rongsheng refinery start in stock

SINGAPORE, Oct 14 (Reuters) - Rongsheng Petrochemical, the trading arm of Chinese private refiner Zhejiang Petrochemical, has bought at least 5 million barrels of crude for delivery in December and January next year in preparation for starting a new crude unit by year-end, five trade sources said on Wednesday.

Rongsheng bought at least 3.5 million barrels of Upper Zakum crude from the United Arab Emirates and 1.5 million barrels of al-Shaheen crude from Qatar via a tender that closed on Tuesday, the sources said.

Rongsheng’s purchase helped absorbed some of the unsold supplies from last month as the company did not purchase any spot crude in past two months, the sources said.

Zhejiang Petrochemical plans to start trial runs at one of two new crude distillation units (CDUs) in the second phase of its refinery-petrochemical complex in east China’s Zhoushan by the end of this year, a company official told Reuters. Each CDU has a capacity of 200,000 barrels per day (bpd).

Zhejiang Petrochemical started up the first phase of its complex which includes a 400,000-bpd refinery and a 1.2 million tonne-per-year ethylene plant at the end of 2019. (Reporting by Florence Tan and Chen Aizhu, editing by Louise Heavens and Christian Schmollinger)

China"s private refiner Zhejiang Petroleum & Chemical is set to start trial runs at its second 200,000 b/d crude distillation unit at the 400,000 b/d phase 2 refinery by the end of March, a source with close knowledge about the matter told S&P Global Platts March 9.

ZPC cracked 23 million mt of crude in 2020, according the the source. Platts data showed that the utilization rate of its phase 1 refinery hit as high as 130% in a few months last year.

Started construction in the second half of 2019, units of the Yuan 82.9 billion ($12.74 billion) phase 2 refinery almost mirror those in phase 1, which has two CDUs of 200,000 b/d each. But phase 1 has one 1.4 million mt/year ethylene unit while phase 2 plans to double the capacity with two ethylene units.

With the entire phase 2 project online, ZPC expects to lift its combined petrochemicals product yield to 71% from 65% for the phase 1 refinery, according to the source.

Zhejiang Petroleum, a joint venture between ZPC"s parent company Rongsheng Petrochemical and Zhejiang Energy Group, planned to build 700 gas stations in Zhejiang province by end-2022 as domestic retail outlets of ZPC.

Established in 2015, ZPC is a JV between textile companies Rongsheng Petrochemical, which owns 51%, Tongkun Group, at 20%, as well as chemicals company Juhua Group, also 20%. The rest 9% stake was reported to have transferred to Saudi Aramco from the Zhejiang provincial government. But there has been no update since the agreement was signed in October 2018.

The integrated Zhejiang Petroleum & Chemical refinery continued to raise its crude throughput to around 2.84 million mt in December, up 7.2% from 1.72 million mt in November, which was up 54% from October, according to JLC data. The refinery ramped up throughput after it was allocated more quotas in late October.

The Hengli Petrochemical (Dalian) Refinery in Liaoning province also raised its throughput by 3.6% month on month to 1.7 million mt in December. This comes after the completion of the maintenance at its secondary units, according to refinery sources.

However, Shandong independent refineries have gradually started to cut crude throughput from around Jan. 22 in response to a directive to cap utilization below 70% during the Winter Olympics, as Beijing aims to ensure that emissions remain under control, refinery sources told S&P Global Platts. But some refinery sources believe the overall impact will not be much more than what occurs every year since the Winter Olympics will be held around the Lunar New Year holidays, when independent refineries are forced to cut crude throughput due to logistics and manpower constraints.

In other news, Sinopec"s Hainan Petrochemical refinery in southern China is expected to export about 50,000 mt of refined oil products in January 2022, according to a refinery source. This was down 55% from 110,000 mt planned for export in December 2021.

PetroChina"s West Pacific Petrochemical Corp. refinery will skip gasoil exports in January after skipping them in December and November due to good demand in the domestic market.

PetroChina"s flagship refinery Dalian Petrochemical in northeastern Liaoning province will raise its gasoline exports to 160,000 mt in January, according to sources with knowledge of the matter. This will be about 357% higher than its planned exports in December. Dalian will double jet fuel exports to 80,000 mt in January, from 40,000 mt last month. Dalian plans to process around 1.3 million mt of crudes in January, translating to 75% of its nameplate capacity, stable on the month.

