us power tong quotation

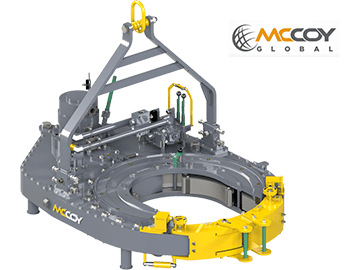

The HD31000 casing tong can handle tubulars as small as 10-3/4″ and as large as 31″ in diameter. Other sizes can be special-ordered. Tong can be mounted on either a CLINCHER® or a FARR® hydraulic backup. Available with McCoy’s patented WinCatt® data acquisition and torque control system for the make-up of tubular connections.

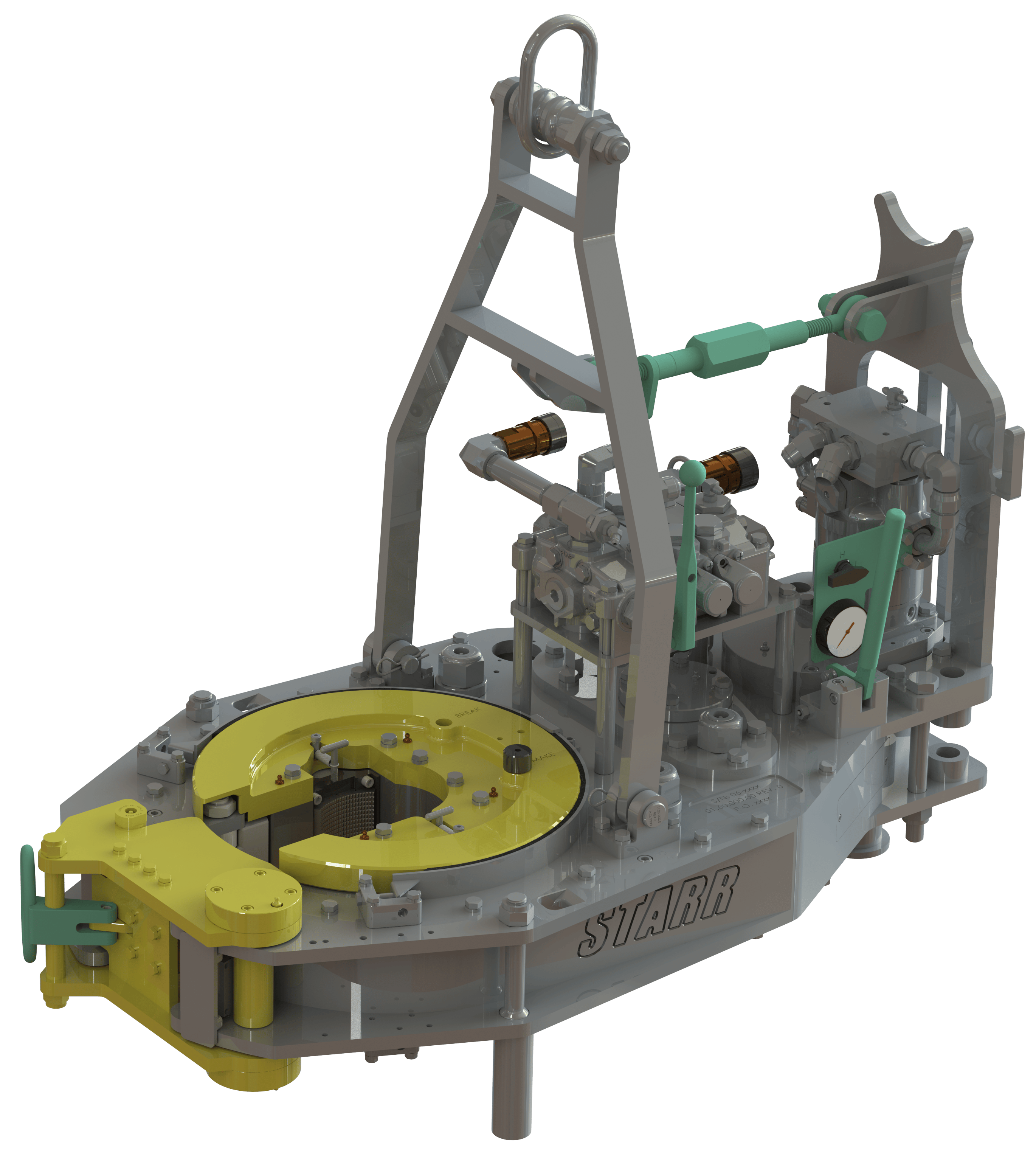

Our power tongs are built to last. With 1 motor options for the 6 1/4” hydraulic power tong, you crew can reach rated torque at 2500 psi. Which means, the tools can reach their rated torque dependably on ever single joint, every day.

