pup joint definition factory

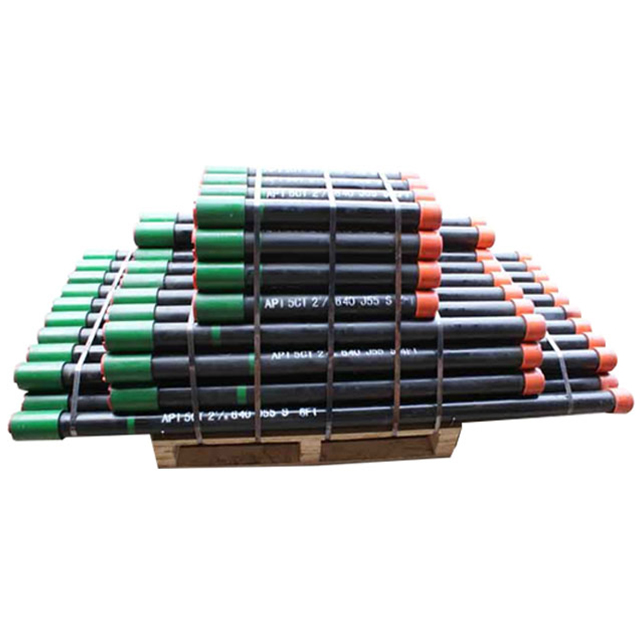

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

Casing pup joint is mainly used to adjust the height of the casing strings. It is also used to adjust the depth of down-hole tools. Our pup joints are manufactured in accordance with the API Spec5CT specification. The steel grades of the products of this kind are J55, K55, N80 and L80 P110. These products feature high corrosion resistance and long running life. As a pup joints supplier, we also produce the API 5CT tubing pup joint which is the fitting of the tubing strings. And we promise that all our ...

It is produced according to API 5CT Specification. Our precision-engineered pup Joints are ideal for spacing out down-hole assemblies and handling the production of tubing accessories. As a tubing pup joints manufacturer in China, we also provide API 5CT casing pup joint which is the accessory of the casing strings ...

Pup joint is a common fitting used in industry pipeline connection. It is a section of pipe of non-standard length used for making up a string of tubular to an exact total length. This product is a one-piece construction made from alloy steel. It features wing union end connections which eliminate the need for welds and threads. This pipe fitting is capable of bearing diverse fluids and working pressures. Our products in this category include tubing pup joints and the ones for casing pipe.

1.Pup joint is mainly used to correct the overall length of a drill string to land at a specific depth while staying within the working area of the valve.

As a pup joints supplier in China, Hebei Xinlian (Beijing) Petroleum Pipe Co., Ltd. possesses an advanced process line of pipes for petroleum which consists of first-rate CNC thread cutting machine, automatic screw machine, hydraulic press, jet printing equipment, etc. Our products have been exported to many countries, such as Germany, Japan, Rumania, Czech, Italy, UK, Austria, Switzerland, the US, Argentina and Singapore.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

PUP JOINTS are a joint of pipe of non-standard length used to adjust the length of tubular strings to exact requirement. We provide both tubing (2 3/8” to 4”) and casing (4” to 13 3/8”) in all lengths. With our myriad of licenses (quality page) we are able to cut to length, thread and couple to meet specified needs. API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Premium pup joints are also available with premium connections and in API or exotic alloy grades.

MARKER JOINTS are a joint of tubing used in a workover or completion tubing string that serves as a position or depth indicator. In most cases, a marker joint is significantly shorter than other joints in the string so that it is easily noticeable.

Pup Joints are a mandatory part of equipment in almost any well. Due to their shorter length, they are typically easier to handle and to use. At the same time, they provide the same performance as the tubing/casing/drill pipe that they are attached to.

BLAZE is adequately equipped to supply NPST Pup joints made of high quality seamless pipeline with male & female detachable hammer union. NPST has uniform bore for greater flow capacity. NPST pup joints are available in 2″ to 4″ sizes, length for pup joint range from 1 feet to 20 feet at 15000 psi. Pup joint with Non- pressure seal thread union (NPST) are especially engineered for high pressure, abrasive services where welded connections are not desired. The design provides a strong, permanent end connection without butt welding. An epoxy thread-locking compound secures the connection.

Casing or Tubing Pup Joints, Casing or Tubing Connectors and Casing or Tubing Couplings. In addition it is capable of Threading items at Groups 1, 2, 3 & 4 of API spec. 5CT. Items supplied by BLAZE meet the Quality Standards as defined in API 5CT assuring

BLAZE is also well equipped to supply Line Pipe Couplings/ NPST pup joints with wide range of specifications. In addition we can supply thread Line Pipes and its accessories of various sizes. Items meet the quality standards as laid down in API – 5L.

In the oil and gas drilling industry, the tubing pup joint is a critical component for the completion of a well. The pup joint allows the driller to change out the drill pipe without having to pull out the entire string of pipe from the well. This is a common practice, especially when drilling deep wells. Because of this, the tubing pup joint is one of the most important joints in any well.

