pup joint well drilling pricelist

BLAZE is adequately equipped to supply NPST Pup joints made of high quality seamless pipeline with male & female detachable hammer union. NPST has uniform bore for greater flow capacity. NPST pup joints are available in 2″ to 4″ sizes, length for pup joint range from 1 feet to 20 feet at 15000 psi. Pup joint with Non- pressure seal thread union (NPST) are especially engineered for high pressure, abrasive services where welded connections are not desired. The design provides a strong, permanent end connection without butt welding. An epoxy thread-locking compound secures the connection.

Casing or Tubing Pup Joints, Casing or Tubing Connectors and Casing or Tubing Couplings. In addition it is capable of Threading items at Groups 1, 2, 3 & 4 of API spec. 5CT. Items supplied by BLAZE meet the Quality Standards as defined in API 5CT assuring

BLAZE is also well equipped to supply Line Pipe Couplings/ NPST pup joints with wide range of specifications. In addition we can supply thread Line Pipes and its accessories of various sizes. Items meet the quality standards as laid down in API – 5L.

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

In the oil and gas drilling industry, the tubing pup joint is a critical component for the completion of a well. The pup joint allows the driller to change out the drill pipe without having to pull out the entire string of pipe from the well. This is a common practice, especially when drilling deep wells. Because of this, the tubing pup joint is one of the most important joints in any well.

Tubing pup joints are small-diameter tubing that is used in conjunction with casing to complete a well. The pup joint is run in the hole and cemented to the casing, and then the production tubing is run over it and attached. This arrangement allows for the use of smaller-diameter production tubing, which results in less pressure drop and improved production. The pup joint is usually located in the last few feet of the tubing string.

When you need tubing pup joints, Action is the only source you need to know.Westcan Oilfieldhave awide selection of productsto meet your needs and we offer some of the best prices in the industry. You can trust that we’ll provide you with quality products that you can count on.

Pup Joint Inc. is a machine shop that sells down hole tubular and casing accessories and equipment. We are a leading supplier of pup joints & accessories with API5CT & premium threads at very competitive prices. Our machine shop is a threading facility for all your threading & precision machining needs. PJI commenced operations in Houma, LA in July of 1997. Our staff has over 65 years of combined experience supplying quality products & services to the oil & gas industry.

ADFO manufactures Pup Joints with Integral Hammer Union end connections.These Pup Joints are used on high pressure discharge lines, choke and kill lines, auxiliary flow and other applications.

Prithviraj Industries manufactures Pup Joints up to 20, 000 psi cold working pressure in sizes: 1, 11 /2, 2, 3, and 4-inch bore sizes, lengths to 20 feet.

Shreeraj Industries offers NPST (Non-pressure Seal Thread) Pups in size 1-3 Fig 602 and 1502. The NPST connection offers a light weight pup capable of 6000-15000 CWP with a connection that isolates the thread from fluid’s flowpath. This connection is permanent and is well suited to abrasive applications where a weldedread more...

- Grant Prideco pup joints are manufactured from the same material as our drill collars. Heat-treatment processes ensure a hardness range of 285-341 Brinell. Charpy V minimum impact strength of 40 ft-lb at 70° F are guaranteed one inch below the surface.

Windlass manufactures Pup Joints with integral hammer lug union end connections. This enables faster, easier make-up and break-out of temporary flow lines.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Upset forging is a process by which a plain end blank is upset at each end to increase the cross section area. We have innovated upsetting by automating our handling table. This automated handling table not only helps us upset at different lengths safely, but also helps us to get pup joints to the highest degree of consistency and accuracy.

The hydro tests all of its pup joints. This non-destructive test uses water pressure and a pressure recorder to determine possible leaks. Our modernized tester can be adjusted to accommodate various lengths of pup joints, and test them at various pressures as required by API and customer specifications.

We has a custom & automated Full Body Ultrasonic Inspection system to inspect its tubing pup joints. We are the first in the industry to build and use a Full Body Ultrasonic Inspection for pup joints to ensure there are no defects on the external and internal surface longitudinal and transverse.

This inspection has greater accuracy than other non destructive tests, one reason is its high penetrating power to allow detection of defects deep in the pup joints. The Full Body UT also has high sensitivity which allows it to detect exceptionally small deficiencies. This inspection ensures that our customers receive the best quality pup joints on the market.

We also manufacture pup joints by profiling from heavy wall mechanical tubing. Profiling of pup joints are done in a high precision and tolerance CNC in order for us to achieve a high level of dimensional tolerances and surface finish.

The wet magnetic particle test is a non-destructive test that detects surface and shallow subsurface defects. Pup joints are inspected for longitudinal and transverse defects using this inspection method.

