nov tubing power tong manufacturer

The Model 300 Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong.

The Model 300M Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong. A feature unique to this model is the ability to breakout and make-up 1-1/8” rods without over torqueing.

The Model 500 Power Tubing Tong has a size range of 1-5/16” to 7”, joint make-up in 5 seconds, and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated. The Model 500 also features an adjustable clutch and air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power.

The Model 600 Power Tubing Tongs feature an adjustable clutch and is available in either air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power. The Model 600 permits joint make-up in 5 seconds and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated.

The Model RSHD Power Tubing Tongs are truly a heavy duty piece of equipment that is for the tough jobs. The Model RSHD has more steel weight and gussets added to the bottom in order to diminish chance of case spreading. This model features a customary chain-driven design, integral sprocket, and outer ring. Lastly, the Model RSHD utilizes a familiar jaw-and-bushing biting system.

The Model 700 features the highest torque of all the Power Tubing/Casing Tongs at 20,000 ft./lbs. at 2000 PSI. This model consists of a light drill pipe, tubing, and casing.

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

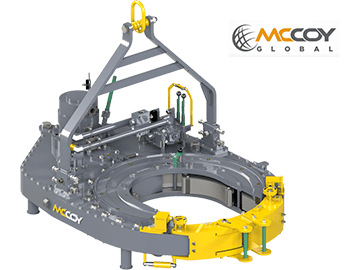

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

Eckel offers several models of torque control systems that are used to monitor the torque turn values when making up tubular connections (Tubing, Casing, & Drill Pipe). Any flaws in the make-up process will be readily shown in a graph.

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

Contact our expert sales staff for pricing, availability and product specifications for the Gill Power Tong right for your application at the link provided on this page.

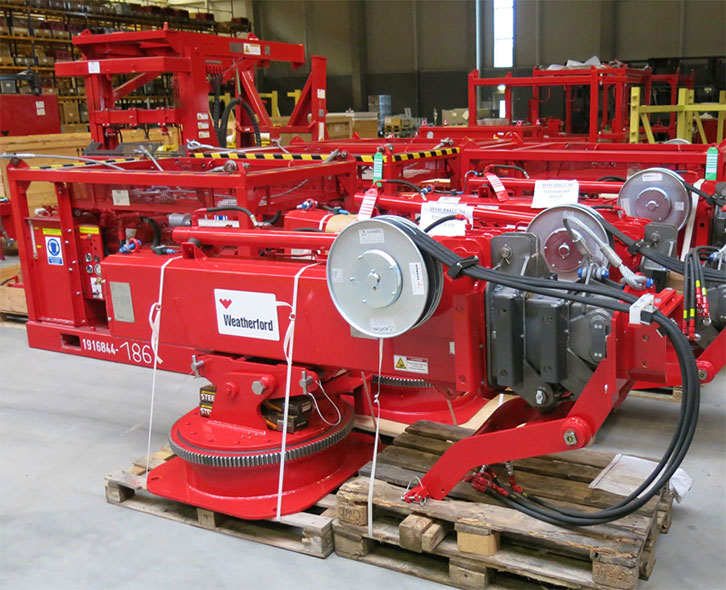

MOT"s Hydraulic Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells. MOT’s

Our TEDA Style power tongs apply correct, uniform torque, reducing costly rod and tubing failures, delivering ample power to make up and break out rods and tubulars from 5/8” rod to 5-1/2” casing. Our series of XQ power tongs come with Bi-Directional jaw systems that save time and enhance safety, and go from make to break with the flip of a knob.

Tongs offer a variety of upgrades from our standard XQ series of TEDA Style models featuring Eaton hydraulic motors for extra torque and reliability, two or three spool directional control valves for more efficient hydraulic operations, and modified structures for higher strength, durability and adaptability to specific job requirements.

Are available from 5-1/2” to 20” pipe and are able to handle both API Standard and PREMIUM (Proprietary Steel Grade) casing connections which require higher torque. Available in a variety of models with hydraulic back-up tongs optional: “KMA", “KHT”, “TQ", “KJD”, “KD” and SE 16-25 with torques ranging from 15,000 ft-lbs up to 55,000 ft-lbs.

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

Type Q2 3/8~10 3/4-48 C Manual Tong is an essential tool in oil drilling operation to fasten or remove the screws of drill pipe and casing joint or coupling. It can be adjusted by changing latch lug jaws and latch steps.

Type Q2 3/8~7-22 LF Manual Tong is used for making breaking out the screws of drill tools and casing in drilling and well servicing operation. The handling size of this type tong can be adjusted by changing latch lug jaws and handling shoulders.

Type Q4~17-135 SDD Manual Tong is used for making up or breaking out the screws of drill tools and casing joint or coupling. It can be adjusted by changing latch lug jaws and handling shoulders.

FYPE Rigid Machinery is one of the leading China manufacturers and suppliers in oil and gas industry. Our company now brings you high quality and competitive price oilfield manual tools drilling power tong, pipe, casing, tubing tong, hydraulic power tong for sale, which is widely used in oilfield. And quick delivery is also offered, please be free to contact our factory.

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for Power Tongs and hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

Spectrum Drilling Tools make manual tongs are equivalent to NOV make HT manual tongs. The manual Tongs are designed for making up and breaking up connections of tubular from lightweight pipes like tubing pipes to heavyweight drill pipes or drill collar pipes. Spectrum drilling tools has 4 different kinds of manual tongs which are used to cover a wide range of pipes ranging from 2.3/8"" to 21"", varying in torque capacity from 10,000 to 100,000 lbs/ft.

Manual Tongs are designed with interchangeable lug jaw which permits each tong to handle different sizes of tubular. By installing hinge jaws (available for some models), bigger tubular sizes can be handled.

We are having all in-house testing facilities to test our manual tongs and ensure the best tongs are supplied to our users. We are following API-7K specifications for manufacturing manual tongs and meeting the quality standards. Spectrum Drilling tools is also ISO certified for manufacturing Manual Tongs.

8613371530291

8613371530291