remanufacturer hydraulic power tong in stock

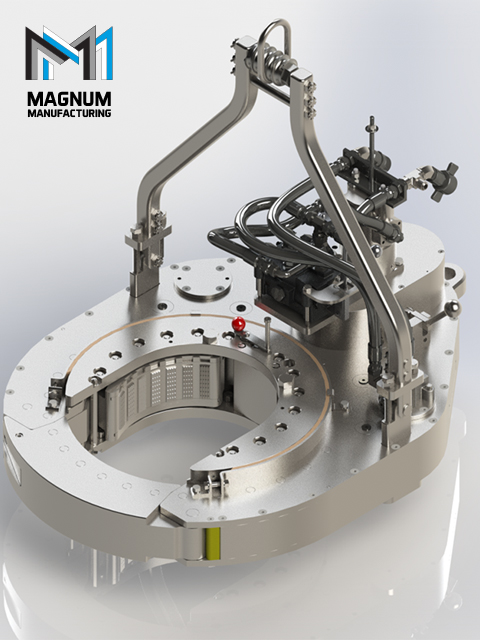

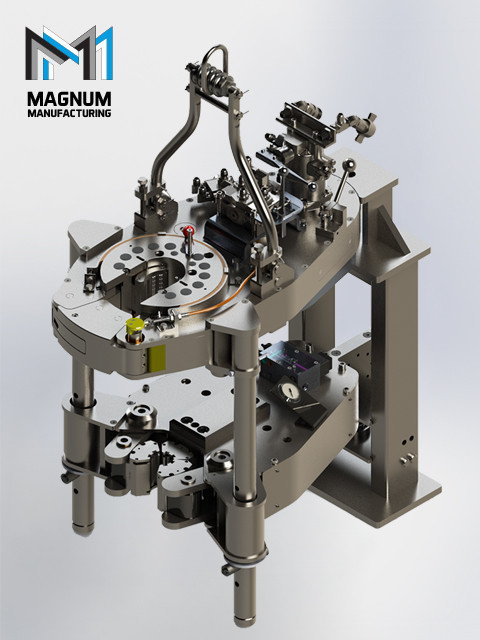

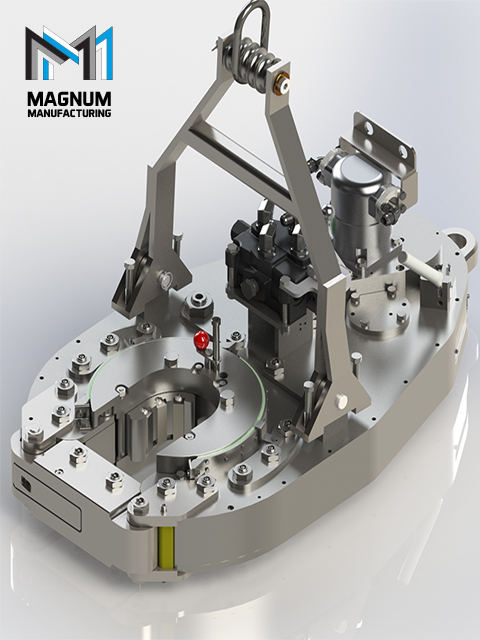

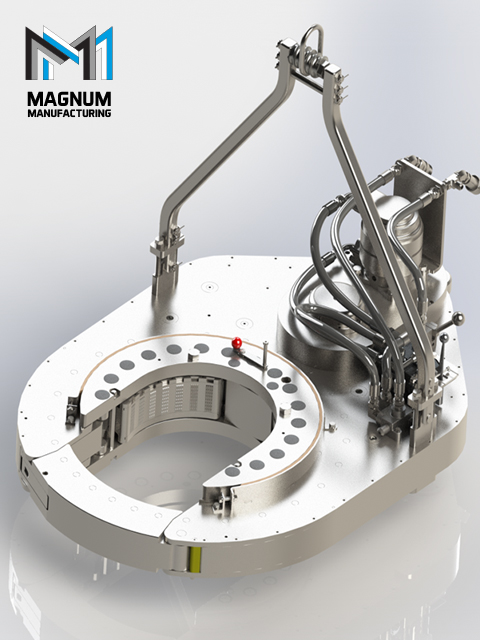

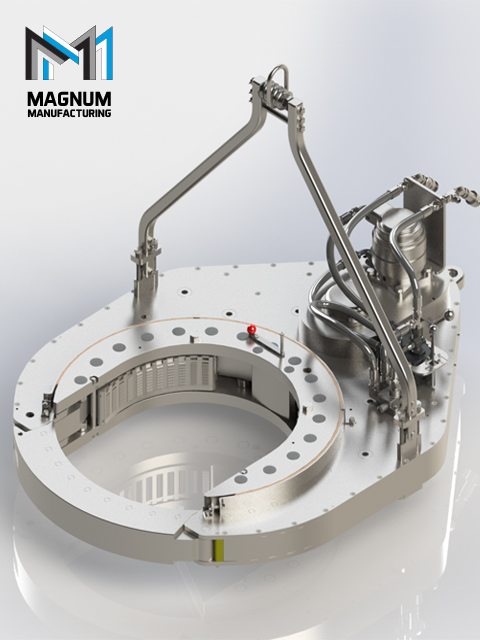

The 9-5/8” power tong with Rineer GA15-13 two-speed hydraulic motor, motor valve, lift cylinder valve, rigid sling, FARR® hydraulic backup, configured for compression load cell.

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for both Starr Power Tongs and McCoy Global hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

All of our power tongs are available with either the McCoy\\\\\\\\\\\\\\\"s patented WinCatt data acquisition software recently updated to the MTT systems or AllTorque\\\\\\\\\\\\\\\"s computer monitoring system for all the torque and turn control system needed in today\\\\\\\\\\\\\\\"s market for the making of tubular connections. Discover our wide selection of McCoy and Starr casing tongs, tubing tongs and power tongs for sale below!

Tongs - Power - BJ sucker rod tong adopts advanced sucker rod or tubing technology and has a compact structure, high reliability and is safe and convenient to operate.

Tongs - Power - New Carter Tool Co. Inc., CT93R Hydraulic powered tubing tong. Complete with 2-3/8" to 3-1/2" jaw assemblies, standard motor, torque gauge assembly, pressure relief valve... More Info

Tongs - Power - New Carter Tool Co., Inc. 5-1/2" CTSX Hydraulic Tubing Tong with heavy case and cover; complete with rigid hanger assy., suspension spring assy., front end control assy.,... More Info

