pup joint crossover pricelist

Find parts you need to repair or maintain your machines. At Alibaba.com, you can shop for pup joint drill pipe at affordable rates to tackle new obstacles and challenges. In the ever-changing industry, you can find what you need and speak to the supplier directly. Thanks to Alibaba’s collection of wholesale pup joint drill pipe you also get to buy these parts at lower prices, which means you can explore new levels every day more comfortably. From bulldozers to dragline excavators, wheel tractor scrapers to shotcrete machines, any part you need for a heavy-duty mining machinery; you can find it at Alibaba.com.

Looking for purpose-built machine parts? Find them at Alibaba.com. From new components to used parts straight from the manufacturers. Plus, if you need custom-made pieces, you can chat with the supplier, give specifications and wait on delivery. From stone crushers to excavator undercarriage parts, buckets, and even drill bits to get you through the rocks, the pup joint drill pipe from Alibaba offers you the chance to continue operating without a hitch. Whether you are looking to introduce concrete into the rock walls for more consistency and safety during mining, then pup joint drill pipe that goes at wholesale prices at Alibaba will be an excellent addition to your machinery.

Before buying a component, you’d want the equipment to suit your application and offer value. The list of pup joint drill pipe at Alibaba.com lets you dig into earth deposits, and the compare tool checks out other similar parts to give you the information you need to make a purchasing decision. You’ll get wholesale pup joint drill pipe that specializes in mining, with reinforced chassis, and run on more powerful engines. Whether you want to transport minerals or the workers to the mining site, introduce explosives or arms to help you remove materials from your mine pits, Alibaba.com has it all.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

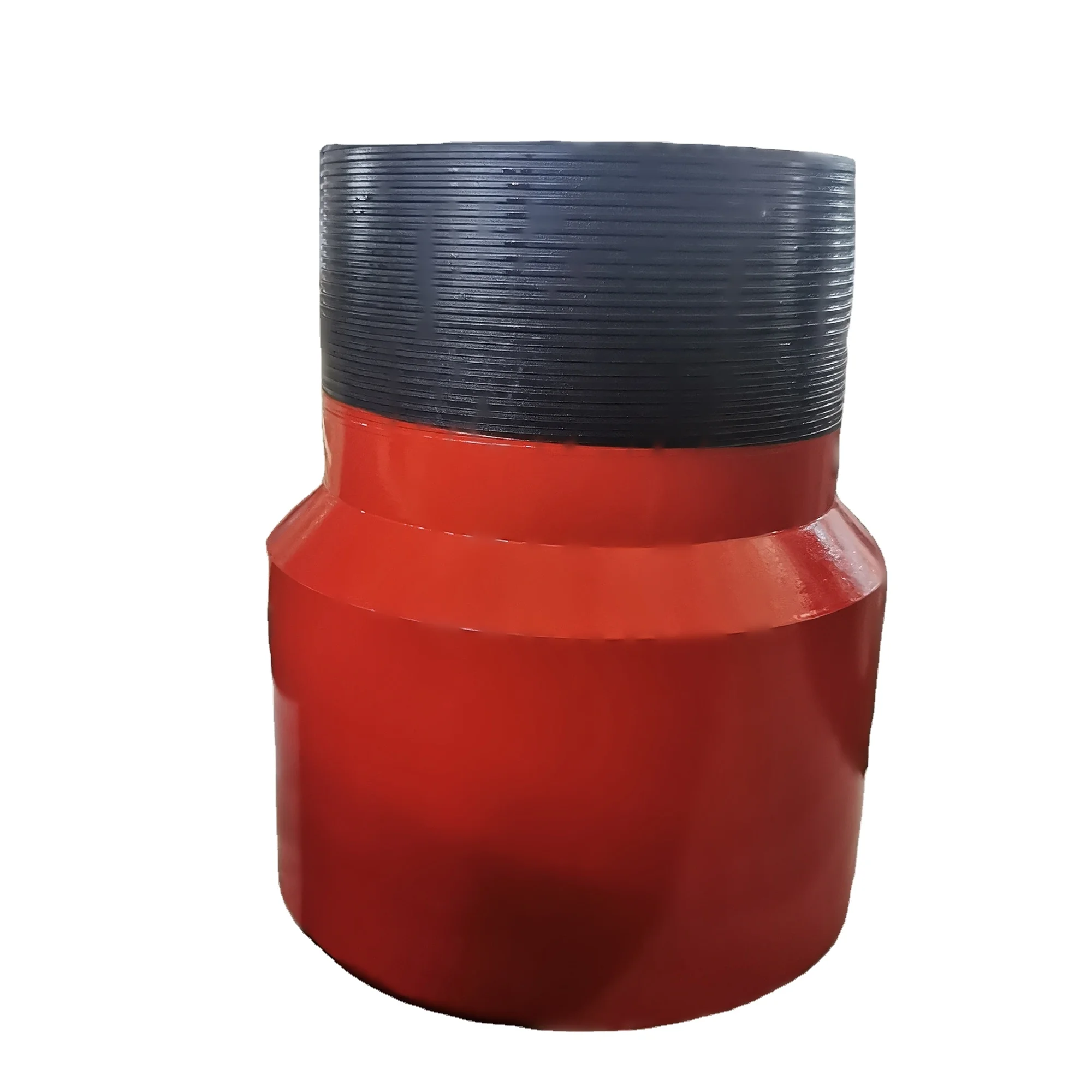

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

We manufacture a wide range of Crossover Couplings. Couplings are used to connect two sizes of pipes, or two different dissimilar threaded parts together. We offer special clearance couplings, special clearance couplings with bevels on both ends, and couplings with the API Seal Ring Modification.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Flow Couplings are heavy wall box by box connectors used in tubing strings and are designed to minimize the effect of internal erosive action caused by production fluids. Flow couplings are located just above or below Landing Nipples, Safety Valves or Control Devices where turbulent flow problems are likely to occur. Crossover flow couplings are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 3" and 6". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover Gas Anchor is an effective and simple design. It will increase oil and gas production, improve efficiency of the lift system, correct artificial lift problems caused by incomplete pump fillage due to gas interference and reduce operating cost.

