power tong operator job description supplier

You’re the one with the power – the power tongs, that is. You control the equipment that threads sections of drill casing to form the pipe that is placed hundreds of metres into the ground. When you arrive at site, the rig crew knows it’s time to get to work. Your strength and dexterity serve you well in this occupation.

Power tong operators control the equipment that threads sections of drill casing into the wellbore. As a member of the oilfield well services team, they are responsible for operating power tongs, torque measuring equipment and tube/casing handling equipment at the well site. Casing is required to maintain an oil or gas well’s structural integrity, prevent the cross-contamination of water with other fluids and control well pressure during the drilling, production and maintenance of the well. Power tong operators must be able to transport equipment to and from the well location, safely rig in and operate the equipment, perform day-to-day inspections, servicing and maintenance of equipment, and complete all required paperwork accurately and on time.

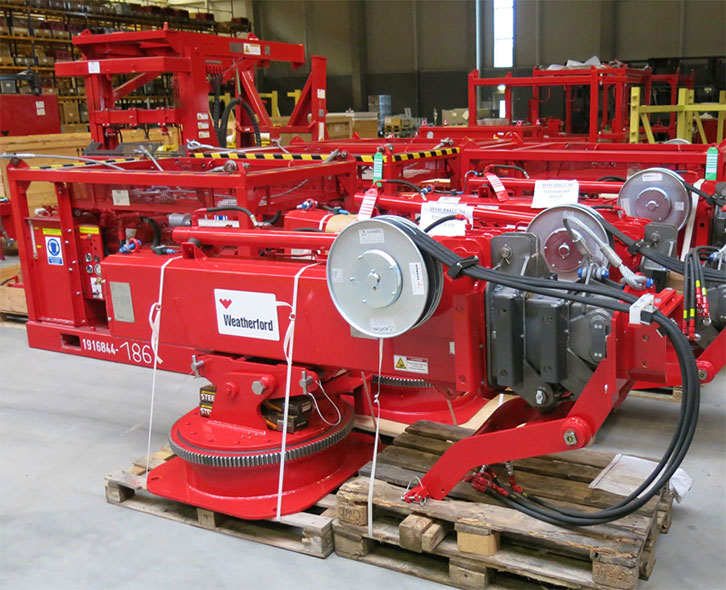

This is a real resume for a Tong Operator in Dayton, Minnesota with experience working for such companies as Valley Paving, Weatherford International, Quality Green Llc. This is one of the hundreds of Tong Operator resumes available on our site for free. Use these resumes as templates to get help creating the best Tong Operator resume.

Parker Wellbore helps energy companies accomplish their drilling and production goals efficiently, reliably, and safely. Our global team supports oil and gas operators with innovative land and offshore drilling services; premium rental tools and well services; and advanced operations and management support. Founded in 1934, Parker Wellbore helps customers manage their costs and mitigate their risks, to achieve their operational goals in a safe and efficient manner. With experience in both harsh-environment regions and complex drilling situations, you can trust Parker Wellbore to get the job done.

Handle and operate casing running equipment, including: casing running tools, power tongs, elevators, power slips, control panels, and hydraulic power units.

To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the knowledge, skill and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

Must have working knowledge of tubular handling equipment, including: casing running tools, power tongs, elevators, power slips, control panels, and hydraulic power units.

If an applicant has a disability, the applicant may request accommodations when needed to enable that person to perform their essential job functions or to allow that person to participate in employment.

As a Thread supervisor, washing and laborer, you will be responsible for performing light duty maintenance within the shop, cleaning casing/tubing on rig locations, and general administrative reporting. The position includes pre-deployment preparation of equipment as well as post-job inspection and maintenance.

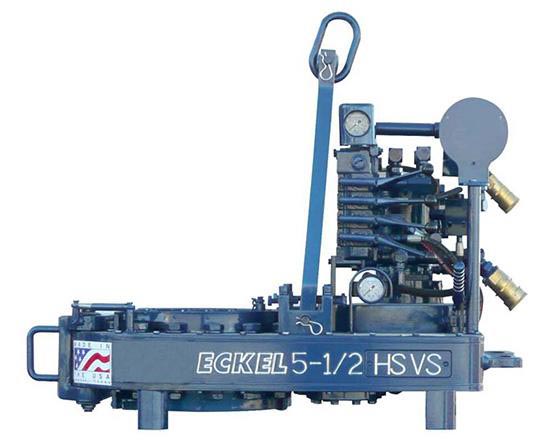

Eckel offers a broad range of accessories to compliment our power tongs. From torque control systems and gauges to case handles and tong straps, Eckel has the right accessory option for your specific application.

