oilfield power tong rebuilders made in china

Find parts you need to repair or maintain your machines. At Alibaba.com, you can shop for power tong at affordable rates to tackle new obstacles and challenges. In the ever-changing industry, you can find what you need and speak to the supplier directly. Thanks to Alibaba’s collection of wholesale power tong you also get to buy these parts at lower prices, which means you can explore new levels every day more comfortably. From bulldozers to dragline excavators, wheel tractor scrapers to shotcrete machines, any part you need for a heavy-duty mining machinery; you can find it at Alibaba.com.

Looking for purpose-built machine parts? Find them at Alibaba.com. From new components to used parts straight from the manufacturers. Plus, if you need custom-made pieces, you can chat with the supplier, give specifications and wait on delivery. From stone crushers to excavator undercarriage parts, buckets, and even drill bits to get you through the rocks, the power tong from Alibaba offers you the chance to continue operating without a hitch. Whether you are looking to introduce concrete into the rock walls for more consistency and safety during mining, then power tong that goes at wholesale prices at Alibaba will be an excellent addition to your machinery.

Before buying a component, you’d want the equipment to suit your application and offer value. The list of power tong at Alibaba.com lets you dig into earth deposits, and the compare tool checks out other similar parts to give you the information you need to make a purchasing decision. You’ll get wholesale power tong that specializes in mining, with reinforced chassis, and run on more powerful engines. Whether you want to transport minerals or the workers to the mining site, introduce explosives or arms to help you remove materials from your mine pits, Alibaba.com has it all.

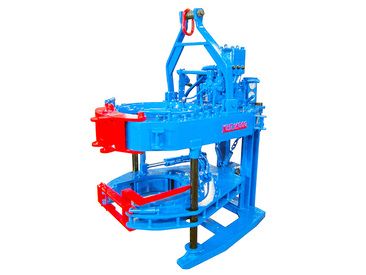

KHT5500 hydraulic power tongs is the open power tongs which is applicable to make up or break out 23/8"-31/2"drill pipes, 23/8"-41/2"tubing and 41/2"-51/2" casing during oil field workover operation. And three-jaw-plate clamping device is adopted in the master tong and back tongs. The device may ensure minimum string damage. It has high operation efficiency and may reduce working intensity of the workers. It can enhance screwing quality of the string and reduce string accidents caused by improper workover operation.

. The tong head is the open structure which is quick and convenient for entering and retreating working position. The integral tong head has good hardness and rigidity;

.The three-jaw-plate clamping device is adopted in the master tong and back tongs. The device may ensure minimum string damage. The front two jaw plates of the master tong are in the swing structure and the back jaw plate is the roller-climbing structure. The assembly and disassembly is very convenient. The optimum tangent-diameter ratio design ensures reliable clamping and easy slope retreating. The back tong is the three-jaw-plate structure pushed by hydraulic cylinder. The structure is simple and the clamping is reliable;

Type Q2 3/8~10 3/4-48 C Manual Tong is an essential tool in oil drilling operation to fasten or remove the screws of drill pipe and casing joint or coupling. It can be adjusted by changing latch lug jaws and latch steps.

Type Q2 3/8~7-22 LF Manual Tong is used for making breaking out the screws of drill tools and casing in drilling and well servicing operation. The handling size of this type tong can be adjusted by changing latch lug jaws and handling shoulders.

Type Q4~17-135 SDD Manual Tong is used for making up or breaking out the screws of drill tools and casing joint or coupling. It can be adjusted by changing latch lug jaws and handling shoulders.

FYPE Rigid Machinery is one of the leading China manufacturers and suppliers in oil and gas industry. Our company now brings you high quality and competitive price oilfield manual tools drilling power tong, pipe, casing, tubing tong, hydraulic power tong for sale, which is widely used in oilfield. And quick delivery is also offered, please be free to contact our factory.

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

The purpose of this utility model just provides a kind of oil field brill and repaiies operation hydraulic power tongs torque wrench moment detection control apparatus.To overcome the deficiency that existing apparatus exists, satisfy the oil field and bore the quality of repairing operation field raising job engineering, to increase work efficiency and economic benefit, the reality that reduces operating cost needs.

The utility model be achieved in that the oil field bore repair operation hydraulic power tongs torque wrench moment detection control apparatus include brill repair the torque signal of installing in the working vehicle obtain mechanism, on the button number of turns obtain mechanism, master controller and moment of torsion controlling organization, do not need doing any change at the hydraulic power tongs of usefulness.

