power tong drilling quotation

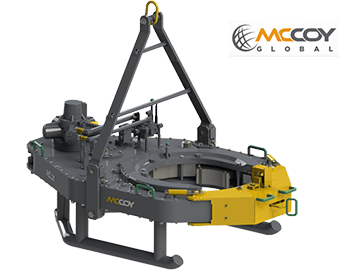

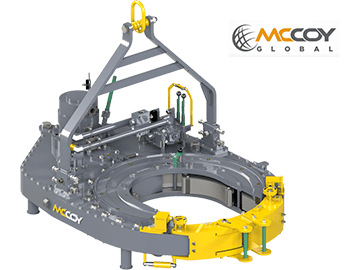

The HD31000 casing tong can handle tubulars as small as 10-3/4″ and as large as 31″ in diameter. Other sizes can be special-ordered. Tong can be mounted on either a CLINCHER® or a FARR® hydraulic backup. Available with McCoy’s patented WinCatt® data acquisition and torque control system for the make-up of tubular connections.

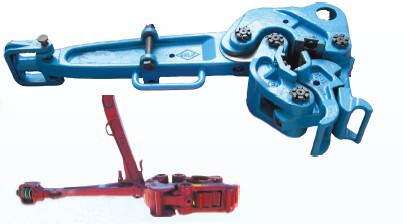

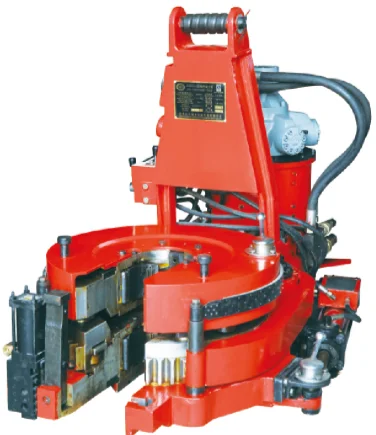

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

Drill pipe, an industrial tubular used for drilling into the ground, are screwed together using a tong to form a drill string. Eckel Drill Pipe Tongs reduce drill time and costs while providing a safe means environment. These tongs are available in sizes 2 3/8 - 10 inches. Available with an array of models to choose from Standard, Hydra-Shift, High Torque, and Ultra High Torque, depending on your torque requirements.

