what is the thread lenght for 2.38 pup joint free sample

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

We manufacture a wide range of Crossover Couplings. Couplings are used to connect two sizes of pipes, or two different dissimilar threaded parts together. We offer special clearance couplings, special clearance couplings with bevels on both ends, and couplings with the API Seal Ring Modification.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

Swages are generally Box x Pin with a transition on the outside diameter and the inside diameter of the swage to assure that there are no sharp corners to set up an area of stress risers. When stress risers occur, there is a chance that the part could fail due to the fact that the part would be prone to crack in these areas.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Flow Couplings are heavy wall box by box connectors used in tubing strings and are designed to minimize the effect of internal erosive action caused by production fluids. Flow couplings are located just above or below Landing Nipples, Safety Valves or Control Devices where turbulent flow problems are likely to occur. Crossover flow couplings are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 3" and 6". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover Gas Anchor is an effective and simple design. It will increase oil and gas production, improve efficiency of the lift system, correct artificial lift problems caused by incomplete pump fillage due to gas interference and reduce operating cost.

Crossover can build these in any of the regular API Grades such as J-55, L-80, or P-110. These are usually only made going up or down one size in either direction such as ¾” to 1” or 1 ½” to 2”.

A saver sub falls under the drill string accessory tool category and a short pipe that is replaceable and expendable without a major investment. This accessory protects the Kelly or topdrive component threads and those components represent a significant capital cost and considerable downtime when replaced. Saver sub are manufactured to the following specs connections, lengths, weights and material grade.

A lift sub falls under the drill string accessory tool category and utilized to mobilize various tools during drilling or fishing operations. Lift Sub are manufactured to the following specs connections, lengths, weights and material grade.

A circulating sub falls under the downhole accessory tool category that regulates flow rates, especially drilling in slimhole wells or wellbore cleanout projects. Circulating sub is manufactured to the following specs connections, lengths, weights and material grade.

Crossover Circulating Sub/Swages are manufactured from AISI 4140/4145. They typically are female hammer union on the top end and an IF pin on the bottom end, but can be manufactured with any size and style connection.

Crossover Drop Ball Circulating Subs are manufactured from AISI 4140/4145. The standard is pin by box. They are activated by dropping a chrome steel ball, which lands on a sleeve and as pressure increases, the pins in the sleeve are sheared. This causes the sleeve to move down and expose four ports in the side of the sub diverting the fluid flow.

A side-entry sub falls under the drilling tool accessory category to allow various drilling, fishing, wireline operations through drill pipe without interference from the rig"s top drive unit. Circulating sub is manufactured to the following specs connections, lengths, weights and material grade.

Crossover Side Entry Subs are manufactured from AISI 4140/4145. They are manufactured from one piece. They are typically rotary shouldered pin by box with 2” 1502 female hammer union, but can be manufactured with any size and style connection.

These can be made Rotary Shoulder Box Up x Pin Down with the ½ union on the side, we can build with any combination of the connections placed anywhere on the sub. All of Crossover’s Side Entry Subs are Integral manufactured which means that the sub is one piece and has no heat affected zone from welding the ½ union onto the body.

The style shown is built from one piece of 4145M bar stock and the excess material milled away and then threaded. There are also Lift Caps which are Cast Steel Castings and are threaded with the correct thread, but the rest of the plug is casts to create the bail.

Some customers request Lift Caps with Pad Eye for lifting. These are also made out 4145M and can be manufactured to fit any of several shackles. They can be built with either the pin or the box facing down.

Crossover Pipe Scrubbing Wire Brush is used to brush and clean the ID of the casing and remove scale, rust, mud residue, and any other particles of debris.

These brushes are generally run on Rotary Shoulder Drill String to Brush the inside of Casing Down Hole. These brushes will remove rust, scale and other contaminates that build up on the inside diameter (ID) of the casing. Usually run in preparation of running a packer or some other piece of equipment that needs a fairly uniform ID to set.

Crossover Inside BOP Valves are manufactured from AISI 4145. Crossover"s one piece design is much more robust than the traditional two piece construction design. Crossover"s one piece design typically allows for standard connection OD"s and shorter overall length parts. This eliminates the service break which allows for quicker disassembly.

Crossover"s Drop-in Check Valve is a retrievable check valve. It is retrievable by means of a retrievable tool (gravel girdie) run in on wireline. When needed the check valve is pumped down the drill string to the landing sub. The dogs are locked in place with pressure from below the valve. The check valve will open to allow circulation and close when circulation is stopped.

A washover pipe is Casing or Pipe shorter in length than a standard tubular string. Made of large-diameter pipe with a cutting surface at the tip, washover pipe is run in the well and then the cutting edge grinds the fish to a smooth surface and continues normal operations. Washover Pipe is manufactured to the following specs connections, lengths, weights and material grade.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

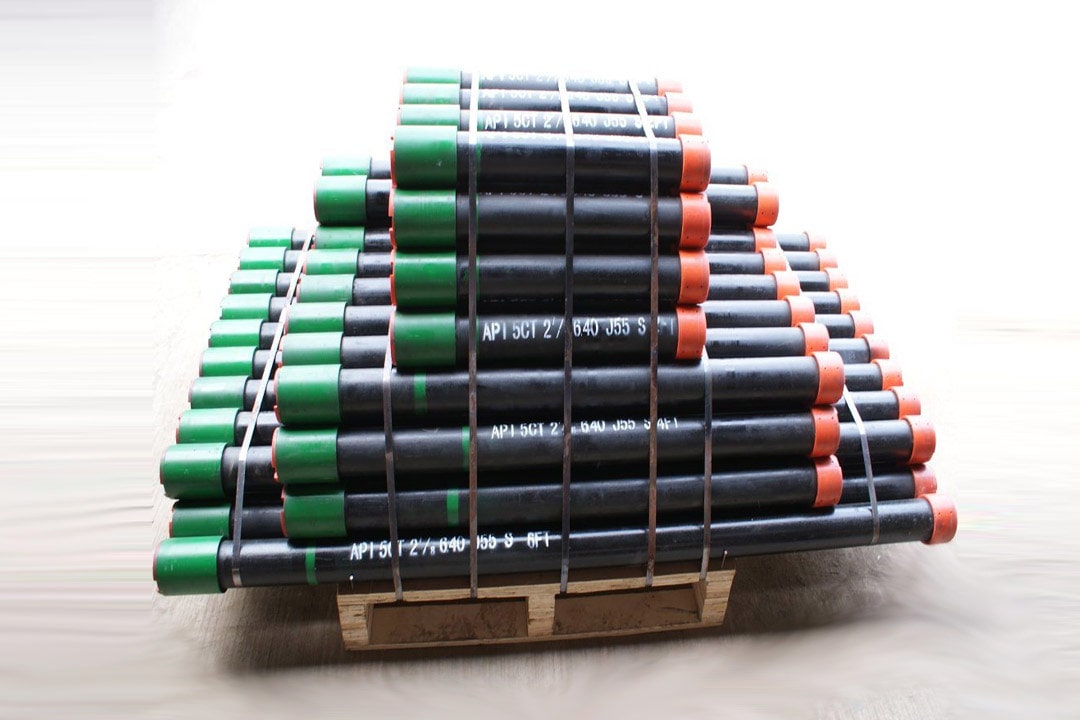

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

DIC is a Manufacturer and Exporter of Crossover Pup Joints in Ajman, UAE. It is used for crossing over from the size of a single connection to the other in the drill string.

We supply crossover pup joints in all sizes, grades, and thread profiles. All our products have passed the ISO certification and API certifications. Our products are tested numerous times under technical guidance and are made from the best quality material.

Goldenman Petroleum Equipment Co.,Limited had explored the international market and enlarged international cooperation 10 years .Due to the competitive price ,good quality and excellent service ,our products are sold to America,Canada,Brazil,Columbia, Venezuela,India,UAE,Russia ,Kazakhastan,Italy,Hungary ,Australia,Syria,Egypt ,etc .and get good reputation from our overseaclients .

Geoscience Australia may also have other information: (see the GA well search page: http://dbforms.ga.gov.au/www/npm.well.search ) *** ENO=353616 -- BASKER 2

HDR DPH: FINAL_TD = FINAL TOTAL DEPTH: The actual measurement along the well path from the reference datum to the bottom of the well (PPDM definition).

HDR DPH: MAX_TVD = MAXIMUM TRUE VERTICAL DEPTH: The maximum true vertical depth from the surface datum reference to the final total depth or deepest point, measured on a straight line (PPDM definition).

