power tong operator job description factory

You’re the one with the power – the power tongs, that is. You control the equipment that threads sections of drill casing to form the pipe that is placed hundreds of metres into the ground. When you arrive at site, the rig crew knows it’s time to get to work. Your strength and dexterity serve you well in this occupation.

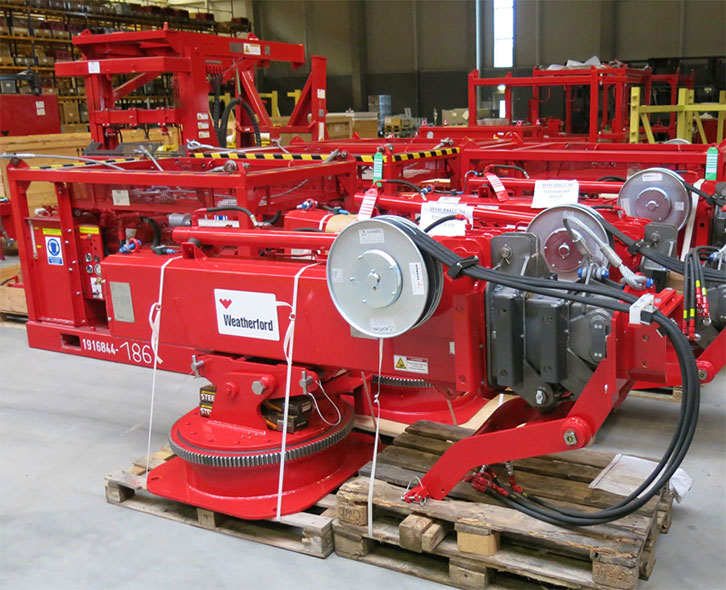

Power tong operators control the equipment that threads sections of drill casing into the wellbore. As a member of the oilfield well services team, they are responsible for operating power tongs, torque measuring equipment and tube/casing handling equipment at the well site. Casing is required to maintain an oil or gas well’s structural integrity, prevent the cross-contamination of water with other fluids and control well pressure during the drilling, production and maintenance of the well. Power tong operators must be able to transport equipment to and from the well location, safely rig in and operate the equipment, perform day-to-day inspections, servicing and maintenance of equipment, and complete all required paperwork accurately and on time.

include but are not limited to: Safely and efficiently performing all tasks on the rig floor and B.O.P. area under the direction and supervision of the Driller. Operating the tongs, slips, and spinners ...

Actively participates in daily pre-tour meeting and pre-job meetings as often as required by the operations. When a deviation from the planned operations is necessary, stop the work, regroup and ...

2 or more years related field experience in the of the following disciplines Torque Turn Systems Power Tong Systems Handling Tool Systems High School diploma (or Secondary School Diploma or equivalent) ...

The Field Specialist IV will rig up, rig down and run TRS (Tubular Running Services) equipment at location with no supervision, lead and train less experienced Operators. Prepare accurate tickets, job ...

of the Floorhand include: Assisting the Derrickhand, Motorhand and Driller on the drill floor while making trips; Operating manual tongs and slips to connect and disconnect drilling pipe and drilling ...

of the Floorhand include: Assisting the Derrickhand, Motorhand and Driller on the drill floor while making trips; Operating manual tongs and slips to connect and disconnect drilling pipe and drilling ...

Well service equipment operators perform various specialized services. Their duties and job titles vary from one employer to another and one type of service to another. In general, they:

Pumping services involve the use of high-pressure pumping equipment and chemicals, fluids, or gases. Different operations require different materials. Pump equipment operators often provide a specific service:

Coil tubing operatorsinsert the continuous coiled tubing used to pump fluids, such as water, oil, acid, and nitrogen gas, down a well. This can stimulate formation, clean out the wellbore, or condition the well for other services. Coiled tubing can also supply mechanical force to operate downhole tools and equipment. It can also be used during fracking operations to reach specific areas of the well bore or for milling out plugs.

Fishing tool operators, sometimes called downhole tool operators, use tools designed to retrieve objects that must be removed from the well bore before work can proceed. They meet with drilling personnel to determine the best method and tool to use. They also direct tool assembly and operation.

Power tong and casing operators use hydraulic power tongs to connect casing as it is lowered into a well. They manage hydraulic controls that provide power, operate the power tongs, and monitor pressure gauges. Pressure gauges ensure the correct amount of pressure is applied to connect casing joints properly. Combined with cementing, casing stabilizes recently drilled well holes.

