power tong safety brands

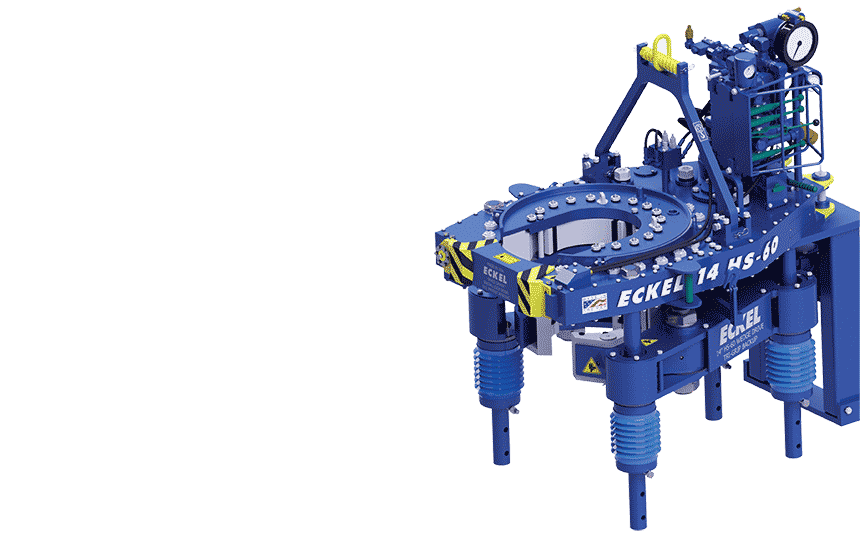

By significantly lessening exposure risks, crew personnel can focus on the tubular requirements to achieve a high integrity connection. Eckel provides a variety of Safety Enhanced features to mitigate safety risks, and return reduces operational costs through preventative accidents, rig time, and connection failure. Let an Eckel tong maximize your next tubing or casing job.