** Sinochem has been in the process of starting up its 12 million mt/year CDU and related refining units at its Quanzhou Petrochemical facility in southern Fujian province, according to a source with knowledge of the matter Jan. 19. The refining and petrochemical units were shut at around Dec. 1, 2021 for maintenance, which lasted for about 40-50 days, according to the maintenance schedule. The refinery will likely process about 450,000 mt to 500,000 mt of crudes for the remainder of February, compared with around 1.2 million mt during normal months.

** Sinopec"s Guangzhou Petrochemical restarted its 8 million mt/year CDU on Dec. 21 following the completion of a scheduled maintenance which started late October, a company source said. With its resumption, the refiner lifted December throughput to 840,000 mt from 440,000 mt in November, the source said. Moreover, the S-zorb that caught fire Nov. 27 during maintenance was fixed and resumed operation, the source added.

** Sinopec"s Fujian Refining and Chemical Co. refinery in southeastern Fujian province has been in the process of restarting from a scheduled maintenance this week, according to a source with knowledge of the matter Jan. 19. The refinery was expected to return to normal operations around Jan. 20, about nine days behind schedule, mainly due to the slow progress in procuring some parts, the source added. The 4 million mt/year crude distillation unit, as well as some secondary units, including the aromatics units, were to be restarted along the way. Following the restart of the CDU, the crude throughput at the refinery will likely increase to around 750,000 mt in January, or 63% of its nameplate capacity. This compares with a run rate of 56%, or 660,000 mt, in December 2021.

** Japan"s ENEOS said Dec. 28 it plans to shut the sole crude distillation unit at its Marifu refinery in the west in late January for scheduled maintenance until early March 2022.

** Idemitsu Kosan restarted the sole 160,000 b/d crude distillation unit at its Aichi refinery in central Japan on Dec. 5 after completing planned maintenance, a spokesperson said Dec. 20.

** PetroChina"s Yunnan Petrochemical refinery in southwestern Yunnan province, has shut its 4 million mt/year residual hydrogenation unit and some of its relative downstream facilities due to a blast. The blast hit the residual hydrogenation unit Dec. 13 morning, according to a press release issued by the Anning city local government in Yuannan. A refining engineer said the closure of residual hydrogenation unit would cut about 30% of the refinery"s daily production.

** Sinopec"s Hainan Petrochemical refinery in southern China plans to completely shut for scheduled maintenance over March-April 2022, a source with the refinery said. This is a routine maintenance that is normally carried out by Chinese refineries every three to four years, according to the source. Sinopec Hainan refinery last carried out complete maintenance over November 2017-January 2018.

** Japan"s ENEOS said it will decommission the 120,000 b/d No. 1 CDU at its 270,000 b/d Negishi refinery in Tokyo Bay in October 2022. It will also decommission secondary units attached to the No. 1 CDU, including a vacuum distillation unit and fluid catalytic cracker. ENEOS will also decommission a 270,000 mt/year lubricant output unit at the Negishi refinery.

** Sinopec is looking to launch its 2 million mt/year crude distillation unit expansion at Luoyang Petrochemical in central China in January, with a new crude pipeline able to supply sufficient feedstock, a refinery source said late December. "We have reconfigured an existing crude pre-treater into a 2 million mt/year CDU to increase the primary capacity to 10 million mt/year. The start-up will be in the next month with the crude pipeline having been put into use in November," the refinery source said. The expansion was initially set to be put into use in H2 2020, but was delayed to H1 2021 due to construction of the 10 million mt/year Rizhao-Puyang-Luoyang crude pipeline and weak demand in oil product market, Platts reported. The source said the expansion needs more crude supplies discharged from Rizhao port in Shandong province and transmitted through the Rizhao-Puyang-Luoyang crude pipeline.

** Chinese Sinopec"s refinery Zhenhai Refining and Chemical currently has a 27 million mt/year refining capacity and a 2.2 million mt/year ethylene plant, after its phase 1 expansion project of 4 million mt/year crude distillation unit and a 1.2 million mt/year ethylene unit was delivered end-June.

** PetroChina"s Guangxi Petrochemical in southern Guangxi province plans to start construction at its upgrading projects at the end of 2021, with the works set to take 36 months. The projects include upgrading the existing refining units as well as setting up new petrochemical facilities, which will turn the refinery into a refining and petrochemical complex. The project will focus on upgrading two existing units: the 2.2 million mt/year wax oil hydrocracker and the 2.4 million mt/year gasoil hydrogenation refining unit. For the petrochemicals part, around 11 main units will be constructed, which include a 1.2 million mt/year ethylene cracker.

