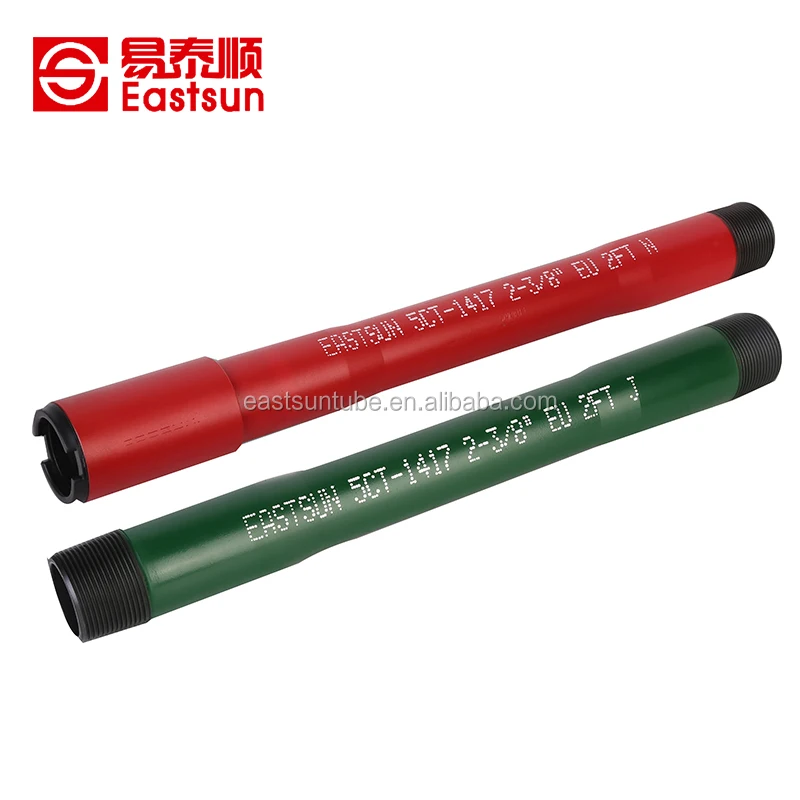

eue pup joint manufacturer

Pup Joint Inc. is a machine shop that sells down hole tubular and casing accessories and equipment. We are a leading supplier of pup joints & accessories with API5CT & premium threads at very competitive prices. Our machine shop is a threading facility for all your threading & precision machining needs. PJI commenced operations in Houma, LA in July of 1997. Our staff has over 65 years of combined experience supplying quality products & services to the oil & gas industry.

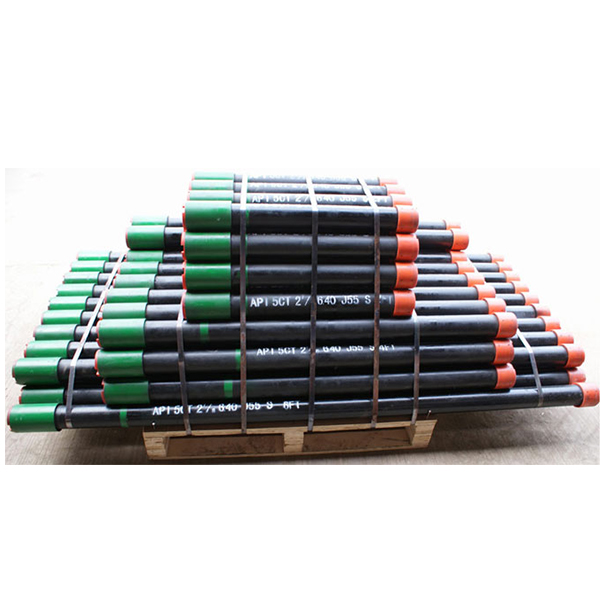

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

These J55, L80, N80Q & P110 pup joints are manufactured from seamless Grade J-55, L80 N80Q and P110 mechanical tubing. The API 5CT tubing pup joint is mainly used to adjust the height of the tubing strings. It is also used to adjust the depth of down-hole tools.