Design philosophy of the present utility model is exactly that torque signal obtains mechanism and connects pressure sensor or pressure transmitter at the convenient place, feed flow path that brill is repaiied in the working vehicle straight-through hydraulic power tongs, and the pressure signal output line on pressure sensor or the pressure transmitter is connected to the torque signal input of master controller.By measuring the pressure signal in the hydraulic power tongs hydraulic circuit, obtain the torque signal that is directly proportional with pressure signal.The last button number of turns is obtained mechanism and is repaiied the liquid path of going back to that leads directly to hydraulic power tongs in the working vehicle at brill conveniently to locate connection traffic sensor or flow transmitter, and the flow signal output line on flow transmitter or the flow transmitter is connected to going up of master controller and detains the lap signal input.By measuring flow signal and the flow velocity signal in the hydraulic power tongs hydraulic circuit, obtain the tach signal of going up the button lap signal and being directly proportional that is directly proportional with flow signal with flow velocity signal.

Repair pressure signal, flow signal and flow velocity signal in the hydraulic power tongs hydraulic circuit in the working vehicle by measuring at brill, obtain torque signal, on detain lap signal, tach signal, safety is obtained required various signals under situation about not contacting directly with hydraulic power tongs like this.

Above-mentioned signal obtains a common feature of mechanism, is exactly to adopt the method for measuring indirectly, obtain hydraulic power tongs torque signal, on detain lap signal, tach signal.The indirect metering system of this employing obtains the structure of signal, its biggest advantage is exactly not change the hydraulic power tongs that is in the adverse circumstances, also can"t help to obtain desired signal on it, so just improved the oil field greatly and bored safety, applicability, the reliability of repairing operation hydraulic power tongs torque wrench moment detection control apparatus and hydraulic power tongs and whole system.

When carrying out torque wrench moment detection control, power supply opening with master controller, master controller just begin the continuous detecting torque signal, on detain lap signal, tach signal, simultaneously can with the continuous detecting moment of torsion, on detain the number of turns, rotary speed data is stored in the master controller, handle through master controller, data are presented on the display screen of instrument.When torque signal, on detain lap signal when surpassing predefined value, the automatically controlled overflow valve action pressure release in the coupled moment of torsion controlling organization of main controller controls reaches the purpose that moment of torsion is controlled.

The utility model obtains mechanism with signal simple in structure and replaces complicated signals collecting transmission system, has improved the reliability of hydraulic power tongs moment of torsion detection control apparatus.The utility model both can reduce production costs, and can reduce construction and operation and maintenance cost again.Use of the present utility model, help improving the quality of job engineering, increase work efficiency and reduce the wastage and increase economic efficiency, make moment of torsion need not to change the hydraulic power tongs that is in the adverse circumstances when detecting control simultaneously, also can"t help to obtain desired signal on it, improved safety, applicability, the reliability of whole system.Make to apply and become possibility.

KHT5500 HYDRAULIC POWER TONGS IS THE OPEN POWER TONGS WHICH IS APPLICABLE TO MAKE UP OR BREAK OUT 2 3/8"-31/2" DRILL PIPES,31/2"-41/2" TUBING AND 4 1/2"-5 1/2" CASING DURING OIL FIELD WORKOVER OPERATION

KHT5500 hydraulic power tongs is the open power tongs which is applicable to make up or break out 2 3 / 8 "-3 1 / 2 " drill pipes, 3 1 / 2 "-4 1 / 2 " tubing and 4 1 / 2 "-5 1 / 2 " casing during oil field workover operation. And three-jaw-plate clamping device is adopted in the master tong and back tongs. The device may ensure minimum string damage. It has high operation efficiency and may reduce working intensity of the workers. It can enhance screwing quality of the string and reduce string accidents caused by improper workover operation.

Straight Tong Die Driver: Used for die slot redressing, the straight tong die driver is the simplest of type of rig tong. Though it is also the simplest type of rig tong to use, it is also the least safe of the three. Its handle and handguard protect hammer blows from falling onto the grip. Straight tong die drivers are lightweight—under eight pounds—and measure in at around 1”.

Angled Tong Die Driver: The angled tong die driver has a grip that’s angled away from the perpendicular tong as well as brass guards for the tong tip and handle, making this rig tong safer than the straight tong die driver. While this tong is safer, however, it’s actually harder to keep the angle tong die driver in place. This driver is similar in length to the straight tong die driver, but is about two pounds heavier, weighing in at over nine pounds.

