piping in order for the customer to connect the BOP stack to the accumulator system (customer supplied). A bulk head is located on the trailer. This bulkhead is equipped with 3 sets of quick couplers suitable in size to connect with the customer supplied accumulator system. All couplers are labeled as to their function. From the bulkhead hydraulic hose is run to a point sufficient in distance from the well center to meet code. At this point steel line (or fire proof hose) is run the length of the trailer to just inside the cellar area at which point it is terminated at a second bulkhead. The purpose of this bulkhead is to allow separate hoses to be run to BOP stack. From bulkhead in the cellar, fire proof hose of sufficient length, complete with quick couplers is supplied to connect with the BOP stack (stack supplied by customer). All hose and fitting sizes, specifications are to be in accordance with applicable codes and customer requirements.

• Qty 2 – guide assemblies with nylon inserts to suit tube rails on inside of derrick legs. Guide assemblies keep top drive aligned to well center and transfer top drive torque top derrick legs.

• Two hydraulic cylinders are mounted below the top drive that can be connected to the bales. These cylinders allow for the bales with elevator to be hydraulically positioned towards the v-door to connect to the drill pipe.

MOT"s Hydraulic Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells. MOT’s

Our TEDA Style power tongs apply correct, uniform torque, reducing costly rod and tubing failures, delivering ample power to make up and break out rods and tubulars from 5/8” rod to 5-1/2” casing. Our series of XQ power tongs come with Bi-Directional jaw systems that save time and enhance safety, and go from make to break with the flip of a knob.

Tongs offer a variety of upgrades from our standard XQ series of TEDA Style models featuring Eaton hydraulic motors for extra torque and reliability, two or three spool directional control valves for more efficient hydraulic operations, and modified structures for higher strength, durability and adaptability to specific job requirements.

Are available from 5-1/2” to 20” pipe and are able to handle both API Standard and PREMIUM (Proprietary Steel Grade) casing connections which require higher torque. Available in a variety of models with hydraulic back-up tongs optional: “KMA", “KHT”, “TQ", “KJD”, “KD” and SE 16-25 with torques ranging from 15,000 ft-lbs up to 55,000 ft-lbs.

8613371530291

8613371530291