nue tubing pup joint factory quotation

BLAZE is adequately equipped to supply NPST Pup joints made of high quality seamless pipeline with male & female detachable hammer union. NPST has uniform bore for greater flow capacity. NPST pup joints are available in 2″ to 4″ sizes, length for pup joint range from 1 feet to 20 feet at 15000 psi. Pup joint with Non- pressure seal thread union (NPST) are especially engineered for high pressure, abrasive services where welded connections are not desired. The design provides a strong, permanent end connection without butt welding. An epoxy thread-locking compound secures the connection.

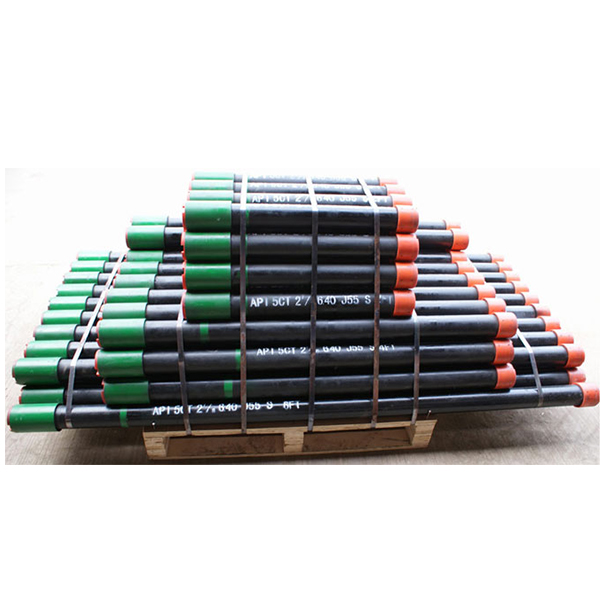

Casing or Tubing Pup Joints, Casing or Tubing Connectors and Casing or Tubing Couplings. In addition it is capable of Threading items at Groups 1, 2, 3 & 4 of API spec. 5CT. Items supplied by BLAZE meet the Quality Standards as defined in API 5CT assuring

BLAZE is also well equipped to supply Line Pipe Couplings/ NPST pup joints with wide range of specifications. In addition we can supply thread Line Pipes and its accessories of various sizes. Items meet the quality standards as laid down in API – 5L.

For oil well tubing pup joints, WORLD IRON&STEEL can provide various cut-to-length oil well tubing pup joint accessories of API standard type (EU, NU, SC, LC, BC, etc.) and BSIG special type according to individual requirements of customers. According to the needs of on-site use, the pup joints can be processed into pup joints with couplings, double male buckle pup joints, conversion pup joints with different buckle types, conversion pup joints with different outer diameter specifications, etc.

API SPEC 5B standard EU, NU, SC, LC and BC threads, BISG self-developed and designed airtight special buckle CBS1: BISG airtight type I special buckle (tubing and casing), CBS2: BISG airtight Type 2 special buckle (tubing and casing), CBS3: BISG airtight type 3 special buckle (tubing and casing), CBSJ: economical low-pressure sealing special buckle (tubing and casing), CB-NUFJ: BISG Direct connection type airtight special buckle (tubing and casing), EU-HT/BC-HT: high torque resistance to top special buckle oil casing

The tubing pup joint offers high strength design to ensure excellent performance for joints of API 5CT drill pipe and tubing. World iron&steel manufacture, supply, sell OCTG, pipe, collar, joints and other accessories in various sizes and specifications, if you are looking for this material, please contact us or get a quotation. Not only do we have all kinds of sizes, but we also have all kinds of sizes that are hard to find.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Flow Couplings are heavy wall box by box connectors used in tubing strings and are designed to minimize the effect of internal erosive action caused by production fluids. Flow couplings are located just above or below Landing Nipples, Safety Valves or Control Devices where turbulent flow problems are likely to occur. Crossover flow couplings are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 3" and 6". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

A washover pipe is Casing or Pipe shorter in length than a standard tubular string. Made of large-diameter pipe with a cutting surface at the tip, washover pipe is run in the well and then the cutting edge grinds the fish to a smooth surface and continues normal operations. Washover Pipe is manufactured to the following specs connections, lengths, weights and material grade.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to Hardness range of 285-341 with a Charpy "V" notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

