oilfield power tong rebuilders and repairs in stock

World Petroleum Supply, Inc stocks a wide selection of West International Consulting, Inc. Power Tongs & Hydraulic Power Units to suit every application. All power tongs products of which are API Certified.

Tongs - Power - BJ sucker rod tong adopts advanced sucker rod or tubing technology and has a compact structure, high reliability and is safe and convenient to operate.

Tongs - Power - New Carter Tool Co. Inc., CT93R Hydraulic powered tubing tong. Complete with 2-3/8" to 3-1/2" jaw assemblies, standard motor, torque gauge assembly, pressure relief valve... More Info

Tongs - Power - New Carter Tool Co., Inc. 5-1/2" CTSX Hydraulic Tubing Tong with heavy case and cover; complete with rigid hanger assy., suspension spring assy., front end control assy.,... More Info

Tongs - Power - New Carter Tool Co. Inc. M-Series power sucker rod tongs, complete with spring hanger assy., gate assy., front end control assy., pressure gauge assy., two 90 degree XH s... More Info

Tongs - Power - New Carter Tool Co., Inc. 4-1/2" RSX Hydraulic Tubing Tong with heavy case and cover; complete with rigid hanger assy., suspension spring assy., front end control assy., ... More Info

Tongs - Power - D D 58-93-2-R Power Tubing Tong is smaller, lighter, and faster than the Foster 5893R. The D D 58-93-2-R Tong is capable of gripping tubulars from 1 5/16" to 7" o.d. More Info

Tongs - Power - FARR TONG MODEL KT 14,000 RINEER GA37 MOTOR, LIFT VALVE ASSEMBLY TORQUE CAPACITY: 50,000 FT/LB SIZE RANGE 4 1.2-14 WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN ... More Info

Tongs - Power - FARR TONG MODEL KT20,000 STAFFA 080 MOTOR, LIFT VALVE ASSEMBLY TORQUE CAPACITY: 50,000 FT/LB SIZE RANGE: 7-20 MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READ... More Info

Tongs - Power - FARR MODEL KT5500 HYDRAULIC TUBING TONG C/W 2 SPEED RINEER MOTOR, SIZE RANGE: 2-3/8 IN. - 5-1/2 IN. OD, TORQUE RTED: 18,700 FT/LB C/W SAFETY DOOR MOST SIZES OF FARR POWER... More Info

Tongs - Power - FARR TONG MODEL KT5500 TORQUE CAPACITY: 18000 FT/LB SIZE RANGE: 2 1/16-5 1/2 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIA... More Info

Tongs - Power - FARR TONG MODEL KT5500 5 1/2 IN. TONG TORQUE CAPACITY: 18,000 FT/LB SIZE RANGE: 2 1/16-5 1/2 IN. OD, RINEER 15-13 MOTOR, HIGH TORQUE CLINCHER BACKUP TRIPLE VALVE ASSEMBLY... More Info

Tongs - Power - FARR TONG MODEL KT7585 TORQUE CAPACITY: 25000 FT/LB SIZE RANGE: 2 1/16-8 5/8 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIA... More Info

Tongs - Power - FARR TONG MODEL KT7585 8 5/8 IN. TONG TORQUE CAPACITY 25,000 FT/LB SIZE RANGE: 2 1/16-8 5/8 IN. OD, RINEER 15-15 MOTOR CLINCHER BACKUP, TRIPLE VALVE MOST SIZES OF FARR PO... More Info

Tongs - Power - FARR TONG MODEL LW9625 TORQUE CAPACITY 12000 FT/LB SIZE RANGE 2 7/8 -9 5/8 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIATE... More Info

Tongs - Power - Farrs newest tubular connection tool offers a significantly reduced rig footprint, while continuing to deliver power & uncompromising reliability. The simple design drast... More Info

Tongs - Power - Farr Canada"s newest tubular connection tool offers a significantly reduced rig footprint, while continuing to deliver power and uncompromising reliability. The simple de... More Info

With our 20,000 sqft facillity and over a century in combined experience, we have been a leading supplier of well servicing equipment and supplies for over 40 years.

We at Maverick Oilfield Specialties understand your needs and are ready to assist you in any way we can. We can handle all your needs, from repairs and general maintainence, to complete rig-up packages. We stock everything from pliers and pipe wrenches, to BOP"s and Power Tongs.