With an investment like this, you don’t want one malfunctioning part to be the reason why your equipment isn’t performing. That’s why we build our tongs to be serviceable, high in quality. By using an ISO 9001:2015 quality system, we maintain a close eye on our products.

Lastly, if you find your team in a bind, and need a part. Starr likely has the part on the shelf. Call us today for a quote, and possible overnight shipping.

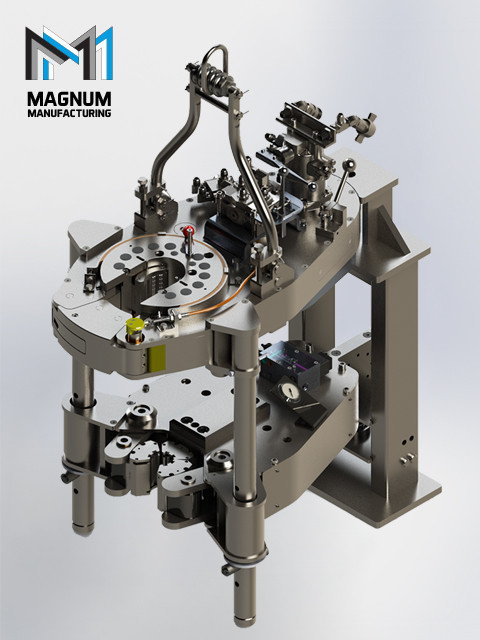

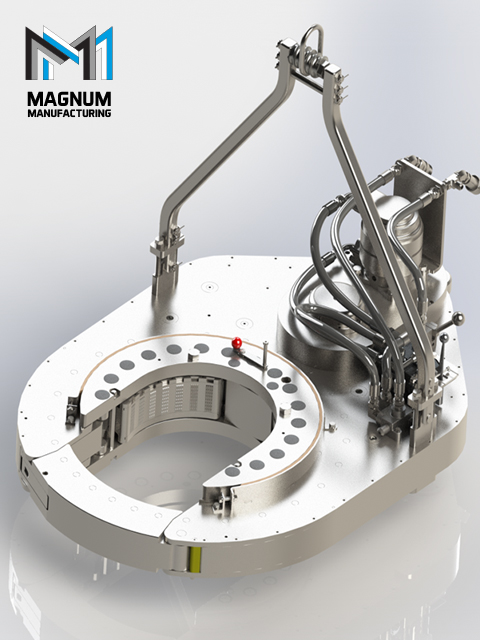

Magnum Manufacturing is a team of experienced casing running engineers and industry-leading professionals tired of working with existing substandard equipment. We have spent decades developing equipment to the highest industry standards, and we personally have been using the equipment we’ve developed. After 30+ years of partnering with a leading American TRS company to ensure optimal performance, we are prepared to stake our reputation on Performance, Longevity, & Safety.

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

The Eckel Top Drive Casing Tong is a tool developed for use on hydraulic top drive rigs to provide a high quality connection while reducing tubular damage and providing a safer enviroment for crews. With an operating capacity of 4 1/2 inch through 10 5/8 inch, is connected to the output stem of the power swivel. After installation the tong becomes an integral part of the swivel, raising and lowering as a unit and transfering the power swivel"s RPM and torque to the pipe/connection.

A guide attached beneath the top drive tong simplifies alignment of the collar within the tong. Once the collar of the pipe is enclosed within the top drive tong, the tong will grip the collar by operating the power swivel. Torque and rotational speed are controlled through the operation of the power swivel. Reversal of the power swivel will cause the tong jaws to release. Tong jaws are spring loaded to retract away from the collar.

Utilizing three gripping jaws and a patented Eckel Cam Biting System to grip the pipe collar. The same type of proven biting system found in the industry leading Eckel Power Tongs. These jaws are spaced evenly about the circumference of the collar to provide even distribution of the gripping forces

We offer a full range of high quality casing and tubing, drill pipe tongs for use in all types of oil and gas drilling, well completion and well servicing activities. Our tongs have been engineered for the high operational torques today"s that premium connections require. Eckel tongs continue to advance the technology of tool service and setting industry standards.

