pup joint octg quotation

Driveshafts are built to transmit power across rotating shafts, even when placed under stress. The driveshaft connects the front and rear axles. It resembles a large metal rod with a circular cross-section to which other components are attached to form a complete assembly. Axle shaft assemblies and drive shafts are used to couple a transmission with either an axle or another component such as a differential on four-wheel-drive vehicles. There are various types of wholesale octg pup joint available for cars, trucks, vans, and more!

Custom driveshafts can be selected and personalized using an assembly that consists of a journal, shaft, bearings, and U-joints all working together. It is important to match the components with the correct specification as per size, type and load applied. Front driveshafts add an aggressive look to vehicles and improve traction under hard acceleration by eliminating the torque reaction. These front driveshafts are made with equal length shafting and universal joints for a great fit without modifications. Rear driveshafts are also important for the vehicle transmission system. They transfer the power produced by the engine to the rear axle assembly with the least amount of friction and heat buildup. Universal driveshafts are used for SUVs, trucks, and other large trucks that have a long wheelbase. These driveshafts are relatively expensive but worth the investment.

Carbon-fiber driveshafts provide a very light yet strong replacement for conventional steel or aluminum shafts. Carbon fiber is a unique material whose strength and stiffness can be tailored to meet specific engineering requirements. That"s not it! We have more wholesale octg pup joint including driveshaft replacement parts, aluminum driveshafts, 2-piece driveshafts, and truck driveshafts.

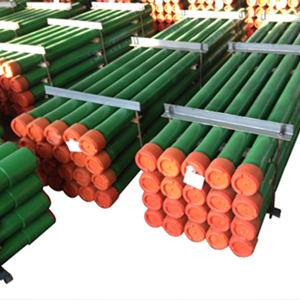

OCPL offers a wide range of OCTG Casing Pup Joints, with both API and premium threads, manufactured at our select API spec. 5CT compliant steel mills.

NOTE:OCTG casing to suit Coupled; Semi-Flush and Flush connections, with casing ID to suit your poundage (including clearance couplings & special drift ID).

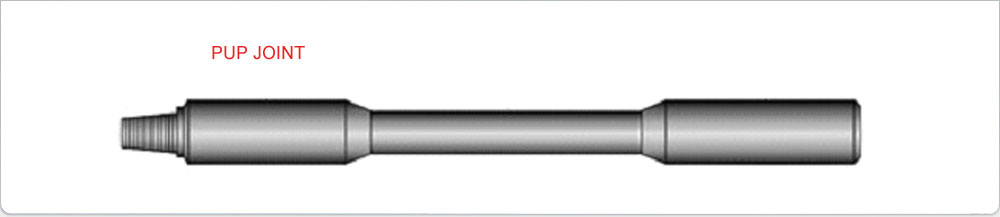

OCTG Pup Joints is one kind of common accessories for connection with casing and tubing. Threaded pup joints are divided into male threaded ends, single male threaded and Female threaded. The size and material is the same as the casing or tubing.

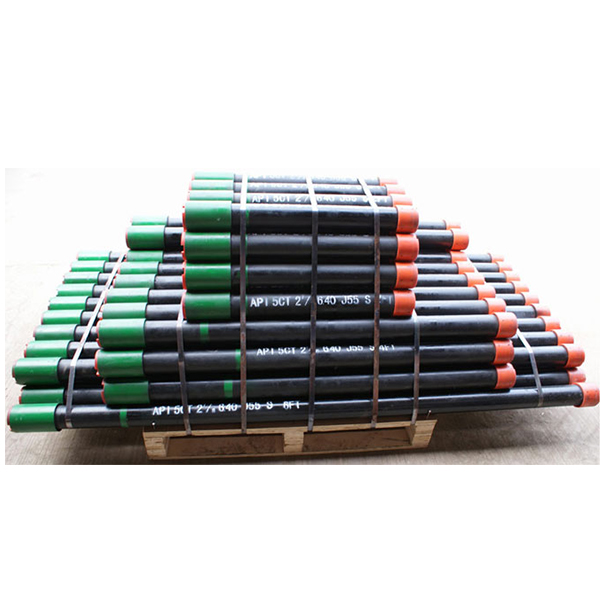

China N80 Pup Joint Manufacturer Derbo Supplies N80 Pup Joint, Hot Rolled, 1.66 Inch, EUE 2.40lb/ft, Oiled, Painting Finish, for Oil & Gas Industries.

