pup joint yield strength api manufacturer

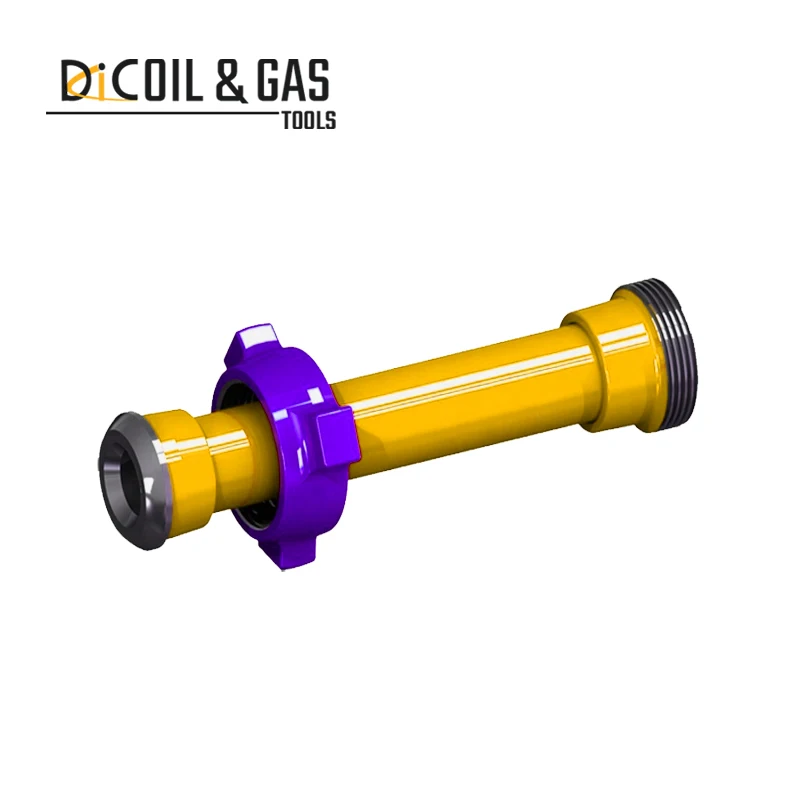

PUP JOINTS are a joint of pipe of non-standard length used to adjust the length of tubular strings to exact requirement. We provide both tubing (2 3/8” to 4”) and casing (4” to 13 3/8”) in all lengths. With our myriad of licenses (quality page) we are able to cut to length, thread and couple to meet specified needs. API casing and tubing pup joints are manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Premium pup joints are also available with premium connections and in API or exotic alloy grades.

MARKER JOINTS are a joint of tubing used in a workover or completion tubing string that serves as a position or depth indicator. In most cases, a marker joint is significantly shorter than other joints in the string so that it is easily noticeable.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

We manufacture a wide range of Crossover Couplings. Couplings are used to connect two sizes of pipes, or two different dissimilar threaded parts together. We offer special clearance couplings, special clearance couplings with bevels on both ends, and couplings with the API Seal Ring Modification.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Flow Couplings are heavy wall box by box connectors used in tubing strings and are designed to minimize the effect of internal erosive action caused by production fluids. Flow couplings are located just above or below Landing Nipples, Safety Valves or Control Devices where turbulent flow problems are likely to occur. Crossover flow couplings are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 3" and 6". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover can build these in any of the regular API Grades such as J-55, L-80, or P-110. These are usually only made going up or down one size in either direction such as ¾” to 1” or 1 ½” to 2”.

A saver sub falls under the drill string accessory tool category and a short pipe that is replaceable and expendable without a major investment. This accessory protects the Kelly or topdrive component threads and those components represent a significant capital cost and considerable downtime when replaced. Saver sub are manufactured to the following specs connections, lengths, weights and material grade.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

Every step of production process is performed with the highest degree of accuracy to meet or exceed API Specifications as well as the Industry Standards.

It is a short drill pipe used to adjust the overall length of drill string. The surface of Drill Pipe Pup joint looks like a smaller version of joint of drill pipe.

