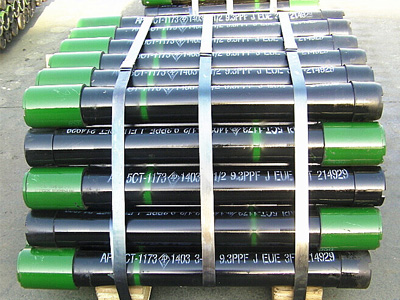

eue tubing pup joint manufacturers factory

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

The oil production well variable-diameter tubing short joint includes a large-diameter pipe and an oil pipe, the left end of the large-diameter pipe is fixedly connected with a small-diameter pipe, and the right end of the large-diameter pipe is fixedly installed with two clamping posts, the large-diameter pipe is The externally fixed and installed bumps are evenly distributed on the left side of the clamping column. The oil production well variable diameter tubing short joint is used in conjunction with embedded pipes and small diameter pipes, as well as fastening bolts and fixed threaded holes, so that the oil production well can be reduced in diameter. The type tubing sub joint can insert the embedded pipe into the inside of the small diameter pipe through the clip and the limit groove. When the fixed threaded hole outside the embedded pipe is aligned with the through threaded hole outside the small diameter pipe, rotate the tightening bolt to make the end of the tightening bolt It is embedded in the inside of the fixed threaded hole to complete the fixed connection between the embedded pipe and the small-diameter pipe. Since the embedded pipe is provided with various types, this oil production well variable-diameter tubing sub can effectively solve the problem of variable diameter.

BLAZE is adequately equipped to supply NPST Pup joints made of high quality seamless pipeline with male & female detachable hammer union. NPST has uniform bore for greater flow capacity. NPST pup joints are available in 2″ to 4″ sizes, length for pup joint range from 1 feet to 20 feet at 15000 psi. Pup joint with Non- pressure seal thread union (NPST) are especially engineered for high pressure, abrasive services where welded connections are not desired. The design provides a strong, permanent end connection without butt welding. An epoxy thread-locking compound secures the connection.

Casing or Tubing Pup Joints, Casing or Tubing Connectors and Casing or Tubing Couplings. In addition it is capable of Threading items at Groups 1, 2, 3 & 4 of API spec. 5CT. Items supplied by BLAZE meet the Quality Standards as defined in API 5CT assuring

BLAZE is also well equipped to supply Line Pipe Couplings/ NPST pup joints with wide range of specifications. In addition we can supply thread Line Pipes and its accessories of various sizes. Items meet the quality standards as laid down in API – 5L.

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

API thread: Pipe thread specified in API 5B standard, including tubing round thread, casing short round thread, casing long round thread, sleeve partial trapezoidal thread, line pipe thread, etc.

Windlass manufactures Pup Joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines.

Prithviraj Industries manufactures Pup Joints up to 20, 000 psi cold working pressure in sizes: 1, 11 /2, 2, 3, and 4-inch bore sizes, lengths to 20 feet.

ADFO manufactures Pup Joints with Integral Hammer Union end connections.These Pup Joints are used on high pressure discharge lines, choke and kill lines, auxiliary flow and other applications.

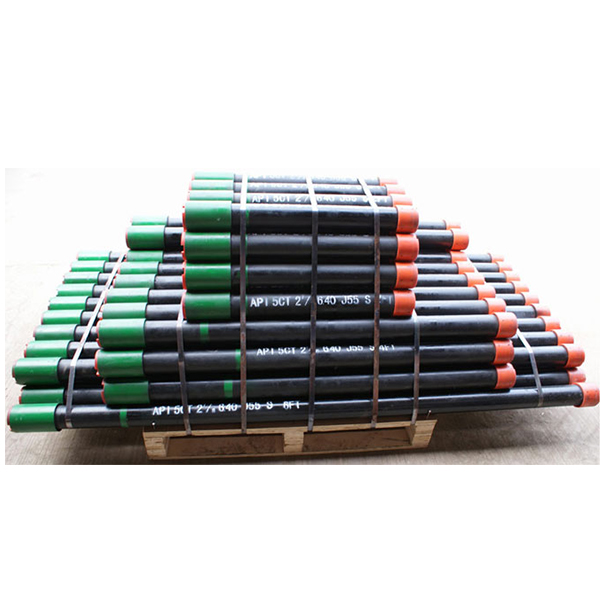

OCTG Pup Joints is one kind of common accessories for connection with casing and tubing. Threaded pup joints are divided into male threaded ends, single male threaded and Female threaded. The size and material is the same as the casing or tubing.

China N80 Pup Joint Manufacturer Derbo Supplies N80 Pup Joint, Hot Rolled, 1.66 Inch, EUE 2.40lb/ft, Oiled, Painting Finish, for Oil & Gas Industries.

PUP JOINTS are a joint of pipe of non-standard length used to adjust the length of tubular strings to exact requirement. We provide both tubing (2 3/8” to 4”) and casing (4” to 13 3/8”) in all lengths. With our myriad of licenses (quality page) we are able to cut to length, thread and couple to meet specified needs. API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Premium pup joints are also available with premium connections and in API or exotic alloy grades.

MARKER JOINTS are a joint of tubing used in a workover or completion tubing string that serves as a position or depth indicator. In most cases, a marker joint is significantly shorter than other joints in the string so that it is easily noticeable.

The drill pipe joint is an important connecting part of the oil drill pipe and drilling tool, and is widely used in the oil drilling industry. Our pup joint drilling is finished with high-quality and unique materials for excellent durability and precise dimensional accuracy. The threads on the fittings are cut on a CNC machine, which ensures high precision of the threads and prolongs the service life of the fittings. Considering the specificity in practical applications, we use phosphate coating or copper plating to enhance the wear and chemical resistance of the joint. This pup joint drilling has good mechanical strength and comprehensive performance and meets international standards, it can be widely used in oil, natural gas, sewage treatment and other industries.

Outside Diameter of Tubing Joint: From 2-3/8"(60 3mm) to 4.5"(114.60mm) Pipe End: EUE/NUE Outside Diameter of Casing Joint: From 4-12"(114 3mm) to 20*(508mm)

PUP JOINT DRILLING, PUP JOINT INC, PUP JOINT, PUP JOINT OIL AND GAS, NPST PUP JOINT, API PUP JOINT DIMENSIONS, PUP JOINTS FOR SALE. DRILL, API, API 5CT, CASING, EUE, PIPELINES, TUBING,

Hot Tags: pup joint drilling, China, suppliers, manufacturers, factory, low price, for sale, in stock, made in China, ERW Structural Pipe, Socket Weld Cap, Class150 Blind Flange, Api 5l Line Pipe, Steel Pipe Reducer, Oil Casing and Tubing

In the oil and gas drilling industry, the tubing pup joint is a critical component for the completion of a well. The pup joint allows the driller to change out the drill pipe without having to pull out the entire string of pipe from the well. This is a common practice, especially when drilling deep wells. Because of this, the tubing pup joint is one of the most important joints in any well.

Tubing pup joints are small-diameter tubing that is used in conjunction with casing to complete a well. The pup joint is run in the hole and cemented to the casing, and then the production tubing is run over it and attached. This arrangement allows for the use of smaller-diameter production tubing, which results in less pressure drop and improved production. The pup joint is usually located in the last few feet of the tubing string.

When you need tubing pup joints, Action is the only source you need to know.Westcan Oilfieldhave awide selection of productsto meet your needs and we offer some of the best prices in the industry. You can trust that we’ll provide you with quality products that you can count on.

8613371530291

8613371530291