WELL_ALIAS BOREHOLE_NAME = UNKNOWN PARISH-0 : [WELL_BORE] WELL_BORE: the BOREHOLE and BORE NUMBER of the well

FORMATION_TOPS SOURCE=WCR 0177 FORM_ID= GIPPSLAND LIMESTONE TOP_DEPTH= 177 BASE_DEPTH= Gippsland Limestone (Age:Tertiary ) ...Member of....SEASPRAY GROUP >>> REMARK =From PE915237 Page 7 (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 1266 FORM_ID= HIGH VELOCITY WEDGE TOP_DEPTH= 1266 BASE_DEPTH= High Velocity Wedge (Age:undisclosed ) >>> REMARK =From PE915237 Page 7 (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 1359 FORM_ID= INTRA-MIO.DOWNLAP SF TOP_DEPTH= 1359 BASE_DEPTH= Intra-Miocene Downlap Surface (Age:undisclosed ) >>> REMARK =From PE915237 Page 7 (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 1755 FORM_ID= LAKES ENTRANCE FM TOP_DEPTH= 1755 BASE_DEPTH= Lakes Entrance Formation (Age:Tertiary ) ...Member of....SEASPRAY GROUP (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 2088 FORM_ID= LATROBE GROUP TOP_DEPTH= 2088 BASE_DEPTH= Latrobe Group (Age:Cretaceous ) (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 2162 FORM_ID= BASE TUNA-FLOUN CHAN TOP_DEPTH= 2161.5 BASE_DEPTH= Base Tuna-Flounder Channe (Age:undisclosed ) (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 2613 FORM_ID= K2 SANDSTONE TOP_DEPTH= 2613 BASE_DEPTH= K2 Sandstone (Age:undisclosed ) >>> REMARK =From PE915237 Page 7 (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 2878 FORM_ID= MA2 SANDSTONE TOP_DEPTH= 2878 BASE_DEPTH= MA2 Sandstone (Age:undisclosed ) >>> REMARK =From PE915237 Page 7 (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 3053 FORM_ID= ZC1 SEISMIC MARKER TOP_DEPTH= 3052.7 BASE_DEPTH= ZC1 Seismic Marker (Age:undisclosed ) >>> REMARK =From PE915237 Page 7 (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 3119 FORM_ID= ZONE 2 RESERVOIR TOP_DEPTH= 3118.7 BASE_DEPTH= ZONE 2 RESERVOIR (Age:CRETATEOUS ) >>> REMARK =From PE915237 Page 7 (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 3233 FORM_ID= ZONE 5 RESERVOIR TOP_DEPTH= 3232.9 BASE_DEPTH= ZONE 5 RESERVOIR (Age:CRETATEOUS ) >>> REMARK =From PE915237 Page 7 (WCR=Well Completion Report)

FORMATION_TOPS SOURCE=WCR 3321 FORM_ID= VOLCANICS UNIT 1 TOP_DEPTH= 3320.9 BASE_DEPTH= VOLCANICS UNIT 1 (Age:CRETATEOUS ) >>> REMARK =From PE915237 Page 7 (WCR=Well Completion Report)

ASSETS (BRIEF) GENERAL DATA_CD_DVD PE012855 BASKER-2 Log Data CD [CD] 2006 PE012855__((_BASKER-2_LOG_DATA_CD_))_.TAR.GZ(795.2m)......... SAM0_685_PE012855__((_BASKER-2_LOG_DATA_CD_))_I_MEDIA_LABELLING.JPG(2.9m)......... PE012855__((_BASKER-2_LOG_DATA_CD_))__FILES_LISTING.TXT(0.0m)......... in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) GENERAL DATA_CD_DVD PE915238 BASKER-2 Final Well Rpt and Data [CD] 2006 PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))_.TAR.GZ(177.2m)......... PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))_.TAR.GZ(177.2m)......... F7746698_068_PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__MEDIA_LABELLING.PDF(0.7m)......... SAM2_196_PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__MEDIA_LABELLING.JPG(2.8m)......... PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__FILES_LISTING.TXT(0.0m)......... in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) GENERAL DATA_CD_DVD PE915239 BASKER-2 End of Well Report and Data [CD] 2006 PE915239__((_BASKER-2_END_OF_WELL_REPORT_AND_DATA_))_.TAR.GZ(12.7m)......... SAM2_197_PE915239__((_BASKER-2_END_OF_WELL_REPORT_AND_DATA_))_I_MEDIA_LABELLING.JPG(2.7m)......... PE915239__((_BASKER-2_END_OF_WELL_REPORT_AND_DATA_))__FILES_LISTING.TXT(0.0m)......... in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) GENERAL DATA_CD_DVD PE915240 BASKER-2 Velocity Survey Reports & Data [CD] 2006 PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))_.TAR.GZ(156.3m)......... SAM2_198_PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))_I_MEDIA_LABELLING.JPG(2.7m)......... PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))__FILES_LISTING.TXT(0.0m)......... in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) GENERAL ESUBS_CD_DVD PE907809 Well Data - Electronic Submissions 2009 [DVD] 2009 (2978 DIGITAL FILES) in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) WELL DAILY_RPT PE907806 Daily Drilling Reports. Various Wells. [CD] 2006 PE907806__((_DAILY_DRILLING_REPORTS._VARIOUS_WELLS._))_.TAR.GZ(383.8m)......... SAM1_579_PE907806__((_DAILY_DRILLING_REPORTS._VARIOUS_WELLS._))_I_MEDIA_LABELLING.JPG(2.8m)......... PE907806__((_DAILY_DRILLING_REPORTS._VARIOUS_WELLS._))__FILES_LISTING.TXT(0.4m)......... in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) WELL DATA_CD_DVD PE012753 BASKER-2 Wireline log data CD [CD] 2005 PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))_.TAR.GZ(8.4m)......... F7746696_033_PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))_I_MEDIA_LABELLING.PDF(0.7m)......... SAM0_942_PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))_I_MEDIA_LABELLING.JPG(3.0m)......... PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))__FILES_LISTING.TXT(0.0m)......... in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) WELL LOG_TAPE_OR_DISK PE012053 Selected Wells, Gippsland & Otway Basin [CD] 2007 in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) WELL LOG_TAPE_OR_DISK PE012305 BASKER-2 TD Wireline Log Data CD [DVD] 2005 PE012305__((_BASKER-2__TD_WIRELINE_LOG_DATA_CD_))_.ISO.GZ(519.0m)......... PE012305__((_BASKER-2__TD_WIRELINE_LOG_DATA_CD_))__MEDIA_LABELLING.PDF(0.1m)......... in: COMPACTUS COMPACTUS_1 55 Collins St

ASSETS (BRIEF) WELL RPT PE909713 BASKER-2 Workover 1 Clean-up Test [CD] 2006 PE909713__((_BASKER-2_WORKOVER_1_CLEAN-UP_TEST_))_.TAR.GZ(2.1m)......... SAM1_692_PE909713__((_BASKER-2_WORKOVER_1_CLEAN-UP_TEST_))_I_MEDIA_LABELLING.JPG(3.0m)......... PE909713__((_BASKER-2_WORKOVER_1_CLEAN-UP_TEST_))__FILES_LISTING.TXT(0.0m)......... in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) WELL WCR_RPT PE911503 BASKER-2 WCR on CD [CD] 2006 PE911503__((_BASKER-2_WCR_ON_CD_))_.TAR.GZ(25.5m)......... BASKER-2 WCR VOLUME 1 BASIC DATA MARCH 2006.PDF(28.7m)......... SAM2_080_PE911503__((_BASKER-2_WCR_ON_CD_))_I_MEDIA_LABELLING.JPG(2.8m)......... PE911503__((_BASKER-2_WCR_ON_CD_))__FILES_LISTING.TXT(0.0m)......... in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) WELL WCR_RPT PE915237 BASKER-2 WCR Vol.2 (interpretive) [CD] 2006 PE915237__((_BASKER-2_WCR_VOL.2__INTERPRETIVE__))_.TAR.GZ(72.4m)......... PE915237__((_BASKER-2_WCR_VOL.2__INTERPRETIVE__))_.TAR.GZ(72.4m)......... SAM2_195_PE915237__((_BASKER-2_WCR_VOL.2__INTERPRETIVE__))_I_MEDIA_LABELLING.JPG(2.6m)......... PE915237__((_BASKER-2_WCR_VOL.2__INTERPRETIVE__))__FILES_LISTING.TXT(0.0m)......... in: COMPACTUS Bay of COMPACTUS_1 used to store tapes