Crossover can build these in any of the regular API Grades such as J-55, L-80, or P-110. These are usually only made going up or down one size in either direction such as ¾” to 1” or 1 ½” to 2”.

Crossover Circulating Sub/Swages are manufactured from AISI 4140/4145. They typically are female hammer union on the top end and an IF pin on the bottom end, but can be manufactured with any size and style connection.

Crossover Drop Ball Circulating Subs are manufactured from AISI 4140/4145. The standard is pin by box. They are activated by dropping a chrome steel ball, which lands on a sleeve and as pressure increases, the pins in the sleeve are sheared. This causes the sleeve to move down and expose four ports in the side of the sub diverting the fluid flow.

Crossover Side Entry Subs are manufactured from AISI 4140/4145. They are manufactured from one piece. They are typically rotary shouldered pin by box with 2” 1502 female hammer union, but can be manufactured with any size and style connection.

These can be made Rotary Shoulder Box Up x Pin Down with the ½ union on the side, we can build with any combination of the connections placed anywhere on the sub. All of Crossover’s Side Entry Subs are Integral manufactured which means that the sub is one piece and has no heat affected zone from welding the ½ union onto the body.

Crossover Pipe Scrubbing Wire Brush is used to brush and clean the ID of the casing and remove scale, rust, mud residue, and any other particles of debris.

Crossover Inside BOP Valves are manufactured from AISI 4145. Crossover"s one piece design is much more robust than the traditional two piece construction design. Crossover"s one piece design typically allows for standard connection OD"s and shorter overall length parts. This eliminates the service break which allows for quicker disassembly.

Crossover"s Drop-in Check Valve is a retrievable check valve. It is retrievable by means of a retrievable tool (gravel girdie) run in on wireline. When needed the check valve is pumped down the drill string to the landing sub. The dogs are locked in place with pressure from below the valve. The check valve will open to allow circulation and close when circulation is stopped.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

Pup Joint Inc. is a machine shop that sells down hole tubular and casing accessories and equipment. We are a leading supplier of pup joints & accessories with API5CT & premium threads at very competitive prices. Our machine shop is a threading facility for all your threading & precision machining needs. PJI commenced operations in Houma, LA in July of 1997. Our staff has over 65 years of combined experience supplying quality products & services to the oil & gas industry.

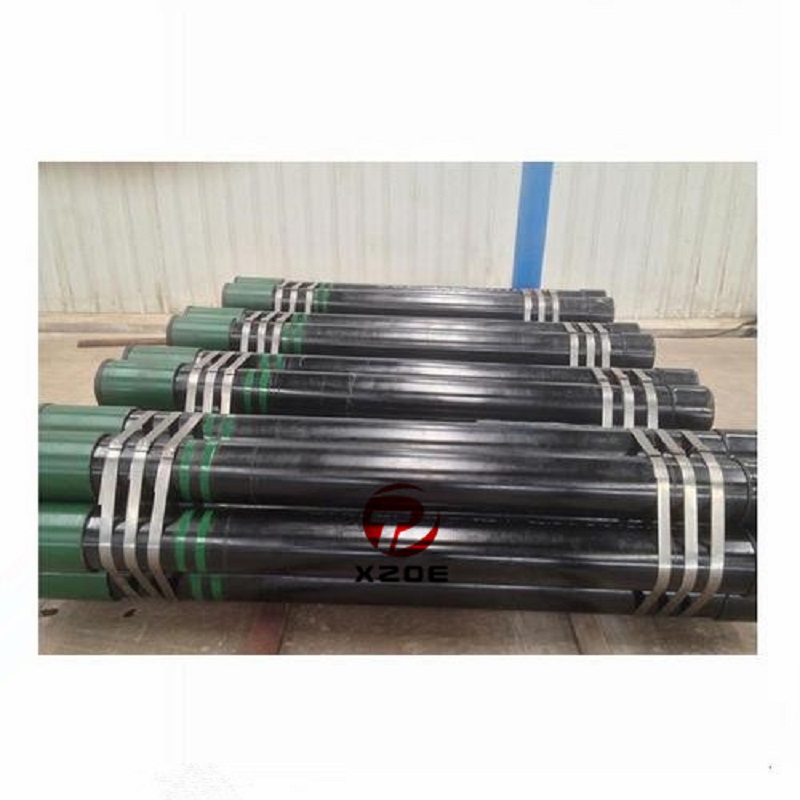

Pup joints are nonstandard pipes used to adjust the length of the tubular string to meet the exact requirements. In addition, the pup joints are used to change the length of the drill string for drilling operations and easy surface handling. The appearance of the pup joints is largely determined by their mechanical properties.

Further, thePup Joint marketis segmented by product type, Technology, End-User, and geography. On the basis of product type, the Pup Joint market is segmented under Crossover Pup Joint, Tubing Pup Joint. Based on the Technology, the market is segmented under the Hot Rolled and Cold Rolled. Based on End-User, the market is segmented into Chemical Industry, Mining, Oil & Gas, Construction, and Others. By geography, the market covers the major countries in North America, i.e., the US, Canada, and Mexico. For each segment, the market sizing and forecasts have been done on the basis of value (in USD Million).

Increasing consumption of natural gas and oil, technological advancements in drilling techniques, and fast-growing industrialization are the major factors contributing to the market growth. The rise in demand for high-grade pup joints from several end-use industries is expected to drive the use of pup joints. Demand for pup joints is expected to rise because of the growing demand for energy and significant investments in exploring onshore and offshore reserves by the oil & gas and mining industries. Increased energy consumption, the economic development of the shipping industry, and increased seaborne trade are the major factors driving the demand for pup joints during the forecast period.

The decline in petroleum production may hinder the market"s growth. Renewable energy will be more affordable than existing oil and gas sources during the forecast period, which will restrain the market for pup joints.