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

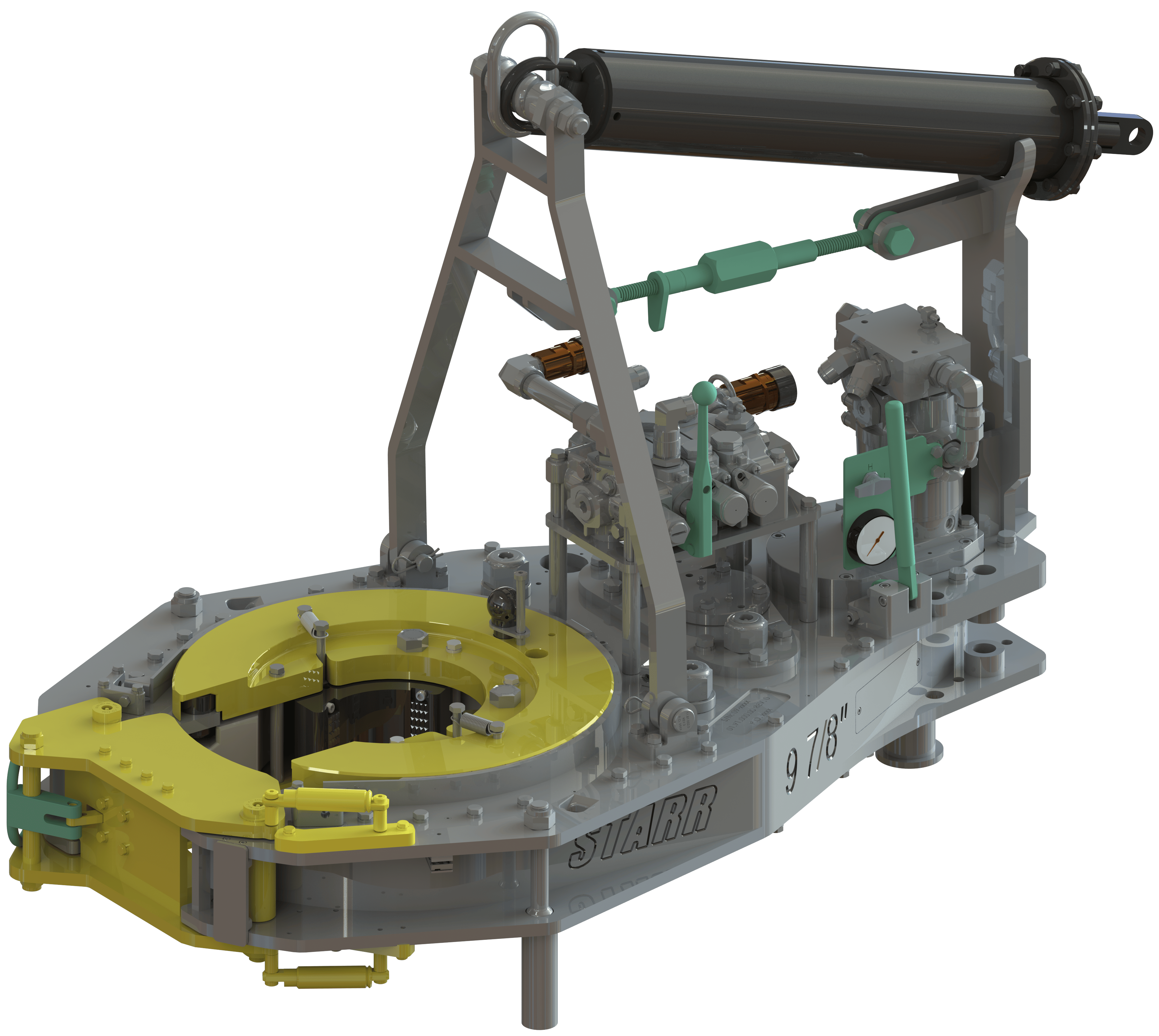

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

The KET Safety Bumpers are used on the ST-80, Mud Buckets, and other miscellaneous rig equipment where hand protection is required. The two piece design allows for easy installation with the size molded into each rubber for easy recognition.