** Sinopec"s Changling Petrochemical in central Hunan province plans to start construction for its newly approved 1 million mt/year reformer in 2021 and to bring its port upgrading project online by end-December.

** China"s privately held refining complex, Shenghong Petrochemical, is likely to start feeding crudes into its newly built 16 million mt/year crude distillation unit, according to a company source in early January. The refinery initially planned to start up at the end of August, but this was postponed to the end of December due to slower-than-expected construction work, and then again to around the Lunar New Year. The construction of the complex started in December 2018. Located in the coastal city of Lianyungang in Jiangsu province, the company"s 16 million mt/year CDU is the country"s single biggest by capacity.

** Chinese privately owned refining and petrochemical complex Zhejiang Petroleum & Chemical has fully started up commercial operation at it 400,000 b/d Phase 2 refining and petrochemical project, parent company Rongsheng Petrochemical said in a document Jan. 12. There are two crude distillation units in the Phase 2 project, each with a capacity of 200,000 b/d. ZPC started trial run at one of the CDUs in November 2020. Due to tight feedstock supplies, the refiner could not feed the other CDU until the end of November 2021, when it gained crude import quota for the project. The nameplate capacity of the company doubled to 800,000 b/d in Phase 2. It will run four CDUs at about 82% of nameplate capacity in January. Rongsheng said Phase 2 adds 6.6 million mt/year aromatics and 1.4 million mt/year ethylene production capacity.

** Saudi Aramco continues to pursue and develop the integrated refining and petrochemical complex in China with Norinco Group and Panjin Sinchen. The joint venture plans to build an integrated refining and petrochemical complex in northeast China"s Liaoning province Panjin city with a 300,000 b/d refinery, 1.5 million mt/year ethylene cracker and a 1.3 million mt/year PX unit.

** Honeywell said China"s Shandong Yulong Petrochemical will use "advanced platforming and aromatics technologies" from Honeywell UOP at its integrated petrochemical complex. The complex will include a UOP naphtha Unionfining unit, CCR Platforming technology to convert naphtha into high-octane gasoline and aromatics, Isomar isomerization technology. When completed Yulong plans to produce 3 million mt/yr of mixed aromatics. Shandong"s independent greenfield refining complex, Yulong Petrochemical announced the start of construction work at Yulong Island in Yantai city at the end of October 2020.

** PetroChina officially started construction works at its greenfield 20 million mt/year Guangdong petrochemical refinery in the southern Guangdong province on Dec. 5, 2018.

The company, 51% owned by private chemical group Zhejiang Rongsheng Holdings, said it has started test production at ethylene, aromatics and other downstream facilities, without giving further details.

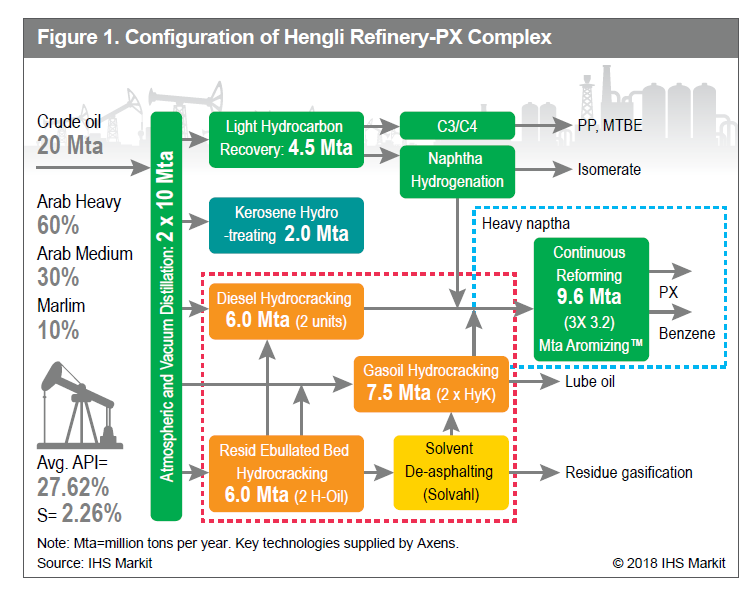

Zhejiang Petrochemical started a first 200,000 barrels per day (bpd) crude processing unit in late May, following on from the start of a 400,000-bpd refinery owned by another private chemical major Hengli Petrochemical.