Tongs - Power - New Carter Tool Co. Inc. M-Series power sucker rod tongs, complete with spring hanger assy., gate assy., front end control assy., pressure gauge assy., two 90 degree XH s... More Info

Tongs - Power - New Carter Tool Co., Inc. 4-1/2" RSX Hydraulic Tubing Tong with heavy case and cover; complete with rigid hanger assy., suspension spring assy., front end control assy., ... More Info

Tongs - Power - D D 58-93-2-R Power Tubing Tong is smaller, lighter, and faster than the Foster 5893R. The D D 58-93-2-R Tong is capable of gripping tubulars from 1 5/16" to 7" o.d. More Info

Tongs - Power - FARR TONG MODEL KT 14,000 RINEER GA37 MOTOR, LIFT VALVE ASSEMBLY TORQUE CAPACITY: 50,000 FT/LB SIZE RANGE 4 1.2-14 WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN ... More Info

Tongs - Power - FARR TONG MODEL KT20,000 STAFFA 080 MOTOR, LIFT VALVE ASSEMBLY TORQUE CAPACITY: 50,000 FT/LB SIZE RANGE: 7-20 MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READ... More Info

Tongs - Power - FARR MODEL KT5500 HYDRAULIC TUBING TONG C/W 2 SPEED RINEER MOTOR, SIZE RANGE: 2-3/8 IN. - 5-1/2 IN. OD, TORQUE RTED: 18,700 FT/LB C/W SAFETY DOOR MOST SIZES OF FARR POWER... More Info

Tongs - Power - FARR TONG MODEL KT5500 TORQUE CAPACITY: 18000 FT/LB SIZE RANGE: 2 1/16-5 1/2 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIA... More Info

Tongs - Power - FARR TONG MODEL KT5500 5 1/2 IN. TONG TORQUE CAPACITY: 18,000 FT/LB SIZE RANGE: 2 1/16-5 1/2 IN. OD, RINEER 15-13 MOTOR, HIGH TORQUE CLINCHER BACKUP TRIPLE VALVE ASSEMBLY... More Info

Tongs - Power - FARR TONG MODEL KT7585 TORQUE CAPACITY: 25000 FT/LB SIZE RANGE: 2 1/16-8 5/8 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIA... More Info