MOT"s Hydraulic Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells. MOT’s

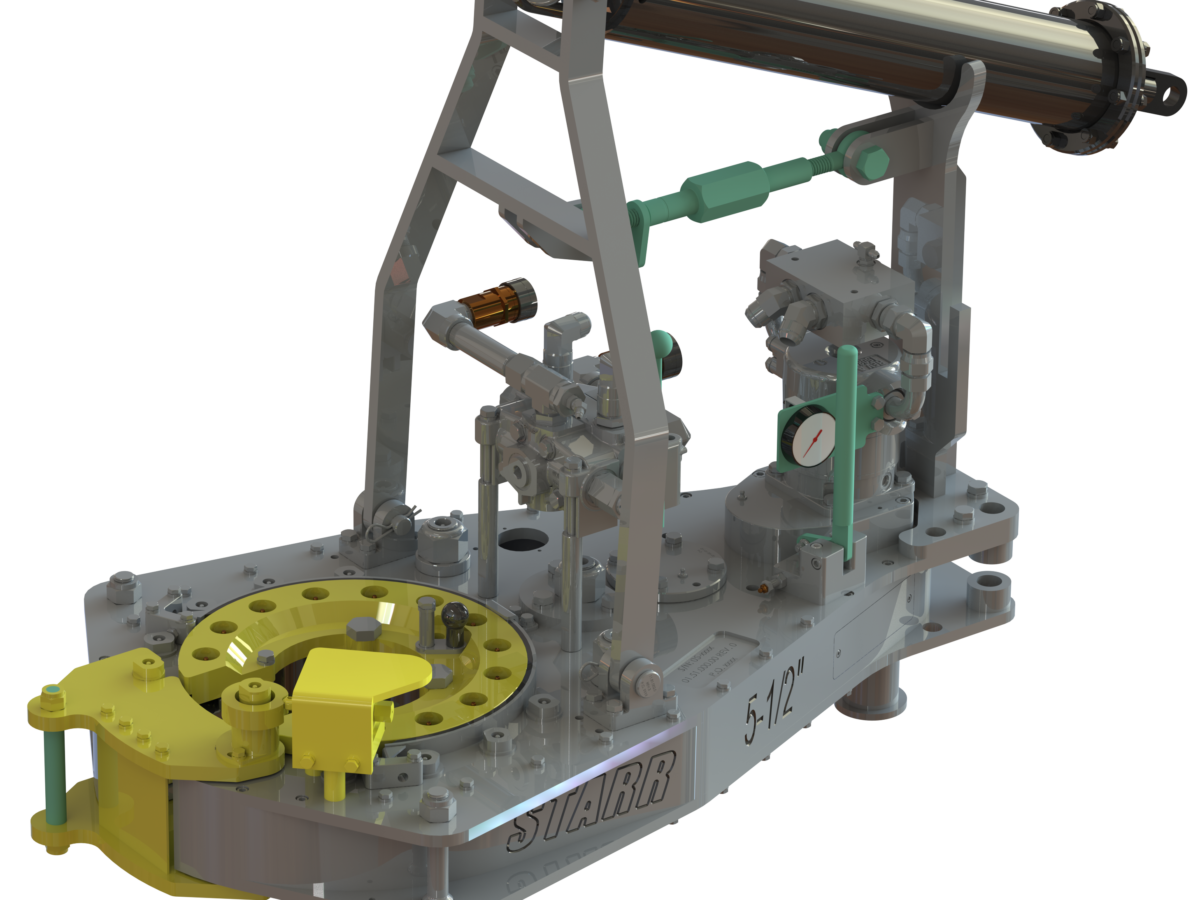

Our TEDA Style power tongs apply correct, uniform torque, reducing costly rod and tubing failures, delivering ample power to make up and break out rods and tubulars from 5/8” rod to 5-1/2” casing. Our series of XQ power tongs come with Bi-Directional jaw systems that save time and enhance safety, and go from make to break with the flip of a knob.

Tongs offer a variety of upgrades from our standard XQ series of TEDA Style models featuring Eaton hydraulic motors for extra torque and reliability, two or three spool directional control valves for more efficient hydraulic operations, and modified structures for higher strength, durability and adaptability to specific job requirements.

Are available from 5-1/2” to 20” pipe and are able to handle both API Standard and PREMIUM (Proprietary Steel Grade) casing connections which require higher torque. Available in a variety of models with hydraulic back-up tongs optional: “KMA", “KHT”, “TQ", “KJD”, “KD” and SE 16-25 with torques ranging from 15,000 ft-lbs up to 55,000 ft-lbs.

Are designed for quick and safe making up and breaking out of drill pipe and drill collars. Our “ZQ” series of hydraulic power drill pipe tongs are widely used in oil and gas drilling, in land and offshore operations around the world. The integrated torque tong and bucking tong eliminate the need for manual tongs and spinning chains, able to handle pipe from2-3/8” up to 8” drill collars, providing torques of up to 92,000 Lbs-Ft.

Our experienced and skilled power tong technicians play a major role in the safety and efficiency of a casing run. This makes the selection of your power tong service company a key component of overall performance.

ProTorque attracts and employs some of the industry’s most talented and experienced casing running technicians. Every detail of a casing run must be considered when looking for cost savings and efficiency; particularly on long production strings where every second counts while maintaining a safe operation. When making-up hundreds of connections, filling on the fly and selecting the correct handling equipment (air or hydraulic powered slips); we save time and effort on long challenging casing runs. ProTorque can meet handling requirements of up to 500 tons of hoist capability.

Casing Tong is a fast, safe, and accurate gear driven tong for making up and breaking out 4” to 16“ diameter casing. With a 32” handle, the tong can produce up to 25,000 lb-ft of torque.

Magnum Manufacturing is a team of experienced casing running engineers and industry-leading professionals tired of working with existing substandard equipment. We have spent decades developing equipment to the highest industry standards, and we personally have been using the equipment we’ve developed. After 30+ years of partnering with a leading American TRS company to ensure optimal performance, we are prepared to stake our reputation on Performance, Longevity, & Safety.