The newly started units at Zhejiang Petrochemical should include a second 200,000-bpd crude unit, a 1.2 million tonnes per year (tpy) ethylene unit and a 2 million tpy paraxylene unit, according to several industry sources with knowledge of the plant"s operations.

BEIJING (Reuters) - Rongsheng Petrochemical , the listed arm of a major shareholder in one of China"s biggest private oil refineries, expects demand for energy and chemical products to return to normal in the country in the second half of this year.

Rongsheng expects to start trial operations of the second phase of the refining project, adding another 400,000 bpd of refining capacity and 1.4 million tonnes of ethylene production capacity in the fourth quarter of 2020.

"We expect the effects of the coronavirus pandemic on energy and chemicals to have basically faded in spite of the possibility of new waves of outbreak," said Quan Weiying, board secretary of Rongsheng, in response to Reuters questions in an online briefing.

But Li Shuirong, president of Rongsheng, told the briefing that it was still in the process of applying for an export quota and would adjust production based on market demand. (Reporting by Muyu Xu and Chen Aizhu; Editing by Jacqueline Wong)

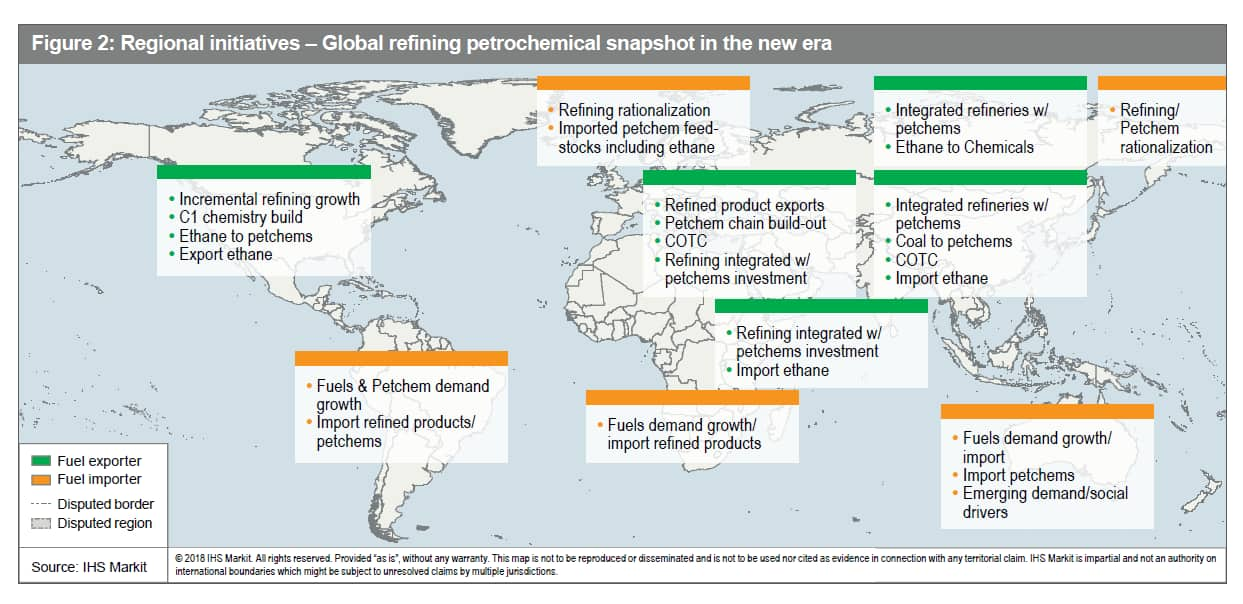

2021 marked the start of the central government’s latest effort to consolidate and tighten supervision over the refining sector and to cap China’s overall refining capacity.[14] Besides imposing a hefty tax on imports of blending fuels, Beijing has instituted stricter tax and environmental enforcement[15] measures including: performing refinery audits and inspections;[16] conducting investigations of alleged irregular activities such as tax evasion and illegal resale of crude oil imports;[17] and imposing tighter quotas for oil product exports as China’s decarbonization efforts advance.[18]

Yet, of the three most recent major additions to China’s greenfield refinery landscape, none are in Shandong province, home to a little over half the country’s independent refining capacity. Hengli’s Changxing integrated petrochemical complex is situated in Liaoning, Zhejiang’s (ZPC) Zhoushan facility in Zhejiang, and Shenghong’s Lianyungang plant in Jiangsu.[21]

As China’s independent oil refining hub, Shandong is the bellwether for the rationalization of the country’s refinery sector. Over the years, Shandong’s teapots benefited from favorable policies such as access to cheap land and support from a local government that grew reliant on the industry for jobs and contributions to economic growth.[22] For this reason, Shandong officials had resisted strictly implementing Beijing’s directives to cull teapot refiners and turned a blind eye to practices that ensured their survival.