Tongs - Power - FARR TONG MODEL KT7585 8 5/8 IN. TONG TORQUE CAPACITY 25,000 FT/LB SIZE RANGE: 2 1/16-8 5/8 IN. OD, RINEER 15-15 MOTOR CLINCHER BACKUP, TRIPLE VALVE MOST SIZES OF FARR PO... More Info

Tongs - Power - FARR TONG MODEL LW9625 TORQUE CAPACITY 12000 FT/LB SIZE RANGE 2 7/8 -9 5/8 OD WITH SAFETY DOOR MOST SIZES OF FARR POWER TONGS ARE IN HOUSTON, IN STOCK READY FOR IMMEDIATE... More Info

Tongs - Power - Farrs newest tubular connection tool offers a significantly reduced rig footprint, while continuing to deliver power & uncompromising reliability. The simple design drast... More Info

Tongs - Power - Farr Canada"s newest tubular connection tool offers a significantly reduced rig footprint, while continuing to deliver power and uncompromising reliability. The simple de... More Info

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

Torque range at 2200 PSI/15.2 MPA High gear 2,400 ft.lbs/3,254 Nm “Low gear 12,000 ft.lbs./16,272 Nm” Maximum RPM at 50 GPM/189 LPM High: 86 RPM Low: 17 RPM Hydraulic Requirements 50 GPM @ 1,000 PSI 189 LPM @ 6.9 Mpa 20 GPM @ 2,200 PSI 75 LPM @ 15.2 Mpa Length 47 inches/119.38 cm Overall Width 31 inches/78.74 cm Space Required on Pipe 8 inches/20.32 cm Maximum elevator diameter Unlimited (Tong comes off pipe) Center line of pipe to center line of anchor handle 34 inches/86.36 cm Weight (approximate) 1,050 lbs./476.7 kg

Find parts you need to repair or maintain your machines. At Alibaba.com, you can shop for power tongs for sale at affordable rates to tackle new obstacles and challenges. In the ever-changing industry, you can find what you need and speak to the supplier directly. Thanks to Alibaba’s collection of wholesale power tongs for sale you also get to buy these parts at lower prices, which means you can explore new levels every day more comfortably. From bulldozers to dragline excavators, wheel tractor scrapers to shotcrete machines, any part you need for a heavy-duty mining machinery; you can find it at Alibaba.com.

Looking for purpose-built machine parts? Find them at Alibaba.com. From new components to used parts straight from the manufacturers. Plus, if you need custom-made pieces, you can chat with the supplier, give specifications and wait on delivery. From stone crushers to excavator undercarriage parts, buckets, and even drill bits to get you through the rocks, the power tongs for sale from Alibaba offers you the chance to continue operating without a hitch. Whether you are looking to introduce concrete into the rock walls for more consistency and safety during mining, then power tongs for sale that goes at wholesale prices at Alibaba will be an excellent addition to your machinery.

Before buying a component, you’d want the equipment to suit your application and offer value. The list of power tongs for sale at Alibaba.com lets you dig into earth deposits, and the compare tool checks out other similar parts to give you the information you need to make a purchasing decision. You’ll get wholesale power tongs for sale that specializes in mining, with reinforced chassis, and run on more powerful engines. Whether you want to transport minerals or the workers to the mining site, introduce explosives or arms to help you remove materials from your mine pits, Alibaba.com has it all.

The 9-5/8” power tong with Rineer GA15-13 two-speed hydraulic motor, motor valve, lift cylinder valve, rigid sling, FARR® hydraulic backup, configured for compression load cell.

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for both Starr Power Tongs and McCoy Global hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

All of our power tongs are available with either the McCoy\\\\\\\\\\\\\\\"s patented WinCatt data acquisition software recently updated to the MTT systems or AllTorque\\\\\\\\\\\\\\\"s computer monitoring system for all the torque and turn control system needed in today\\\\\\\\\\\\\\\"s market for the making of tubular connections. Discover our wide selection of McCoy and Starr casing tongs, tubing tongs and power tongs for sale below!

MOT"s Hydraulic Power Tongs are used for running or pulling tubular strings during well repair, workover, snubbing, drilling and casing operations to extract oil and gas from wells. MOT’s

Our TEDA Style power tongs apply correct, uniform torque, reducing costly rod and tubing failures, delivering ample power to make up and break out rods and tubulars from 5/8” rod to 5-1/2” casing. Our series of XQ power tongs come with Bi-Directional jaw systems that save time and enhance safety, and go from make to break with the flip of a knob.