ASSETS (BRIEF) WELL WELL_WOMP PE913297 BASKER-2 Drilling & Completion Programme [CD] 2005 PE913297__((_BASKER-2_DRILLING___COMPLETION_PROGRAMME_))_.ISO.GZ(33.4m)......... PE913297__((_BASKER-2_DRILLING___COMPLETION_PROGRAMME_))__MEDIA_LABELLING.PDF(0.1m)......... in: COMPACTUS COMPACTUS_1 55 Collins St

ASSETS (BRIEF) WELL DIRECTIONAL PE911503_112BASKER-2 deviation survey data [CD] 2007 PE911503__((_BASKER-2_WCR_ON_CD_))_.TAR.GZ(25.5m)......... BASKER-2 WCR VOLUME 1 BASIC DATA MARCH 2006.PDF(28.7m)......... SAM2_080_PE911503__((_BASKER-2_WCR_ON_CD_))_I_MEDIA_LABELLING.JPG(2.8m)......... PE911503__((_BASKER-2_WCR_ON_CD_))__FILES_LISTING.TXT(0.0m)......... in: WCR_RPT BASKER-2 Well Completion Report on CD

ASSETS (BRIEF) WELL ENVIRO_RPT PE907809_16 Well Environment Reports 2009 [DVD] 2009 (2978 DIGITAL FILES) in: DVD Well Data - Electronic Submissions 2009

ASSETS (BRIEF) WELL EOW_RPT PE915239_1 BASKER-2 End of Well Report [CD] 2006 PE915239__((_BASKER-2_END_OF_WELL_REPORT_AND_DATA_))_.TAR.GZ(12.7m)......... SAM2_197_PE915239__((_BASKER-2_END_OF_WELL_REPORT_AND_DATA_))_I_MEDIA_LABELLING.JPG(2.7m)......... PE915239__((_BASKER-2_END_OF_WELL_REPORT_AND_DATA_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 End of Well Report and Data

ASSETS (BRIEF) WELL FWR_RPT PE915238_3 BASKER-2 Final Well Report [CD] 2006 PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))_.TAR.GZ(177.2m)......... PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))_.TAR.GZ(177.2m)......... F7746698_068_PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__MEDIA_LABELLING.PDF(0.7m)......... SAM2_196_PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__MEDIA_LABELLING.JPG(2.8m)......... PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Final Well Rpt and Data

ASSETS (BRIEF) WELL GEOCHEM PE911503_851BASKER-2 Hydrocarbon Properties Summary [CD] 2007 PE911503__((_BASKER-2_WCR_ON_CD_))_.TAR.GZ(25.5m)......... BASKER-2 WCR VOLUME 1 BASIC DATA MARCH 2006.PDF(28.7m)......... SAM2_080_PE911503__((_BASKER-2_WCR_ON_CD_))_I_MEDIA_LABELLING.JPG(2.8m)......... PE911503__((_BASKER-2_WCR_ON_CD_))__FILES_LISTING.TXT(0.0m)......... in: WCR_RPT BASKER-2 Well Completion Report on CD

ASSETS (BRIEF) WELL LOG_TAPE_OR_DISK PE012753_1 BASKER-2 Wireline Log Data CD [CD] 2005 PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))_.TAR.GZ(8.4m)......... F7746696_033_PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))_I_MEDIA_LABELLING.PDF(0.7m)......... SAM0_942_PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))_I_MEDIA_LABELLING.JPG(3.0m)......... PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Wireline log data CD

ASSETS (BRIEF) WELL LOG_TAPE_OR_DISK PE915238_2 BASKER-2 Wireline Log Data [CD] 2006 PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))_.TAR.GZ(177.2m)......... PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))_.TAR.GZ(177.2m)......... F7746698_068_PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__MEDIA_LABELLING.PDF(0.7m)......... SAM2_196_PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__MEDIA_LABELLING.JPG(2.8m)......... PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Final Well Rpt and Data

ASSETS (BRIEF) WELL LOG_TAPE_OR_DISK PE915239_2 BASKER-2 End of Well Report ASCII data [CD] 2006 PE915239__((_BASKER-2_END_OF_WELL_REPORT_AND_DATA_))_.TAR.GZ(12.7m)......... SAM2_197_PE915239__((_BASKER-2_END_OF_WELL_REPORT_AND_DATA_))_I_MEDIA_LABELLING.JPG(2.7m)......... PE915239__((_BASKER-2_END_OF_WELL_REPORT_AND_DATA_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 End of Well Report and Data

ASSETS (BRIEF) WELL SRVY_RPT PE915240_1 BASKER-2 Velocity Survey Reports [CD] 2006 PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))_.TAR.GZ(156.3m)......... SAM2_198_PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))_I_MEDIA_LABELLING.JPG(2.7m)......... PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Velocity Survey Reports & Data

ASSETS (BRIEF) WELL VELOCITY PE915240_3 BASKER-2 Velocity Survey Report Data [CD] 2006 PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))_.TAR.GZ(156.3m)......... SAM2_198_PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))_I_MEDIA_LABELLING.JPG(2.7m)......... PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Velocity Survey Reports & Data

ASSETS (BRIEF) WELL WELL_LOG PE012753_2 BASKER-2 Wireline log data CD [CD] 2005 PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))_.TAR.GZ(8.4m)......... F7746696_033_PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))_I_MEDIA_LABELLING.PDF(0.7m)......... SAM0_942_PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))_I_MEDIA_LABELLING.JPG(3.0m)......... PE012753__((_BASKER-2_WIRELINE_LOG_DATA_CD_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Wireline log data CD

ASSETS (BRIEF) WELL WELL_LOG PE012855_1 BASKER-2 Logs [CD] 2006 PE012855__((_BASKER-2_LOG_DATA_CD_))_.TAR.GZ(795.2m)......... SAM0_685_PE012855__((_BASKER-2_LOG_DATA_CD_))_I_MEDIA_LABELLING.JPG(2.9m)......... PE012855__((_BASKER-2_LOG_DATA_CD_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Log Data CD

ASSETS (BRIEF) WELL WELL_LOG PE012855_2 BASKER-2 Log Data [CD] 2006 PE012855__((_BASKER-2_LOG_DATA_CD_))_.TAR.GZ(795.2m)......... SAM0_685_PE012855__((_BASKER-2_LOG_DATA_CD_))_I_MEDIA_LABELLING.JPG(2.9m)......... PE012855__((_BASKER-2_LOG_DATA_CD_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Log Data CD

ASSETS (BRIEF) WELL WELL_LOG PE915238_1 BASKER-2 Wireline Log Images [CD] 2006 PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))_.TAR.GZ(177.2m)......... PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))_.TAR.GZ(177.2m)......... F7746698_068_PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__MEDIA_LABELLING.PDF(0.7m)......... SAM2_196_PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__MEDIA_LABELLING.JPG(2.8m)......... PE915238__((_BASKER-2_FINAL_WELL_RPT_AND_DATA_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Final Well Rpt and Data

ASSETS (BRIEF) WELL WELL_LOG PE915240_2 BASKER-2 Velocity Survey Logs [CD] 2006 PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))_.TAR.GZ(156.3m)......... SAM2_198_PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))_I_MEDIA_LABELLING.JPG(2.7m)......... PE915240__((_BASKER-2_VELOCITY_SURVEY_REPORTS___DATA_))__FILES_LISTING.TXT(0.0m)......... in: CD BASKER-2 Velocity Survey Reports & Data

ASSETS (BRIEF) GENERAL REGISTRY_FILE F7703302 PE/16/0535(Part-1) Registry File [PAPER] 2005 in:COMPACTUS COMPACTUS_1 55 Collins St

ASSETS (BRIEF) TITLE DMP_ACCEPTED PE801522 Anzon BASKER-2 VIC/RL6 DMP (2004) [PAPER] 2004 PE801522__((_ANZON_BASKER-2_VIC_RL6_DMP__2004__))_.PDF(0.3m)......... in:REGISTRY_FILE PE/35/0145 /2 Registry File (DMPs) 2004

ASSETS (BRIEF) TITLE FIELD_RPT PE802638 Basker Manta Update [PAPER] 2006 in:WELL_BOX Well Box - Recent Wells 1