The minimum yield strength of Drill Pipe Pup Joint is 120000 PSI, just like the Tool Joint of the Drill Pipe. We manufacture Drill Pipe Pup Joints of all sizes, grades, and thread profiles to meet any custom requirements.

All our products have passed the ISO certification and API certifications.We have become the reliable exporter of Drill Pipe Pup Joint in India. Our products are tested numerous times under technical guidance and are made from best quality material.

Pup Joints are a mandatory part of equipment in almost any well. Due to their shorter length, they are typically easier to handle and to use. At the same time, they provide the same performance as the tubing/casing/drill pipe that they are attached to.

or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order.

Pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing, and casing pup joint is the same as casing.

and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished tubing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Casing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of casing pup joint is the same as casing. Casing pup joints are

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

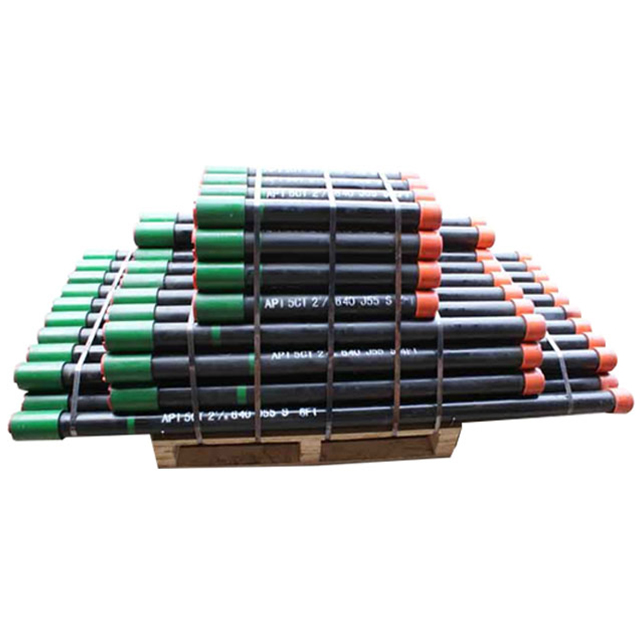

Whole series of API SPEC 5CT oil tubing indicate the steel pipes produced as per API 5CT specification, used for exploiting resources such as petroleum and natural gas,etc. Oil tubing is used to extract oil and natural gas, casing is used as wall of oil and gas well bore.

Whole series of API SPEC 5CT casing pipe indicate the steel pipes produced as per API 5CT specification, used for exploiting resources such as petroleum and natural gas,etc. Tubing is used to extract oil and natural gas, casing is used as wall of oil and gas well bore.

For couplings, pup joints and accessories the analyses requested shall be furnished by the steel manufacturer or processor and shall be taken from material in tubular or bar form.

For Groups 1, 2 and 3, when requested by the purchaser, the manufacturer shall furnish a report giving the heat analysis of each heat of steel used in the manufacture of API 5CT CASING TUBING, coupling stock and couplings furnished on the purchase agreement. In addition the purchaser, upon request, shall be furnished the results of quantitative | analyses for other elements used by the manufacturer to control mechanical properties.

For Grade Q125, the manufacturer shall furnish a report giving the heat analysis of each heat of steel used in the manufacture of API 5CT CASING PIPE, coupling stock and couplings furnished on the purchase agreement. The report shall I include quantitative analyses for other elements used by the manufacturer to control mechanical properties.

One tensile test shall be made as a control on each heat of steel used by the manufacturer for the production of API 5CT CASING PIPE under this International Standard. For electric-welded pipe, these tensile tests shall be made on either the skelp or the finished API 5CT CASING PIPE , at the option of the manufacturer.