The present invention relates to open-head power tongs used in drilling operations, and more particularly, is directed to an improved means of actuating and deactuating the operation of the power tong drive means in response to the opened and closed positions of an access door.

As well known in the drilling industry, power tongs are employed in making-up and breaking-out operations of casings, tubings, rods, pipes and the like. More particularly, power tongs are used to grip and rotate lengths of drill pipe or the like to connect or join several lengths of pipe together to thereby form a drill string in a make-up operation, and in the alternative, to grip and rotate a length of drill pipe to disconnect it from the drill string in a break-out operation.

One type of power tong commonly used today is the open-head tong, such as the one shown and described in U.S. Pat. No. 4,060,014. The open-head tong has a bifrucated frame defining a central opening and a side opening communicating with the central opening for the passing therethrough of a drill pipe or the like. Due to the extreme costs of drilling, open-head tongs have become very popular, in that, they can easily and readily be moved into and out of an operative position when they are needed in the making up and breaking out of drill strings.

In operation, the open-head power tong exerts large rotational torques on the drill pipes, usually the larger the tong, the larger the torque output. Due to these large torque outputs and the resulting forces generated therefrom, the open-head tongs have been provided with an access door that bridges the gap between the bifrucated ends of the tong. The primary purpose of such an access door is to strengthen the tong structure so as to prevent, during the operation of the tong, the bifrucated ends from separating or springing apart, which not only results in damage to the tong, but could also inflict injury to the operating personnel. The access door, in addition to providing structural rigidity to the tong, also provides the operator with safety in bodily protecting him from the rotating pipe gripping and engaging jaws.

Such access doors perform very satisfactorily in providing structural rigidity to the tong and do provide protection to the operators from the rotating components of the tong when the door is properly latched in position during the make-up and break-out operations; however, in an effort to save time, operators have been known to operate the tong with the access door open, and in some instances, the operators have even removed the access door from the tong. Such operator"s carelessness not only causes costly structural damage to the tong, but also results in personal injury to the operator.

In U.S. Pat. No. 2,705,614 there is shown an open-head power tong having an automatic hydraulically powered access door, operably interconnected to the hydraulic cylinders that actuate the jaw gripping mechanism, which must be closed before the jaws can be actuated so as to rotate a drill pipe. Such door interlock mechanism has been specifically designed for the type of tong disclosed and is not readily adaptable to other types of power tongs, such as the one shown in the above-mentioned U.S. Pat. No. 4,060,014. Further, the hydraulic circuitry that is involved with such a powered access door is not only complicated, having expensive components, but is also, costly to maintain and repair. Still further, such door interlock mechanism does not provide adequate safety to an operator, in that, although the operator is protected from the pipe gripping and engaging mechanism when the door is closed, he is also subjected to the risk of having the power operated door being automatically swung into him as it is being closed, thus, creating a potentially dangerous and unsafe condition under which the operator must work.

The present invention obviates the problems experienced with access doors and disadvantages associated with the prior art door-interlock mechanisms by providing, as one of its principle objects, an improved door-interlock mechanism for an open-head power tong that ensures the access door is in a closed position before the tong can be operated, thereby preventing possible structural damage to the tong from operating the tong with the door open, as well as, preventing personal injury to the operators by protecting them from the various rotating components of the tong.

Another object of the present invention is to provide a door-interlock mechanism for an open-head power tong that is simple in structure and adaptable to all types of open-head power tongs.

Accordingly, the present invention, sets forth in an open-head power tong having an access door mounted on the tong and moveable between opened and closed positions, an improved door-interlock mechanism that includes means for controlling the operation of the tong in response to the opened and closed position of the door. More particularly, the control means preferably includes a pneumatic contact valve interconnected with a pneumatically piloted diverter valve operably associated with the power means of the tong such that the power means is placed in either an operative or inoperative condition in response to respective closed and opened positions of the door. Specifically, the pneumatic contact valve is so positioned in the vicinity of the side opening that the door, in its closed position, engages the contact valve thereby actuating the diverter valve to permit operation of the power means, and when, the door is moved from its closed position out of engagement with the contact valve, the contact valve causes the diverter valve to deactuate the power means, thus stopping the operation thereof.

These and other advantages and attainments of the present invention will become apparent to those skilled in the art upon reading of the following detailed description when taken in conjunction with the drawings wherein there is shown and described an illustrative embodiment of the invention.

FIG. 1 is a top plan view of an open-head power tong incorporating the improved door-interlock mechanism of the present invention with the access door being in its closed position in engagement with the contact valve which actuates the diverter valve.