Our proprietary True Grit® have set NEW industry standards in handling Corrosion Resistant Allows (CRA) tubular goods. True Grit® are used on chrome tubulars where reduced die penetration and die marking is desired. TRUE GRIT® dies are long lasting 3 times longer than competing technologies and perform better than any steel tooth die when running (SUPER or HYPER) Chrome. Tubular penetration of the True Grit® is less than half of API allowable surface defect area.

Our renowned free floating Tri-Grip®hydraulic backup provides unparalleled backup performance and is one of the industry"s closest tong mounting backups that minimize pipe bending. The backup utilizes three biting surfaces to insure a secure grip on the tubular to prevent tubular rotation.

Our remotely operated tongs provides a mean to control the tong for make-up and break-out operations. The tong is based upon the standard tong and backup configuration with the exception of hydraulic cylinders on the unit for remote control of the operations of the tong and backup. The functions include the tong door, backing pin, mechanical gear shift, power tong rotation, motor speed and backup gripping. Totally hydraulic with no electrical or electronic devices.

Eckel"s standard diesel or electric power packages at 65 GPM and 2,500 psi (246 LPM / 172 bar) are widely recognized for dependability and long, trouble-free service. Eckel will customize hydraulic power systems in the shortest possible time to meet "nonstandard" requirements for space, fluid flow, auxiliary power, and portability. Diesel driven units are optionally supplied with automatic shutdown systems to prevent engine run away when explosive gases are present. Additional shut downs include engine oil temperature, oil pressure, and fan belt breakage. All controls are either air, mechanical or electrical.

Eckel Manufacturing is committed to maintaining its position as an industry leader of the manufacturing of precision engineered specialty oil field equipment. It is our policy to provide our products at the highest quality that meets our customer"s requirements and demands.

Our trained specialists are on hand in all areas of Russia for technical support during the commissioning of new equipment and when technical issues arise with running and handling of our products.

The quote is the core of GOM Energy Services LLC philosophy and the services provided. Cory Forbes has over 20 years in the Power Tong industry in Sales at a leading manufacturer before starting his own company in REMAN and Repair to Power Tongs.

Our staff consists of professionals from the industry in services, sales and repair. Each service technician has at least 9 years experience in power tong repairs. Our new Shot Peening service has been a great addition to blast the tong casing bodies while we take your existing product and make it as new it was when it was purchased. Click the process below to find out what you can expect in the GOM Energy Services LLC REMAN services.