The lengths for testing shall be selected at random and, when more than one test is required, the selection procedures shall provide samples representing the start and end of the heat-treat cycle (as applicable) and front and back ends of the tubes. When more than one test is required, the test specimens shall be from different lengths, except for upset API 5CT CASING PIPE the test specimens may be taken from both ends of one length.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Tubing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of tubings, and tubing pup joints are made of seamless steel tubings. Material grade of tubing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of tubing pup joint range from 2⅜¡± to 4½¡±, thread of pup joint can be 8RD, 10RD or BTC, and end connection types can be NUE and EUE. length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Tubing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing. Tubing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished tubing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Casing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of casings, and casing pup joints are made of seamless steel casings. Material grade of casing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of casing pup joint range from 4½¡± to 13⅜¡±, thread of pup joint can be 8RD, 10RD or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Casing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of casing pup joint is the same as casing. Casing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished casing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Casing pup joint is mainly used to adjust the height of the casing strings. It is also used to adjust the depth of down-hole tools. Our pup joints are manufactured in accordance with the API Spec5CT specification. The steel grades of the products of this kind are J55, K55, N80 and L80 P110. These products feature high corrosion resistance and long running life. As a pup joints supplier, we also produce the API 5CT tubing pup joint which is the fitting of the tubing strings. And we promise that all our ...

It is produced according to API 5CT Specification. Our precision-engineered pup Joints are ideal for spacing out down-hole assemblies and handling the production of tubing accessories. As a tubing pup joints manufacturer in China, we also provide API 5CT casing pup joint which is the accessory of the casing strings ...

Pup joint is a common fitting used in industry pipeline connection. It is a section of pipe of non-standard length used for making up a string of tubular to an exact total length. This product is a one-piece construction made from alloy steel. It features wing union end connections which eliminate the need for welds and threads. This pipe fitting is capable of bearing diverse fluids and working pressures. Our products in this category include tubing pup joints and the ones for casing pipe.

1.Pup joint is mainly used to correct the overall length of a drill string to land at a specific depth while staying within the working area of the valve.

As a pup joints supplier in China, Hebei Xinlian (Beijing) Petroleum Pipe Co., Ltd. possesses an advanced process line of pipes for petroleum which consists of first-rate CNC thread cutting machine, automatic screw machine, hydraulic press, jet printing equipment, etc. Our products have been exported to many countries, such as Germany, Japan, Rumania, Czech, Italy, UK, Austria, Switzerland, the US, Argentina and Singapore.

API 5CT J55 and K55 casing and tubing are relatively low grade material pipe among all API 5CT pipes, they have same chemical composition and same yield strength 379-552 Mpa but in different tensile, J55 tensile strength minimum 517 Mpa which K55 is 655 Mpa. J55/K55 are lower grade than N80, L80, P110 or T95, so they are a cheaper option material and widely used in non corrosive oil well installation without high strength requirement.

API 5CT defines delivery conditions for steel casing and tubing pipes used for oil wells installation, it covers pup joints, coupling stock, coupling material, and accessory materials, and establishes requirements for three product specification levels (PSL-1, PSL-2, and PSL-3). The requirements for PSL-1 are the basis of this standard.

As we know steel casing pipe is considered as a pipe pile that will stabilize the oil well. Casing is installed in oil well downhole to provide structural integrity to the wellbore and bear external-collapse pressure from rock formations and internal-yield pressure from fluid and gas. It needs to take pressure from its own weight and withstand the torque and transaxial pressure placed on it while running downhole.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

All kinds of Casing and Tubing Jfe Nsct Pup Joint for OCTG produced by our company have reached the national standards. We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We hope to gain the trust and support of our customers, employees, communities and other stakeholders, and work together to make our company stronger, better and bigger.

Pursuant to subsection 38(1) of the Special Import Measures Act, the President of the Canada Border Services Agency made preliminary determinations of dumping and subsidizing on December 12, 2011, respecting the alleged injurious dumping and subsidizing of oil country tubular goods pup joints, made of carbon or alloy steel, welded or seamless, heat-treated or not heat-treated, regardless of end finish, having an outside diameter from 2 3/8 inches to 4 1/2 inches (60.3 mm to 114.3 mm), in all grades, in lengths from 2 feet to 12 feet (61 cm to 366 cm) originating in or exported from the People"s Republic of China.