Hammerless Tong Die Driver: This variety of tong die driver is made up of a hand pipe that can be used to apply pressure to the tong’s tip without using a hammer at all. This option is the safest of the three driver types because there’s no hammer required, it’s also the slowest driver for this same reason. The hammerless tong die driver is about as long and weighs as much as the straight tong die driver.

What oilfield tools does your operation need? Keystone Energy Tools has atool to fit your bill.Contact us today to learn more about how rig tongs can make your work environment safer, and to learn more our other oil and gas industry products.

●The tong head uses inner curved roller climbing and cliping mechanism and needn"t to change any part during making up or breaking out the tubing thread which diameter is "2 7/8″"or"3 1/2″".

—–Liners——Mission Ceramic Liner——Mission Supreme Liner—–Piston Rods——Blak-JAK HydrA-LIGN Piston Rod System——Mission Self Aligning Piston Rod—–Pistons——Mission Green Duo Piston——Mission Slip Seal Bullitt Piston——Mission Supreme Piston——Mission Blue Lightning Piston——Mission White Lightning Bonded Piston——Mission White Lightning Slip Seal Piston—–Valves and Seats——Mission FK-1 Valve——Mission FK-N Valve——Mission Roughneck™ and Roughneck™ HP——Mission Service Master II——Mission Silver Top Valves and Seats——Mission Super Service Vavles and Seats——Service Master Drilling Valve——Supreme Valve and Seat—–Fluid End Modules and Accessories——Fluid End Accessories——-Blak-JAK Torque Pro——-Blak-JAK Torque Pro Lite——-Mission Bushing X-tractor——Liner Retention Systems——Modules (Mission L 7500 Module)—–Fluid Transfer Systems——Brine Filtration System——Centrifugal Pump Unitization Configurations——Custom Cooling Solutions——High Pressure Wash down Systems——NOV Mission Potable/Sanitary Water Pressure Sets——Resources—–Handling Tools——Adapter Rings——Air Operated Elevators——-A-Series Collar Type——-G-Series 18 Degree Center Latch——-Y-Series Slip Type——BHAT——Bushings——-Casing Bushings——-Casing Spiders——-MBH 1250——-MDSP Series——-MPCH Series——-MSPC Series——-MSP Series——-Roller Kelly Bushings——Casing Running Tools——-CRT 350 and 500 Casing Running Tool——Custom Dies and Inserts——Elevator Spiders and FMS——-BJ-250——-BJ-350——-FMS-275——-FMS-375——-V-1000——-V-500——-V-750——Hydraulic Elevators——-BX-3——BX-4-35——BX-4-50——BX-4-75——BX-5——BX-7——BXS Series——H-SJH Type——UX Horse Shoe——Links——-Perfection Links——-Weldless Links——Manual Elevators——-A-Series Collar Type——-DC Dolly——-G-Series 18 Degree Center Latch——-S-Series Auxiliary——-SBX7——-X-Series Collar Type Side Door——-Y-Series Slip Type——Manual Tongs——-HT Manual Tongs——Power Slips——-Power Slip Frame——-PS-15 Power Slip——-PS-16 Power Slip——-PS-21 Power Slip——-PS-30 Power Slip——-PF495 Power Slip——-SLT——Power Tools——-KS-6600——-KS-6800——-SSW-30——-SSW-40——-TW-61 Hydraulic Torque Wrench——Rotary Support Tables——-RST375——-RST495——-RST495 False——-RST495 Heavy——-RST495 Without Slip Ring——-RST605——-RST605 False——-RST605 Heavy——-RST605 Without Slip Ring——-RST755 Without Slip Ring——Slips——-CMS-XL——-DCS Series——-MP Series——-SD Series——-Type C——-UC-3——Resources——-BX Elevators TMS 1 of 2——-BX Elevators TMS 2 of 2——-Handling Tools TMS——-Rotary Support Table TMS—–Hoisting——Drawworks——-AHD Drawworks——–AHD-1000 Active Heave Drilling Drawworks——–AHD-1250 Active Heave Drilling Drawworks——–AHD-500 Active Heave Drilling Drawworks——–AHD-750 Active Heave