Tongs offer a variety of upgrades from our standard XQ series of TEDA Style models featuring Eaton hydraulic motors for extra torque and reliability, two or three spool directional control valves for more efficient hydraulic operations, and modified structures for higher strength, durability and adaptability to specific job requirements.

Are available from 5-1/2” to 20” pipe and are able to handle both API Standard and PREMIUM (Proprietary Steel Grade) casing connections which require higher torque. Available in a variety of models with hydraulic back-up tongs optional: “KMA", “KHT”, “TQ", “KJD”, “KD” and SE 16-25 with torques ranging from 15,000 ft-lbs up to 55,000 ft-lbs.

Are designed for quick and safe making up and breaking out of drill pipe and drill collars. Our “ZQ” series of hydraulic power drill pipe tongs are widely used in oil and gas drilling, in land and offshore operations around the world. The integrated torque tong and bucking tong eliminate the need for manual tongs and spinning chains, able to handle pipe from2-3/8” up to 8” drill collars, providing torques of up to 92,000 Lbs-Ft.

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

Manufacturer of motor operated hydraulic power tongs. Tubing, casing, drill pipe and riser hydraulic power tongs are available. Offered with self aligning throat, speed shifting and radial lock door. Optional torque control system, door interlock, wrap-around dies, integrated hydraulic backups, case handles, tong straps, motor port relief valve and finger guard protection are provided. Suitable for oil or gas drilling, well completion and servicing applications. Secondary services include assembly, engineering, welding, cutting, heat treating, machining, testing and inspection. Serves oil and gas industries. CE certified. Made in the USA.

Wil-Tech provides maintenance, repair, and complete overhaul services for tubing tongs. We stock components for all major brands of pipe handling product, and a variety of not so common components. Our technicians are extremely capable and well equipped to maintain and refurbish your pipe tongs, they offer seal replacements, bearing replacements, gear replacements, backup repair, motor replacements and repair, jaw replacements, and preventative maintenance to reduce the frequency for complete overhaul.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because a properly maintained pipe tubing tong tends to operate longer, more efficiently and safer. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides inspection services for open and closed tubing tongs, our pipe handling department are well equipped and provided thorough inspections on all componentry including; gears, hydraulic motors, fittings, jaws, cylinders, backups, and structural components. Over the course of usage tubing tongs face a barrage of punishment that can reduce efficiency; regular inspections can increase the longevity of your asset, keeping it operating smoothly and safely. Properly functioning tongs reduce operator frustration, reducing risk of injury while improving productivity; as an asset owner that is what you want.

Wil-Tech provides tubing tong rental services. While your tongs are being repaired you don’t have to worry about downtime. Not all malfunctions can be quickly remedied in the field, if your tongs experience a failure during production rest assured our set of rental tongs can get you out of the bind. We offer delivery to site and can pick up your malfunctioning tongs to be brought back to our shop for repair. We hope it doesn’t come to this for our clients but these situations occur and we want to offer our clients the right solution.

Wil-Tech provides paint preparation and painting services for tubing tongs. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s tongs out the door working and looking as close to as new as possible.

Wil-Tech provides performance testing service on all tubing tongs prior to leaving our shop as a quality assurance measure. Our technicians utilize a 50hp test bench to perform a variety of tests on the tubing tongs to ensure functionality, sealing, relief and performance.

Wil-Tech provides troubleshooting services for hydraulic tubing tongs. Whether in our shop or on-site, our technicians and facilities and mobile units are equipped to troubleshoot your tubing tong. If your asset isn’t operating as expected let our technicians identify and resolve the problem.

Wil-Tech services and installs torque gauge and sensing equipment on tubing tongs. Our technicians repair, calibrate and certify gauges. Our component technicians work in tandem with our pipe handling department to ensure your gauges are reporting accurate measurements.

Wil-Tech provides hydraulic top-drive repair and maintenance services. Our technicians thoroughly repair and replace components to ensure your top-drive is as close of an as-new product as possible. We stock a variety of top-drive components and products to keep them function safely and efficiently.

Wil-Tech provides hydraulic top-drive inspection services. Our technicians meticulously inspect and document condition of the hydraulic top-drive and provide a thorough review of their findings. We offer our clients the convenience of performing our inspection services on site and in the field.

