hydraulyc power tong 40 000 in stock

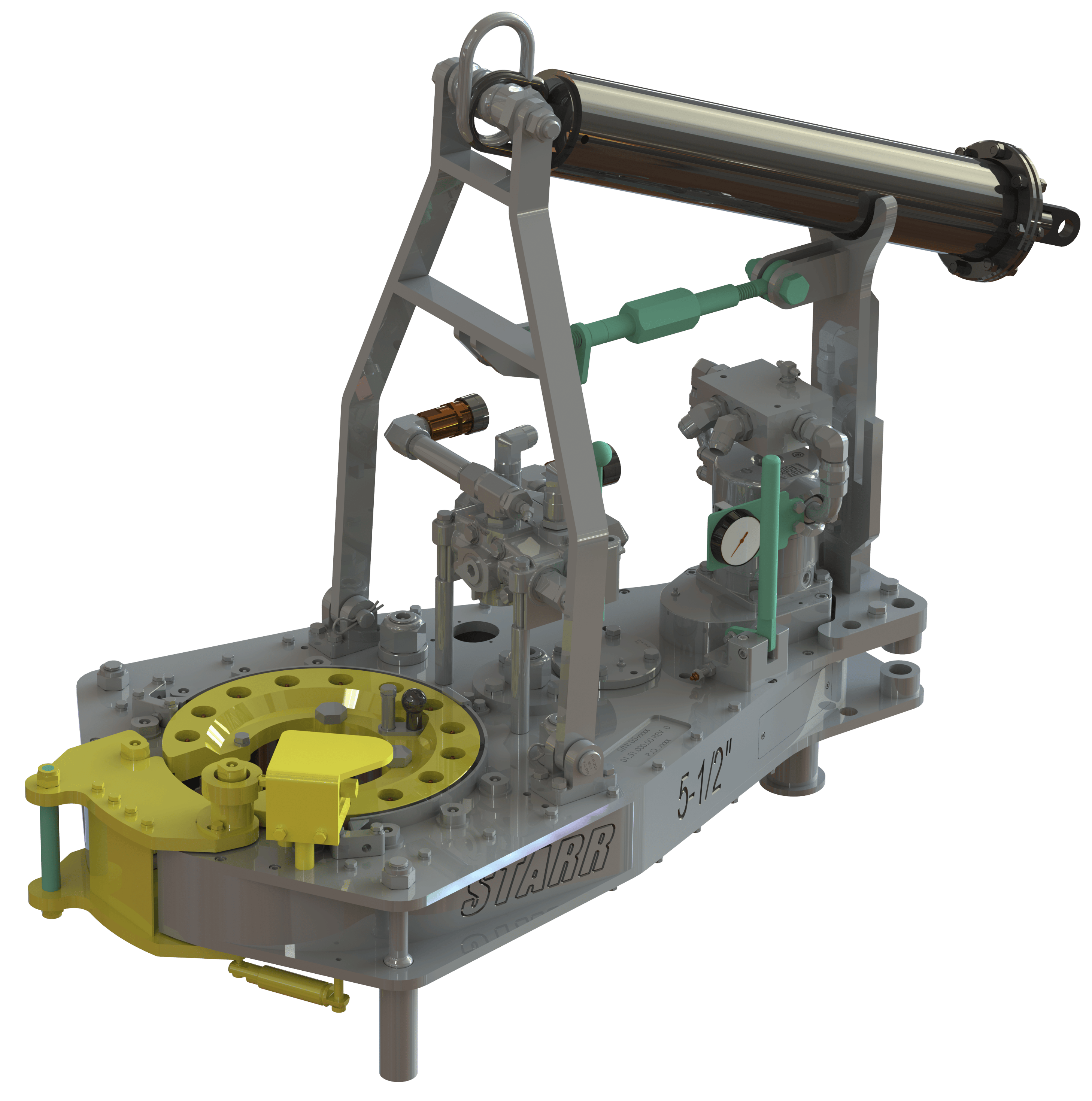

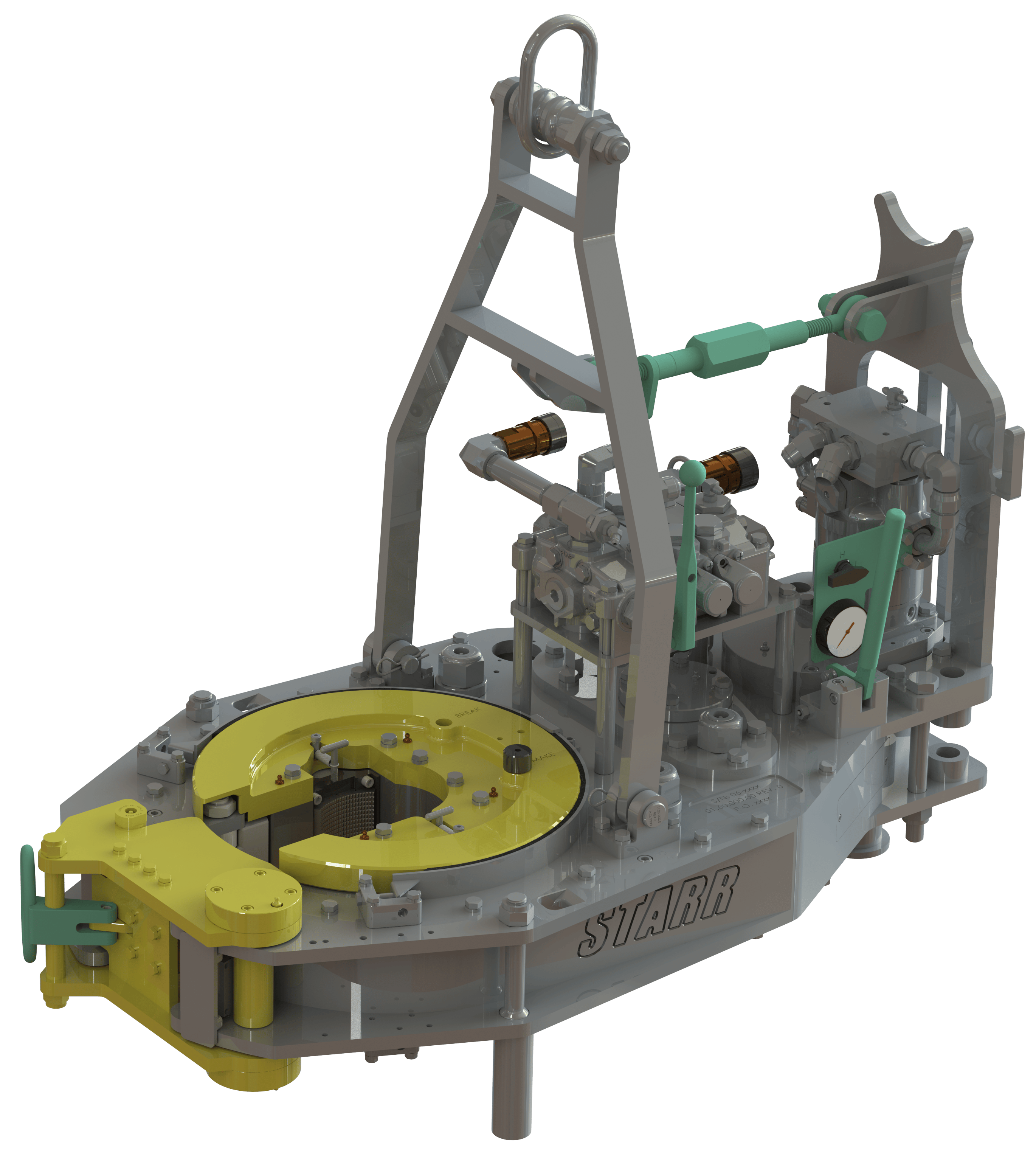

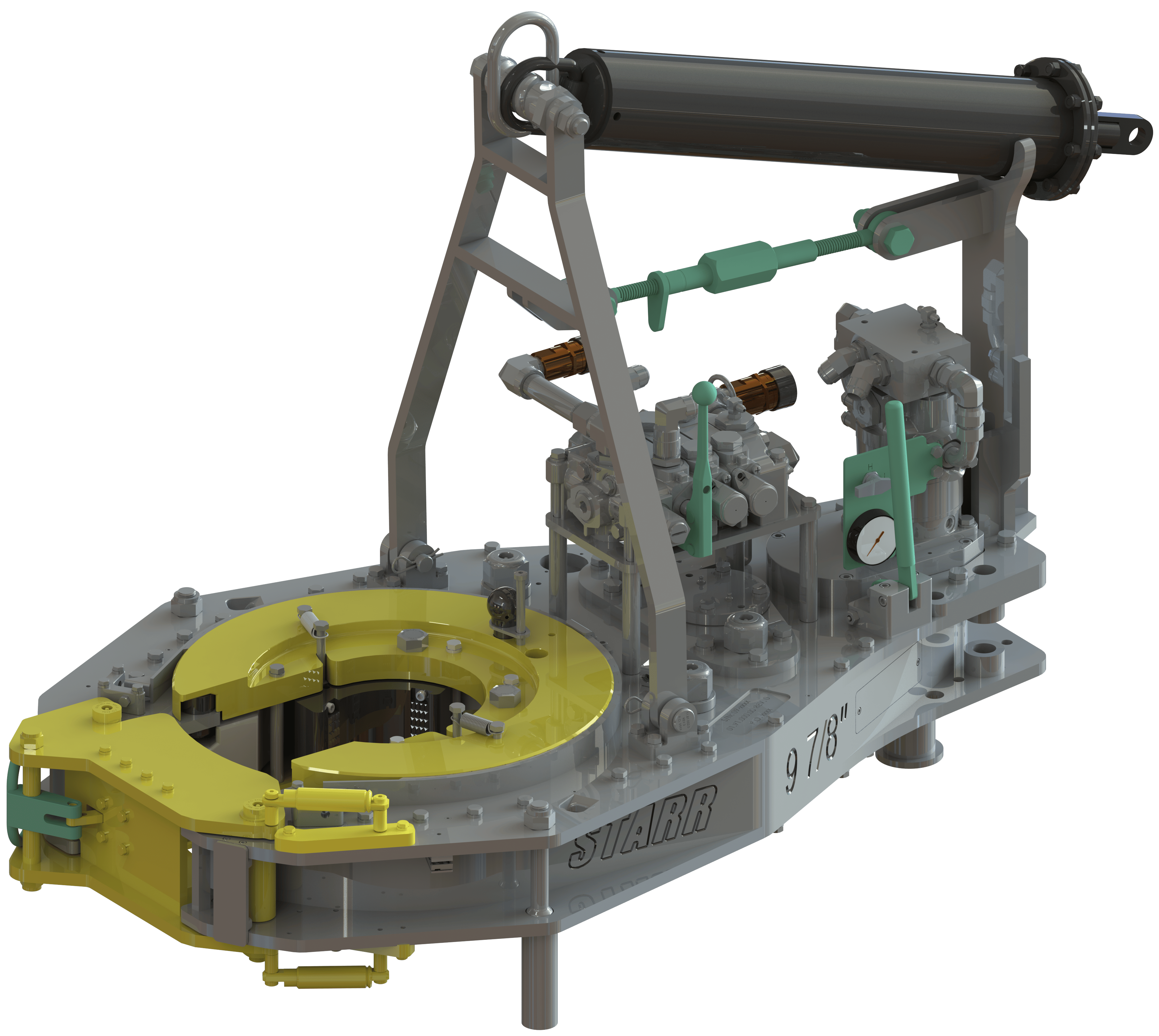

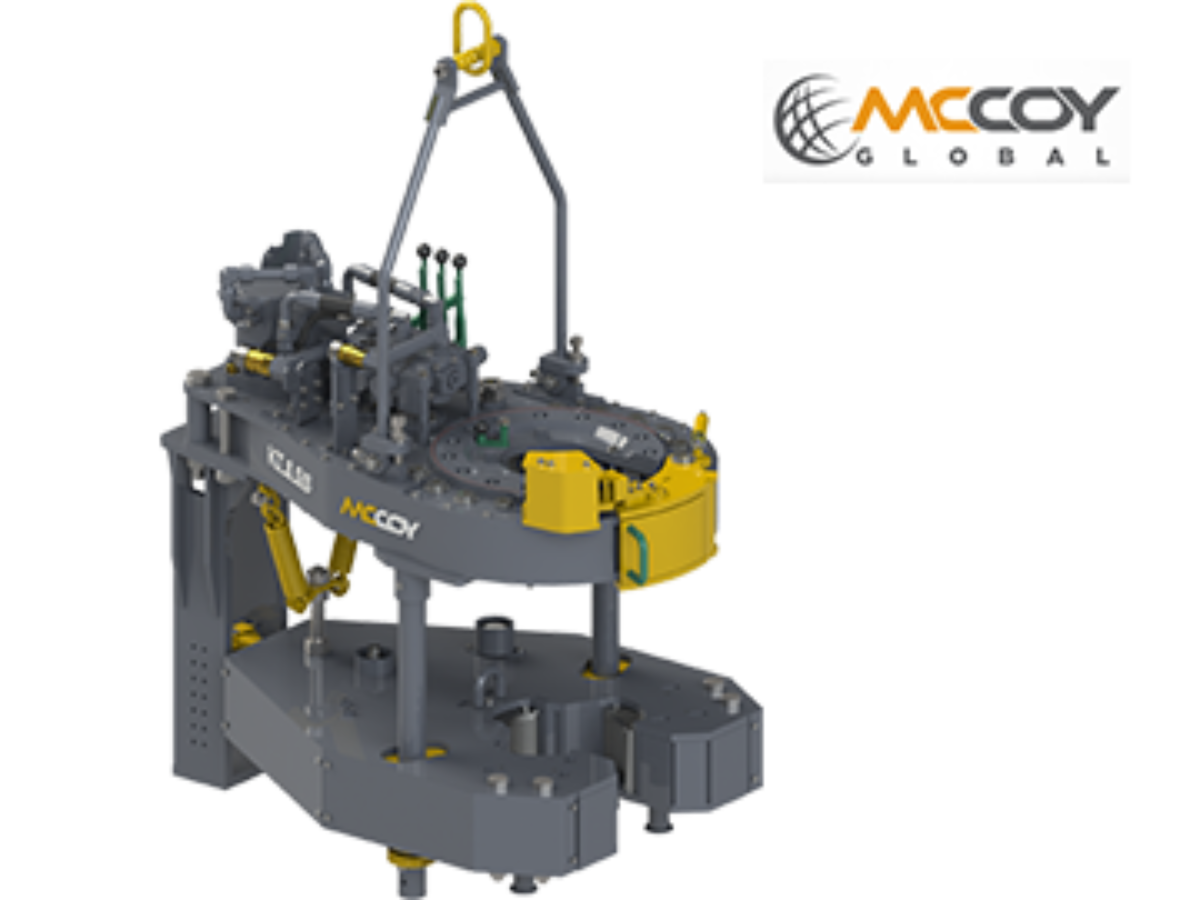

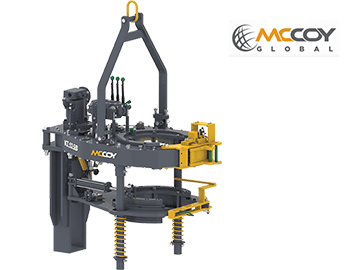

The 9-5/8” power tong with Rineer GA15-13 two-speed hydraulic motor, motor valve, lift cylinder valve, rigid sling, FARR® hydraulic backup, configured for compression load cell.

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for both Starr Power Tongs and McCoy Global hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

All of our power tongs are available with either the McCoy\\\\\\\\\\\\\\\"s patented WinCatt data acquisition software recently updated to the MTT systems or AllTorque\\\\\\\\\\\\\\\"s computer monitoring system for all the torque and turn control system needed in today\\\\\\\\\\\\\\\"s market for the making of tubular connections. Discover our wide selection of McCoy and Starr casing tongs, tubing tongs and power tongs for sale below!

The all new Eckel 9⅞ HS-40 and HS-55 is the result of months of engineering and extensive stress analysis that insures higher performance, reliability, and long life. Eckel 9⅞ HS-40 provides world class performance with up to 40,000 ft-lbs while the Eckel 9⅞ HS-55 has 55,000 ft-lbs maximum torque. The tong features our new patent pending CASE STIFFENER technology that enhances overall torque output. Having a high full 360� rotational torque and speed-shifting capability insures the tong can makeup special torque-turn connections that require continuous rotation. A two-speed Hydra-Shift motor is coupled with a two-speed gear train to provide (4) torque levels and (4) RPM speeds allowing the operator remarkable control of the connection.