On July 22, 2011, the Canada Border Services Agency (CBSA) received a written complaint from Alberta Oil Tool (AOT), a division of Dover Corporation (Canada) Limited of Edmonton, Alberta, (hereafter, “the Complainant”) alleging that imports of certain pup joints originating in or exported from the People"s Republic of China (China) are being dumped and subsidized and causing injury to the Canadian industry.

The Complainant provided evidence to support the allegations that certain pup joints from China have been dumped and subsidized. The evidence also disclosed a reasonable indication that the dumping and subsidizing had caused injury and are threatening to cause injury to the Canadian industry producing these goods.

On September 12, 2011, pursuant to subsection 31(1) of SIMA, the President of the CBSA (President) initiated investigations respecting the dumping and subsidizing of certain pup joints from China.

On September 13, 2011, the Canadian International Trade Tribunal (Tribunal) commenced a preliminary injury inquiry, pursuant to subsection 34(2) of SIMA, into whether the evidence discloses a reasonable indication that the alleged dumping and subsidizing of certain pup joints from China have caused injury or retardation or are threatening to cause injury to the Canadian industry producing the goods. On November 14, 2011, pursuant to subsection 37.1(1) of SIMA, the Tribunal made a preliminary determination that there is evidence that discloses a reasonable indication that the dumping and subsidizing of certain pup joints from China have caused injury or retardation or are threatening to cause injury.

On December 12, 2011, as a result of the CBSA"s preliminary investigations and pursuant to subsection 38(1) of SIMA, the President made preliminary determinations of dumping and subsidizing with respect to certain pup joints originating in or exported from China.

Of the other producers certified to produce the like goods in Canada, only Tenaris Canada (Tenaris), of Sault Ste. Marie, Ontario, confirmed that they are manufacturing them. Tenaris produces like goods which are premium pup joints in relatively small quantities and provided a letter supporting the complaint.

As part of the section 20 inquiry, RFIs were sent to all known producers of pup joints in other countries (excluding China). This list of certified producers was obtained directly from the American Petroleum Institute (API). A total of 139 RFIs were sent to these producers requesting domestic selling price and costing information for pup joints produced at their facilities.

Oil country tubular goods pup joints, made of carbon or alloy steel, welded or seamless, heat-treated or not heat-treated, regardless of end finish, having an outside diameter from 2 3/8 inches to 4 1/2 inches (60.3 mm to 114.3 mm), in all grades, in lengths from 2 feet to 12 feet (61 cm to 366 cm) originating in or exported from the People"s Republic of China.

Pup joints are oil country tubular goods (OCTG) made from carbon or alloy steel pipes used for the exploration and exploitation of oil and natural gas. These pipes may be made by the electric resistance welded (ERW) or seamless production method, and are supplied to meet American Petroleum Institute (API) specifications 5CT or equivalent standard. 5

Pup joints are primarily used for the purpose of adjusting the depth of strings or down hole tools, particularly where exact depth readings in a well are required for any given purpose, such as setting valves, packers, nipples or circulating sleeves. Pup joints are also used with down hole pumps. The number and lengths of pup joints may vary widely from well to well, depending on the various equipment and performance requirements established by engineers of the purchasing end users.

Pup joints may range from 2 feet to 12 feet in length with a permitted tolerance of plus or minus three inches. The sizes are generally 2, 4, 6, 8, 10 and 12 feet in length.

The input pipe is produced in accordance with API 5CT, and may be produced using either seamless or ERW material. While pup joints may be made with ERW pipe, the Canadian market employs predominantly seamless OCTG. All pup joints produced by the Complainant are seamless products. 6

The pup joints subject to these investigations are, by virtue of the characteristics such as the outside diameter range, essentially short lengths of OCTG tubing.