With the help of a strong research and development team and long-term market research, we have developed original BS1387 ERW Welded Pipe, Oil Casing Pipe, ASTM A572 Fluid Pipe that meet the market demand and are loved by consumers. We actively extend the industrial chain in accordance with the principle of supporting and promoting the development of the main business. Our company implements a very strict code of conduct and accepts the supervision of friends and customers from all walks of life. Our company adheres to the business philosophy of "professional, honest, and trustworthy" to serve customers with better quality, lower cost, higher efficiency and more professional perspective. In the future development road, our company will continue to adhere to the quality of technology as the core competitiveness, high-quality products and sincere service as the foundation, to fully meet the needs of customers as its own responsibility, to make the enterprise bigger and stronger, to become a pioneer in the industry.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

All kinds of Casing and Tubing Jfe Nsct Pup Joint for OCTG produced by our company have reached the national standards. We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We hope to gain the trust and support of our customers, employees, communities and other stakeholders, and work together to make our company stronger, better and bigger.

ADFO manufactures Pup Joints with Integral Hammer Union end connections.These Pup Joints are used on high pressure discharge lines, choke and kill lines, auxiliary flow and other applications.

Shreeraj Industries offers NPST (Non-pressure Seal Thread) Pups in size 1-3 Fig 602 and 1502. The NPST connection offers a light weight pup capable of 6000-15000 CWP with a connection that isolates the thread from fluid’s flowpath. This connection is permanent and is well suited to abrasive applications where a weldedread more...

Windlass manufactures Pup Joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines.

API Coupling refers to the steel couplings that used in connecting casing pipe and tubing. Also known by OCTG coupling, it is usually manufactured in seamless type, material grade same with the pipe body (API 5CT K55/J55, N80, L80, P110 etc), same PSL or providing higher grades than requested. Same heat treatment also applicable, except there is an special requirements.

With this purpose, API 5CT standard coupling plays an important feature in connecting casing and tubing line pipes. On the contrary, the biggest different with general steel pipe coupling is: API coupling manufacturing processes is more rigorous, requires a precisely control in the different processes as blew listed.

As we told, one of the important figure of API coupling, that it shall be made of seamless, another is the same grade as the casing or tubing pipe body, and these materials are used for manufacturing the blank coupling.

In case purchase order did not specified heat treatment types, J55/K55 casing or tubing coupling shall be furnished either in as rolled, normalized, normalized and tempered, or quenched and tempered.

Mechanical properties of casing or tubing coupling shall comply to the clauses 7 and 10, covers test frequency, retest provision, etc. And this test records could be shown to third party inspector assigned from the client.

There are several types covered in API 5CT standard for coupling specifications, classified in regular couplings, special clearance couplings, combination couplings, reducing couplings, seal ring couplings, and special bevel tubing regular couplings.

In case specified in the contract, special-clearance (reduced outside diameter Wc) couplings for buttress (BTC connection) casing and external upset (EUE connection) tubing shall be furnished. Unless otherwise specified, special-clearance external upset tubing couplings shall have a special bevel on both ends. The inside and outside edges of the bearing face shall be rounded or beveled. The ends (or root face when beveled) of couplings shall be faced at right angles to the axis.

There are couplings for casing and couplings for tubing, the function is the same that to connect the pipe each other. On the other hand, still there are some differences between the two.

Normally tubing coupling OD maximum is 4 1/2”, as the tubing pipe is applied for the drilling activities (Inside the tubing is the sucker rod to drill/pump the oil), couplings type is more various and rigorous than casing, mostly used is thicken type upset coupling (Internal upset and external upset), for short is EUE coupling, it is the most favorable in tubing connections. Tubing with EU end (EUE) coupling connection also called UPTBG. Because of the end of the tubing is thickened (upset), the connecting stress is better than buttress coupling.

The oil tubing coupling can solve the problem of fatigue fracture in the existing coupling due to stress concentration. Oil tubing end is connected to the inside wall of the coupling in a tapered thread. The coupling body end and oil tubing are connected with same thread pitch flat thread. The coupling is not easy to produce fatigue fracture, and has good connection effect. It can prevent the accident of oil well pipe string break effectively.