We have exclusively designed a line which heat treats each pup joint individually. This setup is versatile and dynamic, as it can be adjusted for various lengths of pup joints and modified accordingly. This gives us the advantage of catering to the needs of our customers extremely quickly. All pup joints are re-straightened after heat treat to ensure the highest quality.

The upset (thread-end finish) refers to the wall of the tool joint at the threaded connection. Drill pipe is offered with an internal upset (IU), an external upset (EU), or an internal-external upset (IEU).

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

All kinds of Casing and Tubing Jfe Nsct Pup Joint for OCTG produced by our company have reached the national standards. We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We hope to gain the trust and support of our customers, employees, communities and other stakeholders, and work together to make our company stronger, better and bigger.

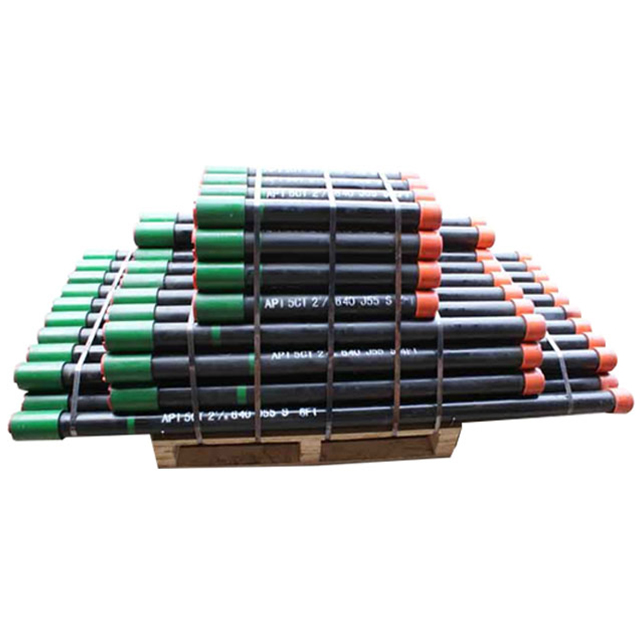

Pup joint is used be adjust height of tubing or casing strings or depth of down-hole tools, and these pup joints are made of seamless steel pipes. Pup joint can be available with tubing pup joint or casing pup joint, and material for pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of tubing pup joint range from 2⅜¡± to 4½¡±, and casing pup joint range from 4½¡± to 13⅜¡±, thread of pup joint can be 8RD, 10RD or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing, and casing pup joint is the same as casing.