Theoretically, subject pup joints may be supplied to meet any grade including and not limited to, H40, J55, K55, M65, N80, L80, L80 HC, L80 Chrome 13, L80 LT, L80 SS, C90, C95, C110, P110, P110 HC, P110 LT, T95, T95 HC, and Q125, or proprietary grades manufactured as substitutes for these specifications. The most common demand in the Canadian market is for J55 or L80 grades.

The grade numbers define the minimum yield strength required of the grade in kilo-pounds [force] per square inch (“ksi” or 1,000 pounds per square inch). Pup joints may also be made to proprietary specifications. The Complainant makes or has the capability to produce pup joints in any of these specifications/grades.

As with all OCTG, a standard pup joint must be able to withstand outside pressure and internal yield pressures within the well. Also, it must have sufficient joint strength to hold its own weight and must be equipped with threads sufficiently tight to contain the well pressure where lengths are joined.

There is a small market segment for perforated pup joints. These are pup joints with holes in the body of the pup joint (usually 3/8 inch although they may have holes or slots of various sizes in the body). The product is produced with API 5CT tubing, though once perforated the product no longer conforms to an API 5CT specification, since it no longer meets the yield strength requirements. Perforated pup joints are employed to allow fluids to enter the production tubing. They can also be used to create a mud anchor. Perforated pup joints are included as goods subject to these investigations.

On March 23, 2010, the Tribunal excluded ‘pup joints’ as part of its finding in Inquiry No. NQ-2009-004 on Certain Oil Country Tubular Goods (OCTG). In that finding, the Tribunal stated:

“The Tribunal hereby excludes pup joints, seamless or welded, heat-treated or not heat-treated, in lengths of up to 3.66 m (12 feet), from its injury finding.” 7

Pup joints are manufactured in Canada by the Complainant using plain end tube as an input. For J55 grade pup joints, a length of J55 OCTG tubing is employed. For L80 grade pup joints, the input is an A-519 mechanical tube with the appropriate steel chemistry for L80 OCTG. The L80 input tube does not qualify for the API 5CT designation until it has been tested in accordance with API requirements. The Complainant performs the testing required.

The production process of the input pipe itself is virtually identical to that employed for OCTG tubing and casing. There are, however, significant subsequent costs associated with transforming the input tubing into pup joints including: cutting to length, end finishing, threading, and testing to meet the certification required.

For J55 grade pup joints, the Complainant produces an upset end by heating (upset forging) and butting to thicken the end of the pipe diameter for threading. J55 tubing is cut 8 inches longer than the required pup joint length to accommodate this process. In the case of L80 grade pup joints, the production process uses profiling rather than upset ends, and accordingly only 1/4 inch of additional length is needed to accommodate finishing. Profiling refers to machining the pipe towards the ends of the pipe so it is thicker at the far ends. This process is used instead of upsetting because upsetting a pipe with steel chemistry for an L80 grade would require the producer to heat-treat the pipe again.

Testing includes drift testing which is an assessment of the straightness within the hollow part of the tube, to ensure no bends or kinks exist after the pup joint was forged, and hydrostatic testing which assesses the pup joint"s ability to withstand internal pressure.

The Complainant, Alberta Oil Tool (AOT) of Dover Corporation, accounts for the major proportion of domestic production of like goods in Canada. The Complainant manufactures pup joints in Canada at its facilities in Edmonton, Alberta.

Dover Corporation (Canada) Limited (Dover) produces and markets a wide range of production service equipment solutions for the oil and gas industry. AOT is a division of Dover, and operates as part of the Norris Production Solutions business unit along with Norris Rods (USA). Norris was founded in 1882. AOT produces and sells its products under the Norris brand, including pup joints.

Among the products produced and sold by the AOT division of Dover are pup joints, sucker rods, drive rods, tubing and casing fittings, butterfly valves and controls.

Regarding the dumping investigation, information was requested from known and potential exporters, vendors and importers, concerning shipments of subject pup joints released into Canada during the Dumping POI of July 1, 2010 to June 30, 2011.