Due to COVID-19, the major end-user industries of pup joints were affected, which will hinder the demand for pup joints since the oil & gas industry is the largest end-user. COVID-19 has had a significant impact on the downstream oil & gas industry due to the significant drop in prices and reduced demand caused by the economic slowdown, which affected production rates in many countries. However, major countries such as the US and Canada implement dynamic and diverse approaches to navigate and deal with what is happening due to COVID-19. As a result, the market will experience moderate growth during the forecast period. The United States is a major revenue generator in the North American pup joint market.

With changes in energy arrangements and expanding political pressures, the market interest in pup joints and comparable items is changing. Government and privately owned businesses are showing a clear interest in finding new oil stores to meet future needs. Ventures by significant oil exploration companies are likely to support the pup joint market.

By Product Type,the Pup Joint Market is segmented into Crossover Pup Joint, Tubing Pup Joint, and Drill Pipe Pup Joint. The Tubing Pup Joint had the highest market share in 2021. Tubing pup joints are likely to have a huge demand because they are also used to handle production tubing accessories. Tubing pup joints are tubing that is short in size and operated for spacing.

By Technology, the Pup Joint Market is segmented into Hot Rolled and Cold Rolled. The Hot Rolled segment had the highest market share in 2021. Under high temperature and pressure processing conditions, the steel tube can be completely devoid of air bubbles, cracks, and porosity. It has a good mechanical effect and excellent intensity.

By End-User, the Pup Joint Market is segmented into Chemical Industry, Mining, Oil & Gas, Construction, and Others. The Oil & Gas segment had the highest market share in 2021. The oil & gas business has been positively impacted by the introduction of several drilling technologies. Due to the reliance on petroleum-based products by various emerging economies, oil & gas dependence has increased. Petroleum is used to make a variety of chemical products, such as fertilizers, pharmaceuticals, and solvents. To meet future demand for oil, both private and public companies are seeking to explore new oil reserves.

The objective of the report is to present a comprehensive analysis of theNorth AmericaPup Joint market to the stakeholders in the industry. The report provides trends that are most dominant in the North AmericaPup Joint market and how these trends will influence new business investments and market development throughout the forecast period. The report also aids in the comprehension of theNorth AmericaPup Joint Market dynamics and competitive structure of the market by analyzing market leaders, market followers, and regional players.

The qualitative and quantitative data provided in theNorth AmericaPup Joint market report is to help understand which market segments and regions are expected to grow at higher rates, factors affecting the market, and key opportunity areas, which will drive the industry and market growth through the forecast period. The report also includes the competitive landscape of key players in the industry along with their recent developments in theNorth AmericaPup Joint market. The report studies factors such as company size, market share, market growth, revenue, Product Type, and profits of the key players in theNorth AmericaPup Joint market.

The report provides Porter"s Five Force Model, which helps in designing the business strategies in the market. The report helps in identifying how many rivals exist, who they are, and how their Product Type quality is in theNorth AmericaPup Joint market. The report also analyses if theNorth AmericaPup Joint market is easy for a new player to gain a foothold in the market, do they enter or exit the market regularly, if the market is dominated by a few players, etc.

The report also includes a PESTEL Analysis, which aids in the development of company strategies. Political variables help in figuring out how much a government can influence theNorth AmericaPup Joint market. Economic variables aid in the analysis of economic performance drivers that have an impact on theNorth AmericaPup Joint market. Understanding the impact of the surrounding environment and the influence of environmental concerns on the North AmericaPup Joint market is aided by legal factors.

- Grant Prideco pup joints are manufactured from the same material as our drill collars. Heat-treatment processes ensure a hardness range of 285-341 Brinell. Charpy V minimum impact strength of 40 ft-lb at 70° F are guaranteed one inch below the surface.

Prithviraj Industries manufactures Pup Joints up to 20, 000 psi cold working pressure in sizes: 1, 11 /2, 2, 3, and 4-inch bore sizes, lengths to 20 feet.

ADFO manufactures Pup Joints with Integral Hammer Union end connections.These Pup Joints are used on high pressure discharge lines, choke and kill lines, auxiliary flow and other applications.

Windlass manufactures Pup Joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines.

Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. These are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Blast joints manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customer’s request. Typical lengths are 10" and 20".

DIC is a Manufacturer and Exporter of Crossover Pup Joints in Ajman, UAE. It is used for crossing over from the size of a single connection to the other in the drill string.

We supply crossover pup joints in all sizes, grades, and thread profiles. All our products have passed the ISO certification and API certifications. Our products are tested numerous times under technical guidance and are made from the best quality material.

Integral pup joints are tubes with two ends made up of high-quality alloy steel. This pup joint works well in high flow pressure applications and has great working capacity. If you are facing any issue with the flow in your piping system, installing a pup joint can help. You can buy integral pup joints online from our website enggpro. Com. Enggpro is a global marketplace for engineering equipment and services that precisely provide leads for engineering products. You can find reliable integral pup joint suppliers and manufacturers here and connect with them without any hindrance. You will not only get the premium quality goods here but also the best prices ever with our E-auction option where you can negotiate with them and have your hands on the desired products. You will also get to connect with the integral pup joint exporters from India, the USA, the Middle East, Europe and other Asian countries. Why go somewhere else, when you can have everything sorted on one single platform.

BLAZE is adequately equipped to supply NPST Pup joints made of high quality seamless pipeline with male & female detachable hammer union. NPST has uniform bore for greater flow capacity. NPST pup joints are available in 2″ to 4″ sizes, length for pup joint range from 1 feet to 20 feet at 15000 psi. Pup joint with Non- pressure seal thread union (NPST) are especially engineered for high pressure, abrasive services where welded connections are not desired. The design provides a strong, permanent end connection without butt welding. An epoxy thread-locking compound secures the connection.

Casing or Tubing Pup Joints, Casing or Tubing Connectors and Casing or Tubing Couplings. In addition it is capable of Threading items at Groups 1, 2, 3 & 4 of API spec. 5CT. Items supplied by BLAZE meet the Quality Standards as defined in API 5CT assuring

BLAZE is also well equipped to supply Line Pipe Couplings/ NPST pup joints with wide range of specifications. In addition we can supply thread Line Pipes and its accessories of various sizes. Items meet the quality standards as laid down in API – 5L.

