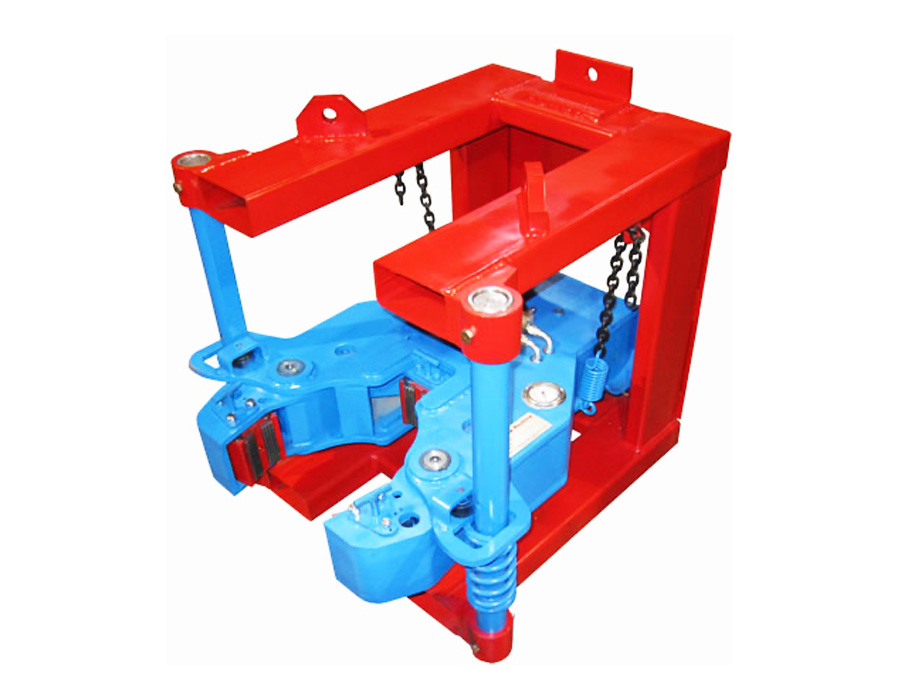

power tong assy 3500-6.5k back up assembly 4 supplier

Our power tongs are built to last. With 1 motor options for the 6 1/4” hydraulic power tong, you crew can reach rated torque at 2500 psi. Which means, the tools can reach their rated torque dependably on ever single joint, every day.

With an investment like this, you don’t want one malfunctioning part to be the reason why your equipment isn’t performing. That’s why we build our tongs to be serviceable, high in quality. By using an ISO 9001:2015 quality system, we maintain a close eye on our products.

Our power tongs are built to last. With 3 motor options for the 13 5/8” hydraulic power tong, you crew can reach rated torque at 3000 psi, 2250 psi, or 2000psi. Which means, the tools can reach 35,000 ft-lb of torque on every single joint, every day.

With an investment like this, you don’t want one malfunctioning part to be the reason why your equipment isn’t performing. That’s why we build our tongs to be serviceable, high in quality. By using an ISO 9001:2015 quality system, we maintain a close eye on our products.

The 9-5/8” power tong with Rineer GA15-13 two-speed hydraulic motor, motor valve, lift cylinder valve, rigid sling, FARR® hydraulic backup, configured for compression load cell.

Eckel customarily provides compression style hydraulic backups to measure the torque exerted in make-up and break-out operations. A load cell bracket is located at the rear of the backup which a compression load cell is inserted.

Eckel also provides tension type backups when operator preferences require a tension configuration. Tension backups unlike compression have identical handle lengths as the tong. This allows the torque gauge assembly to be calibrated for proper torque readings in both tong and tong & backup configurations. The tension load cell is mounted on the rear of the backup between the roller bracket yoke and load cell mount.

Eckel offers a broad range of accessories to compliment our power tongs. From torque control systems and gauges to case handles and tong straps, Eckel has the right accessory option for your specific application.

Eckel offers torque control systems to monitor the torque turn values when making up tubular connections with the system automatically stopping tong operation once reaching a specific torque. Any flaws in the make-up process will be readily shown in a graph.

The Door Interlock is offered as an optional safety feature for use with the power tong to prevent accidental operation of the power tong when the door is open. The door interlock prevents tong operation whenever the tong door is open by impeding hydraulic fluid to the tong motor.

A hydraulic Tri-Grip® or Cam Backup tool is optionally supplied with Eckel tongs. In operation this tool provides a backup when in break-out or make-up situations. This hydraulically operated backup tool, uses hydraulic cylinders and a head arrangement to insure slip-free operation.

A standard feature on many of our tongs. Dies have evolved since tongs became commonplace in the oilfields. Eckel has been at the forefront of this developing technology with the development of larger wrap-around type dies for many of its tong models. We offer coarse tooth design for normal carbon steel pipe and collars and fine tooth for special alloys such as 9, 13, 23, 25 chrome and fiberglass to greatly minimize markings on the tubulars.

Have set a NEW industry standard for handling Corrosion Resistant Alloys (CRA) tubular goods. Eckel True Grit® Dies are used on chrome tubulars where reduced die penetration and die marking is greatly desired. Field tests have shown that Eckel"s True Grit® Dies last up to 3 tme longer than other manufacturer"s grit faced dies. These dies actually perform better than any steel tooth dies when running (SUPER or HYPER) Chrome. Eckel"s True Grit® Dies are heat treated and do not deform.

Designed for improved safety when handling the tong. Up to four Case Handles can be optionally mounted on most tong models. Large top and bottom caps help protect the operator when maneuvering the tong on and off the tubulars.

Eckel continues to set industry safety standards with the optional Finger Guard Option. This shield covers the gap between the tong door and tong body, without limiting door operation. Door will open and close freely.

Industrial strength straps feature a rubber gripping surface to allow for easily pulling the tong on and off the tubular. These optional straps are mounted on the tong door and on both sides of the solid hanger area of the tong using a Lark"s Head Knot.

The adjustable motor port relief valve is used to control or limit the hydraulic pressure to the tong motor thus controlling the maximum torque output of the power tong. The valve controls only the hydraulic pressure to the tong motor leaving full system pressure available for other functions such as lift cylinder and hydraulic backup.

RPM Control: The RPM Control is a flow divider that decreases the amount of hydraulic fluid that reaches the tong, the remaining fluid is returned to the reservoir. By decreasing the amount of fluid reaching the tong the operator is able to control the maximum RPM"s the tong will deliver.

Tongs equipped with the optional Swivel Joints have improved hose life by absorbing system shock when pressured up and preventing twisting, kinking of the hydraulic hoses. In addition tongs are maneuvered more freely on the rig floor on and off the tubular.

The optional torque gauge assembly is used to measure the torque exerted in make-up or break-out operations. Consisting of a hydraulic cylinder and torque gauge connected together by a pressure hose, the torque gauge assembly senses and indicates the torque developed during an operation. For operation, the hydraulic cylinder is connected by a shackle to the rear of the tong; and a snub line is connected to the cylinder. The snub line is tied off to a solid part of the rig structure to form an angle of 90� in order for the gauge to indicate accurate torque readings.

This cylinder provides a means for raising and lowering the tong during operations and is recommended with tongs that have a hydraulic backup due to the extra weight of the tong. The lift cylinder maximum of travel varies depending on tong size.

The optional spring hanger is designed to permit the tong to move up or down to allow for thread length in make-up and break-out operations. When used, the spring hanger should be attached directly to the tong bridle ring and used as a hanger for the tong.

8613371530291

8613371530291