pup joint crossover price

A wide variety of pup joints and crossovers options are available to you, such as energy & mining, construction works and retail.You can also choose from unavailable, 1.5 years and 6 months pup joints and crossovers,As well as from provided, {2}, and {3}. and whether pup joints and crossovers is kazakhstan, russia, or egypt.

Otherwise, Our company manufactures and sells casing and tubing couplings,pup joints, tool joints, adapter pup-joints, adapter couplings, stabilizers, anchors of oil pumps and revolving sand gravitated device of well, etc. We always do business based on the principle of equality and mutual benefit, we provide the high quality and competitive price products.

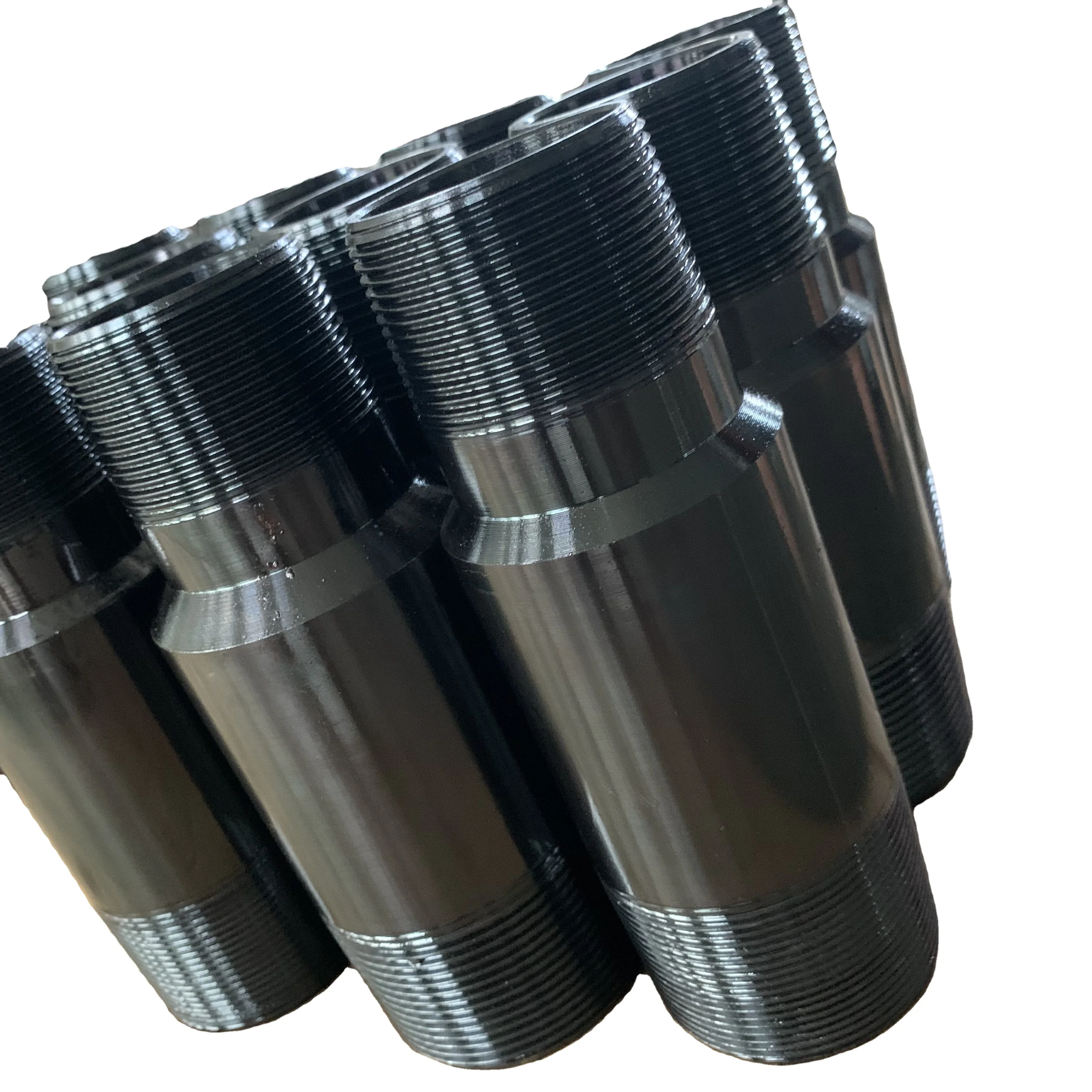

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

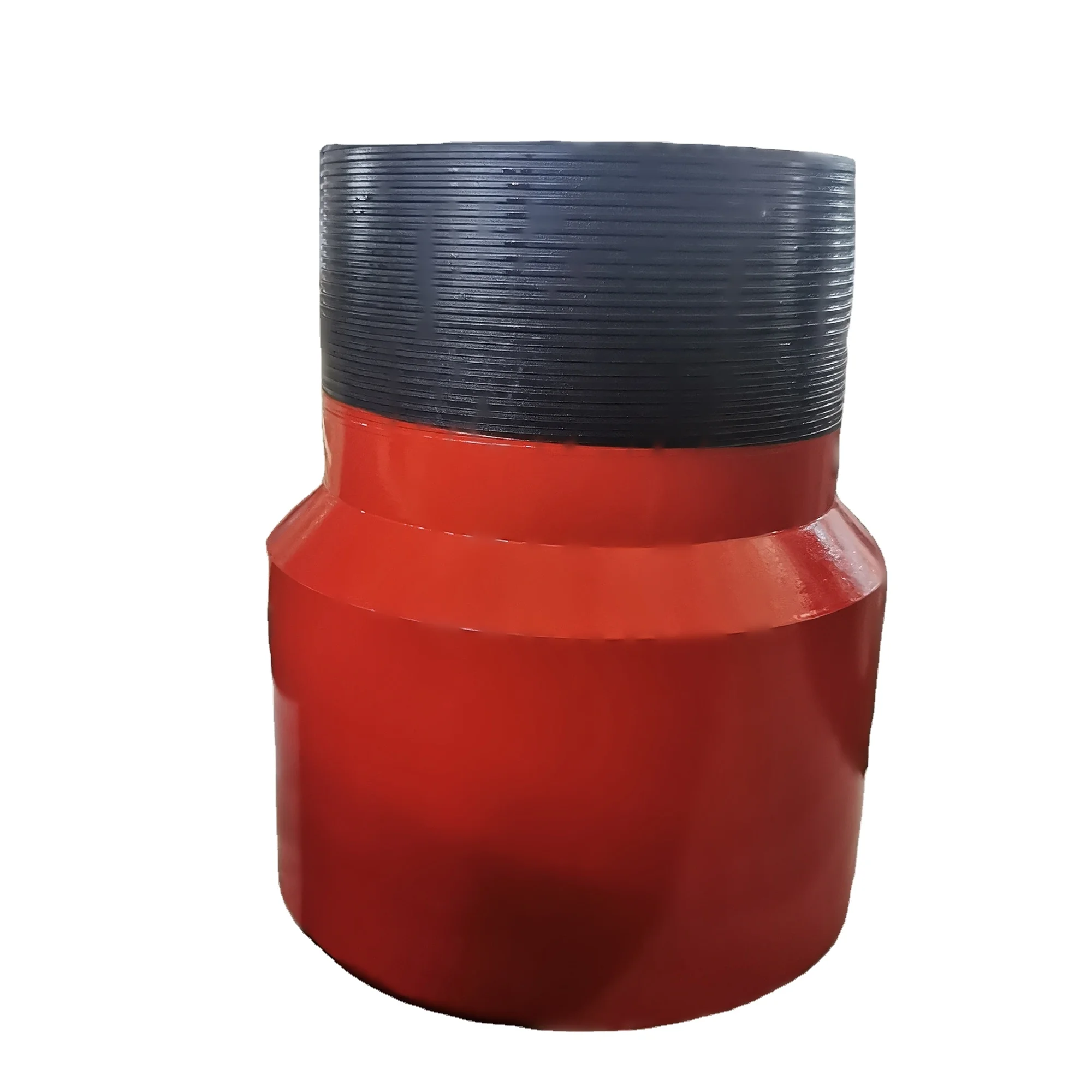

We manufacture a wide range of Crossover Couplings. Couplings are used to connect two sizes of pipes, or two different dissimilar threaded parts together. We offer special clearance couplings, special clearance couplings with bevels on both ends, and couplings with the API Seal Ring Modification.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Flow Couplings are heavy wall box by box connectors used in tubing strings and are designed to minimize the effect of internal erosive action caused by production fluids. Flow couplings are located just above or below Landing Nipples, Safety Valves or Control Devices where turbulent flow problems are likely to occur. Crossover flow couplings are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 3" and 6". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover Gas Anchor is an effective and simple design. It will increase oil and gas production, improve efficiency of the lift system, correct artificial lift problems caused by incomplete pump fillage due to gas interference and reduce operating cost.

Crossover can build these in any of the regular API Grades such as J-55, L-80, or P-110. These are usually only made going up or down one size in either direction such as ¾” to 1” or 1 ½” to 2”.

Crossover Circulating Sub/Swages are manufactured from AISI 4140/4145. They typically are female hammer union on the top end and an IF pin on the bottom end, but can be manufactured with any size and style connection.

