perforated pup joint function for sale

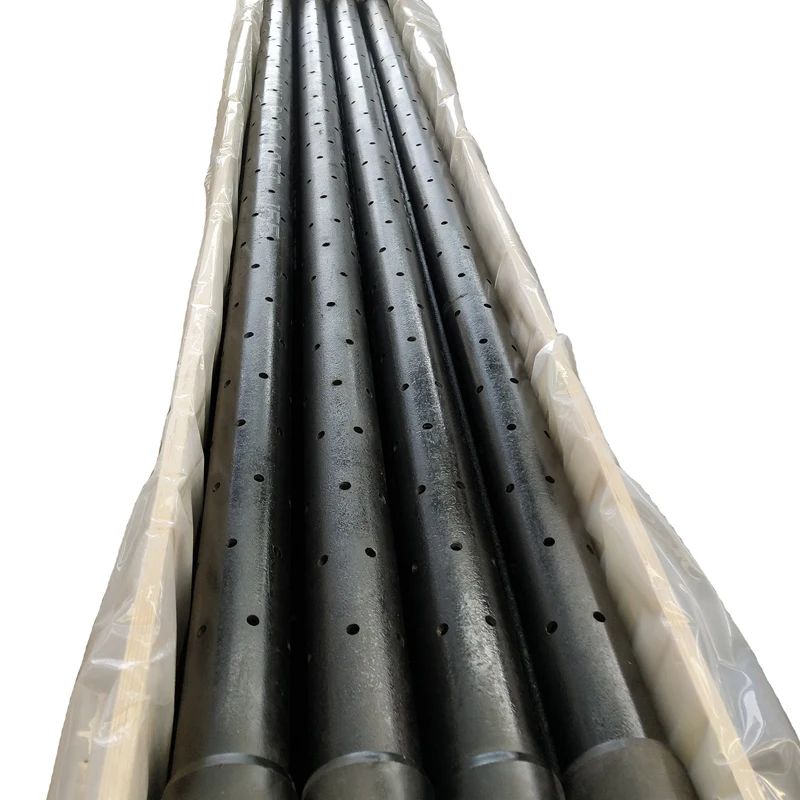

In wells flowing large volumes, a restriction in the tubing such as a gauge hanger, could cause false pressure readings. Vibrations due to flow could also cause extensive damage to delicate gauges, therefore a perforated pup joint (approx. 10ft length) set above the bomb hanger nipple would allow flow to pass unrestricted over the gauges and hanger, thus giving a more accurate pressure/temperature recording within the

Pipe system involves various components, including perforated pup joints and are made from different materials. We offer wholesale perforated pup joints to create a smooth channel for the pipe systems in both commercial and residential areas.

We are Supplier and Exporter of Perforated Pup Joints in UAE. It is usually installed between the bottom of two nipples of a completion. It allows unrestricted fluid or gas flow, which increases the accuracy and reliability of acquired downhole production data.

We supply all sizes, grades, and thread profiles to meet custom requirements. The perforated pup joints are sometimes also known as the perforated production tube. All our products have passed the ISO certification and API certifications. Our products are tested numerous times under technical guidance and are made from the best quality material.

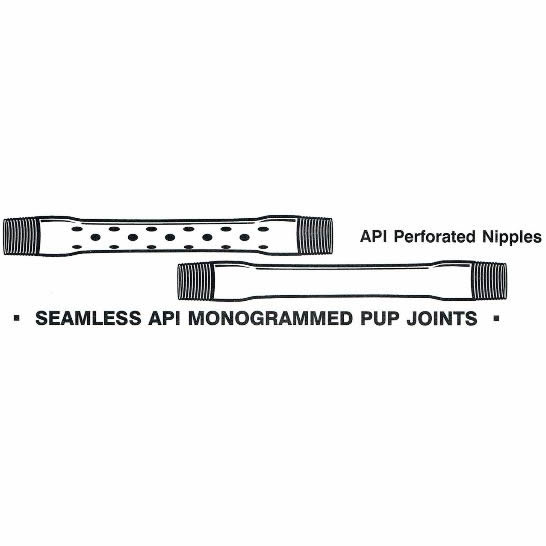

The Praxis Perforated Pup Joint may be incorporated in the completion string for the purpose of bypass flow if bottom hole pressure and temperature gauges are used for reservoir monitoring. The design criteria for a perforated joint is that the total cross-sectional area of the holes should be at least equivalent to the cross-sectional area corresponding to the internal diameter of the tubing.