Wil-Tech provides maintenance, repair, and complete overhaul services for tubing tongs. We stock components for all major brands of pipe handling product, and a variety of not so common components. Our technicians are extremely capable and well equipped to maintain and refurbish your pipe tongs, they offer seal replacements, bearing replacements, gear replacements, backup repair, motor replacements and repair, jaw replacements, and preventative maintenance to reduce the frequency for complete overhaul.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because a properly maintained pipe tubing tong tends to operate longer, more efficiently and safer. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides inspection services for open and closed tubing tongs, our pipe handling department are well equipped and provided thorough inspections on all componentry including; gears, hydraulic motors, fittings, jaws, cylinders, backups, and structural components. Over the course of usage tubing tongs face a barrage of punishment that can reduce efficiency; regular inspections can increase the longevity of your asset, keeping it operating smoothly and safely. Properly functioning tongs reduce operator frustration, reducing risk of injury while improving productivity; as an asset owner that is what you want.

Wil-Tech provides tubing tong rental services. While your tongs are being repaired you don’t have to worry about downtime. Not all malfunctions can be quickly remedied in the field, if your tongs experience a failure during production rest assured our set of rental tongs can get you out of the bind. We offer delivery to site and can pick up your malfunctioning tongs to be brought back to our shop for repair. We hope it doesn’t come to this for our clients but these situations occur and we want to offer our clients the right solution.

Wil-Tech provides paint preparation and painting services for tubing tongs. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s tongs out the door working and looking as close to as new as possible.

Wil-Tech provides performance testing service on all tubing tongs prior to leaving our shop as a quality assurance measure. Our technicians utilize a 50hp test bench to perform a variety of tests on the tubing tongs to ensure functionality, sealing, relief and performance.

Wil-Tech provides troubleshooting services for hydraulic tubing tongs. Whether in our shop or on-site, our technicians and facilities and mobile units are equipped to troubleshoot your tubing tong. If your asset isn’t operating as expected let our technicians identify and resolve the problem.

Wil-Tech services and installs torque gauge and sensing equipment on tubing tongs. Our technicians repair, calibrate and certify gauges. Our component technicians work in tandem with our pipe handling department to ensure your gauges are reporting accurate measurements.

Additionally, we offer an aftermarket torque monitoring systems to create a smart torqueing system. Our mobile IQAN torqueing package, is versatile, mobile, accurate, and easy to both install and use. The IQAN records torque at each connection in a string of tubing, it’s easy and produces reports that drive accountability and quality assurance. Don’t leave any question in your clients mind as to whether the job was done right.

Wil-Tech provides pipe, rod and tubing elevator repair and maintenance services. Our technicians thoroughly refurbish elevators to as close of an as-new product as possible. We stock a variety of elevator components and products to keep them function smoothly and latching securely.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because as with any device securing an overhead load, safety is of the utmost concern.. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides paint preparation and painting services for pipe, rod and tubing elevators. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s elevators out the door working and looking as close to as new as possible.

Wil-Tech provides hydraulic top-drive repair and maintenance services. Our technicians thoroughly repair and replace components to ensure your top-drive is as close of an as-new product as possible. We stock a variety of top-drive components and products to keep them function safely and efficiently.

We encourage our customers with pipe handling equipment to regularly maintain their asset, due to the size of top-drives and being an overhead load during operation, safety is of the utmost concern. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides hydraulic top-drive inspection services. Our technicians meticulously inspect and document condition of the hydraulic top-drive and provide a thorough review of their findings. We offer our clients the convenience of performing our inspection services on site and in the field.

Wil-Tech provides maintenance and repair services for hydraulic kelly spinners. Our technicians perform general maintenance tasks, including seal replacements, bearing replacements, fitting replacements, greasing, chain replacements as well as component replacements and complete overhauls. We encourage our customers with pipe handling equipment to regularly maintain their asset, because a properly maintained pipe Kelly spinner tends to operate longer, more efficiently and safer. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides inspection services for hydraulic kelly spinners, our technicians perform a thorough review of the hydraulic motor, gears, fittings and connections, jaws, bearings and structural components. Regular inspections can identify problems before they end up causing damage and/or injury and should be included in the asset’s preventative maintenance schedule to protect both the asset and its operators.

Wil-Tech provides troubleshooting services for hydraulic kelly spinners. Whether in our shop or on-site, our technicians and facilities and mobile units are equipped to troubleshoot your kelly spinner. If your asset isn’t operating as expected let our technicians identify and resolve the problem.

