perforated pup joint manufacturer

We are Supplier and Exporter of Perforated Pup Joints in UAE. It is usually installed between the bottom of two nipples of a completion. It allows unrestricted fluid or gas flow, which increases the accuracy and reliability of acquired downhole production data.

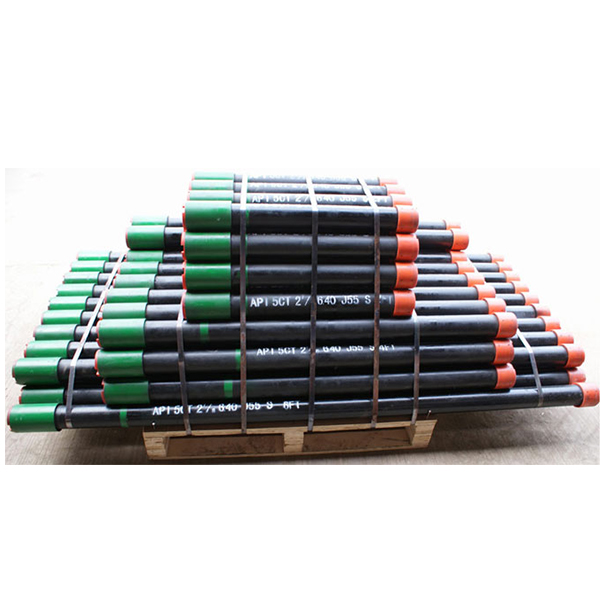

We supply all sizes, grades, and thread profiles to meet custom requirements. The perforated pup joints are sometimes also known as the perforated production tube. All our products have passed the ISO certification and API certifications. Our products are tested numerous times under technical guidance and are made from the best quality material.

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly’s, subs and pup joints, and pipes.

These J55, L80, N80Q & P110 pup joints are manufactured from seamless Grade J-55, L80 N80Q and P110 mechanical tubing. The API 5CT tubing pup joint is mainly used to adjust the height of the tubing strings. It is also used to adjust the depth of down-hole tools.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to Hardness range of 285-341 with a Charpy "V" notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

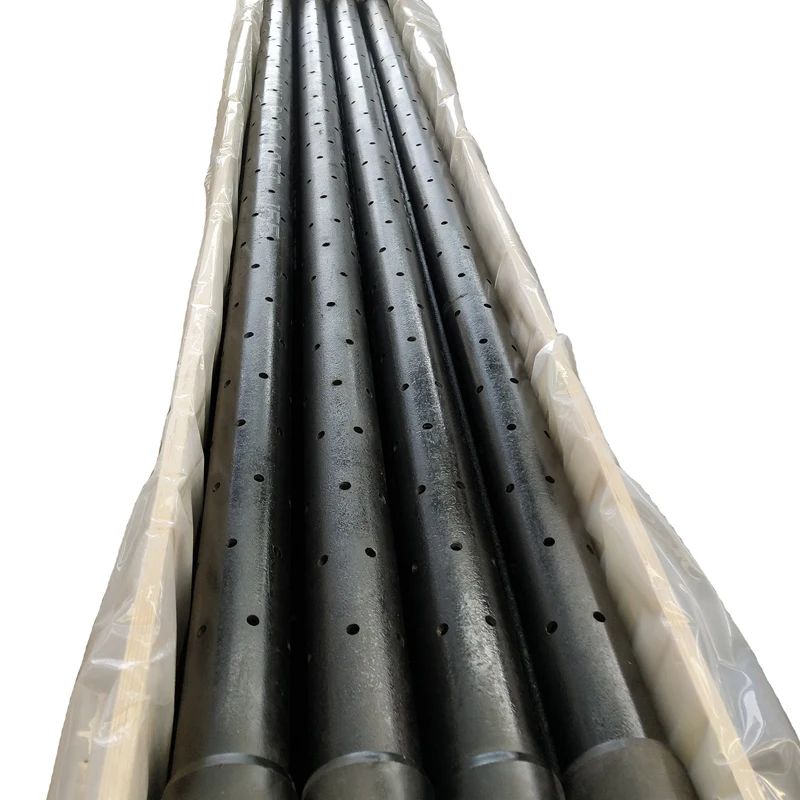

In wells flowing large volumes, a restriction in the tubing such as a gauge hanger, could cause false pressure readings. Vibrations due to flow could also cause extensive damage to delicate gauges, therefore a perforated pup joint (approx. 10ft length) set above the bomb hanger nipple would allow flow to pass unrestricted over the gauges and hanger, thus giving a more accurate pressure/temperature recording within the

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

One is a short Drill Pipe used to adjust the length of the Drill String; The other one OCTG Pup Joint is a pipe of non-standard length, which is used to adjust the length of tubular strings to its exact requirement.

Vigor can manufacture the Tubing Pup Joints by different technology - Upsetting and Machining process. if you have a special requirement on the Pup Joint production process, please just specify.