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

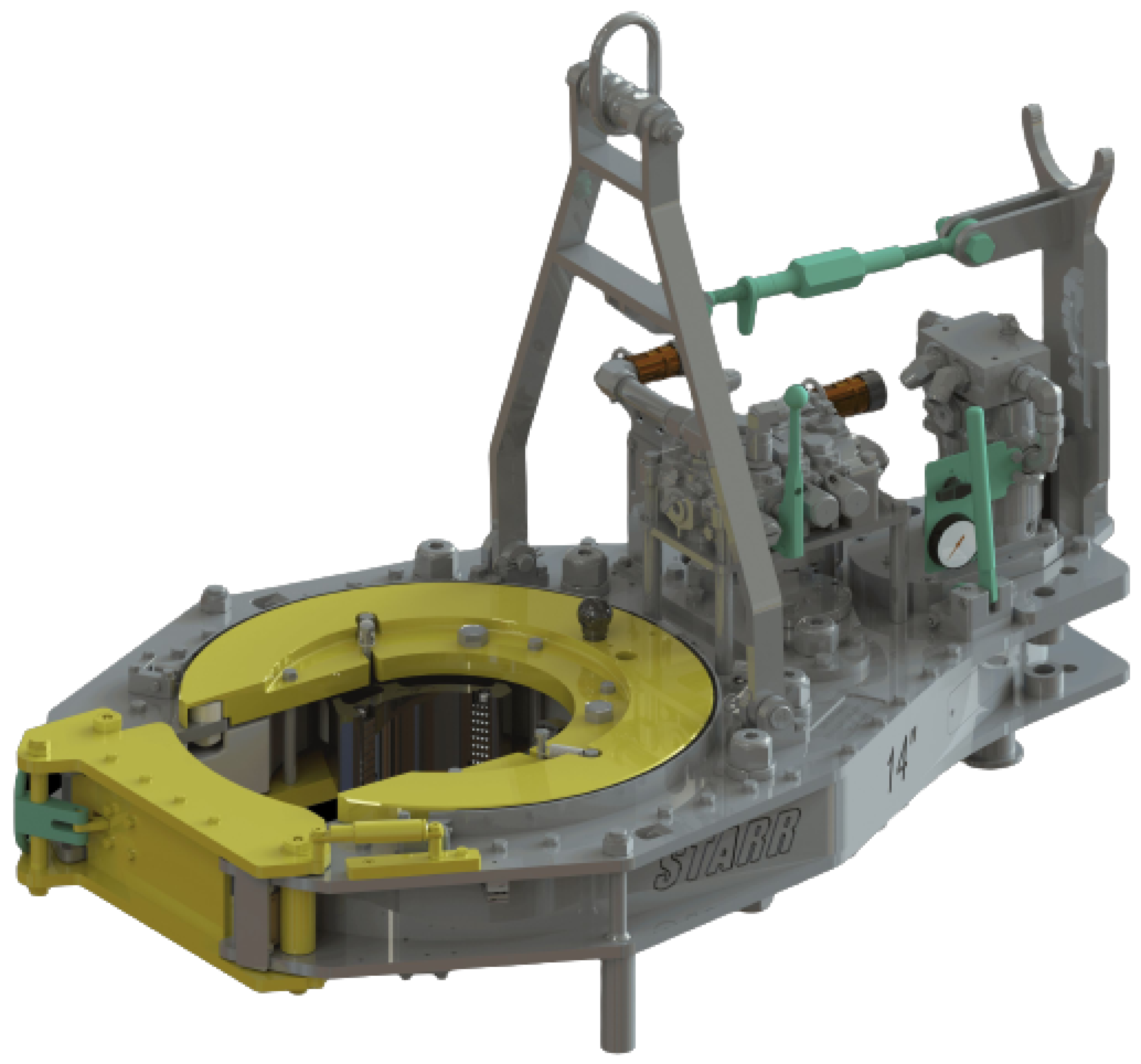

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

Find parts you need to repair or maintain your machines. At Alibaba.com, you can shop for drilling rig tongs for sale at affordable rates to tackle new obstacles and challenges. In the ever-changing industry, you can find what you need and speak to the supplier directly. Thanks to Alibaba’s collection of wholesale drilling rig tongs for sale you also get to buy these parts at lower prices, which means you can explore new levels every day more comfortably. From bulldozers to dragline excavators, wheel tractor scrapers to shotcrete machines, any part you need for a heavy-duty mining machinery; you can find it at Alibaba.com.

Looking for purpose-built machine parts? Find them at Alibaba.com. From new components to used parts straight from the manufacturers. Plus, if you need custom-made pieces, you can chat with the supplier, give specifications and wait on delivery. From stone crushers to excavator undercarriage parts, buckets, and even drill bits to get you through the rocks, the drilling rig tongs for sale from Alibaba offers you the chance to continue operating without a hitch. Whether you are looking to introduce concrete into the rock walls for more consistency and safety during mining, then drilling rig tongs for sale that goes at wholesale prices at Alibaba will be an excellent addition to your machinery.

Before buying a component, you’d want the equipment to suit your application and offer value. The list of drilling rig tongs for sale at Alibaba.com lets you dig into earth deposits, and the compare tool checks out other similar parts to give you the information you need to make a purchasing decision. You’ll get wholesale drilling rig tongs for sale that specializes in mining, with reinforced chassis, and run on more powerful engines. Whether you want to transport minerals or the workers to the mining site, introduce explosives or arms to help you remove materials from your mine pits, Alibaba.com has it all.