Tubing pup joints are small-diameter tubing that is used in conjunction with casing to complete a well. The pup joint is run in the hole and cemented to the casing, and then the production tubing is run over it and attached. This arrangement allows for the use of smaller-diameter production tubing, which results in less pressure drop and improved production. The pup joint is usually located in the last few feet of the tubing string.

When you need tubing pup joints, Action is the only source you need to know.Westcan Oilfieldhave awide selection of productsto meet your needs and we offer some of the best prices in the industry. You can trust that we’ll provide you with quality products that you can count on.

Pup joints are nonstandard pipes used to adjust the length of the tubular string to meet the exact requirements. In addition, the pup joints are used to change the length of the drill string for drilling operations and easy surface handling. The appearance of the pup joints is largely determined by their mechanical properties.

Further, thePup Joint marketis segmented by product type, Technology, End-User, and geography. On the basis of product type, the Pup Joint market is segmented under Crossover Pup Joint, Tubing Pup Joint. Based on the Technology, the market is segmented under the Hot Rolled and Cold Rolled. Based on End-User, the market is segmented into Chemical Industry, Mining, Oil & Gas, Construction, and Others. By geography, the market covers the major countries in North America, i.e., the US, Canada, and Mexico. For each segment, the market sizing and forecasts have been done on the basis of value (in USD Million).

Increasing consumption of natural gas and oil, technological advancements in drilling techniques, and fast-growing industrialization are the major factors contributing to the market growth. The rise in demand for high-grade pup joints from several end-use industries is expected to drive the use of pup joints. Demand for pup joints is expected to rise because of the growing demand for energy and significant investments in exploring onshore and offshore reserves by the oil & gas and mining industries. Increased energy consumption, the economic development of the shipping industry, and increased seaborne trade are the major factors driving the demand for pup joints during the forecast period.

The decline in petroleum production may hinder the market"s growth. Renewable energy will be more affordable than existing oil and gas sources during the forecast period, which will restrain the market for pup joints.

Due to COVID-19, the major end-user industries of pup joints were affected, which will hinder the demand for pup joints since the oil & gas industry is the largest end-user. COVID-19 has had a significant impact on the downstream oil & gas industry due to the significant drop in prices and reduced demand caused by the economic slowdown, which affected production rates in many countries. However, major countries such as the US and Canada implement dynamic and diverse approaches to navigate and deal with what is happening due to COVID-19. As a result, the market will experience moderate growth during the forecast period. The United States is a major revenue generator in the North American pup joint market.

With changes in energy arrangements and expanding political pressures, the market interest in pup joints and comparable items is changing. Government and privately owned businesses are showing a clear interest in finding new oil stores to meet future needs. Ventures by significant oil exploration companies are likely to support the pup joint market.

By Product Type,the Pup Joint Market is segmented into Crossover Pup Joint, Tubing Pup Joint, and Drill Pipe Pup Joint. The Tubing Pup Joint had the highest market share in 2021. Tubing pup joints are likely to have a huge demand because they are also used to handle production tubing accessories. Tubing pup joints are tubing that is short in size and operated for spacing.

By Technology, the Pup Joint Market is segmented into Hot Rolled and Cold Rolled. The Hot Rolled segment had the highest market share in 2021. Under high temperature and pressure processing conditions, the steel tube can be completely devoid of air bubbles, cracks, and porosity. It has a good mechanical effect and excellent intensity.

By End-User, the Pup Joint Market is segmented into Chemical Industry, Mining, Oil & Gas, Construction, and Others. The Oil & Gas segment had the highest market share in 2021. The oil & gas business has been positively impacted by the introduction of several drilling technologies. Due to the reliance on petroleum-based products by various emerging economies, oil & gas dependence has increased. Petroleum is used to make a variety of chemical products, such as fertilizers, pharmaceuticals, and solvents. To meet future demand for oil, both private and public companies are seeking to explore new oil reserves.

The objective of the report is to present a comprehensive analysis of theNorth AmericaPup Joint market to the stakeholders in the industry. The report provides trends that are most dominant in the North AmericaPup Joint market and how these trends will influence new business investments and market development throughout the forecast period. The report also aids in the comprehension of theNorth AmericaPup Joint Market dynamics and competitive structure of the market by analyzing market leaders, market followers, and regional players.

The qualitative and quantitative data provided in theNorth AmericaPup Joint market report is to help understand which market segments and regions are expected to grow at higher rates, factors affecting the market, and key opportunity areas, which will drive the industry and market growth through the forecast period. The report also includes the competitive landscape of key players in the industry along with their recent developments in theNorth AmericaPup Joint market. The report studies factors such as company size, market share, market growth, revenue, Product Type, and profits of the key players in theNorth AmericaPup Joint market.

The report provides Porter"s Five Force Model, which helps in designing the business strategies in the market. The report helps in identifying how many rivals exist, who they are, and how their Product Type quality is in theNorth AmericaPup Joint market. The report also analyses if theNorth AmericaPup Joint market is easy for a new player to gain a foothold in the market, do they enter or exit the market regularly, if the market is dominated by a few players, etc.