Crossover, Inc has been servicing the oil country tubular market since 1979. Our commitment to total quality has made Crossover one of the leading manufacturers in the OCTG market. This assurance is recognized both domestically and internationally by, major oil producers in their promotion and application of Crossover tubular products.

By utilizing current machining technology, modern inspection processes, and systematic up-to-date training of personnel, Crossover has earned the reputation of a dependable leader in the tubular accessory market. We are continually expanding our capabilities, assuring our continued success in our field. Crossover products are marketed through domestic and international supply stores and agents. We pride ourselves with competitive pricing without sacrificing quality and fast delivery.

Crossover is licensed under API Spec 5CT and Spec 7. Under our API approved Quality Assurance Program, all phases of the manufacturing process are closely monitored.

Crossover, InC. ProduCtsCrossover inc. Manufactures a wide range of tubular products. We are an API Licensed Manufacturer and End Finisher of the following equipment for drilling and completing wells.

A) Completion Equipment1. 2. 3. Pup Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Perforated Pup Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 a.) Standard b.) Combination / Reducing c.) Modified (seal rings) Swages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Crossover Subs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Nipples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Bull Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown Bell Nipples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown Wireline Entry Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Ball Catcher Subs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Collet - Type Ball Catcher Sub/Hydro-Trip Sub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Flow Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Blast Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Telescoping Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Wire Line Landing Nipple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Safety Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 a.) Straight Pull b.) Rotation Release Overshot Tubing Seal Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Hammer Union Crossovers, Tees & Crosses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown Polish Bore Receptacles & Seal Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown

B) Rod Pumping Equipment1. 2. 3. 4. 5. 6. Flow Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown Gas Anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Drain Nipples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Combination Sucker Rod Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown Safety Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown Pump Seating Nipples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

C) Drilling Equipment1. 2. 3. 4. 5. 6. 7. Drill Pipe Pup Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3 Bit Subs (with Float Valve Bore) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16 Float Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown Kelly Saver Subs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16 Crossover Subs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16 Drill Collar Lift Subs & Lift Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Circulating / Pump-In Sub / Circulating Swage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Crossover, InC. ProduCtsC) Drilling Equipment (continued)8. 9. Drop Ball Circulating Sub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Drill Pipe / Casing Swages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

D) Fishing Tools1. Mills a.) Junk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-29 b.) Taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 c.) Round Nose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 d.) Drill Pipe / Collars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 e.) Econo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown String / Watermelon Reamer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Safety Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Boot Baskets / Junk Baskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Impression Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Taper Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Die Collars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Swaging Tools - Casing /Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Spears Wire Line / Wire Rope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Crossover, InC. ProduCtsE) Washover Pipe & Accessories1. 2. 3. 4. 5. Washover Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 Drive Subs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 Rotary Shoes and Burning Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-37 Safety Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 Lift Plugs / Subs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

F) Service Tools1. 2. 3. 4. 5. 6. Casing Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-41 Crossover Gravel Pack Tools (Cup Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 Stabbing Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Drifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown Lift Plugs / Subs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Wire Line Grabs a.) Straight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown b.) Crank Shaft Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Test Plugs Low-Torque Test Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Not Shown Casing Scrapers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 Type F BOP CUP Tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Contact Information: Ty Livingston Bill Lindsey Gwen Southworth Glenda BelPhone: (985) 878-6716 Fax: (985) 878-6378 Toll Free (800) 486-6410 Website: crossoverinc.com E-mail: sales@xoindy.com

Crossover, InC.Pup JointsCrossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Other lengths are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee. Diameters: Weights: Lengths: Grades: Connections : 3/4" through 4.5" nominal O.D. Standard or Heavy Wall 2, 3, 4, 6, 8, 10, 12 ft. Standard J-55, N-80, N-80 Q & T, L-80, P-110, and special grades Premium threads available include Atlas Bradford, Baker Hughes, Hydril, Interlock, Kawasaki, Mannesmann, NKEL, NKK, OECO, TKC, VAM and Tenaris

Any length, weight, and grade available upon request. Diameters: 4.5" through 20" nominal O.D. Weights: Standard or Heavy Wall Lengths: Custom lengths available from 2 ft. through 20 ft. Connections: STC, LTC, Buttress, and premium threads Pup Joint Options: Custom Sizes Coating O.D./I.D. Bullet Nose Thread Form Perforations Combinations Threads Special Markings Special Paint Magnetic Particle Special Thread Protection Third Party Inspection Special grades are available upon request including: S-95, 9 chrome, 13 chrome, 21 chrome, 310 stainless, 316 stainless, 316L stainless, titanium, aluminum, exotic alloys

Crossover, InC.Perforated Pup JointsAvailable with standard or special perforation size and spacings. Each joint has four rows of 3/8 inch holes drilled longitudinally along the tube as standard. Optional patterns, hole size, and lengths furnished upon request.

Perforated Pup Joint Diameters: Weights: Lengths: Grades: Connections: 3/4" through 4.5" nominal O.D. Standard or Heavy Wall As required J-55, N-80, N-80 Q & T, L-80, P-110, and special grades EUE, NUE, Buttress, Premium, and T & C

Drill Pipe pup joints are integral-type made of AISI 4140/4145 modified alloy steel bar, fully heat treated to 285-341 BHN and 40 ft-lbs min. impact value. All connections are machined according to API specifications.