Casing coupling is for the dimensions more than 4 1/2 inch. Differently than tubing coupling is, casing coupling normally does not need to be thickened (Non-upset), which means no upset casing coupling, so it has following types:

The oil casing coupling is a necessary piece used to connect the two casing. The coupling manufacturing method is the same as seamless pipe. The steel pipe ends with internal thread to connect with the upper and lower casing. In order to ensure the joint tightness, the precision of screw thread is strictly required.

API 5B covers dimensions, tolerances, and marking for API threads and the gauges that control the acceptance criteria for the threads. It includes thread element gauges, instruments, and requirements for the inspection of threads for line pipe, casing and tubing (round threads), and buttress casing connections. Thread dimensions shown without specifications (or shown as NA) are not subject to inspection of diameter, ovality, and addendum. Thread dimensions shown without tolerances are related to the basis for connection design and are not subject to measurement to determine acceptance of product.

Premium connection is a higher class connection type for used to connect casing or tubing pipelines. The reason to use premium connection is due to it’s high seal performances, high strength, and longer durability.

API casing and tubing coupling dimension ranges from OD 1.05 inch to 20 inch (26.7 mm to 508 mm), wall thickness normally ranges from 0.16 inch to 1 inch (4.2 mm to 22 mm).

Tests for making couplings is similar with the casing and tubing, which includes: Tensile test, flattening test, hydrostatic pressure test, sulfide stress corrosion cracking test, grain size determination, transverse impact test and hardness test.

Octal supplies API couplings for casing and tubing connections, feel free to contact us for any of the request refer to the API or premium connections.

Shiva Engineering Works manufactures Pup Joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines. Integrally forged hammer lug union end connections eliminate welding or threading. Lightest Pup Joint availab more...

Shreeraj Industries offers NPST (Non-pressure Seal Thread) Pups in size 1”-3” Fig 602 and 1502. The NPST connection offers a light weight pup capable of 6000-15000 CWP with a connection that isolates the thread from fluid’s flowpath. This connection is permanent and is well more...

Pup Joint comes with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow line. We are one of the eminent Manufacturers, Exporters and Suppliers of Pup Joint from Maharashtra, India. The manufacturing and testing of our Pu more...

Pup Joint Avail from us a precision-engineered array of Pup Joints, which is ideal for spacing out downhole assemblies and handling production tubing accessories. These pup joints are short length of tubings and set on location due to which the operator can adjust location depth more...

adfo manufactures pup joints with integral hammer union end connections. these pup joints are used on high pressure discharge lines, choke and kill lines, auxiliary flow and other applications. these light weight pup joints are available in lengths ranging 1 feet to 12 feet and s more...

API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Premium pup joints are also available with premium connections and in API or exotic alloy grades. more...

Windlass manufactures Pup Joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines. Integrally forged hammer lug union end connections eliminate welding or threading Lightest Pup Joint available for fast, eas more...

SEW manufactures Pup Joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines. Integrally forged hammer lug union end connections eliminate welding or threading Lightest Pup Joint available for fast, easy han more...

Windlass manufactures pup joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines. more...

NeOz manufactures a complete range of seamless pipe coupling and pup joint so as to meet API 5CT specifications. The coupling are available from sizes 2-7/8" till 20" with regular thread type of STC, LTC and BTC. These are also available in special Grade Pipe as well as premium t more...

MARS has been manufacturing Various Tubing and Casing Couplings & Pup Joints as per API with different material grades and specifications API 5CT Product PUP Joints ( 1.66" to 4-1/2 ") EUE , NUE Max 15 ft Tubing Couplings ( 1.66" to 4-1/2") EUE & NUE Casing Couplings ( more...

OD ¾ to 4-12" for Tubing 4-12 to 20" for casing Length 2, 3, 4, 6, 8, 10 12 ft for tubing 2-20 ft for casing Connection EUE, NUE, Buttress and premium connections for tubing STC, LC , BC and Premium connections for Casing Description API casing and tubing pup joints are manufact more...

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly’s, subs and pup joints, and pipes.

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

8613371530291

8613371530291