perforated pup joint definition in stock

We are Supplier and Exporter of Perforated Pup Joints in UAE. It is usually installed between the bottom of two nipples of a completion. It allows unrestricted fluid or gas flow, which increases the accuracy and reliability of acquired downhole production data.

We supply all sizes, grades, and thread profiles to meet custom requirements. The perforated pup joints are sometimes also known as the perforated production tube. All our products have passed the ISO certification and API certifications. Our products are tested numerous times under technical guidance and are made from the best quality material.

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

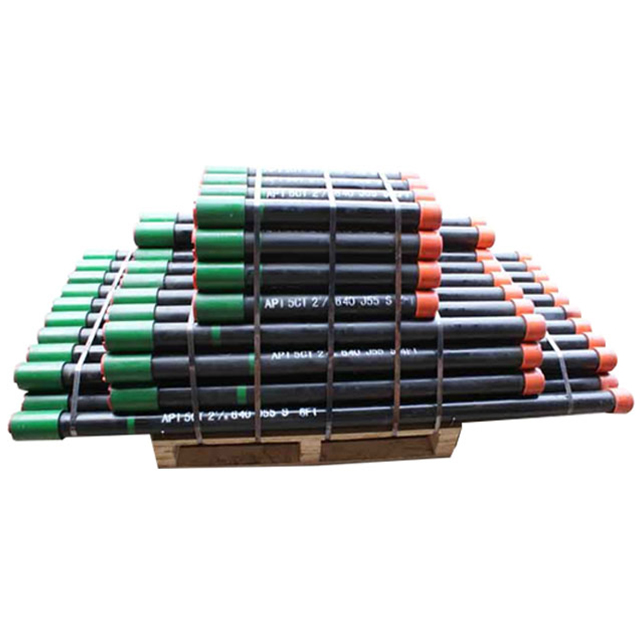

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

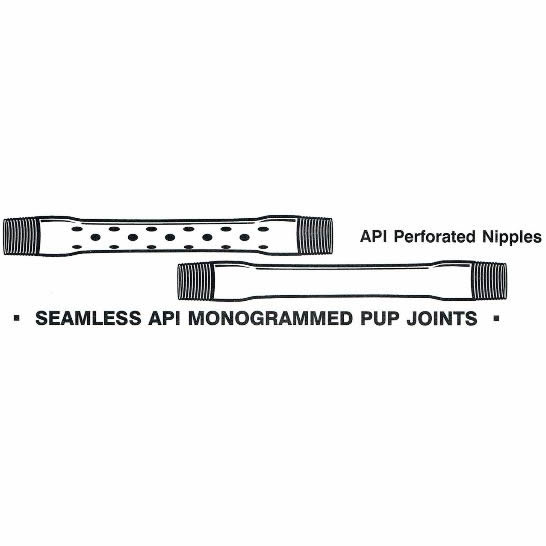

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

In the oil and gas drilling industry, the tubing pup joint is a critical component for the completion of a well. The pup joint allows the driller to change out the drill pipe without having to pull out the entire string of pipe from the well. This is a common practice, especially when drilling deep wells. Because of this, the tubing pup joint is one of the most important joints in any well.

Tubing pup joints are small-diameter tubing that is used in conjunction with casing to complete a well. The pup joint is run in the hole and cemented to the casing, and then the production tubing is run over it and attached. This arrangement allows for the use of smaller-diameter production tubing, which results in less pressure drop and improved production. The pup joint is usually located in the last few feet of the tubing string.

When you need tubing pup joints, Action is the only source you need to know.Westcan Oilfieldhave awide selection of productsto meet your needs and we offer some of the best prices in the industry. You can trust that we’ll provide you with quality products that you can count on.

Swivel Joints and Blast Saves are our widely recognized premium solutions for ensuring the best performance, endurance and quality in intelligent completion design. With dual metal-to-metal seals, they are available in a range of sizes, metallurgies and steel grades, and their upper and lower ends can be customized for many of our premium connections.

Our Swivel Joint premium connectors are designed to solve alignment problems during dual completion or intelligent completion installations. Furthermore, our Swivel Joints Torque Transmission (TT) can withstand torque in excess of the maximum make-up torque of premium connections.

Our Blast Saves are designed to protect control lines from impact or erosion generated by high pressure/high velocity wellbore fluids and particles, or when the control lines are run alongside the production tubing, in front of the perforated wellbore area. Every Blast Save module has ability to automatically align the longitudinal slots when making up the string, while reaching the optimum make-up torque value.

In wells flowing large volumes, a restriction in the tubing such as a gauge hanger, could cause false pressure readings. Vibrations due to flow could also cause extensive damage to delicate gauges, therefore a perforated pup joint (approx. 10ft length) set above the bomb hanger nipple would allow flow to pass unrestricted over the gauges and hanger, thus giving a more accurate pressure/temperature recording within the

The number of strings of casing used for a well depends upon how deep the well is. In some cases, the well may only have two strings of casing to reach from the bottom of the reservoir to the surface; the surface pipe and the final string of casing (also known as the long string or oil string). However, in deeper wells the final string may require more tensile strength or the lower joints may be created with extra support in the event of a collapse. In the event the lower joints are heavier than the rest of the joints on the long string, a similar joint is installed at the top (referred to as the gauge joint). The gauge joint provides the crew with a reference, letting the crew know that any tool going through the first joint will be able to go through all of them.