FIG. 2 is a diagrammatic fragmentary view of the power tong showing the side edge portion of the access door with the door latch removed and with the contact valve being in disengagement with the door which is partly open.

Referring to the drawings, and particularly, to FIG. 1, there is shown, for illustration purposes only, an open-head power tong, being generally indicated by the numeral 10, incorporating the principles of the present invention. The tong illustrated in FIG. 1 is of the type shown and described in U.S. Pat. No. 4,060,014, and thus, for the sake of brevity, since the tong itself forms no part of this invention, only a brief description of the tong will follow.

Briefly, as best seen in FIG. 1, the power tong 10 is comprised of a bifrucated frame structure 12 defining a central drill pipe receiving opening, and a side opening that communicates to the central opening for laterally passing a drill pipe therewithin. Rotatably supported within the frame structure 12 is a pipe engaging and gripping means that includes jaws 14 that swing into and out of the central opening for gripping and rotating a drill pipe disposed within the central opening during make-up and break-out operations of a drill string. The pipe engaging and gripping means with its associated jaws 14 are rotatably driven through a suitable drive train (not shown) by power means such as the hydraulic motor 16 which receives fluid under pressure from a suitable hydraulic pump (not shown) and through a hydraulic control valve 17. The valve 17 is conventional, being moveable between three spool positions; one position being such that the fluid drives the motor in a forward clockwise direction, another position being such that the hydraulic fluid drives the motor in a reverse counterclockwise direction, and the third position being a neutral position wherein fluid passes through the valve to the return line that returns the fluid to a reservoir (not shown) for recirculation thereof.

Also supported on the frame structure 12 is an access door 18, adapted to span or bridge the access opening defined between the bifrucated end portions so as to provide structural rigidity to the power tong 10, as well as, to protect the operator from the various moving components, such as the jaws 14. One end of the access door 18 is hinged to an end of one of the frame bifrucations by a pivot pin 20 whereas the free end of the door is provided with a self-latching arm 22 that engages a latch member 24 mounted on the other bifrucation so as to positively latch the door when it is closed. The door and the door latching mechanism are of the type shown and described in a pending U.S. application, bearing U.S. Ser. No. 791,752; filed Apr. 28, 1977; and entitled TONG LOCKING MECHANISM. The door and the latching mechanism forms no part of this invention and thus a further description will not be given.

To ensure that the tong 10 is only operated when the door 18 is closed, closing the access opening, the tong 10 is provided with an interlock mechanism which basically includes a contact valve 26, engageable by the door 18, and a hydraulic diverter valve 28, operably associated with the hydraulic motor 16 so as to permit flow of hydraulic fluid to the motor, or, in the alternative position, to bypass the flow of hydraulic fluid around the motor.

Now turning to FIG. 3 which schematically represents the various operating components as well as the hydraulic and pneumatic circuitry associated therewith, the operation of the door interlock will be further described. First, it should be noted that both the hydraulic source and the pneumatic source are fully operating with respective fluids being under pressure in inlet lines, the access door 18 being closed, engaged with the actuating arm of the contact valve 26, the piloted diverter valve 28 being detented so as to pass the flow of hydraulic fluid around the motor 16, and with the hydraulic spool control valve 17 being in its neutral position such that fluid passes directly therethrough to the reservoir tank via inlet line 34, passageway 36, return line 38. Thus, as the spool valve 17 is shifted to its forward drive position, hydraulic fluid passes from the inlet line 34, through passageway 40, to line 42, through passageway 44 (of diverter valve 28), to line 46 which directs fluid into the left-hand side of the motor 16, and then via lines 48,49 to passageway 50 of valve 18 which is internally connected to the hydraulic return line 38. If the spool valve 17 is shifted in an opposite direction so as to reverse the direction of the motor 16, fluid flows via line 34, through passageway 52 to line 49 and line 48 to the right side of the motor 16, and then returns via lines 46, passageway 44, line 42 to passageway 54 which is internally connected to return line 38. It can be thus seen that when pressure is applied on the diverter valve 28, it is so positioned to pass hydraulic fluid either to one or the other sides of the motor 16 to thereby drive the rotating components of the tong 10 in either forward or reverse directions depending on the forward or reverse positions of the control valve 17. However, when the pneumatic pressure is relieved from the diverter valve 28, the internal spring forces the valve to the right, thus changing the flow path of the hydraulic fluid so as to bypass the motor 16. In such pressure relief position of the diverter valve 28, the fluid flow path is via lines 49,58, passageway 56 and line 42, thereby bypassing the flow of fluid to the motor 16. Since the flow of fluid through line 46 is blocked, no fluid passes to the motor 16, thus rendering it inoperative.