ASSETS (viaENC)GENERAL REGISTRY_FILE F3112020 PE/35/0145 /2 Registry File (DMPs) 2004 [PAPER] (?2005) (this is a report with at least one enclosure related to BASKER-2)

LINKS HYPERLINKAGES COPYRIGHT_DISCLAIMER ABOUT_DBMAP HOW_TO_GET_OR_SUBMIT_DATA This data has been dumped from Victorian Govt (http://www.dpi.vic.gov.au) dbMap database on 23-FEB-12

ASSETS *** ALSO: Search the Geoscience Australia database for other information: (see http://dbforms.ga.gov.au/www/npm.well.search ) *** ENO=353616 BASKER-2

CORE/CUTTINGS Basker 2 : SAMPLE_TYPE=CUTT 01010 DEPTH_RANGE= 1010.000 TO 3414.000M STORAGE_BAY=232 ROW=ZZ TO ZZ #TRAYS=11 [ <--this shows the actual cores and cuttings that DPI has stored in the DPI Werribee core shed ]

B WELL_DRILL_HISTORY:001 06-AUG-05 600.0 9999.99 Operations For Period 0000 Hrs to 2400 Hrs on 06 Aug 2005 Operations For Period 0000 Hrs to 2400 Hrs on 06 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM P RM 0430 1330 9.00 0.0m Last anchor on rack at o4:22 am. Dip fuel and prepare statement. Pacific Wrangler on tow bridle. Far Grip following. Tow at 4.5 knts. RM TP (RE) RM 1330 1500 1.50 0.0m Towline shackle (85ton) parted at fishplate. Wrangler recover tow line. Rig recover fishplate. RM TP (RE) RM 1500 1630 1.50 0.0m Pass secondary tow bridle to Pacific Wrangler and attach 2nd tow bridle. Port leg of tackle broke behind thimble when loaded. (Leg had twisted previously during attachment process). RM TP (RE) RM 1630 1700 0.50 0.0m Drop #5 anchor to hold rig stern-to-weather. Pay out 600m of chain. Weather deteriorating. Wind 30 knts gusting 40 knts. Position 39� 18.19" S 143� 26.6" E RM TP (RE) RM 1700 1900 2.00 0.0m Attempt to attach re-built primary tow bridle. Wind 40 knts+. RM TP (RE) RM 1900 2400 5.00 0.0m Shut down due to sea height and darkness. Danger of losing seamen overboard. Rig is clear of shipping lanes. Far Grip and Wrangler maintain watch for shipping. Ballast down to storm draught to stabilize rig as #8 anchor being moved on bolster by sea. Operations For Period 0000 Hrs to 0600 Hrs on 07 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM TP (RE) RM 0000 0600 6.00 0.0m Wait on daylight. Weather moderating. Phase Data to 2400hrs, 06 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max Depth RIG MOVE/RIG-UP/PRESPUD(RM) 19.5 06 Aug 2005 06 Aug 2005 19.50 0.812 0.0m Personnel On Board Company Pax DIAMOND OFFSHORE (AUSTRALIA) LLC 50 DIAMOND OFFSHORE (AUSTRALIA) LLC 1 UPSTREAM PETROLEUM 2 ESS 8 DOWELL SCHLUMBERGER 2 GEOSERVICES OVERSEAS S.A. 2 FUGRO SURVEY LTD 5 M-1 AUSTRALIA PTY LTD 1 MO47 CREW 9 MARCOM 1 CAM... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:002 07-AUG-05 .0 9999.99 Re-establish tow. Helicopter for DODI welder. Father badly injured in automobile accident. Operations For Period 0000 Hrs to 2400 Hrs on 07 Aug 2005 Re-establish tow. Helicopter for DODI welder. Father badly injured in automobile accident. Operations For Period 0000 Hrs to 2400 Hrs on 07 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM TP (RE) RM 0000 0600 6.00 0.0m Wait on daylight. Weather moderating. RM TP (RE) RM 0600 1100 5.00 0.0m De-ballast rig to transit draught. Prepare to reinstate tow. RM TU (RE) RM 1100 1200 1.00 0.0m Pass messenger line / tow bridle to Pacific Wrangler. Secure tow. Lift #5 anchor. RM P RM 1200 2400 12.00 0.0m Under tow to Basker #2. Operations For Period 0000 Hrs to 0600 Hrs on 08 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM P RM 0000 0600 6.00 0.0m (IN PROGRESS) On tow to Basker #2. Time Position Speed. Dist trav. Dist to go. Course 06:00 39deg 16.4"S, 144deg 39.3"E 4.16 kts 111.3 198.8 090 12:00 39deg 17.6"S, 145deg 36.0"E 4.80 Kts 140.3 169.8 090 18:00 39deg 17.8"S, 146deg 14.9"E 4.95 Kts 170.0 140.1 090 24:00 39deg 12.2"S, 146deg 48.0"E 4.50 Kts 197.1 113.0 000 Phase Data to 2400hrs, 07 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max Depth RIG MOVE/RIG-UP/PRESPUD(RM) 43.5 06 Aug 2005 07 Aug 2005 43.50 1.812 0.0m Personnel On Board Company Pax DIAMOND OFFSHORE (AUSTRALIA) LLC 49 DIAMOND OFFSHORE (AUSTRALIA) LLC 1 UPSTREAM PETROLEUM 2 ESS 8 DOWELL SCHLUMBERGER 2 GEOSERVICES OVERSEAS S.A. 2 FUGRO SURVEY LTD 5 M-1 AUSTRALIA PTY LTD 1 MO47 CREW 9 MARCOM 1 CAMERON AUSTRALIA PTY LTD 1 Total 81 "Copyright IDS 2005", TF 20050803, ANZON_AU_drllg Page 1 Printed on 11 Aug 2005 [FILE:/02 07-08-2005 DDR BASKER-2 [From:WELL_DAILY]

B WELL_DRILL_HISTORY:003 08-AUG-05 .0 9999.99 Operations For Period 0000 Hrs to 2400 Hrs on 08 Aug 2005 Operations For Period 0000 Hrs to 2400 Hrs on 08 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM P RM 0000 2400 24.00 0.0m On tow to Basker #2. Time Position Speed. Dist trav. Dist to go. Course 06:00 39deg 16.4"S, 144deg 39.3"E 4.16 kts 111.3 198.8 090 12:00 39deg 17.6"S, 145deg 36.0"E 4.80 Kts 140.3 169.8 090 18:00 39deg 17.8"S, 146deg 14.9"E 4.95 Kts 170.0 140.1 090 24:00 39deg 12.2"S, 146deg 48.0"E 4.50 Kts 197.1 113.0 000 Operations For Period 0000 Hrs to 0600 Hrs on 09 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM P RM 0000 0600 6.00 0.0m (IN PROGRESS) On tow to Basker - 2 well Time Position Speed Dist trav. Dist to go. Course 06:00 39deg 45.5"S 147deg 20.1"E, 4.36 kts, 223.4nm, 86.7nm, 070 deg 12:00 39deg 54.4"S 147deg 49.8"E, 4.18 kts, 248.5nm, 61.6nm, 069 deg 18:00 38deg 45.5"S 148deg 20.1"E, 4.36 kts, 274.7nm, 32.4nm, 049 deg 24:00 38deg 31.2"S 148deg 37.5"E 2.50 kts, 289.4nm, 17.6nm, 021 deg Phase Data to 2400hrs, 08 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max Depth RIG MOVE/RIG-UP/PRESPUD(RM) 67.5 06 Aug 2005 08 Aug 2005 67.50 2.812 0.0m Personnel On Board Company Pax DIAMOND OFFSHORE (AUSTRALIA) LLC 49 DIAMOND OFFSHORE (AUSTRALIA) LLC 1 UPSTREAM PETROLEUM 2 ESS 8 DOWELL SCHLUMBERGER 2 GEOSERVICES OVERSEAS S.A. 2 FUGRO SURVEY LTD 5 M-1 AUSTRALIA PTY LTD 1 MO47 CREW 9 MARCOM 1 CAMERON AUSTRALIA PTY LTD 1 Total 81 "Copyright IDS 2005", TF 20050803, ANZON_AU_drllg Page 1 Printed on 11 Aug 2005 [FILE:/03 08-08-2005 DDR BASKER-2 [From:WELL_DAILY]