Drilling Drawworks——-Drilling Drawworks——–AC Gear Driven Drawworks———ADS-10T AC Electric Gear Driven Drawworks———ADS-30Q AC Electric Gear Driven Drawworks———SSGD-1000 AC Gear Driven Drawworks———SSGD-1250 AC Gear Driven Drawworks———SSGD-360 AC Gear Driven Drawworks———SSGD-500 AC Gear Driven Drawworks———SSGD-750 AC Gear Driven Drawworks——–DC Chain Driven Drawworks———1625-UDBE DC Chain Driven Drawworks—–Iron Roughnecks——AR3200 Automated Iron Roughneck——HydraTong™ ARN-270——HydraTong™ MPT-270——Iron Roughneck Accessories——-Casing Module——-Hydraulic Mud Bucket——-Pipe Doper System——Resources——ST 100 Iron Roughneck——ST-120 Iron Roughneck——ST-160 Iron Roughneck——Jacking and Skidding——-Jacking Systems——-Jacking Claw Skidding Systems——-Rack and Pinion Skidding Systems——-Toggle Gripper System ——Lifting and Handling——-Market Segments——–Construction———SUBSEA CONSTRUCTION VESSEL———PIPELAY AND CABLELAY VESSEL———WINDMILL INSTALLATION VESSEL———CRANE VESSEL/ LIFT BOAT———IMR / WELL INTERVENTION VESSEL———ANCHOR HANDLING VESSEL——–Drilling———DRILLSHIP———JACK UP———SEMI SUBMERSIBLE———-FPSO/FPS———-SEMI SUBMERSIBLE/ SPAR/ TLP———-JACKET/ FIXED INSTALLATION——–Production———-FPSO/FPS———-SEMI SUBMERSIBLE/ SPAR/ TLP———-JACKET/ FIXED INSTALLATION——-Product Catalogue——–Anchor Handling Systems———Anchor Handling and Towing Winch———Anchor Handling Equipment Package———Secondary Winch——–Cranes———Next Generation Subsea Knuckle Boom Cranes———Box Boom Cranes———-Knuckle Boom Crane———-Single Boom Crane———-Telescopic Boom Crane———Lattice Boom Cranes———-Around the Leg Crane———-DNS Crane———-MSB Crane———-OC L Crane———-Unit Crane———Heavy Lift Cranes———-Around the Leg Crane———-MSB Crane———-Post Crane———-Tub Mounted Crane———Other Cranes———-A-Frame———-Stevedoring Cranes———Subsea Cranes———-Subsea Box Boom Crane———-Subsea MSB Crane——–Hose Loading Stations——–Mooring Systems———Mooring System for Drilling Units———Mooring System for Production Units——–Pipe Lay and Cable Lay Systems———Cable Lay Systems———Pipe Lay Systems———Tensioner———Upending Control Systems——–Riser Pull In Systems——Motion Compensation——-Crown Mounted Compensators (CMC)——-Direct Line Compensators (DLCs)——-Drill String Compensators (DSCs)——-N-Line Tensioner system——-Resources——-Tensioners——Offshore Units——-Drillship——-Fixed Platforms——-Jackup Rig——-Semi-submersible——-Well Intervention——Pipe Handling——-Horizontal Pipe Handling——–Catwalk Machines——–Catwalk Shuttle——–Pipe Deck Machines (PDM)——–Pipe – Riser Gantry Cranes——–Pipe Transfer Conveyor (PTC)——–PipeCat™ Laydown System——–Robotic Arms———DFMA-P——–DFMA-U——–UHT——-Horizontal-To-Vertical Pipe Handling——–Custom Dies and Inserts——–Hydraulic Mousehole——–Service and Access Baskets——-Pipe Handling Accessories——-Pipe Handling Cranes——-Resources——-Vertical Pipe Handling——–Racking Systems———PRS 4i/HR III———PRS5,6/HR IV———PRS8i and Hydraracker XY (HRXY)——–Standguard——Power Systems——-Hydraulic Power Units——-Motors——-Resources——-Energy Recovery——–Rotary Tables——Rotating Equipment——Structures——-Derricks——Top Drive Systems——-Fixed Electric Top Drives——-Resources——-Washpipe Systems

During last 10 years we had supplied high quality oilfield spare parts and repair service to more than 50ea drilling contractors worldwide as follows:

There are any drilling rigs and oilfield equipment’s spare parts requirements from your company, please let us know, we will supply best solutions to your side.

8613371530291

8613371530291