Regarding the subsidy investigation, information related to potential actionable subsidies was requested from known and potential exporters and the GOC concerning financial contributions made to exporters or producers of subject pup joints released into Canada during the Subsidy POI of January 1, 2010 to June 30, 2011.

In the current case, the Complainant requested that section 20 be applied in the determination of normal values due to the alleged existence of the conditions set forth in paragraph 20(1)(a) of SIMA. The Complainant provided information to support these allegations concerning the Chinese OCTG sector, which includes pup joints.

At the initiation of the investigation, the CBSA had sufficient evidence, supplied by the Complainant and from its own research and past investigation findings, to support the initiation of a section 20 inquiry to examine the extent of GOC involvement in pricing in the OCTG sector, which includes pup joints. The information indicated that Chinese prices in this sector have been influenced by various GOC industrial policies. Consequently, the CBSA sent section 20 RFIs to the GOC and all known Chinese OCTG producers and exporters to obtain information on the matter.

The OCTG sector, which includes pup joints, is the same sector that was examined in the CBSA"s investigations of certain Seamless Steel Casing (2008) and certain OCTG (2010). Each of those section 20 inquiries concluded that domestic prices in the OCTG sector in China are substantially determined by the GOC and that there is sufficient reason to believe that the domestic prices are not substantially the same as they would be in a competitive market.

The following is the CBSA"s analysis of the relevant factors that are present in the Chinese steel industry and which affect the OCTG sector, which includes pup joints.

The 2009 Steel Revitalization/Rescue Plan also applies to the OCTG sector in China, which includes pup joints. The GOC specifically directed one of the cooperating exporters in the OCTG(2010) investigation, which was one of the largest state-owned enterprise (SOE) producers, and possibly the largest seamless OCTG manufacturer, to reorganize with another company.14

The 12th Five-Year Plan also includes restrictions on steel capacity expansion. This plan further supports the initiatives in the NSP and the 2009 Steel Revitalization/Rescue Plan. The CBSA"s section 20 inquiry in the Seamless Steel Casing (2008) investigation confirmed that the GOC"s control of new or additional steel production capacity extended to the OCTG sector, which includes pup joints.22

Strengthening industrial self-discipline and regulating market order. To do this, the supply and demand must be balanced and exports regulated. Enterprises are to establish factories in foreign countries to occupy the international market. This is to avoid anti-dumping actions in the export markets.

As stated above, one GOC directive under the China Steel Pipe Industry 12th Five-Year Plan is to expand the development of OCTG products such as high collapse, anti-corrosion pipe.25 Chinese OCTG producers are not motivated solely by commercial interests, but must operate and be attentive to the GOC"s objectives, which may conflict with commercial interests. Based on the information on the record, the scope of the GOC"s macro-economic policies and measures have resulted in significant influences on pricing within the Chinese steel industry including the OCTG sector, which includes pup joints.

With the sole cooperating exporter/producer of pup joints being export-oriented, there is no information on the record for domestic selling prices of pup joints. In the absence of Chinese domestic prices for pup joints, the CBSA considers it reasonable to examine other goods in the OCTG sector such as casing and tubing, as pup joints are simply shorter lengths of OCTG casing and tubing.

The wide range and material nature of the GOC measures have resulted in significant influence on the Chinese steel industry including the OCTG sector, which includes pup joints. Based on the preceding, the President is of the opinion that:

During the final stage of the dumping investigation, the CBSA will continue the section 20 inquiry and further verify and analyze relevant information. The President may reaffirm his opinion that the conditions of section 20 exist in the OCTG sector, which includes pup joints, as part of the final phase of the investigation, or conclude that the determination of normal values may be made using domestic selling prices and costs in China.

For purposes of this preliminary determination, normal values could not be estimated on the basis of domestic selling prices in China or on the full cost of goods plus profit, because the President formed the opinion that the conditions of paragraph 20(1)(a) of SIMA exist in the OCTG sector, which includes pup joints, in China.