Eckel�s 9⅞ HS-40 Tubing / Casing providing high torque and high continuous rotational torque that you can trust within a compact operational footprint featuring SPACE SAVER® technology.

The 9⅞ HS-40 Tubing / Casing is the result of months of engineering and extensive stress analysis that insures higher performance, reliability, and long life. Eckel 9⅞ HS-40 provides world-class performance with up to 40,000 ft-lbs maximum torque. The tong features our new patented CASE STIFFENER technology that enhances overall torque output. Having a high full 360� rotational torque and speed-shifting capability insures the tong can makeup special torque-turn connections that require continuous rotation. A two-speed Hydra-Shift® motor is coupled with a two-speed gear train to provide (4) torque levels and (4) HS- speeds allowing the operator remarkable control of the connection.

Tong dimensions are a critical design aspect that our engineers worked to reduce for today�s smaller rigs. The result was having one of the industry�s smallest operational footprints tongs for its capacity and torque. The patented SPACE SAVER® door that hydraulically opens vertically, allowing for the tong to work in a much smaller operational area on rig floors and is also less labor-intensive operating. The door opens to the opposite side of the tong operator, allowing full view of the tong throat area while positioning the tong on the tubular. A fast 2-second door operation is all that is required to open or close the door.

The safety door interlock prevents tong operation when the tong door is open. Now enclosed within the tong body, providing tamper-resistant concealment from operator circumvention. Accidental damage of the door interlock by hydraulic fluids, tubular connection, or other external forces is also greatly minimized. A front panel provides access to the door inter-lock for any maintenance required

The 9⅞ HS-40 Casing Tong offers exceptional gripping capabilities handling tubular size from 3½ - 9⅞ in. (88.9 - 250.8) and WD Tri-Grip® Backup size 3½ - 11 in. (88.9 - 279.4). An innovative design allows you to choose either sliding heads or pivot heads configuration upon order. Wrap-Around dies are offered which securely encompass the tubular to limit potential for damage. Therefore, you are assured of your down hole tubular connection integrity.

Our power tongs are built to last. With 2 motor options for the 9-7/8” hydraulic power tong, you crew can reach rated torque at 2,500 psi. Which means, the tools can reach 40,000 ft-lb or 60,000 ft-lb of torque on every single joint, every day.

With an investment like this, you don’t want one malfunctioning part to be the reason why your equipment isn’t performing. That’s why we build our tongs to be serviceable, high in quality. By using an ISO 9001:2015 quality system, we maintain a close eye on our products.

Tongs - Power - STARR 9-7/8 TONGS 40K AND 60K MODELS AVAILABLE, WITH OR WITHOUT INTEGRAL BACKUP. TOOLS ARE SOLD WITH ONE YEAR WARRANTY. ACCESSORIES ARE AVAILABLE IN STOCK ON REQUEST. C... More Info

Tongs - Power - STARR 9-7/8 TONGS 40K AND 60K MODELS AVAILABLE, WITH OR WITHOUT INTEGRAL BACKUP. TOOLS ARE SOLD WITH ONE YEAR WARRANTY. ACCESSORIES ARE AVAILABLE IN STOCK ON REQUEST. C... More Info

At the heart of this innovative hydraulic motor is a patented vane-crossing-vane design, a revolutionary concept in hydraulic power transmission. The design is a bi-rotational power converter utilizing working vanes in the rotating member and sealing vanes in the stationary member, or stator.

With 10 rotor vanes working in four cavities, the motor provides an uninterrupted torque output regardless of angular position. This design thus delivers 40 power strokes per revolution, providing higher average torque with low torque ripple.

The stator vanes function as seals between high- and low-pressure ports within the stator. This allows for more displacement in the stator, giving the Rineer vane motor an optimum power-to-weight ratio. The result: The torque curves are virtually flat with starting and stall torque equal to 90 to 94 percent of theoretical torque.

8613371530291

8613371530291