If you are looking for a competitive, high quality and fast delivery oilfield pup joint in stock, or if you are planning to buy pup joint API from one of the leading casing and tubing pup joint manufacturers, API 5CT pup joint in stock, l8013cr pup joint, nue/nue tubing pup joint manufacturers and suppliers China, please feel free to contact VIGOR.Details of API Spec. 5CT Oil Tubing Pup Joint

Pipe system involves various components, including perforated pup joints and are made from different materials. We offer wholesale perforated pup joints to create a smooth channel for the pipe systems in both commercial and residential areas.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

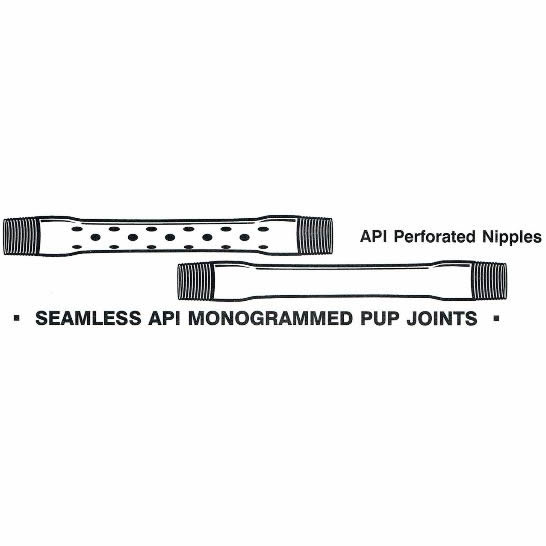

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

Our product range includes a wide range of Perforated Pup Joints, Casing Pup Joints, Tubing Pup Joint, Drill Pipe Pup Joints, Crossover Pup Joints and Integral Pup Joints.

We are Manufacturer of Perforated Pup Joints ,usually installed between the bottom two nipples of a completion.With perforated pup joints,down hole recording devices, such as heat and pressure gauges, can be placed in the lower nipple profile to obtain flowing pressure and temperature measurements. The Perforated Production Tube, sometimes also known as Perforated Pup Joint, allows for unrestricted flow of fluid or gas which increase the accuracy and reliability of acquired down hole production data, which otherwise would be distorted due to flow restrictions.

We are one of the prominent Manufacturer of Casing Pup joints, mainly used to adjust the height of the casing strings. It is also used to balance the depth of down-hole tools. Our Casing pup joints are made in accordance with the API 5CT specifications. These Pup Joints feature high corrosion resistance and long running life. We have become a reliable Exporter of Casing Pup Joints in India made from the high quality raw material.

We are one of the prominent Manufacturer,Exporter and supplier of Tubing Pup joints, made according to API 5CT specifications. Our Tubing pup joints are made out of seamless tubing and machined to final dimensions, each piece marked with a distinctive job number fully traceable. We manufacture tubing pup joints of all sizes, grades, and thread profiles to meet any custom requirements. All our products have passed the ISO certification and API certifications.

We are Manufacturer of Drill Pipe Pup Joints,an important drill stem component for special drilling or testing operations. Every step of production process is performed with the highest degree of accuracy to meet or exceed API Specifications as well as the Industry Standards. It is a short drill pipe used to adjust the overall length of drill string. The surface of Drill Pipe Pup joint looks like a smaller version of joint of drill pipe.

We are Manufacturer of Crossover Pup Joints ,used for crossing over from the size of a single connection to the other in the drill string. Crossover Pup Joints are made from seamless mechanical tube, each piece marked with distinctive job number and heat number fully traceable. Crossovers are used to adapt the standard 3-1/2” bypass system thread to the production tubing by the way of coupling. We manufacture Casing Pup Joints of all sizes, grades, and thread profiles to meet any custom requirements. All our products have passed the ISO certification and API certifications.We have become the reliable exporter of Crossover Pup Joints in India. Our products are tested numerous times under technical guidance and are made from best quality material.

We are Manufacturer of Integral Pup Joints, used for transporting high pressure flow in fracturing manifold, cementing manifold, maintenance manifold and test manifold. These are made from high quality alloy steel, integrally constructed, forged ended features seamless upset construction. Standard Integral Pup Joints are available in different models, pressure and temperature rating. Integral Pup Joints can be manufactured in two models; one is plain integral pup joint another is pup joints with retaining shoulder.

We are one of the prominent Manufacturer and Exporter of PUP joints, an important part of equipment in almost any well. They are typically easy to handle and use due to their shorter length. They provide almost same performance as the tubing/casing drill pipe. Pup joints varying lengths of tubing and casing are used to adjust the production string length as close as possible to the required value. PUP joints are used to space out the distance between tubing and casing components. These are also used to adjust the bottom of downhole tools. We provide various thread type and thread size combinations of PUP Joints.

Perforated Production Tubes are joints of tubing with machined holes along four lines 90o apart along the length of the tube. Perforated Production Tubes are usually installed between the bottom two nipples of a completion. With this tool, downhole recording devices, such as temperature and pressure gauges, can be installed in the lower nipple profile to acquire flowing pressure and temperature measurements. The upper nipple provides a point to plug the tubing below a packer. This facilitates packer setting or workover operations. The Perforated Production Tube, sometimes called a Ported or Perforated Pup Joint, allows for unrestricted flow of fluid or gas. The use of this tool enhances the accuracy and reliability of acquired downhole production data, which otherwise would be distorted due to flow restrictions. The Perforated Production Tube comes standard with 200% flow area of the production string it is connected to.

8613371530291

8613371530291