Wil-Tech provides maintenance and repair services for hydraulic kelly spinners. Our technicians perform general maintenance tasks, including seal replacements, bearing replacements, fitting replacements, greasing, chain replacements as well as component replacements and complete overhauls. We encourage our customers with pipe handling equipment to regularly maintain their asset, because a properly maintained pipe Kelly spinner tends to operate longer, more efficiently and safer. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides inspection services for hydraulic kelly spinners, our technicians perform a thorough review of the hydraulic motor, gears, fittings and connections, jaws, bearings and structural components. Regular inspections can identify problems before they end up causing damage and/or injury and should be included in the asset’s preventative maintenance schedule to protect both the asset and its operators.

Wil-Tech provides troubleshooting services for hydraulic kelly spinners. Whether in our shop or on-site, our technicians and facilities and mobile units are equipped to troubleshoot your kelly spinner. If your asset isn’t operating as expected let our technicians identify and resolve the problem.

Wil-Tech provides testing services for hydraulic kelly spinners, our technicians test for function, leaks, reliefs as well as performance on a 50HP test bench. All spinners are tested post-assembly, before leaving our shop.

Wil-Tech provides maintenance, repair, and complete overhaul services for rod tongs. We stock components for all major brands of pipe handling product, and a variety of not so common components. Our technicians are extremely capable and well equipped to maintain and refurbish your pipe tongs, they offer seal replacements, bearing replacements, gear replacements, backup repair, motor replacements and repair, jaw replacements, and preventative maintenance to reduce the frequency for complete overhaul.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because a properly maintained pipe rod tong tends to operate longer, more efficiently and safer. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger.

Wil-Tech provides inspection services for open and closed rod tongs, our pipe handling department are well equipped and provided thorough inspections on all componentry including; gears, hydraulic motors, fittings, jaws, cylinders, backups, and structural components. Over the course of usage rod tongs face a barrage of punishment that can reduce efficiency; regular inspections can increase the longevity of your asset, keeping it operating smoothly and safely. Properly functioning tongs reduce operator frustration, reducing risk of injury while improving productivity; as an asset owner that is what you want.

Wil-Tech provides rod tong rental services. While your tongs are being repaired you don’t have to worry about downtime. Not all malfunctions can be quickly remedied in the field, if your tongs experience a failure during production rest assured our set of rental tongs can get you out of the bind. We offer delivery to site and can pick up your malfunctioning tongs to be brought back to our shop for repair. We hope it doesn’t come to this for our clients but these situations occur and we want to offer our clients the right solution.

Wil-Tech provides paint preparation and painting services for rod tongs. Wil-Tech houses an industrial part washing unit, sandblasting cabinet and paint booth for full service component paint preparation and painting. Our technicians take pride in sending our client’s tongs out the door working and looking as close to as new as possible.

Wil-Tech provides performance testing service on all rod tongs prior to leaving our shop as a quality assurance measure. Our technicians utilize a 50hp test bench to perform a variety of tests on the rod tongs to ensure functionality, sealing, relief and performance.

Wil-Tech provides troubleshooting services for hydraulic rod tongs. Whether in our shop or on-site, our technicians and facilities and mobile units are equipped to troubleshoot your rod tong. If your asset isn’t operating as expected let our technicians identify and resolve the problem.

Wil-Tech services and installs torque gauge and sensing equipment on rod tongs. Our technicians repair, calibrate and certify gauges. Our component technicians work in tandem with our pipe handling department to ensure your gauges are reporting accurate measurements.

Wil-Tech provides maintenance and repair services for hydraulic spiders. Our technicians thoroughly refurbish tubing spiders to as close of an as-new product as possible. We stock a variety of components and products to keep them gripping and latching securely.

We encourage our customers with pipe handling equipment to regularly maintain their asset, because as with any device securing downhole tools, safety is of the utmost concern. Operating pipe handling equipment can be dangerous as it is, don’t let neglect add to the danger. Save yourself the cost of the damages and fishing tools and ensure you’re properly maintain your hydraulic spiders.

Wil-Tech provides inspection services for hydraulic tubing spiders, our technicians perform a thorough review of the hydraulic cylinders, jaws and structural components. Regular inspections can identify problems before they end up causing damage and/or injury and should be included in the asset’s preventative maintenance schedule to protect the asset, its operators and its owner.

8613371530291

8613371530291