hydraulic power tong manufacturer quotation

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

XQ140 micro-marking and no-marking hydraulic power tongs is a special equipment and open power tongs which is applicable to make up or break out 41/2"-51/2" casing during oil field work over operation. Master and back tong device adopts jaw plate type multi-point clamping mechanism.Can choose contour coated rig dies or pyramid tooth , to ensure the column minimum damage, and can improve the pipe thread connection quality, reduce due to improper work over pipe accident etc..

1. The tongs head is the open structure which is quick and convenient for entering and retreating working position. The integral tong head has good hardness and rigidity.

2. Master tong is roller climbing two jaw plate structure,can install arc tooth die ,the contact surface is more larger and clamp no deformation, The assembly and disassembly is very convenient. The optimum tangent-diameter ratio design ensures reliable clamping and easy slope retreating.The back tong is the three-jaw-plate structure pushed by hydraulic cylinder. The structure is simple and the clamping is reliable; The minimum damage to the tubular column can be ensured, and the main body of the pipe string can be clamped.

6. Master and back tong adopt integral frame structure,back tong is floating connection,The master and back tong adjustable distance, reduce the damage of pipe string shackle;

7. Use with double pump hydraulic station,allows initial makeup speeds of 15~25rpm,makeup speed is reduced as the shoulder is approached,drop to as low as 1-6rpm.

A hydraulic power tong is a type of equipment used for work. Experienced hydraulic power tongs, also called as hydraulic power tanks, are different types of equipment that is used to work on pressure-sensitive surfaces.

Explore different kinds of hydraulic power tongs on Alibaba.com, including wholesale hydraulic power tongs for excavator power tongs for sale, include hydraulic power tongs for small, medium, and large-scale work.

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

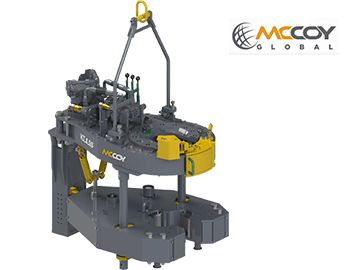

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

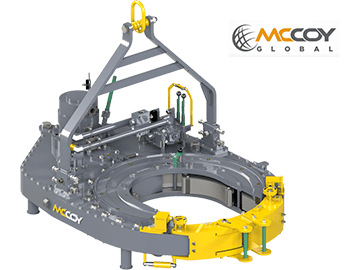

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

The quote is the core of GOM Energy Services LLC philosophy and the services provided. Cory Forbes has over 20 years in the Power Tong industry in Sales at a leading manufacturer before starting his own company in REMAN and Repair to Power Tongs.

Our staff consists of professionals from the industry in services, sales and repair. Each service technician has at least 9 years experience in power tong repairs. Our new Shot Peening service has been a great addition to blast the tong casing bodies while we take your existing product and make it as new it was when it was purchased. Click the process below to find out what you can expect in the GOM Energy Services LLC REMAN services.

Manufacturer of oil well casing hydraulic power tongs. Provides make-up and break-out capabilities when running casing tubular in the drill hole. Available from 5 1/2 to 36 in. capacity and 15,000 up to 2,00,000 ft·lb torque. Offered with self aligning throat, speed shifting and radial lock door. Suitable for handling high torque and lightweight casing. Secondary services include assembly, engineering, welding, cutting, heat treating, machining, testing and inspection. Serves oil and gas industries. CE certified. Made in the USA.

8613371530291

8613371530291