octg pup joint mid-continent brands

From small beginnings in 1978, Mid-Continent has grown over the past more than 30 years to become one of the region’s major stockists of oilfield tubular products.

This value is further enhanced when you experience the quality of the products we deliver and the integrity of our service – hallmarks of the Mid-Continent brand.

We also offer comprehensive services to supply and consign our OCTG tubular products within a supply-chain management framework, according to your inventory and time-frame requirements.

To complete the repertoire of services that we provide, you can also leave cleaning, inspection, coating, hardbanding, make & break, testing and refurbishing of your OCTG products to us.

Our strengths are our value to you because these translate into faster delivery and at lower prices than if you were to buy directly from source.This value is further enhanced when you experience the quality of the products we deliver and the integrity of our service – hallmarks of the Mid-Continent brand.

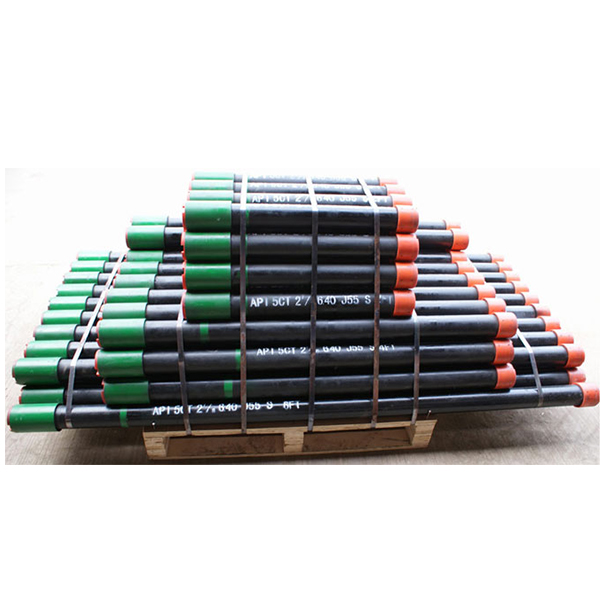

Our supplier partners include producing mills in every continent of the globe, and we proudly represent them to distribute OCTG tubing, casing, couplings, pup joints, and line pipe in the demanding US and Canadian oil and gas markets, as well as in all Latin America region.

We also offer comprehensive services to supply and consign our OCTG tubular products within a supply-chain management framework, according to your inventory and time ...

Couplings are short lengths of pipe used to connect 2 joints of tubing or casing. They come with painted colour codes on their external surface to indicate their grades.

OCTG Tubular Inspection & Maintenance. STANDARD DRILL STRING & BOTTOM HOLE ASSEMBLIES Drill String and Bottom Hole Assembly Inspections are normally carried …

Joint Venture & Partnership. Airtrust also has a number of key joint venture companies, outside of its subsidiary businesses: Tubular Resources. A joint venture ...

Divisions Oil & Gas Equipment Supplies Division. Mid-Continent is a major supplier of a comprehensive range of products and services for Oil & Gas, Shipbuilding ...

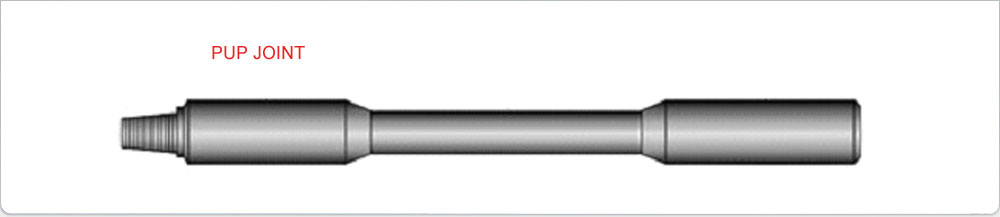

A pup joint is a pipe of non-standard length used to adjust the length of tubular strings to its exact requirement. API casing and tubing pup joints are manufactured ...