When ordering or requesting a quote, please specify: * Nominal Size (See Diagram Section A) * Bore (See Diagram Section B) * Tool Joint O.D. (See Diagram Section C) * Size, type, & location of connections (example: 4.5 IF Box up x 4.5 Pin Down) * Length (See Diagram Section G) * 18 Degrees tapered or square shouldered * Plastic, pressed steel or steel thread protectors

Crossover, InC.Crossover Drill Pipe Pup JointsStandard Size (in/mm)Elevator Upset Dia. (D) Nominal Size (A) Bore (B) Tool Joint O.D. (C) Connection Size & Type Tong Space Length Box (E) Pin (F) Available Length* (G) ft/mm 5 / 1524 10 / 3048 15 / 4572 20 / 6096 5 / 1524 10 / 3048 15 / 4572 20 / 6096 5 / 1524 10 / 3048 15 / 4572 20 / 6096 5 / 1524 10 / 3048 15 / 4572 20 / 6096 5 / 1524 10 / 3048 15 / 4572 20 / 6096 5 / 1524 10 / 3048 15 / 4572 20 / 6096 5 / 1524 10 / 3048 15 / 4572 20 / 6096 Approx. Weight lbs/kg 145 / 66 23 / 140 310 / 141 395 / 179 180 /82 290 / 132 395 / 179 505 / 229 170 / 77 245 / 111 315 / 143 390 / 177 220 / 100 350 / 159 480 / 218 610 / 277 205 / 93 315 / 143 420 / 191 525 / 238 255 / 116 425 / 193 595 / 270 765 / 347 230 / 104 375 / 170 520 / 236 665 / 302

Crossover, InC.Coupling Dimensions, Weights and Make-Up Loss FactorsManufactured in accordance with APSCTTUBINGCpig O.D., in. P i p e Cpig Length, In. Size EUE NUE BTC 2 3/8 2 /87

Right & Left hand threads, Acme 8, Armco Seal Lock or Buttress Threads, Sharp Threads & Other Special Threads are also available4 info@CrossoverInc.com (800) 486-6410 ~ (985) 878-6716 www.CrossoverInc.com 4

Crossover, InC.NipplesCrossover adapter nipples, tubing & casing nipples, and seating nipples are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughought the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

Our seamless pipe adapter nipples are available with grooved, threaded, square cut or beveled ends or in combinations of these ends. Lengths: 3 - 12 Crossover casing nipples are available in standard lengths with beveled, grooved, or plain ends or threaded to API specifications for casing threads, short and long, combunation, right and left hand. Materials: Lengths: J-55, K-55, N-80, P-110 8 - 36 in increments of 2 (longer sizes available upon request).

Crossover, InC.Wireline Entry Guides /Ball Catcher SubsCrossover Wireline Entry Guides may be plain or with shear-out ball seat, are installed on the bottom end of the tubing to allow the tubing string to be pressured. When the differential pressure at the tool reaches a predetermined value, the ball and seat are pumped out of the tool. After the ball seat has been pumped out, these subs allow unrestricted access from the tubing into the casing below the tubing string. These products are available in a variety of configurations. The tool illustrated here offers both a reentry guide to simplify wireline operations as well as an optional conical guide to facilitate easy entry when running the tubing through the top of a liner or into a sealbore packer. They can also be furnished with a mule shoe or half mule shoe bottom. Other options include a solid pump-out plug and expendable valves. They can also be furnished in a box X box configuration for those applications where it is necessary to run additional tubing or completion equipment below the shear-out ball seat sub.

Crossover, InC.Collet Cather SubThe Collet Catcher Sub is installed in the tubing string below a hydraulically actuated tool such as a hydrostatic packer to provide a method of applying the tubing pressure required to activate the tool. To set a hydrostatic packer, a ball is circulated through the tubing and packer to the Sub, and sufficient tubing pressure is applied to activate the setting mechanism in the packer. After the packer is set, a pressure increase to approximately 2,500 psi (17, 23 MPa) shears screws to allow the ball seat to move down until the fingers snap back into the groove. The sub is then full opening, and the ball passes on the down tubing.

Crossover, InC.Blast JointsCrossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8 to 4 1/2 OD. Any length, grade of material, and threading is available at the customers request. Both API and Premium threads are available.

Crossover flow couplings are manufactured from seamless mechanical tube in all sizes. Any length, grade of material, and threading is available at the customers request. Both API and Premium threads are available.

Crossover, InC.Splined Expansion JointThe splined expansion joint is designed for use in both single and multiple string completions to compensate for tubing movement. The tube provides 10 feet of movement and utilizes rugged seals for reliable continuous service. The telescoping action permits the tool to be used as a bumper sub or jar when retrieving the installation. Shear screws may be installed to initially position the expansion joint in its extended, collapsed, or mid-stroke position at one foot intervals. A rotation lock lets the operator rotate through the expansion joint in any position. Features & Benefits Shear screw can easily be added or removed to adjust shear value. Tool can be locked in fully extended, fully collapsed, or midstroke position with shear screws. Full length keys provide transmission of torque through full length of travel. Metal goods suitable for H2S service per NACE Standard MR-01-75-88. Also available in stainless steel for H2S and CO2 environments.

The swivel expansion joint is a swivel joint until extended to the full stroke when a clutch engages and allows torque to be transmitted through the joint. Standard stroke length is nine feet with other lengths available upon request. This tool is available in all sizes.

Crossover, InC.Straight Pull / Shear OutCrossover, Inc. Straight Pull / Shear Out safety jointis used between packers in dual and triple completions. It is also used when rotational release is not desired. When run above the upper packer in a single string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations.

The safety joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand square threads facilitate release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the safety joint

Crossover, InC.Overshot Tubing Seal DividerThis equipment is usually recommended for use in wells where sand or trash present a problem in retrieving wireline plugs. The inner mandrel incorporates an integral nipple profile where a plug can be installed. The divider overshot is run on the tubing and latched on the divider mandrel, protecting the plug choke from trash, sand, and debris. A simple turn of the tubing (at the divider) is designed to release divider mandrel.

Crossover, InC.Drain NipplesThe Crossover Type H drain nipple provides a method of draining the tubing by pressure (differential between tubing and annulus fluid). It requires no mechanical manipulation and provides a positive means of dumping the fluid in the tubing string, permitting the fluid level in the well to equalize. It is also less expensive than perforating tubing. It helps eliminate pollution, fire hazard, and the expense and wasted time of wet jobs. Offers full tubing ID and provides a means to pump down the tubing to kill a gassy well. Features & Benefits You can run oversize tubing pumps without having to pull a wet tubing string. You can run hydraulic tubing anchors without fear of having to drag the anchor from the well in a set position. You can run tubing to greater depths in pumping wells because the fluid can be dumped eliminating the necessity of lifting the heavy fluid load with the tubing string in the event of stuck pumps. A simplified design incorporating a minimum number of working parts. Large drain ports permit rapid draining for more efficient draining of heavy crude. The drain is furnished with multiple shear pins.