In order to perforate the casing, it is essential for the crew to know what the bottom hole pressure is inside the pipe, as well as to anticipate the inside pressure of the formation. If the pressure is miscalculated and is greater in the formation than what is inside of the casing; the instant the perforations are created through the pipe, the fluids will rush into the casing (forced by the bottom hole pressure) and blow the perforated gun up the hole. It will go up the hole at such a tremendous speed that it will wad up the electrical line and create numerous problems.

Since the tubing has to reach a specific depth within the well, and be placed without being cut or threaded; tubing is usually available in a wide range or random lengths, typically ranging from 28-32 feet (with shorter lengths referred to as pup-joints). Pup joints (see Figure 1) are added to the top of the tubing string, and are used for final spacing (also, click here if you’d like to know more about Tubing String basics, Perforation Placement, Measuring Pipe Diameter, Running and Pulling a Tubing String, and basic troubleshooting of the Tubing String!)

The mud anchor is a full joint of tubing placed at the bottom of the string that may be cut off to a certain length. It is generally between 16-24 feet, and used for:

In order for the oil and/or water to enter the tubing string located in the reservoir, it has to be perforated. While there are a number of ways to accomplish this task, the most common options include:

Installing a perforated pup joint over the mud anchor with a collar in between the two pieces. While the typical length is usually between 3 or 4 feet, perforated pup joints (see Figure 2) can be as small as 2 feet or as large as 12 feet. These holes in the tubing are around 1 inch in diameter and are placed a few inches apart on all sides. The purpose of these small holes is to prevent large objects from entering into the tube.

Using a short joint or leaving the bottom of the pipe open just below the seating nipple. (Typically very few operators will use this method. This is due to the risk of large objects entering the pump and causing it to stop functioning.)

Using a perforated mud anchor with an electric drill, or by cutting holes using an oxyacetylene torch. Generally these holes are 3-6 inches apart, and are placed no farther than 6 inches below the upset on each of the four sides (extending anywhere from 2-4 feet).

n: 1. a material used in a cylinder on rotating shafts of an engine or pump in the stuffing box of a valve, or between flange joints to maintain a leak proof seal. 2. the specially fabricated filling in packed fractionation columns and absorbers.

n: 1. a well completion method in which the producing zone or zones are cased through, cemented, and perforated to allow fluid flow into the wellbore. 2. a well completed by this method.

n: a special type of nuclear log that measures the depth of each casing collar. Knowing the depth of the collars makes it easy to determine the exact depth of the formation to be perforated by correlating casing-collar depth with formation depth.

v: 1. to use the drawworks to lift the bit (or other tool) off bottom by raising the drill stem. 2. to use an air hoist to lift a tool, a joint of drill pipe, or other piece of equipment.

The Expandable Pup Joint is a cylindrical liner, made of highly ductile alloy radially expandable, with an external rubber covering for optimum sealing.

The releasing pup joint effectively solves the problem of release when mud adheres to an oil and gas layer tester and makes same stuck midway during drilling.

Products SEAMLESS STEEL PIPE OCTG API 5CT CASING PIPE CASING COUPLING API 5CT Tubing PUP JOINT HOLLOW SECTION PIPE Boiler Steel Pipe LSAW STEEL PIPE Galvanized steel pipe ERW STEEL PIPE SSAW STEEL PIPE Structural pipe piling Scaffolding Steel Pipe

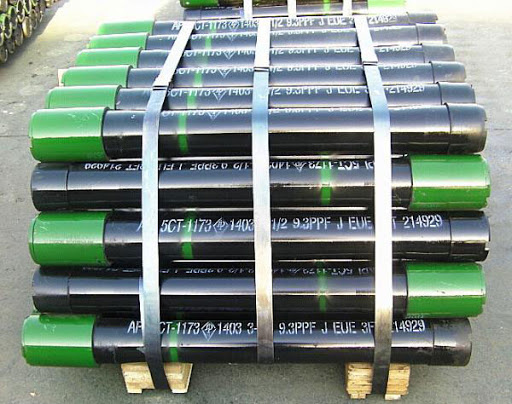

Products : API SPEC 5CT Seamless Steel Tubes Applications : It is widely used for oil casing and tubing in oil wells Grades : J55, K55, N80, L80-1, L80-9Cr, L80-13Cr, P110, Q125, K55 D10, L80 D10. Special Service : Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156 Produce Process : Hot Rolled, Cold Drawn, Hot Expanded. Accessories : Pup Joint , Coupling (Coupling Stock), Blast Joint, Crossover etc.

Hebei Borun Petroleum Pipe Manufacturing Co., Ltd, as the subsidiary business of BORUN, is focused on making Casing Pipe, EU Tubing Pipe too the accessorie such as Couplings, Pup Joints, Thread Protectors. The factory covers an area of 50000m2 and has more than 300 staffs. Equipped with 3 production lines and complete set of screening machine, we can supplying quality products and ideal service for the customers.

A pup joint is a pipe of non-standard length used to adjust the length of tubular strings to its exact requirement. There are 2 kinds of pup joints according to API 5CT standard: one is for casing pipe, the other is for tubing. All the pup joints are made from new prime API raw materials and are identifiable throughout the manufacturing process via mill certifications and other trace-ability measures.

This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H. Peotroleum and natureal gas industies – Steel pipes for use as casing or tubing for wells.

8613371530291

8613371530291