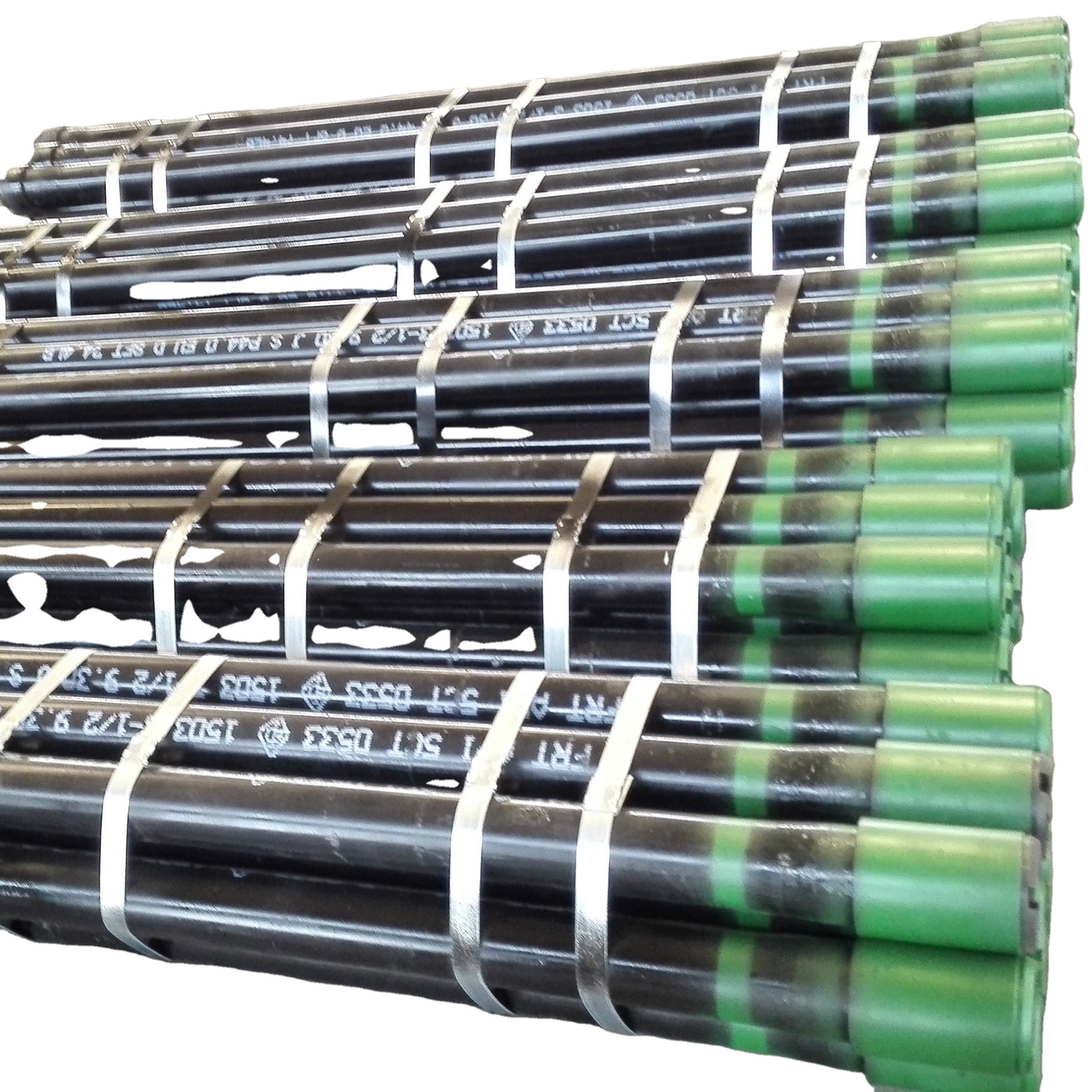

Tubing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of tubings, and tubing pup joints are made of seamless steel tubings. Material grade of tubing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of tubing pup joint range from 2⅜¡± to 4½¡±, thread of pup joint can be 8RD, 10RD or BTC, and end connection types can be NUE and EUE. length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Tubing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing. Tubing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished tubing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Casing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of casings, and casing pup joints are made of seamless steel casings. Material grade of casing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of casing pup joint range from 4½¡± to 13⅜¡±, thread of pup joint can be 8RD, 10RD or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Casing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of casing pup joint is the same as casing. Casing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished casing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Pup joints are nonstandard pipes used to adjust the length of the tubular string to meet the exact requirements. In addition, the pup joints are used to change the length of the drill string for drilling operations and easy surface handling. The appearance of the pup joints is largely determined by their mechanical properties.

Further, thePup Joint marketis segmented by product type, Technology, End-User, and geography. On the basis of product type, the Pup Joint market is segmented under Crossover Pup Joint, Tubing Pup Joint. Based on the Technology, the market is segmented under the Hot Rolled and Cold Rolled. Based on End-User, the market is segmented into Chemical Industry, Mining, Oil & Gas, Construction, and Others. By geography, the market covers the major countries in North America, i.e., the US, Canada, and Mexico. For each segment, the market sizing and forecasts have been done on the basis of value (in USD Million).

Increasing consumption of natural gas and oil, technological advancements in drilling techniques, and fast-growing industrialization are the major factors contributing to the market growth. The rise in demand for high-grade pup joints from several end-use industries is expected to drive the use of pup joints. Demand for pup joints is expected to rise because of the growing demand for energy and significant investments in exploring onshore and offshore reserves by the oil & gas and mining industries. Increased energy consumption, the economic development of the shipping industry, and increased seaborne trade are the major factors driving the demand for pup joints during the forecast period.

The decline in petroleum production may hinder the market"s growth. Renewable energy will be more affordable than existing oil and gas sources during the forecast period, which will restrain the market for pup joints.

Due to COVID-19, the major end-user industries of pup joints were affected, which will hinder the demand for pup joints since the oil & gas industry is the largest end-user. COVID-19 has had a significant impact on the downstream oil & gas industry due to the significant drop in prices and reduced demand caused by the economic slowdown, which affected production rates in many countries. However, major countries such as the US and Canada implement dynamic and diverse approaches to navigate and deal with what is happening due to COVID-19. As a result, the market will experience moderate growth during the forecast period. The United States is a major revenue generator in the North American pup joint market.

With changes in energy arrangements and expanding political pressures, the market interest in pup joints and comparable items is changing. Government and privately owned businesses are showing a clear interest in finding new oil stores to meet future needs. Ventures by significant oil exploration companies are likely to support the pup joint market.

By Product Type,the Pup Joint Market is segmented into Crossover Pup Joint, Tubing Pup Joint, and Drill Pipe Pup Joint. The Tubing Pup Joint had the highest market share in 2021. Tubing pup joints are likely to have a huge demand because they are also used to handle production tubing accessories. Tubing pup joints are tubing that is short in size and operated for spacing.

By Technology, the Pup Joint Market is segmented into Hot Rolled and Cold Rolled. The Hot Rolled segment had the highest market share in 2021. Under high temperature and pressure processing conditions, the steel tube can be completely devoid of air bubbles, cracks, and porosity. It has a good mechanical effect and excellent intensity.