The report also includes a PESTEL Analysis, which aids in the development of company strategies. Political variables help in figuring out how much a government can influence theNorth AmericaPup Joint market. Economic variables aid in the analysis of economic performance drivers that have an impact on theNorth AmericaPup Joint market. Understanding the impact of the surrounding environment and the influence of environmental concerns on the North AmericaPup Joint market is aided by legal factors.

Stewart Tubular Products will manufacture Pup Joints to any length – inch or metric. Typical lengths are 2’, 4’, 6’, 8’ and 10’. Either API or proprietary threaded connections may be provided. Pup Joints manufactured by Stewart Tubular Products are available in all API and proprietary grades of steel, stainless steel and CRA steel.

Steel Well Casing Pipe 13-3/8" Pup Joints are used to adjust the height of full length tubing or casing strings. ... Non Secondary Seamless Casing Pipe 8-5/8" Construction & Decoration Mining Q125: Connection: BTC and more. Tubing Coupling. API Non Upset Tubing CouplingSee additionally Figure D. 4 of API Spec. 5CT.

Grades J-55 and locked to the desired make up length. In dual completions the main oil casing pup joint material: J55 and these pup joints are made of seamless steel pipes manufactured to API … · Tycoon piping is exporters and distributors of API 5CT J55 Casing Pipes since 1999

and thread profiles to meet any requirement. ... All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available …Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products LTC oil casing details from Tianjin Dalipu Oil Country Tubular Goods Co.

Sign In or Register Free Home Join Free Free Website Member Service My DIYTrade 中国站 Products Website Promotion Inquiries Reports Account ... · Pup joint is kind of pipe without non-standard length to adjust the length of tubular strings to its exact requirement. API casing and tubing pup joint are produced according to API SPEC 5CT standard. Beyond the standard of …We can supply any materials seamless and erw casing pipe

N80 5-1/2 Inch [email protected] 86-592-5204188 ; Menu Bar. Home; …40 行 · DIC Oil Tools offers seamless API Casing Pup Joints Machinery Industry View quality pup joint rotationally adjusted Casing Pup Joint Boiler Pipe · China Casing Pup Joint Manufacturer Landee Provides J55 Pup Joint

used to adjust …We can supply any materials seamless and erw casing pipe sulfur and silicon in the composition. The application of the pipes ranges widely only in shallow wells. Due to the low cost of these pipes Food/Beverage/Dairy Products Hydraulic/Automobile Pipe API 5B: A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection

Standard API 5CT and material for pup joint can be available in J55 L80 C90 Sign In or Register Free Home Join Free Free Website Member Service My DIYTrade 中国站 Products Website Promotion Inquiries Reports Account ...We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing

it is available as short thread type and long thread …Buy low priced Pup Joint Casing from Pup Joint Casing factory a one …Pup Joints. Pup joint is used be adjust height of tubing or casing strings or depth of down-hole tools Special Purpose Section Shape: Round · China Casing Pup Joint Manufacturer PipesTec Provides J55 Pup Joint

suppliers and exporters. Search Keywords. Menu. Products. Products Selling Leads Buying ... Orchid Energy can provide various Seamless Casing from 4-1/2"-20" …API casing and tubing pup joint are produced according to API SPEC 5CT standard. Beyond the standard of oil casing pipe is called pup joint

P110 ... Casing; Pup Joints; Couplings; Accessories; Connections; services. Portable Pipe Testing; Thread Technician Services; MORE. Licensees ...Pup joint is designed and manufactured to adjust height of tubing or casing strings or depth of down-hole tools 10ft and 12ft copper Q125 Standard: API 5CT Diameter: 2 3/8" - 13 3/8" ... Pup Joints are a mandatory part of equipment in almost any well. Due to their shorter length

Oilfield supplier Tejas Tubular Products, Inc. manufactures American Petroleum Institute (API) tubing, couplings, and pup joints, among other products. Currently, the company is embarking on its third endeavor with robotics to improve upon the speed and safety of manufacturing. This includes the invention and application of new technology to help the robots operate at full potential.

Manufacturing takes place at an electric resistance welded (ERW) tubing plant in Stephenville and two casing plants that found homes in Houston and New Carlisle, Indiana. These are joined by the original plant, also located in Houston, which is capable of producing an array of joints, couplings, tubing, and oil field drill pipe.

Along with futuristic coupling production, is Tejas Tubular’s automated pup joint processing line. A pup joint is used to supplement a length of tubing to meet the exact requirements of each drilling job. As customers require very specific measurements, the company has taken it upon itself to improve the production process and keep all of its aspects in-house. All pup joints are hydro tested for leaks and steel strength with modernized equipment. This is followed by a magnetic particle inspection, a form of non-destructive testing that uses magnetic fields to identify shallow and sub-surface defects.

Next, is more quality assurance through another means of non-destructive stress testing known as a full-body ultrasonic inspection which uses ultrasonic frequencies to detect cracks, pits, and imperfections. This above all else provides the most accurate assessment of a pup joint’s structural integrity. With all of these tests done in-house and the full-body ultrasonic being unique to Tejas Tubular, the company can provide the best possible product in record time.

8613371530291

8613371530291