Eckel offers torque control systems to monitor the torque turn values when making up tubular connections with the system automatically stopping tong operation once reaching a specific torque. Any flaws in the make-up process will be readily shown in a graph.

The Door Interlock is offered as an optional safety feature for use with the power tong to prevent accidental operation of the power tong when the door is open. The door interlock prevents tong operation whenever the tong door is open by impeding hydraulic fluid to the tong motor.

A hydraulic Tri-Grip® or Cam Backup tool is optionally supplied with Eckel tongs. In operation this tool provides a backup when in break-out or make-up situations. This hydraulically operated backup tool, uses hydraulic cylinders and a head arrangement to insure slip-free operation.

A standard feature on many of our tongs. Dies have evolved since tongs became commonplace in the oilfields. Eckel has been at the forefront of this developing technology with the development of larger wrap-around type dies for many of its tong models. We offer coarse tooth design for normal carbon steel pipe and collars and fine tooth for special alloys such as 9, 13, 23, 25 chrome and fiberglass to greatly minimize markings on the tubulars.

Designed for improved safety when handling the tong. Up to four Case Handles can be optionally mounted on most tong models. Large top and bottom caps help protect the operator when maneuvering the tong on and off the tubulars.

Eckel continues to set industry safety standards with the optional Finger Guard Option. This shield covers the gap between the tong door and tong body, without limiting door operation. Door will open and close freely.

Industrial strength straps feature a rubber gripping surface to allow for easily pulling the tong on and off the tubular. These optional straps are mounted on the tong door and on both sides of the solid hanger area of the tong using a Lark"s Head Knot.

The adjustable motor port relief valve is used to control or limit the hydraulic pressure to the tong motor thus controlling the maximum torque output of the power tong. The valve controls only the hydraulic pressure to the tong motor leaving full system pressure available for other functions such as lift cylinder and hydraulic backup.

RPM Control: The RPM Control is a flow divider that decreases the amount of hydraulic fluid that reaches the tong, the remaining fluid is returned to the reservoir. By decreasing the amount of fluid reaching the tong the operator is able to control the maximum RPM"s the tong will deliver.

Tongs equipped with the optional Swivel Joints have improved hose life by absorbing system shock when pressured up and preventing twisting, kinking of the hydraulic hoses. In addition tongs are maneuvered more freely on the rig floor on and off the tubular.

The optional torque gauge assembly is used to measure the torque exerted in make-up or break-out operations. Consisting of a hydraulic cylinder and torque gauge connected together by a pressure hose, the torque gauge assembly senses and indicates the torque developed during an operation. For operation, the hydraulic cylinder is connected by a shackle to the rear of the tong; and a snub line is connected to the cylinder. The snub line is tied off to a solid part of the rig structure to form an angle of 90� in order for the gauge to indicate accurate torque readings.

This cylinder provides a means for raising and lowering the tong during operations and is recommended with tongs that have a hydraulic backup due to the extra weight of the tong. The lift cylinder maximum of travel varies depending on tong size.

The optional spring hanger is designed to permit the tong to move up or down to allow for thread length in make-up and break-out operations. When used, the spring hanger should be attached directly to the tong bridle ring and used as a hanger for the tong.