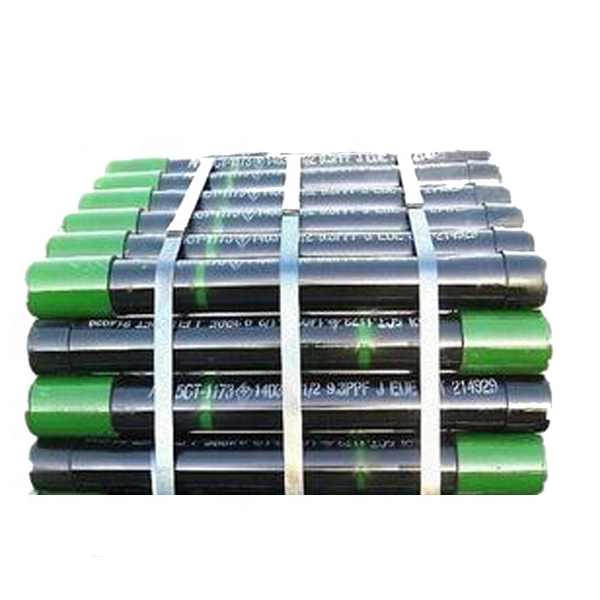

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

We care about your needs, we pay attention to the quality of Steel Pipe Seamless Nipple & Pup Joint; Oil OCTG Casing & Tubing Pup Joint Oilfield Services J55/K55/N80/L80/P110/C95/T95/80s, your satisfaction is our eternal pursuit, quality and integrity is our goal. We strictly and seriously fulfill our contracts, keep our promises and strengthen our network system of after-sales service. We set up a sense of quality service and do our best to do the entrusted project of each contracted customer.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

All kinds of Casing and Tubing Jfe Nsct Pup Joint for OCTG produced by our company have reached the national standards. We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We hope to gain the trust and support of our customers, employees, communities and other stakeholders, and work together to make our company stronger, better and bigger.

Crossover has been servicing the oil country tubular market since 1979. Our commitment to total quality has made us one of the leading manufacturers in the OCTG market. This assurance is recognized both domestically and internationally by major oil producers in their promotion and application of Crossover tubular products.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

Global Steel distributes casing markers, pup joints and tubing pup joints which are manufactured according to API 5CT. Pup joints are available in 2 ft (0.61m), 4 ft (1.22m), 6 ft (1.83m), 8 ft (2.44m) and 10 ft (3.05m) lengths external upset (EUE). Casing marker joints are available in longer lengths (custom lengths as requested). Grades range from J55 and P110 to L80. Premium connections and threads are also available upon request. Fully detailed Mill Test Reports (MTRs) are available.

Integral Pup Joints are high pressure fluid control situation. They are widely used in the acidic operating environment in high-pressure pipelines. Integral Pup Joints are made from high strength steel, with a special toughening process. It uses Acme threaded connection, making the demolition convenient, fast and reliable. Multiple seal designs and high precision are to ensure the sealing performance of the product.

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly�s, subs and pup joints, and pipes.

We provide many of the most common tools and accessories used in OCTG. As a single source supplier, we added this capability to complement the full-length threading and ease the supply chain with a one-stop supplier.

PUP JOINTS are a joint of pipe of non-standard length used to adjust the length of tubular strings to exact requirement. We provide both tubing (2 3/8” to 4”) and casing (4” to 13 3/8”) in all lengths. With our myriad of licenses (quality page) we are able to cut to length, thread and couple to meet specified needs. API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Premium pup joints are also available with premium connections and in API or exotic alloy grades.

MARKER JOINTS are a joint of tubing used in a workover or completion tubing string that serves as a position or depth indicator. In most cases, a marker joint is significantly shorter than other joints in the string so that it is easily noticeable.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to Hardness range of 285-341 with a Charpy "V" notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Trident Steel offers OCTG casing from domestic and international mills for hydrocarbon (oil and gas) extraction. Our casing is available in a variety of grades, including API J55, HCL80, HCP110 and more. Serving as the structural retainer for the walls of a drilled hole, Trident Steel offers a range of casing sizes so that customers can select the exact product for their needs. We also offer a variety of end finishes and specialties including a variety of semi-premium and premium connections. We are able to ship our casing products to any U.S. location, and we maintain stocking points in the Permian, Mid-Continent, Rockies, and Gulf Coast areas for quick delivery.

8613371530291

8613371530291