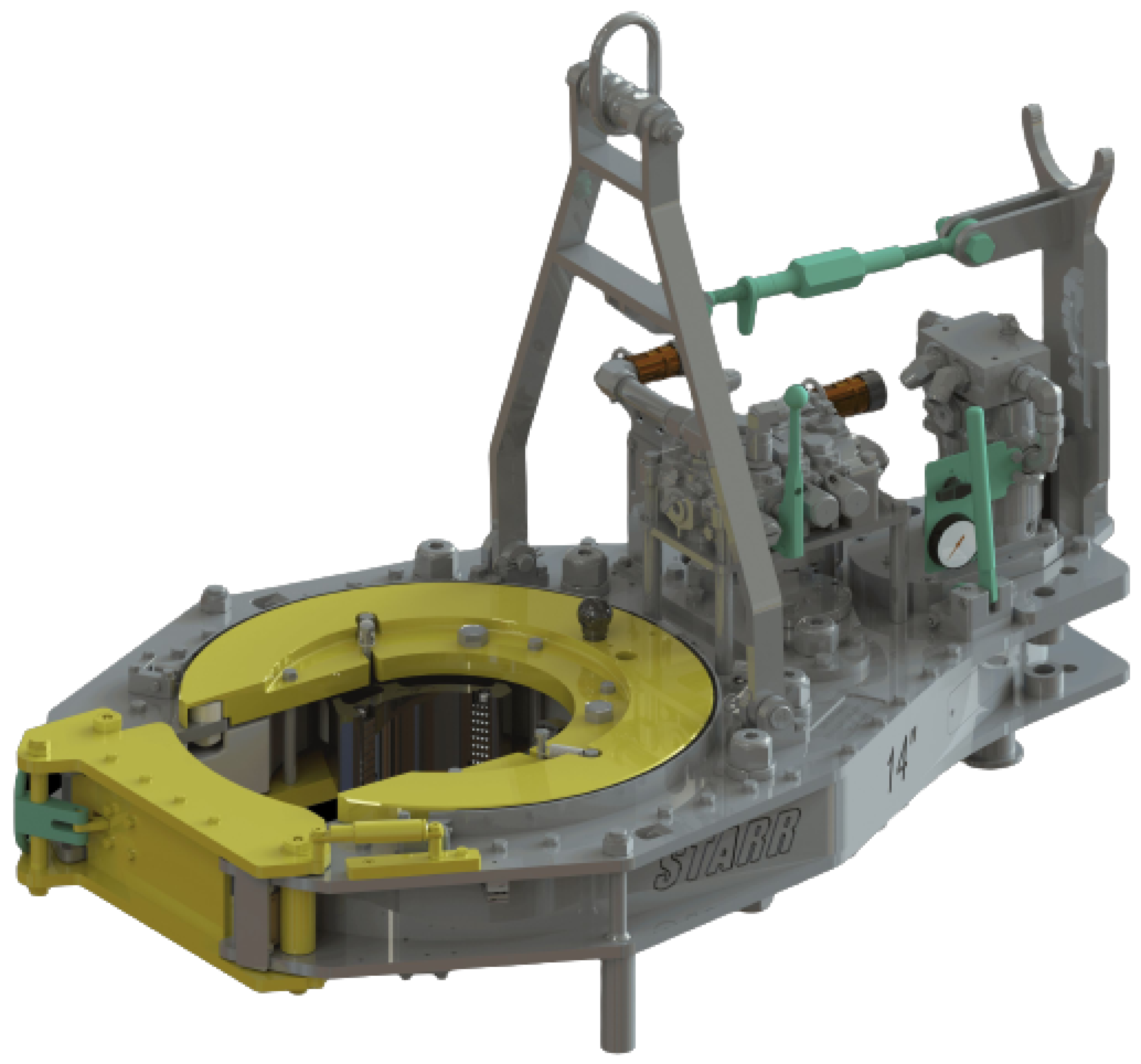

The 14-100 hydraulic power tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 7- to 14-in. casing. The tong has a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

Our 14-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 6 5/8- to 14-in. casing. The tong has a unique gated rotary, a free floating backup, and a hydraulic door interlock.

The 16-25 hydraulic casing tong provides 25,000 ft-lb (33,900 N∙m) of torque capacity for running and pulling 6 5/8- to 16-in. casing. The tong features a unique gated rotary and as many as seven contact points that create a positive grip without damaging the casing.

Rigged up without rig modifications, our 21-300 riser tong is the only tong capable of producing 300,000 ft-lb (406,746 N∙m) of continuous rotational torque in both makeup and breakout mode. The power it achieves in a compact size compares with a conventional 24-in. casing tong.

The 24-50 high-torque casing tong provides 50,000 ft-lb (67,790 N∙m) of torque capacity for running and pulling 10 3/4- to 24-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

The 30-100 high-torque casing tong provides 100,000 ft-lb (135,600 N∙m) of torque capacity for running and pulling 16- to 30-in. casing. The tong features a unique gated rotary, a free-floating backup, and a hydraulic door interlock.