In calculating the weighted average estimated margin of dumping for the country, the overall estimated margins of dumping found in respect of each exporter are weighted according to each exporter"s volume of subject pup joints exported to Canada during the Dumping POI.

Based on the preceding, 100% of pup joints from China were dumped by an estimated weighted average margin of dumping of 125.7%, expressed as a percentage of the export price.

The estimated weighted average margin of dumping of certain pup joints from China is above 2% and is, therefore, not insignificant. As well, the volume of dumped goods from China is above 3%, and is, therefore, not negligible.

Hengshui Weijia is a producer and exporter of certain pup joints to Canada. The company was incorporated in August 2009 as a Sino-foreign joint venture.30 Hengshui Weijia is a limited liability company, which is privately held by a Chinese limited liability company, and a Canadian limited liability company, WestCan Oilfield Supply Ltd., which owns 49% of Hengshui Weijia.31

As previously explained, given the current absence of surrogate pricing or cost information, import pricing from other countries or any other pup joint pricing that would be usable for the purposes of a preliminary determination, normal values were estimated by advancing the export price of the goods by the estimated margin of dumping determined for the initiation of the investigation, which was calculated at 32.4%. The estimated margin of dumping for Hengshui Weijia is 32.4 %, expressed as a percentage of the export price.

In conducting its investigation, the CBSA sent a subsidy RFI to the GOC, as well as to the potential exporters located in China that had been identified through internal CBSA documentation. Information was requested in order to establish whether there had been financial contributions made by any level of government, including SOEs possessing, exercising or vested with government authority, and, if so, to establish if a benefit has been conferred on persons engaged in the production, manufacture, growth, processing, purchase, distribution, transportation, sale, export or import of certain pup joints; and whether any resulting subsidy was specific in nature. The GOC was also requested to forward the RFIs to all subordinate levels of government that had jurisdiction over the exporters. The exporters were requested to forward a portion of the RFI to their input suppliers, who were asked to respond to questions pertaining to their legal characterization as SOEs.

In summary, the GOC provided information concerning the amounts received by the identified exporters of pup joints to Canada for four subsidy programs. These programs are:

The GOC identified 18 subsidy programs that were not used by the exporters of pup joints during the POI and for the remainder of the 80 listed subsidy programs identified by the CBSA, the GOC either indicated that there was no such program, it had no information on the program or that the GOC disagreed with the CBSA on the nature of the subsidy.

Based on the information available to the President, on December 12, 2011, the President made preliminary determinations of dumping and subsidizing respecting certain pup joints originating in or exported from the People"s Republic of China, pursuant to subsection 38(1) of SIMA.

Pursuant to subsection 8(1) of SIMA, provisional duties, payable by the importer in Canada, will be applied to dumped and subsidized subject pup joints that are released during the provisional period commencing on the day the preliminary determinations are made, and ending on the earlier of the day on which the President causes the investigations to be terminated pursuant to subsection 41(1) or the day on which the Tribunal makes an order or finding. The imposition of provisional duties is needed to prevent the injury which, as per the Tribunal"s preliminary determination, was caused by the dumping and subsidizing of subject pup joints.

If the Tribunal makes a finding that the dumping has caused injury, retardation or is threatening to cause injury, anti-dumping duties in an amount equal to the margin of dumping will be levied, collected and paid on imports of subject pup joints.

If the Tribunal makes a finding that the subsidizing has caused injury, retardation or is threatening to cause injury, countervailing duties in the amount equal to the amount of subsidy on the imported goods will be levied, collected and paid on imports of subject pup joints.

DIC OIL TOOLS is well-reputed manufacturer and exporter of Oil and Gas Equipment. Our products are manufactured by using best material and modern techniques, which make them extremely up to the standard in this challenging domain. The offered products are highly appreciated among customers due to their corrosion resistance, robust design, optimum finish and high tensile strength. Also, these are available in various sizes, dimensions and patterns in order to meet the requirements of customers.

8613371530291

8613371530291