Wil-Tech provides maintenance, repair, and complete overhaul services for rod tongs. We stock components for all major brands of pipe handling product, and a variety of not so common components. Our technicians are extremely capable and well equipped to maintain and refurbish your pipe tongs, they offer seal replacements, bearing replacements, gear replacements, backup repair, motor replacements and repair, jaw replacements, and preventative maintenance to reduce the frequency for complete overhaul.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because a properly maintained pipe rod tong tends to operate longer, more efficiently and safer. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides inspection services for open and closed rod tongs, our pipe handling department are well equipped and provided thorough inspections on all componentry including; gears, hydraulic motors, fittings, jaws, cylinders, backups, and structural components. Over the course of usage rod tongs face a barrage of punishment that can reduce efficiency; regular inspections can increase the longevity of your asset, keeping it operating smoothly and safely. Properly functioning tongs reduce operator frustration, reducing risk of injury while improving productivity; as an asset owner that is what you want.

Wil-Tech provides rod tong rental services. While your tongs are being repaired you don’t have to worry about downtime. Not all malfunctions can be quickly remedied in the field, if your tongs experience a failure during production rest assured our set of rental tongs can get you out of the bind. We offer delivery to site and can pick up your malfunctioning tongs to be brought back to our shop for repair. We hope it doesn’t come to this for our clients but these situations occur and we want to offer our clients the right solution.

Wil-Tech provides paint preparation and painting services for rod tongs. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s tongs out the door working and looking as close to as new as possible.

Wil-Tech provides performance testing service on all rod tongs prior to leaving our shop as a quality assurance measure. Our technicians utilize a 50hp test bench to perform a variety of tests on the rod tongs to ensure functionality, sealing, relief and performance.

Wil-Tech provides troubleshooting services for hydraulic rod tongs. Whether in our shop or on-site, our technicians and facilities and mobile units are equipped to troubleshoot your rod tong. If your asset isn’t operating as expected let our technicians identify and resolve the problem.

Wil-Tech services and installs torque gauge and sensing equipment on rod tongs. Our technicians repair, calibrate and certify gauges. Our component technicians work in tandem with our pipe handling department to ensure your gauges are reporting accurate measurements.

Additionally, we offer an aftermarket torque monitoring systems to create a smart torqueing system. Our mobile IQAN torqueing package, is versatile, mobile, accurate, and easy to both install and use. The IQAN records torque at each connection in a string of rod, it’s easy and produces reports that drive accountability and quality assurance. Don’t leave any question in your clients mind as to whether the job was done right.

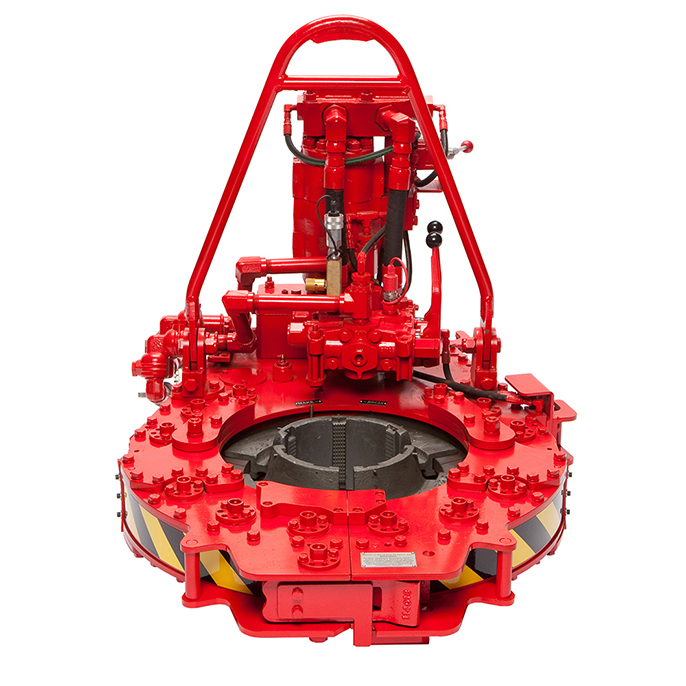

Wil-Tech provides maintenance and repair services for hydraulic spiders. Our technicians thoroughly refurbish tubing spiders to as close of an as-new product as possible. We stock a variety of components and products to keep them gripping and latching securely.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because as with any device securing downhole tools, safety is of the utmost concern. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger. Save yourself the cost of the damages and fishing tools and ensure you’re properly maintain your hydraulic spiders.