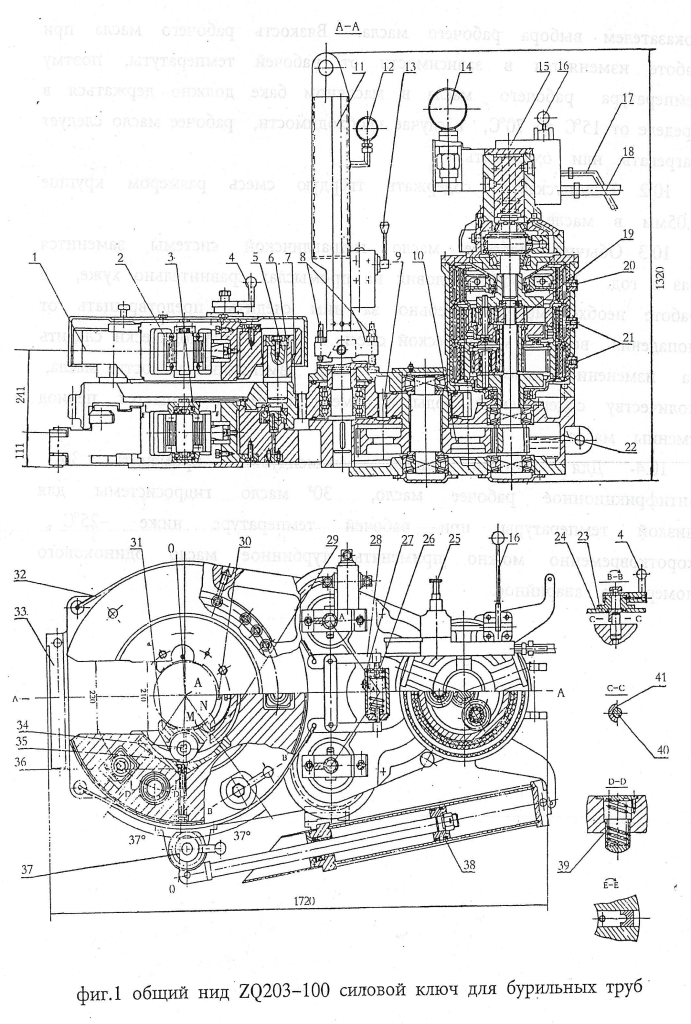

ZQ203-125 Drill pipe power tong is updated power tong of ZQ203-100 drill pipe tong, it is suitable for petroleum and mine drilling operation. Tong head is opening type, it can automatically release the drill pipe and the property is flexible. This tong makes up or breaks out without any cat head, manual tong and spinning rope (or spinning chain). The structure is the combination together with spinner and torque tong.

Using this tong can ensure safety, save labor force and enhance drilling efficiency. It is special suitable for frequent round trip and long drilling period.

ZQ203-125 Drill pipe tong has a great improvement comparing with ZQ203-100 Drill pipe tong, it has bigger torque and improved structure, installed with hydraulic lift for adjusting the height of this power tong itself.

KHT14000 Casing Power Tong is used to make up and break out for casing operation in oil fields. It has greatly reduced the labor of worker, enhanced connection quality of thread and diminished accidents in inappropriate casing operation. The power tong has the following features as well:

Jiangsu Xinxiang share Co., Ltd was founded in 1994, its predecessor was established in 1955, it‘s located in high-tech industrial concentration zone of Nantong City, Jiangsu Province; near to a new developing international deep-water port Yangkou Port which commitment to ship 200,000 tons goods; world famous modern city Shanghai is only 2.5 hours away from it by car; company registered capital is 60,000,000 RMB, the total assets is 119.85 million RMB, it covers an area of 160,000 square meters and currently over 500 employees. Jiangsu Xinxiang Share Co., Ltd is "self-import and export enterprise", "private technology enterprises in Jiangsu Province", "high-tech enterprises in Jiangsu Province", it is top ten companies of the first national large and medium-sized industrial enterprises in independent innovation capacity of the industry; it accessed to API7, 7K, 8A, 8C, and has the right to use the logo, and also passed the ISO9001:2000 quality system certification in the earlier stage within the same industry.

Tongs - Power - BJ sucker rod tong adopts advanced sucker rod or tubing technology and has a compact structure, high reliability and is safe and convenient to operate.