In wells flowing large volumes, a restriction in the tubing such as a gauge hanger could cause false pressure readings. Vibrations due to flow could also cause extensive damage to delicate gauges, therefore a perforated pup joint (approx. 10ft length) set above the bomb hanger nipple would allow flow to pass unrestricted over the gauges and hanger, thus giving a more accurate pressure/temperature recording within the limitations of the gauge.

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

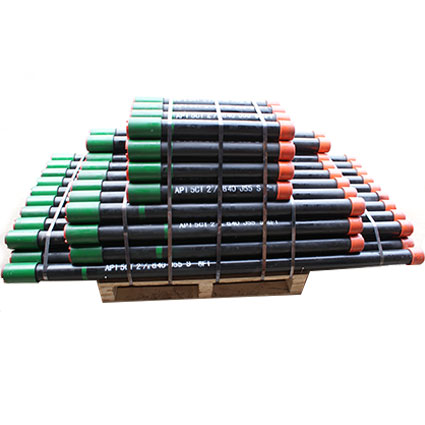

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

Failure: Deformation, fracture, surface damage and loss of original function under specific service conditions. The main forms of oil casing failure are: crushing, slipping, cracking, leakage, corrosion, adhesion, wear and the like.

In order to avoid damage to the oil casing, attention should be paid to the support of the Wholesale LTC Casing Coupling For sale during the design and manufacturing process, and the joint position of the oil casing should be paid attention to during the installation process.

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

Swivel Joints and Blast Saves are our widely recognized premium solutions for ensuring the best performance, endurance and quality in intelligent completion design. With dual metal-to-metal seals, they are available in a range of sizes, metallurgies and steel grades, and their upper and lower ends can be customized for many of our premium connections.

Our Swivel Joint premium connectors are designed to solve alignment problems during dual completion or intelligent completion installations. Furthermore, our Swivel Joints Torque Transmission (TT) can withstand torque in excess of the maximum make-up torque of premium connections.

Our Blast Saves are designed to protect control lines from impact or erosion generated by high pressure/high velocity wellbore fluids and particles, or when the control lines are run alongside the production tubing, in front of the perforated wellbore area. Every Blast Save module has ability to automatically align the longitudinal slots when making up the string, while reaching the optimum make-up torque value.

A pup joint is a pipe without standard length. API SPEC 5CT pup joints are used to adjust the height of full length tubing or casing strings to exact requirement. They are also applied to adjust the depth of downhole tools. In order to cater to the needs of customers, JST is offering a broad range of API SPEC 5CT OCTG pup joints.

2.With our sophisticated manufacturing facility, we produce these joints by using high grade raw materials (which are sourced from vendors of high repute) and cutting edge technology to ensure their sturdy design and longer functionality.

Jiangyin Changjiang Steel Tube Making Factory is a leading manufacturer and supplier of seamless steel pipes and various special pipes in China. We mainly manufacture structure pipe, fluid pipe, high pressure boiler pipe, API pipe, marine pipe, alloy pipe, tubing, casing, line pipe, OCTG pup joint (such as API SPEC 5CT pup joint), etc. Our company sets up a steel tube technology R & D center with advanced pipe testing equipment. Through strict testing process, we are able to produce high quality steel pipes for customers. Our products have been exported to the Middle East, CIS, Southeast Asia, Africa, South America, North America, Europe, Australia and many other countries and regions.

8613371530291

8613371530291