It can be understood from the foregoing that the described interlock-mechanism controls the operation of the hydraulic motor 16, and thus the operation of the tong 10, in response to the open and closed positions of the access door 18, such that the tong 10 can only be operated with the access door 18 in its closed position, and thereby eliminating the possibility of structural damage to the tong from operating same with the door open, as well as, providing safety to the operator from exposure to the various operating components of the tong.

It is thought that the invention and many of its attendant advantages will be understood from the foregoing description and it will be apparent that various changes may be made in form, construction, and arrangement of the improved door interlock mechanism without departing from the spirit and scope of the invention or sacrificing all of its material advantages, the form hereinabove described being merely a preferred or exemplary embodiment thereof.

Class 1 license required for Picker or Crane operators. Also have winch tractor work coordinated with Kindersley area and have ongoing work through our Coiled…

Previous experience as an operator, coiled tubing, frac, frac op, rotational, rotator, fly in/fly out, rigs, truck driver, oilfield, oil & gas, oil and gas,…

Trade certification, 4th Class Power Engineering and/or GPO certification are assets but not required. The Production Operator will be responsible to maintain…

Previous experience as an operator, coiled tubing, frac, rotational, rotator, fly in/fly out, rigs, truck driver, oilfield, oil & gas, oil and gas, energy,…

Valid Class 5 driver"s license. Physically fit (documented by a doctor’s certificate recognizing job requirements). This job requires extended work hours.

Possess a valid fourth-class power engineering certificate in the province of Saskatchewan. Independent Energy Corp*. is a privately funded corporation focused…

1a license and plastic fusion experience an asset. Looking for a Backhoe/Mini excavator Operator with experience digging around live gas lines and other…

Previous experience as an operator, coiled tubing, frac, rotational, rotator, fly in/fly out, rigs, truck driver, oilfield, oil & gas, oil and gas, energy,…

Class 5 license is an asset. Confined space entry to remove debris and perform detailed cleaning. Assist the Operator with the set up and control hoses attached…

Previous experience as an operator, coiled tubing, frac, rotational, rotator, fly in/fly out, rigs, truck driver, oilfield, oil & gas, oil and gas, energy,…

Class 5 license with a G endorsement or ability to obtain. Power mobile equipment operator certificate for skid steer or able to obtain.PBN Construction— Saskatoon, SK

The Production Operator will operate, monitor and test oil/gas wells as per Vermilion and regulatory guidelines and requirements; assist with operational and…

The Operator will monitor and test oil/gas wells as per Vermilion and Regulatory guidelines and requirements; assist with operational and engineering strategies…

This is a list of worldwide Tong Operator jobs in the oil and gas industry. The Tong Operator position is categorised as Drilling Rig jobs, vacancies and careers. There are currently jobs available in Houston, USA, Scotland, Aberdeen, Norway, Stavanger, Australia, Perth, UK, London, China, Beijing, India, Chennai, Indonesia, Jakarta, Brazil, Rio, Nigeria, Lagos, Luanda, Angola. Contact the companies to find the Tong Operator job salary and benefits.

BG Group is a fast growing organisation. We have a constant requirement for experienced Well Engineering professionals to work in our UK and international assets. We are interested in hearing from you if you have experience in any of the areas listed below. Experience gained in a Service Company or Operator Environment is equally valued. ...

You will have extensive and in depth Technical Safety discipline experience in the key areas of facilities engineering, covering onshore and offshore oil and gas production and associated facilities in a client/operator environment, at senior level. Exposure to working within different geographical environments would also be advantageous.

More Subsea Oil and Gas Companies, Products, Projects, Drilling Rigs and JobsPerth, AustraliaPerth is the oil capital and the largest city in Australia"s largest state Western Australia. Perth"s 1.5 million inhabitants correspond to more than two thirds of the state"s inhabitants. Western Australia is one-third the size…

Directional DrillingQuick Guide: What is directional drilling and how to get directional drilling jobs! What is Directional Drilling? Directional drilling or deviation drilling is an oil and gas exploration drilling technique used to change the direction…

Underwater WeldingQuick Guide: What is underwater welding and how to get underwater welding jobs! What is Underwater Welding? Underwater welding, a term for methods adapted for subsea welding, for the purpose of repairing damage to ships…

8613371530291

8613371530291