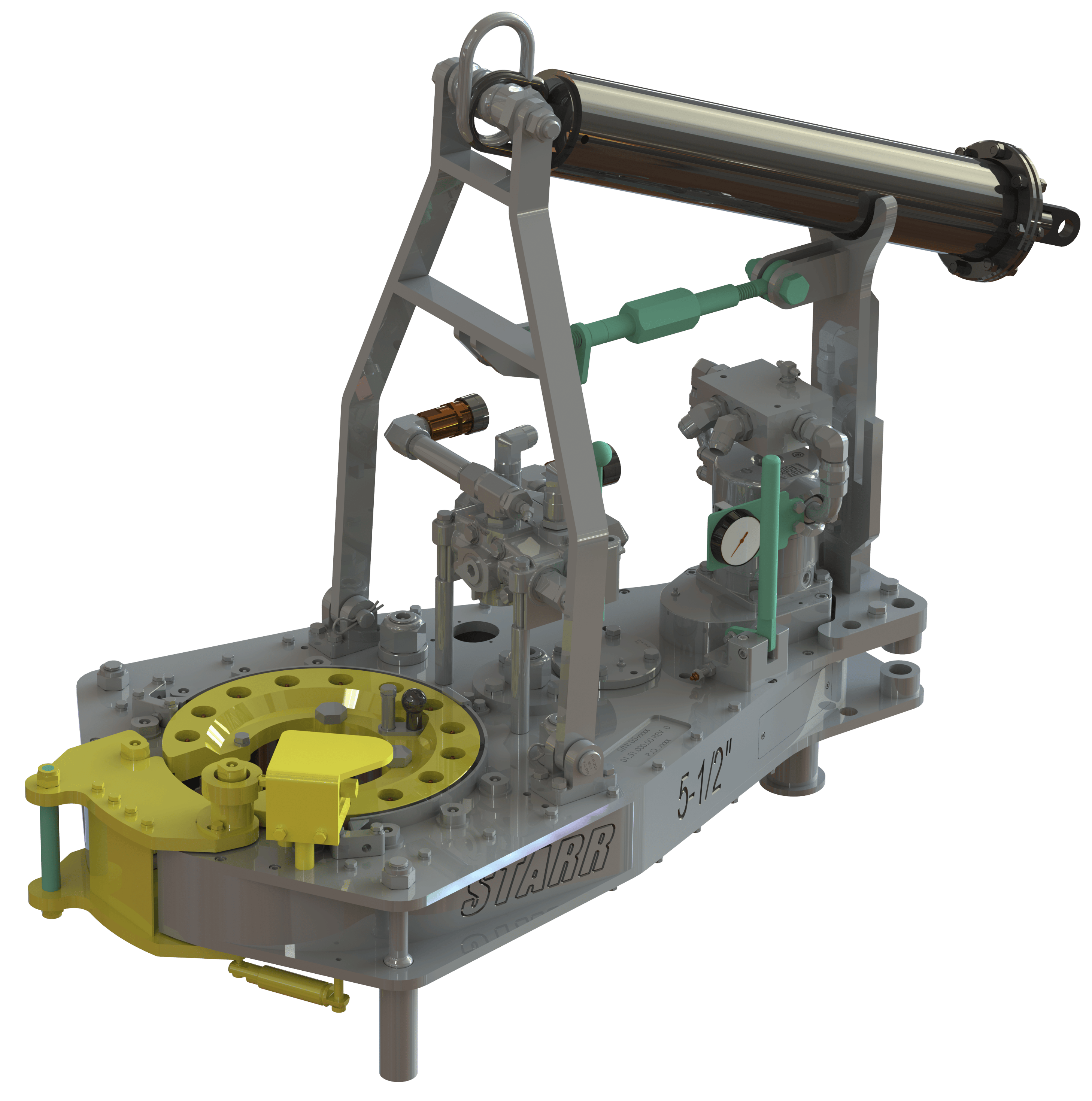

The 5.5-15 hydraulic tubing tong provides 15,000 ft-lb (20,340 N∙m) of torque capability for makeup and breakout of 1.66- to 5.5-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

The 7.6-30 hydraulic tubing tong provides 30,000 ft-lb (40,670 N∙m) of torque capability for makeup and breakout of 2 3/8- to 7 5/8-in. tubing and premium or standard connections on corrosion‑resistant alloy tubulars. The tong features an ergonomic, lightweight design with a free-floating hydraulic backup.

Our SpeedTork 8.0-70 tong provides torques up to 70,000 ft-lb (94,900 N∙m) and 360° rotation in makeup and breakout operations. It can torque drillpipe connections, drillstring components, drilling tools, packers, couplings, and valves.

Straight Tong Die Driver: Used for die slot redressing, the straight tong die driver is the simplest of type of rig tong. Though it is also the simplest type of rig tong to use, it is also the least safe of the three. Its handle and handguard protect hammer blows from falling onto the grip. Straight tong die drivers are lightweight—under eight pounds—and measure in at around 1”.

Angled Tong Die Driver: The angled tong die driver has a grip that’s angled away from the perpendicular tong as well as brass guards for the tong tip and handle, making this rig tong safer than the straight tong die driver. While this tong is safer, however, it’s actually harder to keep the angle tong die driver in place. This driver is similar in length to the straight tong die driver, but is about two pounds heavier, weighing in at over nine pounds.

Hammerless Tong Die Driver: This variety of tong die driver is made up of a hand pipe that can be used to apply pressure to the tong’s tip without using a hammer at all. This option is the safest of the three driver types because there’s no hammer required, it’s also the slowest driver for this same reason. The hammerless tong die driver is about as long and weighs as much as the straight tong die driver.

What oilfield tools does your operation need? Keystone Energy Tools has atool to fit your bill.Contact us today to learn more about how rig tongs can make your work environment safer, and to learn more our other oil and gas industry products.

KHT14000 Casing Power Tong is used to make up and break out for casing operation in oil fields. It has greatly reduced the labor of worker, enhanced connection quality of thread and diminished accidents in inappropriate casing operation. The power tong has the following features as well:

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291