Wil-Tech provides inspection services for hydraulic tubing spiders, our technicians perform a thorough review of the hydraulic cylinders, jaws and structural components. Regular inspections can identify problems before they end up causing damage and/or injury and should be included in the asset’s preventative maintenance schedule to protect the asset, its operators and its owner.

Wil-Tech provides paint preparation and painting services for tubing spiders. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s spiders out the door working and looking as close to as new as possible.

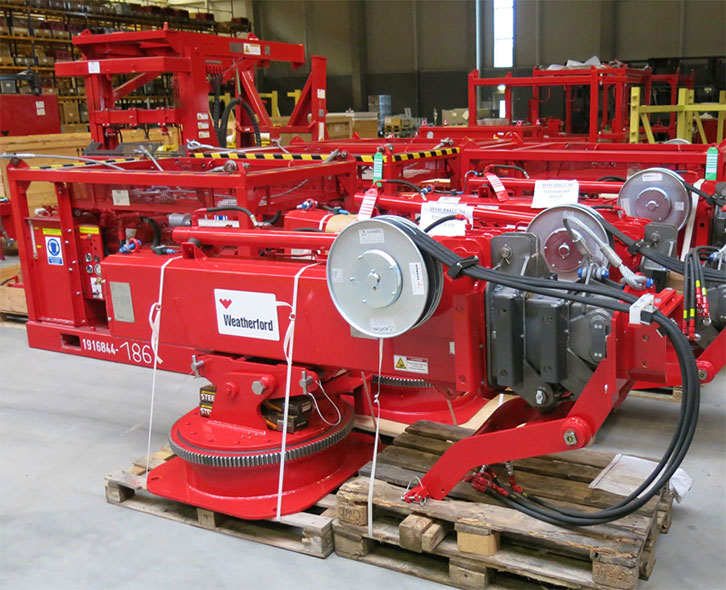

Here at TIOT, we pride ourselves in only selling high-quality, new and refurbished oilfield tools and equipment. We carry a wide range of oilfield tools for sale and rent, including: elevators, power tongs, power units, tong test stands, casing running tools, casing tools and rotary tools. We repair, recertify and test all of our drill pipe and casing handling equipment in house including inspecting, welding, machining, MPI and load tests. We’re API and ISO Certified from the American Petroleum Institute. Texas International Oilfield Tools stocks and distributes for several manufactures including Alltorque, ConTech, Tesco, McCoy, Starr, and Volant. Explore our wide range of tubular running equipment and pipe handling tools today!

Texas International Oilfield Tools stocks its own inventory of new, used, reconditioned and certified tools and equipment. With our 30 years in the industry we have a huge network to provide any drill pipe, tubular or casing tool needed for your operations. Call us Today!