Other sizes available upon request After calculating the surface pressure required, select a drain unit equal to or exceeding the calculated requirement. The proper drain unit is made up in the tubing string and always runs above the tubing anchor or subsurface pump, approximately two to three joints, to avoid sand or foreign materials and allow alignment above any offset created by the anchor. To open the drain, simply apply pressure down the tubing string, by hand pump or similar method, to equal the calculated surface pressure. Allow the tubing to drain and equalize with the annulus fluid level and pressure before pulling.14

Crossover, InC.Rotary Subs, Lift Subs & Lift PlugsCrossover rotary subs are made with adequate fishing neck and tong space length. When Ordering or requesting a quote please specify: On all subs Sub use (such as kelly sub, x-over drill pipe to drill collar, x-over drill collar to drill collar, bit sub, etc.) so we can give you the correct bevel diameter. Overall length Largest diameter Bore Size & type of connections, indicating pin or box, & special joint features such as bore back or stress relief groove On reduced section subs, add the following specifications: Diameter of reduced section Length of reduced section: 18 or 24 inches On bit subs, add the following specifications: Float bore, size and type On kelly saver subs with rubber protector specify: Desired OD of protector

Lift SubsAll Crossover lift subs are made with AISI 4140/4145. They are machined and heat-treated according to drill collar specifications.When ordering or requesting a quote, please specify: Drill collar OD (A) Tool joint OD (B) Tapered, square shoulder or combination Drill pipe OD (C) Drill collar connection size & type (D) Bore Pressed steel or steel thread protectors

Lift PlugsIf specified, Crossover lift plugs will be center bored to reduce weight. All are manufactured from AISI 4140/4145 modified alloy steel and are heat-treated.When ordering or requesting a quote, please specify: Drill collar OD (A) Drill collar connection size & type Lifting plate OD (B) Bore (C)

Crossover, InC.Stabbing GuidesStabbing Guides allow for quicker, easier stabbing and addsprotection from stabbing damage. The latch holds the stabbing guide in place on both new and worn box O.D.s. The spring loaded lever, when triggered, releases the guide for quick removal after stabbing.

Crossover, InC.Flag SubThe flag sub is placed immediately below the plug dropping head and swivel. The position of the flag indicates that the pump-down plug has been released from the head and has moved down the drill pipe.

Crossover, InC.Drop-in Check ValveThe Drop-In Check Valve is easily installed. When backflow protection is desired, the valve may be added in any of the following ways. It there is no backflow, the valve is dropped into the open tool joint. The Kelly is then connected and the valve can be pumped into the landing sub. Once the valve has landed, no further action is required. If backflow exists or is likely, a Kelly Valve or Safety Valve should be used. If a Lower Kelly Valve is to be used, close the kelly valve and remove the kelly. Stab the Drop-In Check Valve and make up the connection. It may be desirable to use a short sub or wash pipe between the kelly and the valve during this operation. Once the Kelly is made up, the Kelly valve should be opened as pumping is started. Pumping should be continued until the Drop-In Check Valve can be inserted between the swivel and the Upper Kelly Cock. If pipe is being tripped and backflow is encountered, a safety valve may be used. Stab the open safety valve and make it up. Close the safety valve. Set the Drop-In Check Valve in the box of the safety valve. Stab and make up the Kelly over the Drop-In Check Valve. Open the safety valve as pumping is started. When the Drop-In Check valve is seated, pumping may be stopped and the pipe may be worked as necessary. To recover the Drop-In Check Valve, trip the landing sub to the surface. Break the lower connection and unscrew the stop ring. When the stop ring is removed, the valve may be slipped out the pin end of the landing sub.

Crossover, InC.Taper MillsCrossover taper mills utilize the smaller diameter, lower-mill end to enter a collapsed section of casing. Then, through a combination of spudding, rotating action, the carbide covered reamer-edges mill away the undersized section to full mill diameter. The taper mill is equally effective for deburring whipstock windows. Available in ODs from 3 to 12 and in 16 to 54 lengths. The cutting surface is covered with cutting grade tungsten carbide in a nickel-silver matrix. This results in a sturdy, impact resistant tool. The cutting surface is self-sharpening for maximum useful life. The circulation ports are designed to efficiently remove the cuttings while cooling the cutting surfaces. Crossover mills are simple and easy to use. Tag the fish and pick up 2-3 feet. Rotate at 80-120 RPM and lower slowly to contact fish. Continue rotating and apply approximately 2000# per inch of mill diameter. For example, an 8 OD mill would run with 2,000 x 8.25 = 16,500#. Please note that varying weight and rotary speed may improve results.

Rugged Crossover junk mills make milling jobs easy even when cutting the toughest fish such as alloy-steel packers, squeeze tools, perforating guns, drill pipe, tool joints, reamer blades, and rock bits. Crossover junk mills are available concave, convex, or flat bottom in various combinations of fishing necks and stabilizers. Any specific length neck, stabilizer, or combination of both may also be ordered. Available in all sizes with 4 to 8 blades in 10 to 64 lengths. The cutting surface is covered with cutting grade tungsten carbide in a nickel-silver matrix. This results in a sturdy, impact resistant tool. The cutting surface is self-sharpening for maximum useful life. The circulation ports are designed to efficiently remove the cuttings while cooling and cutting surfaces. Crossover mills are simple and easy to use. Tag the fish and pick up 2-3 feet. Rotate at 80-120 RPM and lower slowly to contact fish. Continue rotating and apply approximately 2000# per inch of mill diameter. For example, an 8 OD mill would run with 2,000 x 8.25= 16,500#. Please note that varying weigh and rotary speed may improve results.

