pup joint oil in stock

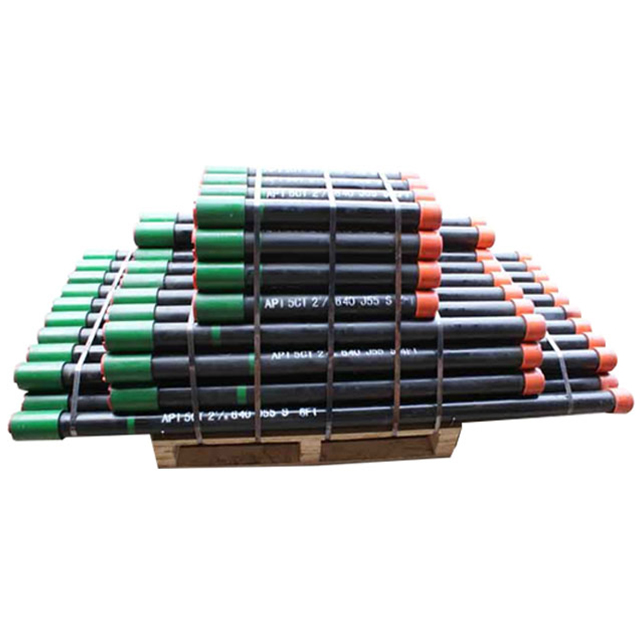

These J55, L80, N80Q & P110 pup joints are manufactured from seamless Grade J-55, L80 N80Q and P110 mechanical tubing. The API 5CT tubing pup joint is mainly used to adjust the height of the tubing strings. It is also used to adjust the depth of down-hole tools.

Manufacturer of pressure, rig concept, well intervention, drilling, down-hole and tubular products. Pressure products include centering shear and fixed bore pipe rams, blowout preventers, diverter systems, connectors, check and gate valves, chokes, actuators, flow heads, manifolds, catchers, packers, hydrate seals, casing heads, casing and tubing head spools, adapters, and hangers. Rig concept products include rig packages, derricks, masts, and skidding systems. Drilling products include electric and hydraulic top drives, makeup/breakout units, pipe handling units, cabins, operation stations, chairs, automatic drillers, anti-collision systems, and navigators, and draw works. Down-hole products include coiled tubing orienteers, drilling motors and jars, and survey and shock tools. Tabular products include drill pipe connections, collars, Kelly�s, subs and pup joints, and pipes.

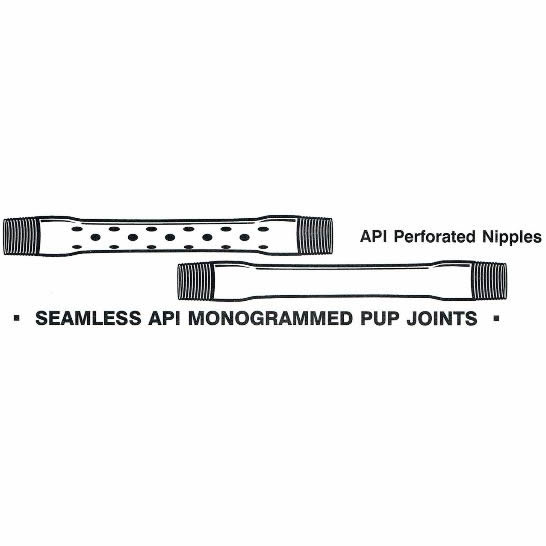

PUP JOINTS are a joint of pipe of non-standard length used to adjust the length of tubular strings to exact requirement. We provide both tubing (2 3/8” to 4”) and casing (4” to 13 3/8”) in all lengths. With our myriad of licenses (quality page) we are able to cut to length, thread and couple to meet specified needs. API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Premium pup joints are also available with premium connections and in API or exotic alloy grades.

MARKER JOINTS are a joint of tubing used in a workover or completion tubing string that serves as a position or depth indicator. In most cases, a marker joint is significantly shorter than other joints in the string so that it is easily noticeable.

One is a short Drill Pipe used to adjust the length of the Drill String; The other one OCTG Pup Joint is a pipe of non-standard length, which is used to adjust the length of tubular strings to its exact requirement.

Vigor can manufacture the Tubing Pup Joints by different technology - Upsetting and Machining process. if you have a special requirement on the Pup Joint production process, please just specify.

If you are looking for a competitive, high quality and fast delivery oilfield pup joint in stock, or if you are planning to buy pup joint API from one of the leading casing and tubing pup joint manufacturers, API 5CT pup joint in stock, l8013cr pup joint, nue/nue tubing pup joint manufacturers and suppliers China, please feel free to contact VIGOR.Details of API Spec. 5CT Oil Tubing Pup Joint

In the oil and gas drilling industry, the tubing pup joint is a critical component for the completion of a well. The pup joint allows the driller to change out the drill pipe without having to pull out the entire string of pipe from the well. This is a common practice, especially when drilling deep wells. Because of this, the tubing pup joint is one of the most important joints in any well.

Tubing pup joints are small-diameter tubing that is used in conjunction with casing to complete a well. The pup joint is run in the hole and cemented to the casing, and then the production tubing is run over it and attached. This arrangement allows for the use of smaller-diameter production tubing, which results in less pressure drop and improved production. The pup joint is usually located in the last few feet of the tubing string.

When you need tubing pup joints, Action is the only source you need to know.Westcan Oilfieldhave awide selection of productsto meet your needs and we offer some of the best prices in the industry. You can trust that we’ll provide you with quality products that you can count on.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

In most completions, the length of tubing available at surface is not enough for proper wellhead installation and operation. Pup joints and varying lengths of tubing are used to adjust the production string length as close as possible to the desired value. Then, the adjustable union or joint is installed, rotationally adjusted, and locked to the desired makeup length. In dual completions, the tool can be used to adjust the length of the short string.

The adjustable, telescoping action of the union or joint allows it to be set and locked at any desired position within its adjustment length while maintaining pressure integrity in the tubing string. Once the tool is in place, the desired amount of tension, weight, and rotational torque can be applied through it to the tubing.

Flow iron pup joints from Cameron deliver maximum total life cycle cost savings, even in the oil and gas industry’s most demanding applications. For all of your flow iron requirements, from high-stage-count hydraulic fracturing to cementing, well testing, and even abrasive flowback, you can count on Cameron for high reliability and low cost.

Prefabricated Pup joints & fittings are used for temporary operations and removable piping systems. Each component is fitted with wing union ends for fast and easy installation. Commonly used in upstream oil & gas well sites, it can be useful in all industrial applications.

Multiphase oil and gas well effluent, drilling fluids, water, chemicals, abrasive and corrosive fluids, cement, refined hydrocarbons, hydraulic oil, etc.

Swivel Joints and Blast Saves are our widely recognized premium solutions for ensuring the best performance, endurance and quality in intelligent completion design. With dual metal-to-metal seals, they are available in a range of sizes, metallurgies and steel grades, and their upper and lower ends can be customized for many of our premium connections.

Our Swivel Joint premium connectors are designed to solve alignment problems during dual completion or intelligent completion installations. Furthermore, our Swivel Joints Torque Transmission (TT) can withstand torque in excess of the maximum make-up torque of premium connections.

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

8613371530291

8613371530291