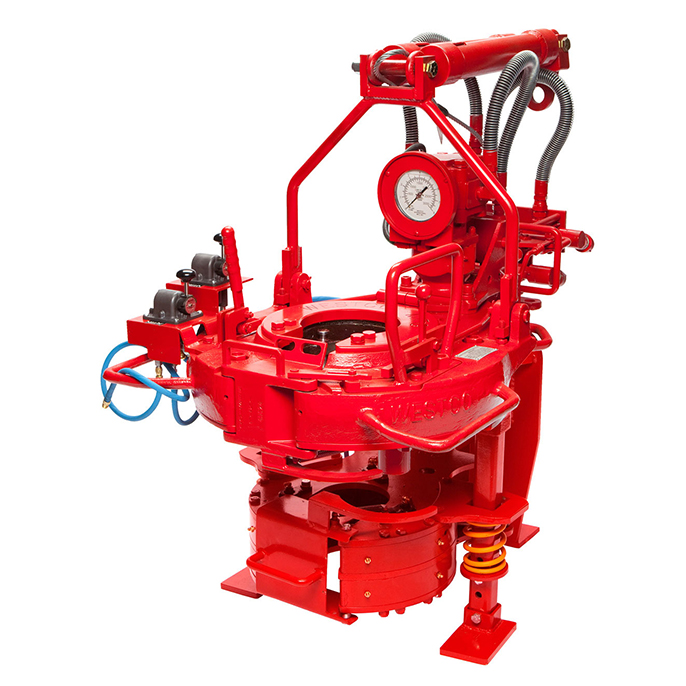

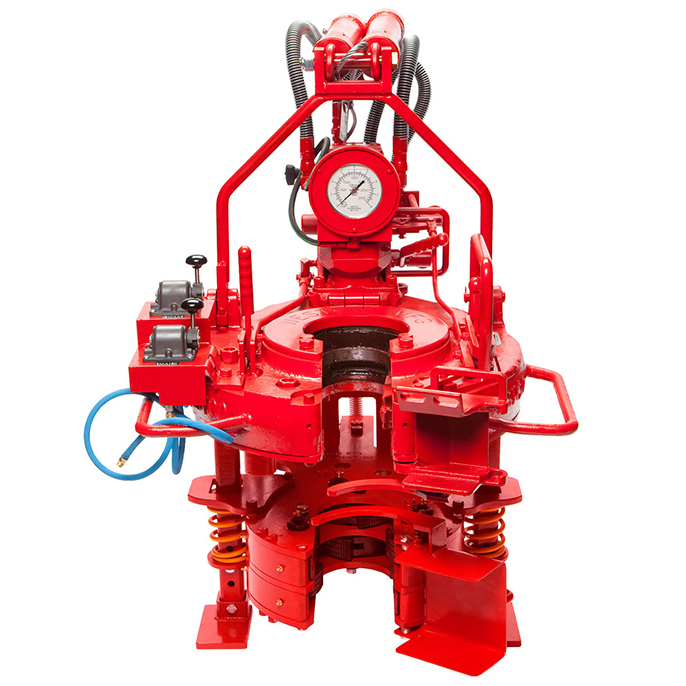

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

Tong Line Pull Gauges and Tong Torque Gauges both tell the operator the amount of torque being applied to oilfield tongs; however, they perform this necessary task differently. Although they both measure the force applied to the pipe in make up and break out situations, how they measure this force is what makes these two gauges different. Knowing which tong gaugewill work best for your application and employees is all important in selecting a tong gauge.

The biggest difference between these two gauges is how and what they measure. A tong line pull gauge measures true force (force/pounds), so what you see on the gauge is exactly what’s being applied to the pipe. Basically, it’s the what-you-see-is-what-you-get gauge. A tong torque gauge, on the other hand, measures the force that is being applied to the load cell and reads this force in foot/pounds. A more detailed explanation of both gauges follows.

A tong line pull gauge is universal. As long as the tong is a manual tong, a tong line pull gauge will fit on any hydraulic tong system. No matter what the tong’s handle length, a tong line pull gauge will measure force/pounds. The advantage to these gauges is that because they are universal, they can be used on any manual tong system. For example, you have two tongs, one with a 48 inch handle, and one with a 36 inch handle. You can use a tong line pull gauge with each tong, either the 48 inch handle or 36 inch handle, and measure the force pounds being applied to the drill pipe. Having this gauge on hand can be very useful when you have to move from different manual tong systems with different handle lengths. These systems, consisting of gauge, hose, and load cell, are great for the driller who wants to measure force/pounds on a variety of manual tongs.

Handle lengths are measured from the center of the tong to the end of the handle. If this measurement is in inches, it will need to be converted to feet in order to find max torque.

Once you have the max torque needed and the handle length in feet, you can complete the formula. The example below shows the formula in action. If you want to measure the maximum torque of 18,000 foot/pounds and you have a handle length of 34 inches, the calculations will look like this:

In this instance, when trying to determine foot/pounds and the reading he needs on the gauge, the driller will need to multiply 2.83 by the reading on the gauge (in this instance 6360.42) to make sure he’s reaching the torque required. Alternately, the drilling can use the maximum torque required, divide it by the handle length to determine what the optimal reading will be.

Tong torque gauges can be used on manual tongs or power tongs, but the handle length must never change because these gauges are not universal. A tong torque gauge is calibrated to a specific tong handle length and thus reads in foot/pounds instead of force/pounds. The advantage to the gauge readings being foot/pounds is that the driller does not have to convert the gauge measurement in order to know the foot pounds being imposed on the drill string. By doing the math beforehand, the driller will avoid any miscalculations that could cause possible twistoffs. The calculations are completed when the system is calibrated, taking the worry out of the driller’s hands and making the measurement of torque easier in the field. These systems, consisting of gauge, hose, and load cell, are great for the driller who wants to measure foot pounds without calculations in the field.

If you aren"t sure where to head to buy your supplies of top-quality oil field products , give us a try. We"re family-owned and operated, and have been in business since 1998. Conveniently located in Casper, WY, we have over 45 years of experience serving the area. We continue to have a lot of repeat customers who depend on us to get their oil field equipment supplies and repairs done hassle-free! We"re fully insured too!

8613371530291

8613371530291