Crossover Drop Ball Circulating Subs are manufactured from AISI 4140/4145. The standard is pin by box. They are activated by dropping a chrome steel ball, which lands on a sleeve and as pressure increases, the pins in the sleeve are sheared. This causes the sleeve to move down and expose four ports in the side of the sub diverting the fluid flow.

Crossover Side Entry Subs are manufactured from AISI 4140/4145. They are manufactured from one piece. They are typically rotary shouldered pin by box with 2” 1502 female hammer union, but can be manufactured with any size and style connection.

These can be made Rotary Shoulder Box Up x Pin Down with the ½ union on the side, we can build with any combination of the connections placed anywhere on the sub. All of Crossover’s Side Entry Subs are Integral manufactured which means that the sub is one piece and has no heat affected zone from welding the ½ union onto the body.

Crossover Pipe Scrubbing Wire Brush is used to brush and clean the ID of the casing and remove scale, rust, mud residue, and any other particles of debris.

Crossover Inside BOP Valves are manufactured from AISI 4145. Crossover"s one piece design is much more robust than the traditional two piece construction design. Crossover"s one piece design typically allows for standard connection OD"s and shorter overall length parts. This eliminates the service break which allows for quicker disassembly.

Crossover"s Drop-in Check Valve is a retrievable check valve. It is retrievable by means of a retrievable tool (gravel girdie) run in on wireline. When needed the check valve is pumped down the drill string to the landing sub. The dogs are locked in place with pressure from below the valve. The check valve will open to allow circulation and close when circulation is stopped.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

TSI Flow Products Crossovers are available in a multitude of configurations and sizes ranging from 1” to 4”. TSI Crossovers can rate up to a maximum of 15,000 PSIG working pressure depending on the configuration. Crossovers are also available with the DC15 connection. For more information regarding the DC15 connection or custom configurations please contact your local TSI Flow Products.

DIC is a Manufacturer and Exporter of Crossover Pup Joints in Ajman, UAE. It is used for crossing over from the size of a single connection to the other in the drill string.

We supply crossover pup joints in all sizes, grades, and thread profiles. All our products have passed the ISO certification and API certifications. Our products are tested numerous times under technical guidance and are made from the best quality material.

Transparency Market Research delivers key insights on the global pup joint market. In terms of revenue, the global pup joint market is estimated to expand at a CAGR of ~7%during the forecast period, owing to numerous factors regarding which TMR offers thorough insights and forecasts in the global pup joint market report.

In the report, TMR predicts that the global pup joint market would be largely driven by factors such as increase in demand for oil & gas and increase in number of explorations. Rise in demand for high-grade pup joints, use of advanced drilling technology, and penetration in developing nations are set to drive the global pup joint market during the forecast period.

According to the pup joint market report, the product type segment includes crossover pup joint, drill pipe pup joint, and tubing pup joint; the technology segment includes hot rolled and cold rolled; the end use segment includes oil & gas, chemical industry, mining, construction, and others. Based on product type, drill pipe pup joint accounts for major share. Increase in drilling activities in various countries contributes maximum to this segment. The segment is projected to expand at a significant rate in the near future.

The oil & gas segment holds maximum share in the global pup joint market. Economic growth and high demand for electricity has increased the demand for offshore exploration and production activities worldwide.

Volatility in raw material prices has an obvious impact on pup joint manufacturers. Fluctuating prices of raw materials have impact on the production of pup joints.

Rising demand for oil & gas is set to increase drilling activities. New drilling technologies such as horizontal drilling and hydraulic fracturing is expected to have a positive impact on the oil & gas market. These factors are expected to drive the demand for pup joints during the forecast period.

Middle East & Africa holds a major share of the global pup Joint market followed by Europe. Key players largely depend on geographical expansion, promotions, and technological advancements to cater to customer demand and gain a competitive edge in the global pup joint market.

Middle East & Africa accounted for approximately 30% share of the global pup joint market in 2018, followed by North America and Europe. It is anticipated to maintain its dominance in the market during the forecast period. Domestic production capacity is increasing in several countries; exploring undeveloped sites and exploring new sites for drilling is projected to generate more options for business growth.

Key players operating in the global pup joint market include Anvil International, AZZ Inc., Dmh United Steel Industry Co., Ltd, Forum Energy Technologies, Inc., National Oilwell Varco, Oil Country Tubular Limited, Sledgehammer Oil Tools Pvt. Ltd, Stewart Tubular Products, Texas Pipe Works Inc., and TPS-Technitube Röhrenwerke GmbH.

8613371530291

8613371530291