Once the casing is run and held in place with cement, production tubing is run into the oilwell. Joints of tubing are connected together with couplings to make up a ...

OCTG Services Tubular maintenance and Inspection. Due to the steadily increase of the hazardous drilling conditions, the standards for the inspections of Oil Country ...

We keep long-term strategic cooperation relationship with Baoji Baoshi Petroleum Thread Gauges Inspection ... The institute has established a thorough OCTG thread ...

In 2000, it decided to acquire a division owned by NorSea, giving it the skills and capacity for the production of threads on casing, tubing and drillpipe, as well as the production of special OCTG (Oil Country Tubular Goods) products.

This acquisition has increased ITM’s workshops to four main bases in Norway: the NorSea base in Tananger, the CCB base at Ågotnes, Florø with Fjordbase and Kristiansund with Vestbase. Today ITM is one of the leading suppliers of machining services on casing, tubing and drillpipe as well as pup joints and x-overs from bar material. Providing workshop services, the company’s speciality also lies in the fact that it holds most of the licences for threads that are used on the Norwegian Continental Shelf. The machining, threading and fabrication of special products related to pipes are carried out in all of its workshops. Qualified according to ISO 9001:2000 and approved by Achilles, ITM has also been involved in machining parts and equipment for export to other countries like

[65]ANDMIR stated that IT/VIT is different in form and function than traditional OCTG products and that IT/VIT is not supplied to meet equivalent API 5CT specifications and/or enhanced proprietary standards. In terms of form, IT/VIT is two joints of casing and/or tubing welded together with varying products inside the annulus which is used to increase or maintain insulation. Conversely, OCTG is a single threaded tube. In terms of function, IT/VIT contrasts with OCTG in that OCTG is used to convey fluids or gas in an oil well, whereas IT/VIT’s principal function is to insulate the medium fluid in an effort to save energy.

[67]Furthermore, ANDMIR stated that once the material is cut and separated, one would need to dispose of the insulation wrapping material and before this product could be re-deployed as OCTG, a surface treatment of outer and/or inner tube would be required as the product would have been sandblasted. Also, during the pre-stressing process, the IT/VIT is elongated and welded under specifically controlled procedures, which in some cases causes the steel to bow. This bowing can push the straightness of the product outside API criteria, or can limit the ability for easy threading. This post IT/VIT product would require testing by an API certified shop (i.e. drift test) in order to be re-sold.

[69]Continental Steel further stated that if VIT is OCTG, then we might consider slotted liners, coiled tubing, and other tubular goods used in the oil and gas industry as OCTG since it falls under the broad scope of a tubular good for the oil country.

[70]Continental Steel explained that the VIT produced by their company could not be feasibly disassembled, stating that “it is inconceivable to cut and rethread the VIT we supply to use as OCTG because the cost of the pipe is significantly greater than the cost of 2 pipes due to the cost for the vacuum and insulation technology in our VIT.”

[72]The company also provided invoices on the confidential record which demonstrate the amount by which their VIT sells at a premium over regular OCTG.

[74]Exceed and Golden Ring asserted that VIT is not generally regarded or used in the same way as OCTG, and therefore should not be included in the product definition of regular OCTG. Exceed stated that they are unaware of any firm that would consider VIT as OCTG and that it would not be practical to use VIT in place of regular OCTG where there is no steam injection.

[80]Producers have realized regular OCTG tubing is not a best fit technically for SAGD wells, as the majority of heat is lost into the surface formations and cap rocks before even reaching the targeted oil reservoirs during the fluid transportation in wellbores.

[83]Exceed provided a detailed account of the production steps on the confidential record, to demonstrate the complexity of VIT in relation to regular OCTG.

[84]Exceed also stated that contrary to the Applicant’s premise that imported VIT could be disassembled at low cost into its OCTG components, and thus potentially be used to circumvent anti-dumping duties on regular OCTG, the cost per meter of OCTG goods imported from China using the CBSA assigned “normal value” is still considerably lower than the cost of imported VIT from China. Exceed provided financial data on the protected record in support of this position.