Crossover, InC.Pilot MillsCrossover pilot mills mill casing, liners, rotary shoes or large ID tubing at rates of up to 15ft./hr. Kulstrite covered blades are flat or slightly concave with self-sharpening features for longer life between dressings. They are available in all sizes. A 60 degree included taper on these short taper mills and Kulstrite covered spiraled reamer edges dress or clean out belled casing and liner, and require less weight and torque to do the job. Available in all sizes and in 16 to 34 lengths. Crossover junk mills are available with a skirt or guide sleeve to align the mill with the fish and keep it from rotating off the fish. Used when the top of the fish is split or distorted, the skirt or guide provides directionally stable cutting action and eliminates the possibility of casing damage. Available in all sizes. Crossover impact mills are specifically designed to withstand the hammering action necessary to bust up rock bit cones. The large circulation ports provide circulation for both cutting removal and cooling. Available in all sizes. When ordering mills or requesting a quote, please specify: 1. OD of cutting edge 2. OD of body 3. Length 4. Connection 5. Application for which mill is to be used

Crossover, InC.Reamer Watermellon MillCrossover Reamers/Watermelon Mills are excellent for reaming tight spots in casing. The have box-up and pin-down connections for running in drill collar string. Slightly spiraled Reamer blades are toughened with Sintered Tungsten Carbide. They are available in all sizes.

The Crossover Safety Joint is built tough to provide safe and easy release and make-up whenever disengagement becomes necessary. This tool was designed to transmit torque in either direction when placed in the drill, fishing and washover string. A. In drill strings, the Crossover Safety Joint should be located above the drill collars to avoid compression B. In Fishing Strings, the Crossover Safety Joint should be located just above the fishing tool, but below jar or bumper. C. In Washover Strings, the Crossover Safety Joint should be located between the drill pipe and washover pipe. Crossover washover safety joints are provided with a tool joint box thread and a washover pin thread. Operational Components The Crossover Safety Joint consists of a pin section, box section, and a friction ring. The internal connection of the safety joint is a coarse acme thread to facilitate easy backoff and reengagement. A knurled ring between the box and pin section maintains torsional integrity until backoff procedure is initiated. An O-ring seal contains pressure while the safety joint is made up. Operation To disengage to Crossover Safety Joint, place pipe in tension and apply left-hand torque. Hold torque while slowly lowering pipe until safety joints break. Continue to unscrew safety joint to the left. To reengage the Crossover Safety Joint, lower pipe until top section of safety joint lands on box section. Apply one point of weight. Rotate left one or two turns. Then, rotate to the right until torque builds up indicating safety joint is made up.

Crossover, InC.Boot BasketsAll Crossover junk/boot basket bodies are made from materials heat treated to drill collar specifications. All connections are protected by a phosphate surface coating to minimize galling on initial makeup.

Crossover impression blocks have a soft lead bottom section which when set on top of the fish and string weight applied, an accurate indication of the fish and location can be obtained. This allows the operator to select the correct fishing tool for the job there by saving costly trips in and out of the hole.

Crossover, InC.Taper TapsCrossover taper taps are the most economical internal catch pulling tools for freeing stuck fish. Their hardened cutting teeth are machined on a shallow taper to provide an excellent catch for all types of downhole equipment. Taper Taps are furnished either plain or threaded for skirts. If threaded, a skirt or oversized guide can be run if hole conditions require. Plain or fluted wickers are also available in standard sizes. Sizes range other than standard are available on request.

Crossover die collars are the most economical external catch tools for freeing stuck fish. The shallow-tapered, hardened teeth provide excellent engagement. Crossover die collars are available with plain or lipped bottom or threaded bottom for attaching a lipped guide.Taper Taps (Right- hand or left-hand available)Nominal Size In. Outside Dia. In. To Catch In. Total Length In. Dia. Smallest Wicker In. Dia. Largest Wicker In. Complete Assembly No. 5/8 S.R. 1 ID 1 ID 16 3/8 1 TT-1 11 S.R. 1 5/8 ID 1 1/4ID 18 1 TT-2 12 1 13/16 W.F.J. 1 13/16 ID 1 3/8 ID 18 5/8 1 5/8 TT-3 15 1 EUE 1.9 1 PIPE 18 1 TT-4 16 7/8 S.R. 2 5/16 7/8 ID 1 ID 20 1 TT-5 19 1 EUE 2 3/8 1 PIPE 20 7/8 1 7/8 TT-6 20 2 3/8 EUE 3 1/16 2 3/8 OD PIPE & CPL 23 1 5/8 2 5/8 TT-7 23 2 3/8 REG. 3 1/8 2 3/8 REG. 23 5/8 1 5/8 TT-8 24 2 3/8 I.F. 3 3/8 2 3/8 PIPE I.F. HYD I.F. 23 1 3/8 2 3/8 TT-9 31 2 7/8 REG. 3 2 7/8 REG. 23 7/8 1 7/8 TT-10 36 2 7/8 I.F. 4 2 7/8 PIPE I.F.HYD. I.F. 23 1 2 TT-11 41 3 REG. 4 3 REG. 29 1 2 TT-12 56

Crossover, InC.Casing Swedge, Rope Spear & Junk BasketsCasing SwedgeCrossover casing swedges are an economical method of repairing collapsed casing. The swedge can also be used as drift prior to running production tools to ensure no restriction down hole. The swedge has a shallow taper on the bottom end to allow for efficient swedging and a taper on the top for easy entry into tight spots on the return trip. Crossover casing swedges have generous fluid passages milled helically in the body OD to ensure 360 degrees swedging and ease of tripping. It may be advisable on occasion to use multiple swedges with varying ODs to return casing to usable size. For maximum effect and safety, Crossover recommends that these casing swedges be run using drill collars, bumper sub and jars.

The Crossover rope spear is one of the most reliable and efficient tools of its type. The smallest tools, used for retrieving wireline, are of solid construction. The larger tools, for retrieving control line and rubber control line protectors, have a through bore for circulation purposes. These tools are utilized in offshore completion workover operations. The tools feature a simple design with barbs welded onto the shank.