B WELL_DRILL_HISTORY:004 09-AUG-05 .0 9999.99 On tow to Basker - 2 well Operations For Period 0000 Hrs to 2400 Hrs on 09 Aug 2005 On tow to Basker - 2 well Operations For Period 0000 Hrs to 2400 Hrs on 09 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM P RM 0000 2400 24.00 0.0m On tow to Basker - 2 well Time Position Speed Dist trav. Dist to go. Course 06:00 39deg 45.5"S 147deg 20.1"E, 4.36 kts, 223.4nm, 86.7nm, 070 deg 12:00 39deg 54.4"S 147deg 49.8"E, 4.18 kts, 248.5nm, 61.6nm, 069 deg 18:00 38deg 45.5"S 148deg 20.1"E, 4.36 kts, 274.7nm, 32.4nm, 049 deg 24:00 38deg 31.2"S 148deg 37.5"E 2.50 kts, 289.4nm, 17.6nm, 021 deg Operations For Period 0000 Hrs to 0600 Hrs on 10 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM TP (WOW) RM 0000 0500 5.00 0.0m Attempt run-in to location. 2 nm from location. Rough weather pulling Rig and Pacific Wrangler backward (East) at 1.5 knts). Wind 25knts gusting 35 knts. Seas 3m. 70-75 ton pull on towline. RM TP (WOW) RM 0500 0600 1.00 0.0m (IN PROGRESS) Weather deteriorating. Wind and sea rising 40 knts 4 -5 m. Unable to make way. Travelling east at 2 knts. Phase Data to 2400hrs, 09 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max Depth RIG MOVE/RIG-UP/PRESPUD(RM) 91.5 06 Aug 2005 09 Aug 2005 91.50 3.812 0.0m Bulk Stocks Name Unit In Used Adjust Balance Barite Bulk MT 56.65 56.6 Bentonite Bulk MT 35.27 35.3 Diesel m3 311.7 2.9 308.8 Fresh Water m3 363.5 12.5 351.0 Drill Water m3 156.3 17.7 138.6 Cement G MT 47.11 47.1 Pumps Pump Data - Last 24 Hrs Slow Pump Data No. Type Liner (in) MW (ppg) Eff (%) SPM (SPM) SPP (psi) Flow (gpm) Depth (m) SPM1 (SPM) SPP1 (psi) Flow1(gpm) SPM2 (SPM) SPP2 (psi) Flow2 (gpm) SPM3 (SPM) SPP3 (psi) Flow3 (gpm) 1 National 12P160 6.50 0 "Copyright IDS 2005", TF 20050803, ANZON_AU_drllg Page 1... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:005 10-AUG-05 650.0 9999.99 Towed rig to within 10nm of Basker - 2 location. Unable to make headway into weather for run-in to drop anchor. Moved rig to shallow water to drop #8 anchor and waiting on wind and swell to drop before moving location and anchoring Operations For Period 0000 Hrs to 2400 Hrs on 10 Aug 2005 Towed rig to within 10nm of Basker - 2 location. Unable to make headway into weather for run-in to drop anchor. Moved rig to shallow water to drop #8 anchor and waiting on wind and swell to drop before moving location and anchoring Operations For Period 0000 Hrs to 2400 Hrs on 10 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM TP (WOW) RM 0000 0500 5.00 0.0m Attempt run-in to location. 2 nm from location. Rough weather pulling Rig and Pacific Wrangler backward (East) at 1.5 knts). Wind 25knts gusting 35 knts. Seas 3m. 70-75 ton pull on towline. RM TP (WOW) RM 0500 0830 3.50 0.0m Weather deteriorating. Wind and sea rising 40 knts 4 -5 m. Unable to make way. Travelling east at 2 knts. RM TP (WOW) RM 0830 0930 1.00 0.0m Drop #8 anchor and pay out 650m chain. Anchor holding. Position 38� 12" 26.6 S 148� 58" 07.1 E RM TP (WOW) RM 0930 2400 14.50 0.0m Rig heading 273�. Deballast rig to storm draught. 0800 hrs, 40kt wind, seas 2.0m, swell 2.0m, pitch 2.5 deg, roll 3.0 deg 1200 hrs, 40kt wind, seas 3.0m, swell 3.0m, pitch 2.5 deg, roll 3.0 deg 1800 hrs 45kt wind, seas 2.5m, swell 5.0m, pitch 3.0 deg, roll 2.0 deg 2400 hrs 40kt wind, seas 3.0m, swell 3.0m, pitch 3.0 deg, roll 2.0 deg Operations For Period 0000 Hrs to 0600 Hrs on 11 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM TP (WOW) RM 0000 0600 6.00 0.0m Continue to wait on weather to abate off location before anchoring operations can continue. 0600 hrs wind 45kts, seas 2.5m, swell 5.0m, pitch 2.5 deg, roll 2.5 deg Phase Data to 2400hrs, 10 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:006 11-AUG-05 20.0 81.00 Waited on weather to subside to continue rig tow to Basker - 2 location. Started deballasting rig from survival draft in preparation to continue tow to Basker - 2 location Operations For Period 0000 Hrs to 2400 Hrs on 11 Aug 2005 Waited on weather to subside to continue rig tow to Basker - 2 location. Started deballasting rig from survival draft in preparation to continue tow to Basker - 2 location Operations For Period 0000 Hrs to 2400 Hrs on 11 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM TP (WOW) RM 0000 2300 23.00 0.0m Continue to wait on weather to abate off location before anchoring operations can continue. 0600 hrs wind 45kts, seas 2.5m, swell 5.0m, pitch 2.5 deg, roll 2.5 deg 1200 hrs wind 40kts, seas 3.0m, swell 3.0m, pitch 2.0 deg, roll 2.0 deg 1800 hrs wind 33kts, seas 3.0m, swell 3.0m, pitch 2.0 deg, roll 2.0 deg 2200 hrs wind 26kts, seas 3.0m, swell 2.0m, pitch 2.0 deg, roll 2.0 deg RM TP (WOW) RM 2300 2400 1.00 0.0m Start deballasting rig from survival draft of 20m to moving draft of 10.7m Operations For Period 0000 Hrs to 0600 Hrs on 12 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM TP (WOW) RM 0000 0600 6.00 0.0m Continue deballasting rig from survival draft of 20m to moving draft of 10.7m Phase Data to 2400hrs, 11 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max Depth RIG MOVE/RIG-UP/PRESPUD(RM) 139.5 06 Aug 2005 11 Aug 2005 139.50 5.812 0.0m Bulk Stocks Name Unit In Used Adjust Balance Barite Bulk MT 0 56.6 Bentonite Bulk MT 0 35.3 Diesel m3 0 10.4 294.9 Fresh Water m3 25 24.1 356.6 Drill Water m3 0 0 132.7 Cement G MT 0 47.1 Pumps Pump Data - Last 24 Hrs Slow Pump Data No. Type Liner (in) MW (ppg) Eff (%) SPM (SPM) SPP (psi) Flow (gpm) Depth (m) SPM1 (SPM) SPP1 (psi) Flow1(gpm) SPM2 (SPM) SPP2 (psi) Flow2 (gpm) ... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:007 12-AUG-05 200.0 81.00 Deballasted rig at standby location. Picked up # 8 anchor. Towed rig to Basker 2 location. Far Grip set # 4 anchor. Far grip running # 8 anchor Operations For Period 0000 Hrs to 2400 Hrs on 12 Aug 2005 Deballasted rig at standby location. Picked up # 8 anchor. Towed rig to Basker 2 location. Far Grip set # 4 anchor. Far grip running # 8 anchor Operations For Period 0000 Hrs to 2400 Hrs on 12 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM TP (WOW) RM 0000 0730 7.50 0.0m Continue deballasting rig from survival draft of 20m to moving draft of 10.7m to resume tow to Basker - 2 location. 0600 hrs - Rig hauled in on # 8 anchor and lifted same while completing deballast 0715 hrs - Anchor # 8 racked. Rig stripping tanks to complete deballast to transit draft RM P RM 0730 1500 7.50 0.0m Continue tow rig to Basker 2 location 1200 hrs 38deg 15.4"S, 148deg 49.1"E, Speed 2.1kts, Travelled 317.3nm, To go 3.6nm RM TP (OTH) AH 1500 1630 1.50 0.0m Far Grip alongside rig to pick up anchor # 4 PCC PCC fouled on rig pontoon Far Grip unfoul PCC from rig pontoon and secure anchor # 4 PCC to boat RM P AH 1630 2045 4.25 0.0m Rig payed out 200m of chain on anchor # 4 Far Grip following rig holding onto anchor # 4 RM P AH 2045 2115 0.50 0.0m At anchor # 4 drop point, Far Grip puts # 4 anchor on bottom at 20:50 hrs Rig continues to be towed to Basker 2 location while rig pays out on # 4 anchor chain RM TP (VE) AH 2115 2215 1.00 0.0m Problems with Nav equipment screen on Far Grip. Far Grip unable to strip back PCC to rig until Nav screen fixed Fugro on rig work with Far Grip to fix Nav screen RM P AH 2215 2400 1.75 0.0m Far Grip strip back # 4 PCC to rig # 4 PCC to rig - 2307 hrs Anchor # 8, MV Far Grip PCC to boat - 2337 hrs Run anchor - 2342 hrs Operations For Period 0000 Hrs to 0600 Hrs on 13 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM P AH 0000 0600... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:008 13-AUG-05 1000.0 81.00 Continued to run anchors and pretensioned. Moved rig onto location and ballasted down to drilling draft. Started to pick up tubulars for spudding well. Operations For Period 0000 Hrs to 2400 Hrs on 13 Aug 2005 Continued to run anchors and pretensioned. Moved rig onto location and ballasted down to drilling draft. Started to pick up tubulars for spudding well. Operations For Period 0000 Hrs to 2400 Hrs on 13 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description RM P AH 0000 0600 6.00 0.0m Anchor # 8, MV Far Grip 0020 hrs - Anchor on bottom 0111 hrs - PCC passed to rig Anchor # 1, MV Far Grip 0145 hrs - PCC passed to boat 0206 hrs - running out anchor 0240 hrs - anchor on bottom - Boat reports PCC parted 4m from boat end Anchor # 5, MV Far Grip 0330 hrs - PCC passed to boat 0402 hrs - running out anchor 0433 hrs - anchor on bottom 0550 hrs - PCC back to rig Anchor # 1 slipping at at 123 tonne tension, indicating wrong orientation RM TP (RE) AH 0600 1145 5.75 0.0m MV Far Grip Rigging up "J" Hook to chase out anchor # 1 0715 hrs - Far Grip "J" hooks # 1 chain and begins chasing back to anchor 0815 hrs - Far Grip reports "J" hook come off chain 0837 hrs - Far Grip hooked chain again, chasing out to anchor 1001 hrs - Far Grip reports "J" hook at anchor 1010 hrs - Anchor # 1 off bottom 1032 hrs - Anchor # 1 at Far Grip roller, wrong way round - unable to get to get anchor on deck of boat 1100 hrs - Far Grip advised that decision made to run anchor "as is" without installing new PCC 1135 hrs - Anchor # 1 on bottom 1147 hrs - Far Grip chasing back to rig with "J" hook RM P AH 1145 2300 11.25 0.0m 1147 hrs - MV Wrangler shortens tow wire 1222 hrs - Rig retreived tow wire MV Wrangler rigged down tow system, rigged up to run anchors MV Far Grip rigged down "J" hook gear, rigged up to run anchors Anchor # 2, MV Far Grip 1320 hrs - PCC secured on boat - anchor upside down - correct orientation of anchor 1434 hrs - Run out # ... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:009 14-AUG-05 1000.0 208.00 Continued to pick up tubulars for spudding well. Picked up 36" BHA and ran in hole. Spudded well and drilled to 208m. Filled hole with PHG. POOH and racked back BHA. Ran 30 x 20" conductor leaving PGB 2.5m above seabed Operations For Period 0000 Hrs to 2400 Hrs on 14 Aug 2005 Continued to pick up tubulars for spudding well. Picked up 36" BHA and ran in hole. Spudded well and drilled to 208m. Filled hole with PHG. POOH and racked back BHA. Ran 30 x 20" conductor leaving PGB 2.5m above seabed Operations For Period 0000 Hrs to 2400 Hrs on 14 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description SH P PUP 0000 0730 7.50 0.0m Continue pick up 5" DP - total of 1000m of DP picked up Made up 30" cementing stand and running tool. ROV completed 70m radius from well centre seabed scan on video SH P HBHA 0730 1100 3.50 176.0m Picked up 36" BHA. RIH to seafloor. Checked Anderdrift OK. 0�. Water depth confirmed at 154.5m RKB to Mudline at drilling draft of 23.5m = 176m LAT Rig position at 1.3m @ 70deg off location SH P TI 1100 1200 1.00 176.0m ROV observed tag. 177m RKB. Air gap 21.5m. Tide +1.0m. SH P DA 1200 1330 1.50 208.0m Drilled 36" hole to 208m. Pumped 75 bbls of PHG every half stand SH P CHC 1330 1430 1.00 208.0m Took Anderdrift survey at TD = 1.5 deg Circulated 100 bbl PHG out of hole then spotted 230 bbls of PHG in hole SH P TO 1430 1530 1.00 208.0m Pulled out of hole with 36" BHA. No drag noted. Racked back BHA SH P CRN 1530 2200 6.50 208.0m Moved PGB under rotary table. Rigged up and ran 30" conductor through PGB Latched conductor into PGB and installed guidelines Ran in hole with conductor on landing string until 20" shoe at seabed SH TP (OTH) RM 2200 2230 0.50 208.0m 20" shoe approx 2m forward of hole centre. ROV unable to push pipe into hole. Reposition rig so that casing shoe above hole centre SH P CRN 2230 2300 0.50 208.0m Ran in hole with 30" conductor and land... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:010 15-AUG-05 1000.0 472.00 Cemented 30" conductor in place Waited on cement to harden Pulled 30" running tool Laid down 36" BHA Picked up 17 1/2" BHA Ran in hole, drilled out shoe Drilled 17 1/2" hole to 472m Operations For Period 0000 Hrs to 2400 Hrs on 15 Aug 2005 Cemented 30" conductor in place Waited on cement to harden Pulled 30" running tool Laid down 36" BHA Picked up 17 1/2" BHA Ran in hole, drilled out shoe Drilled 17 1/2" hole to 472m Operations For Period 0000 Hrs to 2400 Hrs on 15 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description CH P CMC 0000 0130 1.50 208.0m Cemented 30" conductor in place as per program. Pumped 50 bbls preflush with fluoresene dye added Mixed and pumped 173 bbls of 15.8 ppg cement slurry at 5 bpm Displaced cement with 35.5 bbls seawater. Fluoresene dye observed in returns at seabed CH P WOC 0130 0730 6.00 208.0m Wait on cement to harden Note - 0n 0-5 deg bulls eye - 0.75 deg to starboard; on 0-2 deg bulls eye - 0.5 deg to starboard CH P CRN 0730 0830 1.00 208.0m Released 30" running tool with 5 turns LH and pulled out of hole with tool No change to PGB bullseyes reading. SLM out of hole. No change to top of PGB measurement = 174.5m MSL CH P CRN 0830 1030 2.00 208.0m Torque up service breaks on Cameron 18 3/4" running tools. M/U one running tool to stand of 5" DP and rack back same M/U second running tool to 2m pup joint and lay down on deck CH P HBHA 1030 1130 1.00 208.0m Hold JSA and lay down BHA from 36" hole section SH P HBHA 1130 1530 4.00 208.0m Held JSA and picked up BHA for 17 1/2" hole section SH P HBHA 1530 1630 1.00 208.0m Stabbed into 30" wellhead with 17 1/2" bit and tested MWD - OK SH P DFS 1630 1730 1.00 208.0m Tagged top of cement at 206m. Drilled cement and shoe to 209m SH P DA 1730 2400 6.50 472.0m Drill 17 1/2" hole from 209 - 472m Operations For Period 0000 Hrs to 0600 Hrs on 16 Aug 2005 Phse Cls (RC) Op From To Hrs Depth... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:011 16-AUG-05 1006.0 1006.00 Drilled from 472 - 1006m MSL. Swept hole with 150 bbls PHG Spotted 1.5 times hole volume of PHG in hole Pulled out of hole Operations For Period 0000 Hrs to 2400 Hrs on 16 Aug 2005 Drilled from 472 - 1006m MSL. Swept hole with 150 bbls PHG Spotted 1.5 times hole volume of PHG in hole Pulled out of hole Operations For Period 0000 Hrs to 2400 Hrs on 16 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description SH P DA 0000 1900 19.00 996.0m Drilled 17 1/2" hole from 472 - 996m. Pumped 30 bbls PHG every half stand. Spotted 50 bbls PHG around BHA at connections. SH TP (RE) RR 1900 1930 0.50 996.0m Circulated at 100 SPM with # 1 mud pump while repairing # 2 mud pump. Mud pump # 3 still not available SH P DA 1930 2030 1.00 1,006.0m Continued to drill 17 1/2" hole from 996 - 1006m Tide corrected MSL depth Pumped 30 bbl PHG every half stand Spotted 50 bbl PHG around BHA at connections SH P CHC 2030 2130 1.00 1,006.0m Pumped 150 bbls PHG and swept out of hole with seawater. Displaced hole with 925 bbls of 8.6 ppg PHG followed by 250 bbls of 9.5 ppg weighted gel kill mud. SH P TO 2130 2400 2.50 1,006.0m Pulled out of hole from 1006m MSL 30K overpull at 836 and 786m Wiped hole once with no further overpull Operations For Period 0000 Hrs to 0600 Hrs on 17 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description SH P TO 0000 0200 2.00 1,006.0m Continued to POOH from section TD No more overpull encountered Jetted top of wellhead on way out of hole SH P HBHA 0200 0300 1.00 1,006.0m Laid down MWD, stabs, pony DC and bit SH P HT 0300 0330 0.50 1,006.0m Laid down 30" CART stand SH P RRC 0330 0430 1.00 1,006.0m Made up Dowell DeepSea Express cement head to stand of HWDP and racked back in derrick SH P CRN 0430 0600 1.50 1,006.0m Held JSA Rigged up for and ran 13 3/8" casing Phase Data to 2400hrs, 16 Aug 2005 Phase Phase Hrs Start On Finish On ... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:012 17-AUG-05 1006.0 1006.00 Operations For Period 0000 Hrs to 2400 Hrs on 17 Aug 2005 Operations For Period 0000 Hrs to 2400 Hrs on 17 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description SC P TO 0000 0200 2.00 1,006.0m Continued to POOH from section TD No more overpull encountered Jetted top of wellhead on way out of hole SC P HBHA 0200 0300 1.00 1,006.0m Laid down MWD, stabs, pony DC and bit SC P HT 0300 0330 0.50 1,006.0m Laid down 30" CART stand SC P RRC 0330 0430 1.00 1,006.0m Made up Dowell DeepSea Express cement head to stand of HWDP and racked back in derrick SC P CRN 0430 0500 0.50 1,006.0m Held JSA Rig up for and run 13 3/8" casing. SC P CRN 0500 1200 7.00 1,006.0m Picked up shoe track and test float and shoe. Run 13 3/8" csg. SC P CRN 1200 1300 1.00 1,006.0m Made up Deep Sea Express head SC P CRN 1300 1400 1.00 1,006.0m Ran in with landing string and landed out 18 3/4" Wellhead housing into 30" housing. Confirmed locked in with 60k overpull. SC P CMC 1400 1500 1.00 1,006.0m Hold JSA with cementer and crew. Rigged up and tested cement line with 3500 psi. SC P CIC 1500 1600 1.00 1,006.0m Circulated casing capacity at 95 SPM and 400 psi. SC P CMC 1600 1800 2.00 1,006.0m Mixed and pump cement as per program. Lead @ 12.5 ppg total slurry 348 bbls. Tail @ 15.8 ppg total slurry 175 bbls. Good returns noted at sea bed with ROV while cementing. SC P CMC 1800 1900 1.00 1,006.0m Displaced cement with rig pump and bumped plug with 3248 stks and 1400 psi. Hold for 10 minutes , good test ( 500 psi over final circulating pressure ) Check float holding. Good returns of cement noted at sea bed with ROV while displacing cement. SC P CMC 1900 1930 0.50 1,006.0m Rigged down cement lines. SC P TO 1930 2030 1.00 1,006.0m Released wellhead running tool and POOH same. SC P TO 2030 2100 0.50 1,006.0m Service break and lay down Deepsea Express. BOP P BOP ... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:013 18-AUG-05 1006.0 1006.00 Operations For Period 0000 Hrs to 2400 Hrs on 18 Aug 2005 Operations For Period 0000 Hrs to 2400 Hrs on 18 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description BOP P BOP 0000 1330 13.50 1,006.0m Continue to run BOP"S on marine riser. Test choke and kill lines each 4 joints, 250psi / 5000psi BOP P BOP 1330 1500 1.50 1,006.0m Made up slip joint and landing joint. BOP P BOP 1500 1800 3.00 1,006.0m Made up choke and kill lines and booster lines to slip joint, via goosenecks. BOP P BOP 1800 1830 0.50 1,006.0m Latch tensioner landing ring to slip joint. BOP TU (RE) BOP 1830 1930 1.00 1,006.0m Troubleshoot tensioner landing ring ( SDL ring ). 1 x hydraulic Locking Dog failed to operate, freed up same. BOP P BOP 1930 2200 2.50 1,006.0m Pressure up on tensioners. Attached storm saddles, to Pod wireline for Pod hoses. Position rig back over location. BOP P BOP 2200 2400 2.00 1,006.0m Land and latch BOP, took 50 kips overpull on both Pods. Secured Pod hoses in storm saddles. Secured compensator line to slip joint for wireline. NOTE # BULLSEYE READINGS. Prior landing , BOP 3/4 stb fwd, riser 1/4 stb. After landing , BOP 3/4 stb, riser 1/2 stb Operations For Period 0000 Hrs to 0600 Hrs on 19 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description IH P BOP 0000 0130 1.50 1,006.0m Release landing joint and stroke out slip joint. IH P BOP 0130 0230 1.00 1,006.0m Pick up and install divertor. IH P BOP 0230 0300 0.50 1,006.0m Rig down riser running equipment. IH P BOP 0300 0430 1.50 1,006.0m Made up CART tool and ran in hole and seated same. IH P BOP 0430 0530 1.00 1,006.0m Perform connection test,250psi/5000psi. Pressure tested on both Pods. IH P BOP 0530 0600 0.50 1,006.0m Unseat CART tool and pull out same. Phase Data to 2400hrs, 18 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max Depth RI... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:014 19-AUG-05 1006.0 1006.00 Attempted to run velocity survey. Engine of wireline unit failed at 40m. Pulled out of hole and rigged down wireline. Began to pick up BHA and make up drillpipe. Operations For Period 0000 Hrs to 2400 Hrs on 19 Aug 2005 Attempted to run velocity survey. Engine of wireline unit failed at 40m. Pulled out of hole and rigged down wireline. Began to pick up BHA and make up drillpipe. Operations For Period 0000 Hrs to 2400 Hrs on 19 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description BOP P BOP 0000 0130 1.50 1,006.0m Release landing joint and stroke out slip joint. BOP P BOP 0130 0230 1.00 1,006.0m Pick up and install divertor. BOP P BOP 0230 0300 0.50 1,006.0m Rig down riser running equipment. BOP P BOP 0300 0430 1.50 1,006.0m Made up CART tool and ran in hole and seated same. BOP P BOP 0430 0530 1.00 1,006.0m Perform connection test,250psi/5000psi. Pressure tested on both Pods. BOP TU (BORC) BOP 0530 0800 2.50 1,006.0m Unseat CART tool and attempt to pull out same. Hanging up on middle pipe rams, function rams and work through. Pull out and laid down same. E1 P RP 0800 1030 2.50 1,006.0m Hold JSA and rigged up wireline. Made up and ran Log #1, Velocity survey E1 TU (OTH) RP 1030 1200 1.50 1,006.0m Pulled out Velocity survey tools and laid down same. Rigged down wireline, due to Unit failure. Unit main engine problem. IH P PLD 1200 1300 1.00 1,006.0m Hold JSA and laid down 9" DC IH P HBHA 1300 1500 2.00 1,006.0m Make up 12 1/4" Directional BHA, DHM set at 1.15 degrees. IH P HT 1500 1600 1.00 1,006.0m Upload MWD IH P HBHA 1600 1800 2.00 1,006.0m Cont make-up 12 1/4" BHA to 200m IH P PUP 1800 2000 2.00 1,006.0m Hold JSA and pick up 5" drill pipe, cont run in from 200m to 344m. Total 144m of pipe picked up. IH P TO 2000 2130 1.50 1,006.0m Pull out from 344m to 200m and rack pipe in derrick. IH P HT 2130 2230 1.00 1,006.0m ... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:015 20-AUG-05 1689.0 1539.00 Drilled ahead in Mars and interbedded Calcarenites of the Gippsland Limestone Formation. Backgroung gas averaging C1 1000ppg, C2 15ppm, C3 10ppm, no noticeable gas peaks. Average ROP 40m/hr. Operations For Period 0000 Hrs to 2400 Hrs on 20 Aug 2005 Drilled ahead in Mars and interbedded Calcarenites of the Gippsland Limestone Formation. Backgroung gas averaging C1 1000ppg, C2 15ppm, C3 10ppm, no noticeable gas peaks. Average ROP 40m/hr. Operations For Period 0000 Hrs to 2400 Hrs on 20 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description IH P SM 0000 0100 1.00 1,006.0m Simulate well kick and perform choke drill. Record CLFL. Simulate bringing pumps on line and shutting pumps down during kill. IH P PUP 0100 0330 2.50 1,066.0m Continue to pick up 5" drill pipe from 344m to 889m. IH P TI 0330 0400 0.50 1,006.0m Run in hole from 889m to TOC at 982m IH P DFS 0400 0630 2.50 1,006.0m Drill cement and plugs and float equipment. Start to displace to 8.74ppg mud while drilling shoe track. IH P DM 0630 0700 0.50 1,066.0m Drill 12�" hole f/ 1005m to 1008m. Circulate clean. IH P LOT 0700 0730 0.50 1,066.0m POOH f/ 1008m to csg shoe @1000m. LOT w/ 8.5 ppg. 622psi equivalent to 12.5ppg. IH P CMD 0730 0800 0.50 1,066.0m SCRs @ 1000m #2 pump 30spm 150psi. 40 spm 190psi, 50 spm 210 psi. #3 pump 30spm 140psi, 40spm 170psi, 50 spm 200psi. IH P DM 0800 2400 16.00 1,539.0m Drill 12�" hole f/ 1008m to 1539m. Operations For Period 0000 Hrs to 0600 Hrs on 21 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description IH P DM 0000 0500 5.00 1,689.0m Cont drill 12 1/4" hole to 1689m IH P CHC 0500 0600 1.00 1,689.0m (IN PROGRESS) Circulate hole clean, flow check and slug pipe. Phase Data to 2400hrs, 20 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max Depth RIG MOVE/RIG-UP/PRESPUD(RM) 154.5 06 Aug 2005 12 Aug 2005 154.50 6.438 ... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:016 21-AUG-05 1989.0 1893.00 Drill ahead in the Gippsland Limestone and into the Lakes Entrance Formation. Lakes Entrance at 1755m MD 1733.5m SS. Operations For Period 0000 Hrs to 2400 Hrs on 21 Aug 2005 Drill ahead in the Gippsland Limestone and into the Lakes Entrance Formation. Lakes Entrance at 1755m MD 1733.5m SS. Operations For Period 0000 Hrs to 2400 Hrs on 21 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description IH P DM 0000 0500 5.00 1,689.0m Cont drill 12 1/4" hole to 1689m IH P CHC 0500 0630 1.50 1,689.0m Circulate hole clean, flow check and slug pipe. IH P TO 0630 0830 2.00 1,689.0m Pulled out of hole from 1690m to 716m. IH P PUP 0830 1000 1.50 1,689.0m Pick up drill pipe from 716m to 1004m. IH P TO 1000 1030 0.50 1,689.0m Pulled out of hole from 1004m to 716m. IH P PUP 1030 1200 1.50 1,689.0m Pick up drill pipe from 716m to 1004m. IH P TO 1200 1230 0.50 1,689.0m Pulled out of hole from 1004m to 716m. IH P PUP 1230 1430 2.00 1,689.0m Pick up drill pipe from 716m to 1090m. IH P TI 1430 1600 1.50 1,689.0m Run in hole with pipe from derrick from 1090m to 1689m. No fill recorded. IH P DA 1600 1930 3.50 1,783.0m Drill 12 1/4" hole from 1689m to 1783m. IH P DM 1930 2030 1.00 1,789.0m Slide from 1783m to 1789m. IH P DA 2030 2400 3.50 1,893.0m Drill 12 1/4" hole from 1789m to 1893m. Operations For Period 0000 Hrs to 0600 Hrs on 22 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description IH P DA 0000 0600 6.00 2,007.0m Drill 12 1/4" hole from 1893m to 2007m. Slide from 1928m to 1938m.( 1hr ) Slide from 1956m to 1959m. ( .5hr) Slide from 1985m to 1989m ( .5hr) Phase Data to 2400hrs, 21 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max Depth RIG MOVE/RIG-UP/PRESPUD(RM) 154.5 06 Aug 2005 12 Aug 2005 154.50 6.438 0.0m ANCHORING(A) 32 12 Aug 2005 13 Aug 2005 186.50 7.771 0.0m PRESPUD(PS) 8.5 13... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:017 22-AUG-05 2497.0 1006.00 Rotary/slide drilling 12-1/4" hole 1893 - 2438m Operations For Period 0000 Hrs to 2400 Hrs on 22 Aug 2005 Rotary/slide drilling 12-1/4" hole 1893 - 2438m Operations For Period 0000 Hrs to 2400 Hrs on 22 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description IH P DA 0000 2400 24.00 2,438.0m Drill 12 1/4" hole from 1893m to 2438m. Slide from 1928m to 1938m.( 1hr ) Slide from 1956m to 1959m. ( .5hr) Slide from 1985m to 1989m ( .5hr) Flow check @ 2166m Operations For Period 0000 Hrs to 0600 Hrs on 23 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description IH P DA 0000 0500 5.00 2,497.0m Drill 12 1/4" hole from 2438m to 2497m Slide from 2465m to 2476m ( 1 hr ) Slide from 2482m to 2497m ( 2 hr ) Unable to set tool face, pipe stacking, 100psi DHM Diff on last slide. ( Last survey @ 2472m, inc 2.07, az 337.28 ) IH U TO 0500 0600 1.00 2,497.0m Flow check and pull out of hole from 2497m Phase Data to 2400hrs, 22 Aug 2005 Phase Phase Hrs Start On Finish On Cum Hrs Cum Days Max Depth RIG MOVE/RIG-UP/PRESPUD(RM) 154.5 06 Aug 2005 12 Aug 2005 154.50 6.438 0.0m ANCHORING(A) 32 12 Aug 2005 13 Aug 2005 186.50 7.771 0.0m PRESPUD(PS) 8.5 13 Aug 2005 14 Aug 2005 195.00 8.125 0.0m CONDUCTOR CASING(CC) 9.5 14 Aug 2005 14 Aug 2005 204.50 8.521 209.0m CONDUCTOR HOLE(CH) 18.5 14 Aug 2005 15 Aug 2005 223.00 9.292 209.0m SURFACE HOLE(SH) 33 15 Aug 2005 16 Aug 2005 256.00 10.667 1,006.0m SURFACE CASING(SC) 24.5 16 Aug 2005 17 Aug 2005 280.50 11.688 1,006.0m RISER AND BOP STACK(BOP) 35 17 Aug 2005 19 Aug 2005 315.50 13.146 1,006.0m EVALUATION PHASE (1)(E1) 4 19 Aug 2005 19 Aug 2005 319.50 13.312 1,006.0m INTERMEDIATE HOLE(IH) 84 19 Aug 2005 22 Aug 2005 403.50 16.812 2,438.0m General Comments 00:00 TO 24:00 Hrs ON 22 Aug 2005 "Copyright IDS 2005", TF/JG 20050815, ANZON_AU_drllg Page 1 Printed on 23 Aug 2005 WBM Dat... [From:WELL_DAILY]

B WELL_DRILL_HISTORY:018 23-AUG-05 2497.0 2497.00 Drilled ahead to 2497 mMDRT. Pulled out of hole to change bit. Hung up at BOPs on the way out of hole. Suspected problem with the BOP rams or wear-bushing. Attempted to get free. Operations For Period 0000 Hrs to 2400 Hrs on 23 Aug 2005 Drilled ahead to 2497 mMDRT. Pulled out of hole to change bit. Hung up at BOPs on the way out of hole. Suspected problem with the BOP rams or wear-bushing. Attempted to get free. Operations For Period 0000 Hrs to 2400 Hrs on 23 Aug 2005 Phse Cls (RC) Op From To Hrs Depth Activity Description IH P DA 0000 0500 5.00 2,497.0m Drill 12 1/4" hole from 2438m to 2497m Slide from 2465m to 2476m ( 1 hr ) Slide from 2482m to 2497m ( 2 hr ) Unable to set tool face, pipe stacking, 100psi DHM Diff on

8613371530291

8613371530291