Special applications and tough requirements demanded that we respond with a new tong designed and built with today"s pipe handling challenges in mind, the 8⅝ Hydra-Shift® HT. By utilizing a two-speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor, the operator has a more flexible choice of torque/RPM"s to work with during make-up or break-out. At the beginning of the job, the operator will choose a tong gear ratio that is most appropriate for the current tubular connection and shift the variable speed motor handle into high or low as required. This tong also offers sliding heads with wrap-around dies, which provides evenly applied pressure to the pipe and a greater pipe gripping coverage, which reduces tubular damage. This tong not only offers the operator the speed options down to the slow speed parameter now demanded by the pipe manufacturers and oil companies, but it also has the option of speeds of 100 RPM"s when required. Available torque: 40,000 ft-lb

The Tri-Grip® Backup is the industry standard for reliable make-up and break-out of tubular connections that are optionally supplied with Eckel tongs. Utilizing two hydraulic cylinders and a three head arrangement ensures a slip-free operation. The backup is suspended at an adjustable level below the power tong employing three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for the connection"s thread travel. The Tri-Grip® uses two pivoting heads and one stationary. The Eckel Tri-Grip® Backup has exceptional gripping capabilities with Rig Die

Texas International Oilfield Tools (TIOT) offers a free standing test stand for testing of hydraulic casing and tubing power tongs. The test stand is designed to resist torque applied by a power tong through a test mandrel.

The test stand is an air operated device that utilizes a hydraulic active dual spring disc brake chamber in order to apply friction force (“brake” action) to the rotating (or stationary) test mandrel mechanism. The power tong is tested by applying torque to the test stand’s mandrel. The test stand’s brake is activated by pushing and twisting clockwise the red control box button on the control box. A brake foot pedal is supplied as backup for the mini power unit. Using the control box mounted on the test stand, the black knob regulates pressure.

This is a list of worldwide Tong Operator jobs in the oil and gas industry. The Tong Operator position is categorised as Drilling Rig jobs, vacancies and careers. There are currently jobs available in Houston, USA, Scotland, Aberdeen, Norway, Stavanger, Australia, Perth, UK, London, China, Beijing, India, Chennai, Indonesia, Jakarta, Brazil, Rio, Nigeria, Lagos, Luanda, Angola. Contact the companies to find the Tong Operator job salary and benefits.

BG Group is a fast growing organisation. We have a constant requirement for experienced Well Engineering professionals to work in our UK and international assets. We are interested in hearing from you if you have experience in any of the areas listed below. Experience gained in a Service Company or Operator Environment is equally valued. ...

You will have extensive and in depth Technical Safety discipline experience in the key areas of facilities engineering, covering onshore and offshore oil and gas production and associated facilities in a client/operator environment, at senior level. Exposure to working within different geographical environments would also be advantageous.

More Subsea Oil and Gas Companies, Products, Projects, Drilling Rigs and JobsPerth, AustraliaPerth is the oil capital and the largest city in Australia"s largest state Western Australia. Perth"s 1.5 million inhabitants correspond to more than two thirds of the state"s inhabitants. Western Australia is one-third the size…

Directional DrillingQuick Guide: What is directional drilling and how to get directional drilling jobs! What is Directional Drilling? Directional drilling or deviation drilling is an oil and gas exploration drilling technique used to change the direction…

Underwater WeldingQuick Guide: What is underwater welding and how to get underwater welding jobs! What is Underwater Welding? Underwater welding, a term for methods adapted for subsea welding, for the purpose of repairing damage to ships…

Straight Tong Die Driver: Used for die slot redressing, the straight tong die driver is the simplest of type of rig tong. Though it is also the simplest type of rig tong to use, it is also the least safe of the three. Its handle and handguard protect hammer blows from falling onto the grip. Straight tong die drivers are lightweight—under eight pounds—and measure in at around 1”.

Angled Tong Die Driver: The angled tong die driver has a grip that’s angled away from the perpendicular tong as well as brass guards for the tong tip and handle, making this rig tong safer than the straight tong die driver. While this tong is safer, however, it’s actually harder to keep the angle tong die driver in place. This driver is similar in length to the straight tong die driver, but is about two pounds heavier, weighing in at over nine pounds.

Hammerless Tong Die Driver: This variety of tong die driver is made up of a hand pipe that can be used to apply pressure to the tong’s tip without using a hammer at all. This option is the safest of the three driver types because there’s no hammer required, it’s also the slowest driver for this same reason. The hammerless tong die driver is about as long and weighs as much as the straight tong die driver.

What oilfield tools does your operation need? Keystone Energy Tools has atool to fit your bill.Contact us today to learn more about how rig tongs can make your work environment safer, and to learn more our other oil and gas industry products.

8613371530291

8613371530291