Tongs - Power - New Carter Tool Co. Inc., CT93R Hydraulic powered tubing tong. Complete with 2-3/8" to 3-1/2" jaw assemblies, standard motor, torque gauge assembly, pressure relief valve... More Info

Tongs - Power - New Carter Tool Co., Inc. 5-1/2" CTSX Hydraulic Tubing Tong with heavy case and cover; complete with rigid hanger assy., suspension spring assy., front end control assy.,... More Info

Tongs - Power - New Carter Tool Co. Inc. M-Series power sucker rod tongs, complete with spring hanger assy., gate assy., front end control assy., pressure gauge assy., two 90 degree XH s... More Info

Tongs - Power - New Carter Tool Co., Inc. 4-1/2" RSX Hydraulic Tubing Tong with heavy case and cover; complete with rigid hanger assy., suspension spring assy., front end control assy., ... More Info

Tongs - Power - D D 58-93-2-R Power Tubing Tong is smaller, lighter, and faster than the Foster 5893R. The D D 58-93-2-R Tong is capable of gripping tubulars from 1 5/16" to 7" o.d. More Info

Tongs - Power - FARR TONG MODEL KT 14,000 RINEER GA37 MOTOR, LIFT VALVE ASSEMBLY TORQUE CAPACITY: 50,000 FT/LB SIZE RANGE 4 1.2-14 WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN ... More Info

Tongs - Power - FARR TONG MODEL KT20,000 STAFFA 080 MOTOR, LIFT VALVE ASSEMBLY TORQUE CAPACITY: 50,000 FT/LB SIZE RANGE: 7-20 MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READ... More Info

Tongs - Power - FARR MODEL KT5500 HYDRAULIC TUBING TONG C/W 2 SPEED RINEER MOTOR, SIZE RANGE: 2-3/8 IN. - 5-1/2 IN. OD, TORQUE RTED: 18,700 FT/LB C/W SAFETY DOOR MOST SIZES OF FARR POWER... More Info

Tongs - Power - FARR TONG MODEL KT5500 TORQUE CAPACITY: 18000 FT/LB SIZE RANGE: 2 1/16-5 1/2 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIA... More Info

Tongs - Power - FARR TONG MODEL KT5500 5 1/2 IN. TONG TORQUE CAPACITY: 18,000 FT/LB SIZE RANGE: 2 1/16-5 1/2 IN. OD, RINEER 15-13 MOTOR, HIGH TORQUE CLINCHER BACKUP TRIPLE VALVE ASSEMBLY... More Info

Tongs - Power - FARR TONG MODEL KT7585 TORQUE CAPACITY: 25000 FT/LB SIZE RANGE: 2 1/16-8 5/8 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIA... More Info

Tongs - Power - FARR TONG MODEL KT7585 8 5/8 IN. TONG TORQUE CAPACITY 25,000 FT/LB SIZE RANGE: 2 1/16-8 5/8 IN. OD, RINEER 15-15 MOTOR CLINCHER BACKUP, TRIPLE VALVE MOST SIZES OF FARR PO... More Info

Tongs - Power - FARR TONG MODEL LW9625 TORQUE CAPACITY 12000 FT/LB SIZE RANGE 2 7/8 -9 5/8 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIATE... More Info

Tongs - Power - Farrs newest tubular connection tool offers a significantly reduced rig footprint, while continuing to deliver power & uncompromising reliability. The simple design drast... More Info

Tongs - Power - Farr Canada"s newest tubular connection tool offers a significantly reduced rig footprint, while continuing to deliver power and uncompromising reliability. The simple de... More Info

DrillingParts.com is in no way affiliated with the companies referenced in this website. References and/or mention of company names or the accompanying computer code are for ID purposes only and are not Trade Marks or Trade Names used by or affiliated with DrillingParts.com. Although under affiliate program agreements, DrillingParts.com may earn on qualifying purchases completed through third party associates such as Amazon, eBay and our marketplace vendors.

These gauges (CTT101 Series) display the amount of torque in foot pounds per joint when using power tongs to run oilfield tubular. They are available for all makes and models of power tongs and even dual scale variations are available. The systems come with either compression or tension-type load cells, which provide precision checks of make up torque for all oilfield tubular.

The CTT100 Series Tong Line Pull Systems are available from 10,000 to 30,000 single line pull for use in all torquing applications. The universal tong line pull system can be used with a veriety of tong systems and can be moved from rig to rig as needed. When you need a gauge to work in most of your tong applications with a variety of tong handle lenghts, you can trust taht the CTT100 series will provide the best measurement you can get.