Crossover, InC.Core-Type Junk BasketThe Crossover core-type junk basket is a rugged junk fishing device, using either a mill shoe or flat bottom type shoe in conjunction with two sets of free revolving finger type catchers. The catchers are of rivetless construction. They may be easily redressed on the job, eliminating the necessity of returning them to the shop for replacement. The upper catcher is designed to effectively break the core which is cut by the shoe. The fingers extend only halfway to the center. The lower catcher has alternately short and long fingers which extend almost to the center of the tool to effectively collect and retain odd pieces of junk or cores. Alternate mill shoes available are the Type B and Type C. The Type B is similar to Type A in design, but with Sintered Tungsten Carbide dressing. The Type C is flat bottomed and dressed with Sintered Tungsten Carbide. Other shoe types are available. Operation of the Crossover junk basket is simple, requiring only slow rotation and circulating fluid, to retrieve junk.

Crossover, InC.Crossover, Inc. Reverse Circulating Junk BasketA major problem impeding drill operation is the accumulation of junk on the bottom of the well. Rock bit cones, bearings, broken slips, bits of wireline, various hand tools, slivers and debris from twistedoff drill strings, and mill cuttings are just some examples of the type of junk that can be recovered by any one of the Crossover junk recovery systems. Reverse Circulation Junk Basket The reverse circulating junk basket (RCB) is a superior tool for removal of such items as slips, hand tools, and any other small pieces of junk form the well. The RC uses reverse circulation to aid in the recovery of debris. Operational Components The RCB consists of a reversing sub with intergral ball seat and reversing valve, a barrel, jund catcher, and mill shoe. The reversing valve on the RCB is a permanent part of the tool and requires no maintenance other than normal clean up between jobs. Accessories Two types of shoes are available to fit the Crossover reverse circulation junk basket. 1. Type B shoe- This shoe has cutting teeth dressed with sintered tungsten carbide. 2. Type C shoe- This is a flat bottom shoe dressed with sintered tungsten carbide. Operation The junk basket is run into the hole. When bottom is reached, normal circulation is begun. The basket is slowly rotated. A ball is then dropped and pumped down to indicate circulation at the tool. The coring action is then begun. This, combined with the reverse circulation, guarantees that any junk on the bottom is pumped up into the barrel and caught by the catcher assembly. The tool is removed from the hole after cutting 24 inches of core.

Crossover, InC.Washover PipeCrossover washover pipe has a two-step, double-shouldered thread joint with flush outside and inside diameters. This buttress-type thread assures quick makeup and high torsional strength. A wide assortment of sizes is available ranging from 3 to 20.

Joint Yield (N-80) ft.-lb.3,000 3,000 3,500 4,000 5,000 6,000 5,000 7,000 7,000 7,000 9,000 10,000 9,000 11,000 13,000 16,000 11,000 12,000 14,000 16,000 20,000 16,000 20,000 25,000 18,000 21,000 23,000 20,000 23,000 27,000 32,000 24,000 24,000 25,000 30,000 35,000 30,000 32,000 35,000 40,000 35,000 35,000 40,000 45,000 50,000 60,000 50,000 60,000 65,000 65,000 80,000 100,000 110,000 150,000 180,000 200,000

Crossover, InC.Washover Safety JointsThe Crossover washoover safety joint is used in connecting drill pipe to your washover string. It provides a dependable means of releasing the drill pipe from the washover pipe if the washover string becomes stuck. The lower half of the washover safety joint remains with the washpipe when parted and is full bore to match the washpipe, making subsequent re-entry of other tools possible. A coarse pitch safety thread, in combination with the friction ring, assures prpoer release when required. Washover safety joints are made from heat treated alloy steel and are stronger than the pipe that they are designed to run on. The safety joint should be made up properly in the string. This is done by making up the lower half into the washpipe. Make up the top half into the lower half with the same torque as applied to the washpipe connections. To release the safety joint, bump down sharply on the safety joint with drill striing while holding a safe, left hand torque. Raise the string slowly while maintaining torque. The upper half will unscrew from the lower half, and the friction ring will remain with the retrieved upper half. To re-engage the joint, carefully feel for contact with the lower half, then appply a small amount of weight. Make one revolution to the left, then turn slowly to the right, while maintaining the small amount of weight. An increase in torque will signify that the joint has made up.

Washover Safety Joint SpecificationsWashover Pipe Size (inches) 5 3/8 5 3/4 7 7 3/8 7 5/8 8 8 1/8 8 5/8 9 9 5/8 10 3/4 11 3/4 Tool Joint Size (inches) Washover Pipe Thread To Order To Order To Order To Order To Order To Order To Order To Order To Order To Order To Order To Order Max. OD of Tool (inches) 5 3/8 5 3/4 7 3/8 7 1/2 8 8 1/8 8 1/4 8 3/4 9 3/8 10 1/8 11 1/4 12 Min. ID of Tool (inches) 2 1/8 2 11/16 3 3 3 3/4 3 3/4 3 2 3/4 2 3/4 2 3/4 3 1/2 3 1/2 Length (inches)36 36 39 1/2 39 1/2 41 5/8 40 5/8 41 41 1/2 41 1/2 41 1/2 46 3/4 46 1/2

Crossover, InC.Lift PlugsCrossover lift plugs are designed to give an efficient method of handling washover strings and have a sufficient shoulder diameter to support handling of the washover string. They are available in all thread types and sizes.

Crossover, InC.Crossover Casing RollersUse The CROSSOVER CASING ROLLER is used specifically to recondition and restore buckled, collapsed or dented tubing and casing to their normal internal diameter and roundness. It is designed to enter into the smaller I.D. of the damaged casing. As it is rotated and forced downward, it exerts lateral pressure on the casing to restore it to its normal I.D.

CONSTRUCTION CROSSOVER CASING ROLLERS are manufactured from alloy steels selected for their ability to resist wear. The Roller consist of an eccentric Mandrel upon wh

8613371530291

8613371530291