By End-User, the Pup Joint Market is segmented into Chemical Industry, Mining, Oil & Gas, Construction, and Others. The Oil & Gas segment had the highest market share in 2021. The oil & gas business has been positively impacted by the introduction of several drilling technologies. Due to the reliance on petroleum-based products by various emerging economies, oil & gas dependence has increased. Petroleum is used to make a variety of chemical products, such as fertilizers, pharmaceuticals, and solvents. To meet future demand for oil, both private and public companies are seeking to explore new oil reserves.

The market is characterized by the existence of a number of well-known firms. These companies control a large portion of the market, have a wide Product Type portfolio, and have a North America presence. In addition, the market comprises small to mid-sized competitors that sell a limited variety of items, some of which are self-publishing organizations.

The objective of the report is to present a comprehensive analysis of theNorth AmericaPup Joint market to the stakeholders in the industry. The report provides trends that are most dominant in the North AmericaPup Joint market and how these trends will influence new business investments and market development throughout the forecast period. The report also aids in the comprehension of theNorth AmericaPup Joint Market dynamics and competitive structure of the market by analyzing market leaders, market followers, and regional players.

The qualitative and quantitative data provided in theNorth AmericaPup Joint market report is to help understand which market segments and regions are expected to grow at higher rates, factors affecting the market, and key opportunity areas, which will drive the industry and market growth through the forecast period. The report also includes the competitive landscape of key players in the industry along with their recent developments in theNorth AmericaPup Joint market. The report studies factors such as company size, market share, market growth, revenue, Product Type, and profits of the key players in theNorth AmericaPup Joint market.

The report provides Porter"s Five Force Model, which helps in designing the business strategies in the market. The report helps in identifying how many rivals exist, who they are, and how their Product Type quality is in theNorth AmericaPup Joint market. The report also analyses if theNorth AmericaPup Joint market is easy for a new player to gain a foothold in the market, do they enter or exit the market regularly, if the market is dominated by a few players, etc.

The report also includes a PESTEL Analysis, which aids in the development of company strategies. Political variables help in figuring out how much a government can influence theNorth AmericaPup Joint market. Economic variables aid in the analysis of economic performance drivers that have an impact on theNorth AmericaPup Joint market. Understanding the impact of the surrounding environment and the influence of environmental concerns on the North AmericaPup Joint market is aided by legal factors.

TechniFactory OCTG TPS Technitube Rohrenwerke GmbH is your partner for OCTG. Besides manufacturing premium tubing of highest quality, we are also highly specialized in the production of Pup Joints and other accessories. Our production facilities allow an individual and cost-effective new production. Thanks to a big stock of prematerial, we can realize short lead times for your requirements. To support our clients, we have set up the biggest Tubing Pup Joint stock in Europe with more than 3.500 Pup Joints ready on the shelf. Starting from Macaroni sizes up to heavy wall test strings and with different connections we offer a huge range of specifications. What is a Pup Joint? Pup Joints are shorter versions of tubing and casing, used to adjust the length of a string to its" exact requirements. There are many different cases where Pup Joints are necessary: to reach an exact reservoir depth, for setting packers at an exact location within the borehole, to space out your string prior to hanging it and many more. What are the benefits? Pup Joints are a mandatory party of equipment in almost any well. Due to their shorter length, they are typically easier to handle and to use. At the same time, they provide the same performance as the tubing/ casing/drill pipe that they are attached to. TPS Pup Joints have a lot more advantages beyond that.

Integral pup joints are tubes with two ends made up of high-quality alloy steel. This pup joint works well in high flow pressure applications and has great working capacity. If you are facing any issue with the flow in your piping system, installing a pup joint can help. You can buy integral pup joints online from our website enggpro. Com. Enggpro is a global marketplace for engineering equipment and services that precisely provide leads for engineering products. You can find reliable integral pup joint suppliers and manufacturers here and connect with them without any hindrance. You will not only get the premium quality goods here but also the best prices ever with our E-auction option where you can negotiate with them and have your hands on the desired products. You will also get to connect with the integral pup joint exporters from India, the USA, the Middle East, Europe and other Asian countries. Why go somewhere else, when you can have everything sorted on one single platform.

More Subsea Oil and Gas Companies, Products, Projects, Drilling Rigs and JobsUnderwater WeldingQuick Guide: What is underwater welding and how to get underwater welding jobs! What is Underwater Welding? Underwater welding, a term for methods adapted for subsea welding, for the purpose of repairing damage to ships…

Directional DrillingQuick Guide: What is directional drilling and how to get directional drilling jobs! What is Directional Drilling? Directional drilling or deviation drilling is an oil and gas exploration drilling technique used to change the direction…

8613371530291

8613371530291