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

If you’ve worked with us before, you’ll know what we mean. We are remarkably dedicated to the success of our customers. That’s what drives us and everything we do. From the bottom up, we’ve built our company to deliver the highest quality hydraulic tongs faster than anyone else.

We offer modular spring hangers, which attach to the tong bridle and act as a hanger for the tong. In-turn, providing thread compensation to limit stresses during makeup. Give us a call today for pricing and shipping details.

K&S Power Tongs committs to providing quality casing services in a safe, reliable, cost efficient and timely manner. Safety is everyone’s full time job and we are committed to the prevention and elimination of all safety nad health hazards. All operators are specially trained and industry safety certified. Safety is never compromised. Unsafe acts are never tolerated and our employees are held accountable to work safe.

K&S Power Tongs offers coventional and integral power tong services, volant casing running tools, computer torque-turn systems, power thread washing, thread inspection, handling equipment rentals and light oilfield hauling.

Our company offers quality services and competitive rates with strict guidelines to minimize impact on the environment and maximize utilization of safety skills. We offer a level of professionalism that builds solid relationships in this industry, growing to advance our equipment to meet the technology advancement in the oilfield.

Expro’s designs and manufactures power tongs to meet the strict criteria of our customers. Expro’s inventories over 3,000 hydraulic power tongs in different models, sizes and torque capacities, ranging from tubing sizes up through 38-inch casing size. All Expro’s tongs are equipped to work in conjunction with the DATA-TREK® system, as well as the tong door interlock system for safety, and may be equipped with integral backups.

Casing Tongs: Casing power tongs are used to make or break casing tubulars placed in the drill hole in order to maintain the opening of the well. They come in a variety of sizes that measure anywhere from 5 ½ feet to 36 feet, and are designed to deal with lightweight, or high torque casing. Casing tongs are also available in a variety of models, with torques ranging from 15,000 to 200,000 foot-pounds. Consistent operations among the different models minimize the need for employee training.

Tubing Tongs: The main purpose of tubing power tongs is to run tubulars in order to extract oil and gas from reservoirs. Ruggedly designed, they provide steady, and reliable performance, even at higher torques. Like casing tongs, they also come in a variety of models depending on your torque specifications.

Drill Pipe Tongs: Drill pipe power tongs form drill strings by screwing together drill pipe, and industrial tubular used for drilling into the ground. These tongs are effective at lowering drill time, and reducing costs. Designed for safe, and quick make-up, they come in sizes 2.36 to 10 inches, and include a variety of models.

Riser Tongs: Risers are similar to pipelines in that they are conduits that move materials from the blowout preventer, located on the seafloor, to a drilling rig or floating production structure. Like flowlines, drilling risers transfer mud during the drilling stages while production risers carry over production materials, and hydrocarbons. Manufacturers of premium pipes have created threaded risers that are sealable, fatigue-resistant, and high-pressure– ideal for deep-water drilling.

Flush joint connections are used in numerous cases when running gravel pack screens. This makes it possible to shorten the length of the tong gripping portions between the screens. This change causes an increase in the productive area of the screens across the production zones in which long screen sections are run.

Expandable casing presents several issues for its make-up and running. Due to the deformity of the pipe from its original size, cautious and careful handling is required. Special tongs with jaws that can grip nonconventional diameters should be used for expandable casing. These tongs include false rotary tables and bowls, and slips for managing the inner strings.

Since power tongs are subject to heavy-duty use, and the maintenance requires a specialized workshop, your maintenance and repair provider should be able to assist you wherever, and whenever you need. Regular and consistent routines for maintenance, and spare parts are a must, and should be available as soon as possible to avoid downtime. Modern power tongs are high-end, sophisticated pieces of equipment that require a high level of expertise to operate, and repair. If you’re ever in need of patented Premiere casing, tubing, orcementing tools, contact the professionals at Premiere Inc. They have the services and products you’re looking for, as well as the expertise you need.

8613371530291

8613371530291