But with the start-up of advanced liquids-to-chemicals complexes in neighboring provinces, Shandong’s competitiveness has diminished.[23] And with pressure mounting to find new drivers for the provincial economy, Shandong officials have put in play a plan aimed at shuttering smaller capacity plants and thus clearing the way for a large-scale private sector-led refining and petrochemical complex on Yulong Island, whose construction is well underway.[24] They have also been developing compensation and worker relocation packages to cushion the impact of planned plant closures, while obtaining letters of guarantee from independent refiners pledging that they will neither resell their crude import quotas nor try to purchase such allocations.[25]

In 2016, during the period of frenzied post-licensing crude oil importing by Chinese independents, Saudi Arabia began targeting teapots on the spot market, as did Kuwait. Iran also joined the fray, with the National Iranian Oil Company (NIOC) operating through an independent trader Trafigura to sell cargoes to Chinese independents.[27] Since then, the coming online of major new greenfield refineries such as Rongsheng ZPC and Hengli Changxing, and Shenghong, which are designed to operate using medium-sour crude, have led Middle East producers to pursue long-term supply contracts with private Chinese refiners. In 2021, the combined share of crude shipments from Saudi Arabia, UAE, Oman, and Kuwait to China’s independent refiners accounted for 32.5%, an increase of more than 8% over the previous year.[28] This is a trend that Beijing seems intent on supporting, as some bigger, more sophisticated private refiners whose business strategy aligns with President Xi’s vision have started to receive tax benefits or permissions to import larger volumes of crude directly from major producers such as Saudi Arabia.[29]

The shift in Saudi Aramco’s market strategy to focus on customer diversification has paid off in the form of valuable supply relationships with Chinese independents. And Aramco’s efforts to expand its presence in the Chinese refining market and lock in demand have dovetailed neatly with the development of China’s new greenfield refineries.[30] Over the past several years, Aramco has collaborated with both state-owned and independent refiners to develop integrated liquids-to-chemicals complexes in China. In 2018, following on the heels of an oil supply agreement, Aramco purchased a 9% stake in ZPC’s Zhoushan integrated refinery. In March of this year, Saudi Aramco and its joint venture partners, NORINCO Group and Panjin Sincen, made a final investment decision (FID) to develop a major liquids-to-chemicals facility in northeast China.[31] Also in March, Aramco and state-owned Sinopec agreed to conduct a feasibility study aimed at assessing capacity expansion of the Fujian Refining and Petrochemical Co. Ltd.’s integrated refining and chemical production complex.[32]

In Asia and the Middle East, at least nine refinery projects are beginning operations or are scheduled to come online before the end of 2023. At their current planned capacities, they will add 2.9 million barrels per day (b/d) of global refinery capacity once fully operational.

The scheduled expansions follow a period of reduced global refining capacity. Net global capacity declined in 2021 for the first time in 30 years, according to the IEA. The new refinery projects would increase production of refined products, such as gasoline and diesel, and in turn, they might reduce the current high prices for these products.

China’s refinery capacity is scheduled to increase significantly this year. The Shenghong Petrochemical facility in Lianyungang has an estimated capacity of 320,000 b/d, and they report that trial crude oil-processing operations began in May 2022. In addition, PetroChina’s 400,000 b/d Jieyang refinery is expected to come online in the third quarter of 2022. A planned 400,000 b/d Phase II capacity expansion also began operations earlier this year at Zhejiang Petrochemical Corporation’s (ZPC) Rongsheng facility. More information on these expansions is available in our Country Analysis Executive Summary: China.

Outside of China, the 300,000 b/d Malaysian Pengerang refinery (also known as the RAPID refinery) restarted in May 2022 after a fire forced the refinery to shut down in March 2020. In India, the Visakha Refinery is undergoing a major expansion, scheduled to add 135,000 b/d by 2023.