[86]GERI provided a financial analysis which contrasted the position that dismantling IT/VIT into its input casing and OCTG tubes was not costly, stating that such dismantling to recover individual pipes would result in a net loss, when compared to the market price for the input OCTG.

“The bottom line is that VIT is a tool designed to reduce heat loss, reducing water/steam consumption in the production of oil. It contributes to the sustainability of the heavy oil industry and the reduction of the industry’s carbon footprint. OCTG has no such properties.”

“is used as a tool to reduce heat losses to the oil reservoir and to guarantee the structural integrity of the cased and cemented wells. Both functions are essential to ensure an environmentally sustainable production of oil from these oil reservoirs. The use of IT/VIT reduces the steam needed per barrel of oil produced, reduces the CO2 production and protects the cemented well casing from catastrophic structural failures. Therefore, to equate typical OCTG to VIT would be an unjustifiable, unproductive measure.”

“The idea of importing joints of VIT and then cutting off the ends, pulling out the inner pipe, disposing of all chemicals and insulation materials, which are contained in the space between inner and outer pipe, re-thread, acquire and buck on couplings with the purpose to sell such “cannibalized” VIT joints as two joints of OCTG is not viable, neither technically nor commercially.”

[97]With respect to the commercial issue cited by Imex in this scenario, Imex provided financial figures on the confidential record which supported their position that the conversion costs of re-conditioned tubing and casing joints would be very labor intensive, require specialized facilities and ultimately be more expensive than simply buying casing and tubing from China at normal values.

[98]TPCO is a Chinese producer and exporter of OCTG. TPCO stated it has no record of supplying VIT to Canada; however, the company is developing a VIT product and may ship VIT to Canada in the future.

[99]TPCO identified IT/VIT as a tool for oil production, with the items defined in seamless casing and OCTG 1 as the material for processing IT/VIT. Consequently, TPCO stated that IT/VIT should not be included into the existing cases.

[100]TPCO cited the different manufacturing processes and technology in making IT/VIT in support of this position. For example, the welding, insulating and vacuuming is quite different from the typical manufacturing process of OCTG products. TPCO also noted that the API 5CT specification makes no reference to VIT processing.

[101]In terms of usage, TPCO stated that OCTG generally includes casing and tubing. Casing is cemented downhole, while the tubing is used to bring the oil from downhole to the surface. The purpose of VIT is to provide temperature protection to reduce heat loss and improve production efficiency when steam is injected downhole.

[102]TPCO used the example of an FCD (Flow Control Device) as something made from OCTG to enhance/benefit the oil production but does not mean it is OCTG. They asserted this is analogous to the case of VIT.

[103]TPCO also stated that the ease of disassembly alleged in the application is not something they have ever seen in practice as it would be neither cost effective nor practical from a sales perspective to disassemble these parts. First of all, cutting the thread and welded part from the body would make the body too short for typical OCTG requirements. Secondly, there is no warranty for cut parts. As such, to make the cut body sellable, inspections and tests would be required before a shop could issue a mill test certificate (MTC). TPCO stated that this would require at least $500 CAN/Metric Tonne extra compared to OCTG prices, which is prohibitively expensive for a secondary material in the market.

Since the product costs and sales price of IT/VIT is much higher than that of OCTG, IT/VIT cannot easily, and at low cost, be disassembled into its original basic API 5CT casing/tubing components.

[107]Zibo identified 14 differences between OCTG and IT/VIT, which included the physical characteristics, technical specifications, uses of the goods, marking; packaging, distribution channels, mother pipes, applicable standards, product structure, manufacturing process, product control, repair and maintenance, production costs, and sales prices.

[109]Zibo characterized OCTG as “merely parts of components in IT/VIT” and that “the manufacturing process of IT/VIT is much more complex than that of OCTG, so [the] production cost of IT/VIT is much higher than that of OCTG.”

8613371530291

8613371530291