Quality tongs improve the efficiency and safety of drill floor operations. These large-capacity, self-locking wrenches apply torque where needed when making up or breaking out tubing. Just like a plumber using opposing pipe wrenches, rig tongs are always used in opposing pairs. One set of tongs is tied off with a cable or chain to the derrick, and the other is pulled with mechanical catheads.

Tongs used during makeup (tightening) operations are called makeup tongs; the ones used during breakout (the process of unscrewing drill string components) are called breakout tongs. Depending on the specific application, there are also riser tongs, chisel tongs, rotary tongs and manual tongs.

During makeup operations, the “lead tongs” (pronounced “leed”) are the pipe tongs suspended in the derrick or mast and operated by a chain or a wire rope connected to the makeup cathead or the breakout cathead.

The tong pull line is a length of wire rope with one end connected to the end of the tongs and the other to the cathead on the drawworks. When the driller actuates the cathead, it takes in the tong line and exerts force on the tong to either make up or break out drill pipe.

The lead-tong hand is the crew member operating the lead tongs when drill pipe and drill collars are being handled and pipe is going into the hole. For breakout operations, breakout tongs are used to start unscrew sections of pipe from one another, primarily drill pipe coming out of the hole.

Tong dies play a key part in helping power tongs or manual tongs grip tool joints. Running in or pulling out tubular at oil rigs, the tool joints are adjusted with power tongs or manual tongs.

Dies are pieces of serrated steel installed in the tongs that grip the tool joint of drill pipe when the tongs are latched onto the pipe. Tong dies are made of alloy steel, and their hardened surfaces resist wear. The inner ductile core minimizes the shock of impact and torque.

During makeup, how much force should be applied to the tongs to get the torque needed? The formula to determine torque value when you use the rig tong to make-up the connection is this:

Keystone’s K-Series tubing tongs are pull-tested and complete documentation is available with each purchase. Designed for heavy-duty service of tubing 1.050 to 3.875-inch OD, they offer a wraparound design with approximately a 300-degree die contact to prevent crushing of thin wall tubing.

Tubing tongs may have a simple design compared to other types of drilling equipment, but don’t let that fool you—they are powerful and essential tools that provide critical support to drilling operations on a daily basis. important

Essentially, tubing tongs provide stability and allow workers to better handle tubular components. All drilling operations should be equipped with specialized tubing tongs appropriate for the size of equipment and scope of the work onsite.

While the tools are functionally identical, drilling sites typically have designated tongs for makeup and breakout. Makeup tongs are used to tighten joints and components of the drill string to keep them secure once they are active. Breakout tongs, on the other hand, are used for loosening operations when pieces or components need to be unscrewed or detached from the string.

Tongs look and function much like ordinary wrenches, although there are several design considerations to account for the extreme forces involved such as:

Just like opposing wrenches, tubing tongs are used in pairs when handling tubing or other drilling components. The “lead tongs” are connected directly to the derrick, while the second set is handled separately. The two tongs work together to provide enough

When it comes to tongs or wrenches, torque is the most important measurement to keep in mind. Tongs used in drilling operations are typically rated for a certain amount of torque, which is the rotational force required to turn an object about its longitudinal axis. From a mathematical perspective, torque is calculated by multiplying applied force by the length of the tong’s handle. This means that force applied at the end of the handle is magnified at the eye, so the people or equipment applying the force expend less energy to accomplish the same task.

Tongs are essentially levers that magnify applied force when generating torque, which greatly reduces the force needed to perform the operation. This improves efficiency by cutting down on power costs, as well as reducing the strain placed on the derrick’s infrastructure. Tongs also make the entire work environment safer by helping workers reliably stabilize and handle the equipment, making basic drilling processes more consistent and controllable.

The most important qualities of tubing tongs are strength, reliability, and usability. The best designs attempt to address all three of these needs by balancing them according to operators’ needs. Just like many other drilling tools, tongs should only be used for approved torque levels and functions. Operators should also monitor their tongs regularly to ensure they are properly maintained and in good repair before use.

8613371530291

8613371530291