One is a short Drill Pipe used to adjust the length of the Drill String; The other one OCTG Pup Joint is a pipe of non-standard length, which is used to adjust the length of tubular strings to its exact requirement.

Vigor can manufacture the Tubing Pup Joints by different technology - Upsetting and Machining process. if you have a special requirement on the Pup Joint production process, please just specify.

If you are looking for a competitive, high quality and fast delivery oilfield pup joint in stock, or if you are planning to buy pup joint API from one of the leading casing and tubing pup joint manufacturers, API 5CT pup joint in stock, l8013cr pup joint, nue/nue tubing pup joint manufacturers and suppliers China, please feel free to contact VIGOR.Details of API Spec. 5CT Oil Tubing Pup Joint

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly’s, subs and pup joints, and pipes.

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

DIC is a Manufacturer and Exporter of Crossover Pup Joints in Ajman, UAE. It is used for crossing over from the size of a single connection to the other in the drill string.

We supply crossover pup joints in all sizes, grades, and thread profiles. All our products have passed the ISO certification and API certifications. Our products are tested numerous times under technical guidance and are made from the best quality material.

We are one of the prominent Suppliers and Exporters of Tubing Pup Joints in UAE. Tubing pup joints produced according to API 5CT Specification. Our precision-engineered tubing pup Joints are ideal for spacing out down-hole assemblies and handling the production of tubing accessories. We supply tubing pup joints in all sizes and grades. All our products have passed the ISO certification and API certifications.

We are highly appreciated among our clients for providing the best quality tubing pup joints and other oilfield equipment. Our products are tested numerous times under technical guidance and are made from the best quality material. Standard and non–standard sizes are available as per customer requirements.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

It is produced according to API 5CT Specification. Our precision-engineered pup Joints are ideal for spacing out down-hole assemblies and handling the production of tubing accessories. As a tubing pup joints manufacturer in China, we also provide API 5CT casing pup joint which is the accessory of the casing strings.

Our tubing pup joints have passed the ISO9001:2000 international quality management system certification and the API certificate of the American Petroleum Institute.

1.Before sale, our company can provide samples and plans for clients according to the given budget. The costs should be borne by clients. We also provide some wearing-parts of the tubing pup joint like thread protector.

2.The delivery time depends on the order quantity. The minimum quantity is 20 t. We provide the pup joints to clients and positively cooperate with the third party on the supervision and inspection arranged by the clients.

Casing pup joint is mainly used to adjust the height of the casing strings. It is also used to adjust the depth of down-hole tools. Our pup joints are manufactured in accordance with the API...

Pipe system involves various components, including eue pup joint and are made from different materials. We offer wholesale eue pup joint to create a smooth channel for the pipe systems in both commercial and residential areas.

Pipe system involves various components, including 2 7 8 eue pup joint and are made from different materials. We offer wholesale 2 7 8 eue pup joint to create a smooth channel for the pipe systems in both commercial and residential areas.

The oil production well variable-diameter tubing short joint includes a large-diameter pipe and an oil pipe, the left end of the large-diameter pipe is fixedly connected with a small-diameter pipe, and the right end of the large-diameter pipe is fixedly installed with two clamping posts, the large-diameter pipe is The externally fixed and installed bumps are evenly distributed on the left side of the clamping column. The oil production well variable diameter tubing short joint is used in conjunction with embedded pipes and small diameter pipes, as well as fastening bolts and fixed threaded holes, so that the oil production well can be reduced in diameter. The type tubing sub joint can insert the embedded pipe into the inside of the small diameter pipe through the clip and the limit groove. When the fixed threaded hole outside the embedded pipe is aligned with the through threaded hole outside the small diameter pipe, rotate the tightening bolt to make the end of the tightening bolt It is embedded in the inside of the fixed threaded hole to complete the fixed connection between the embedded pipe and the small-diameter pipe. Since the embedded pipe is provided with various types, this oil production well variable-diameter tubing sub can effectively solve the problem of variable diameter.

8613371530291

8613371530291