New projects in the Middle East are also likely to be an important source of new refining capacity. The 400,000 b/d Jizan refinery in Saudi Arabia reportedly came online in late 2021 and began exporting petroleum products earlier this year. More recently, the 615,000 b/d Al Zour refinery in Kuwait—the largest in the country when it becomes fully operational—began initial operations earlier this year. A new 140,000 b/d refinery is scheduled to come online in Karbala, Iraq, this September, targeting fully operational status by 2023. A new 230,000 b/d refinery is set to come online in Duqm, Oman, likely in early 2023.

These estimates do not necessarily include all ongoing refinery capacity expansions. Moreover, many of these projects have already been subject to major delays, and the possibility of partial starts or continued delays related to logistics, construction, labor, finances, political complications, or other factors may cause these projects to come online later than estimated. Although the potential for project complications and cancellations is always a significant risk, these projects could otherwise account for an increase of nearly 3.0 million b/d of new refining capacity by the end of 2023.

Abu Dhabi National Oil Company (ADNOC) has signed a broad framework agreement with China’s Rongsheng Petrochemical to explore domestic and international growth opportunities in support of ADNOC’s 2030 growth strategy.

The companies will examine opportunities in the sale of refined products from ADNOC to Rongsheng, downstream investment opportunities in both China and the United Arab Emirates (UAE) and the supply of liquified natural gas (LNG) to Rongsheng.

Under the terms of the deal, the companies will also study chances to increasing the volume and variety of refined product sales to Rongsheng as well as ADNOC’s participation as the China firm’s strategic partner in refinery and petrochemical projects. This could include an investment in Rongsheng’s downstream complex.

In return, Rongsheng will also look at investing in ADNOC’s downstream industrial ecosystem in Ruwais, UAE, including a proposed gasoline-to-aromatics plant as well as reviewing the potential for ADNOC to supply LNG to Rongsheng for use within its own complexes in China.

Rongsheng’s chairman Li Shuirong added that the cooperation will ensure that its project, which will have a refining capacity of up to 1 million bbl/day of crude oil, has adequate supplies of feedstock.

Saudi Aramco today signed three Memoranda of Understanding (MoUs) aimed at expanding its downstream presence in the Zhejiang province, one of the most developed regions in China. The company aims to acquire a 9% stake in Zhejiang Petrochemical’s 800,000 barrels per day integrated refinery and petrochemical complex, located in the city of Zhoushan.

The first agreement was signed with the Zhoushan government to acquire its 9% stake in the project. The second agreement was signed with Rongsheng Petrochemical, Juhua Group, and Tongkun Group, who are the other shareholders of Zhejiang Petrochemical. Saudi Aramco’s involvement in the project will come with a long-term crude supply agreement and the ability to utilize Zhejiang Petrochemical’s large crude oil storage facility to serve its customers in the Asian region.

Phase I of the project will include a newly built 400,000 barrels per day refinery with a 1.4 mmtpa ethylene cracker unit, and a 5.2 mmtpa Aromatics unit. Phase II will see a 400,000 barrels per day refinery expansion, which will include deeper chemical integration than Phase I.

ZHOUSHAN, China/SINGAPORE (Reuters) - State oil giant Saudi Aramco signed an agreement on Thursday to invest in a refinery-petrochemical project in eastern China, part of its strategy to expand in downstream operations globally.

The memorandum of understanding between the company and Zhejiang province included plans to invest in a new refinery and co-operate in crude oil supply, storage and trading, according to details released by the Zhoushan government after a signing ceremony in the city south of Shanghai.

Zhejiang Petrochemical, 51 percent owned by textile giant Zhejiang Rongsheng Holding Group, is building a 400,000-barrels-per-day refinery and associated petrochemical facilities that was expected to start operations by the end of this year.

Aramco also owns part of the Fujian refinery-petrochemical plant with Sinopec and Exxon Mobil Corp, and has plans to build a 300,000-bpd refinery with China"s Norinco. It is also in talks with PetroChina to invest in a refinery in Yunnan.

The 400,000 barrels-per-day oil refinery will be accompanied by two ethylene plants. It will also include an oleflex propane dehydrogenation unit, which is expected to produce 600,000t of polymer-grade propylene.

The integrated refinery and petrochemical project is expected to produce more than 20 petrochemical products such as gasoline, diesel, jet coal, paraxylene, high-end polyolefin, and polycarbonate. Aromatics for plastic resins, films, and fibers will be produced in the first phase, using Honeywell"s UOP technology.

The refinery will utilize three UOP Unicracking process units to convert vacuum gas oil and distillate into petrochemical feedstock. The phase will also include production facilities for aromatics and blend stocks along with normal butane.

8613371530291

8613371530291