zhejiang rongsheng holding group co ltd free sample

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

© 2023 Fortune Media IP Limited. All Rights Reserved. Use of this site constitutes acceptance of our Terms of Use and Privacy Policy | CA Notice at Collection and Privacy Notice | Do Not Sell/Share My Personal Information | Ad Choices

FORTUNE is a trademark of Fortune Media IP Limited, registered in the U.S. and other countries. FORTUNE may receive compensation for some links to products and services on this website. Offers may be subject to change without notice.

S&P Index data is the property of Chicago Mercantile Exchange Inc. and its licensors. All rights reserved. Terms & Conditions. Powered and implemented by Interactive Data Managed Solutions.

This company operates as a holding firm for a group of subsidiaries engaged in polyester, spinning, false-twisting, coal chemicals, real estate, venture investment business activities. It was incorporated in 2006 and has its registered office in Hangzhou, China. As a holding company, it handles the administrative affairs and services and grants management services to its subsidiaries, as well as provides financial support and control function for the board. Furthermore, the firm is responsible for managing the group and its overall legal structure, tax planning, financial and equity structures. It is also in -charge in various matters relating to policy, strategic planning, marketing, selecting and manning senior management positions, approving investments and budgets, and the overall ongoing monitoring of the group"s performance.

Although many capital projects suffered setbacks and delays during the COVID-19 pandemic, new refining and petrochemicals capacity additions are being built around the world. These projects are enabling refiners and petrochemicals producers to satisfy increasing demand for clean transportation fuels and petrochemical products.

Using Gulf Energy Information’s Global Energy Infrastructure database, the editors of Hydrocarbon Processing have selected 11 nominees for the 2021 Top Projects awards. The winners and nominees of this prestigious award will have a considerable impact on the hydrocarbon processing industry, whether though capital cost, satisfying domestic or regional demand, diversifying product offerings, increasing operational efficiency, mitigating emissions and increasing energy efficiency, and/or producing cleaner fuels and petrochemical products. The winners of this prestigious award over the past several years have included:

The 11 projects nominated this year span the globe and represent nearly $76 B in capital investments. Once completed, the nominees’ facilities will add more than 2.1 MMbpd of additional refining capacity and a significant amount of new petrochemicals production capacity—more than 5 MMtpy of ethylene capacity, 9.5 MMtpy of ethylene derivatives capacity and nearly 8 MMtpy of aromatics capacity.

The more than $7-B complex is being developed by Gulf Coast Growth Ventures, a JV between ExxonMobil and SABIC. The facility, located in San Patricio, Texas, will consist of a 1.8-MMtpy ethane cracker that will feed a 1.1-MMtpy monoethylene glycol unit and two PE units, with a total installed capacity of 1.3 MMtpy.

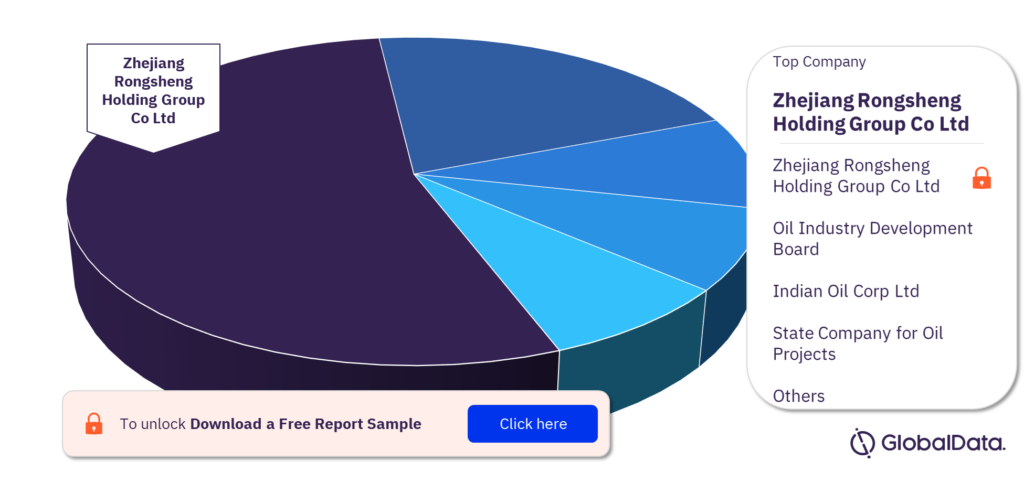

Zhejiang Petrochemical Co. Ltd.—a JV of Zhejiang Rongsheng Holding Group Co. Ltd., Juhua Group Corp., Tongkun Group Co. Ltd. and Zhoushan Marine Comprehensive Development Investment Co. Ltd.—is building one of the largest integrated facilities in the world. The integrated refining and petrochemical complex is being built approximately 280 km south of Shanghai on Zhoushan Island.

The $24-B mega-complex will be built in two phases. Phase 1 includes the construction of a 400,000-bpd refinery, a 5.2-MMtpy aromatics complex, a 4-MMtpy PX plant, a 600,000-tpy PDH unit and a 1.4-MMtpy ethylene plant. Additional processing units will produce derivatives such as PE, PP, ethylene oxide, ethylene glycol and ethylene vinyl acetate. Phase 1 was completed in 2019. Phase 2, scheduled to be completed in 2021, will double the size of the plant—total refining capacity could top 800,000 bpd, with production of aromatics, ethylene and PX doubling to 10.4 MMtpy, 2.8 MMtpy and 8 MMtpy, respectively. The facility is part of China’s goal to mitigate imports and produce more raw materials for downstream processing.

PetroChina is investing more than $10 B to build a refining and integrated complex in Jieyang. The capital-intensive project includes the construction of a 400,000-bpd refinery that will provide feedstock for integrated petrochemical units. The petrochemical units will produce 1.2-MMtpy of ethylene and 2.6-MMtpy of aromatics. Operations are scheduled to begin around mid-2022.

Earlier this year, Bayport Polymers—a JV between Total Energies and Borealis—started operations on a 1-MMtpy ethane cracker in Port Arthur, Texas. The plant will produce ethylene feedstock for a 625,000-tpy PE unit being developed in Pasadena, Texas. The PE site is scheduled to begin operations in early 2022. The total cost of the joint project is approximately $1.7 B.

The $2.6-B, two-phase project is part of the country’s development program to process natural gas from Kazakhstan’s Tengiz field into high-value petrochemical products. The integrated complex is being built in Kazakhstan’s National Industrial Technopark in the country’s Atyrau region. Phase 1 includes the construction of a nearly 630,000-tpy propane dehydrogenation unit to produce 500,000 tpy of PP. Phase 2 includes the construction of a gas separation plant to supply ethane to a downstream 1.25-MMtpy PE unit. Phase 1 of the complex is scheduled to begin operations in 1Q 2022. At the time of this publication, the ethane cracker and derivative units were scheduled to begin operations by the end of the year.

Inter Pipeline is investing approximately $4 B in Canada’s first integrated propane dehydrogenation (PDH)/PP complex. The plant will process 22,000 bpd of locally-sourced propane to produce 525,000 tpy of PP. The project will use technology from Honeywell UOP and W. R. Grace. Fluor was responsible for detailed engineering and procurement, and Kiewit is the primary constructor on the project. Operations are scheduled to begin in early 2022.

BAPCO’s Modernization Program (BMP) is one of the largest projects to ever be conducted in Bahrain. According to BAPCO, the more than $6-B BMP will increase refining capacity from 267,000 bpd to 380,000 bpd, improve crude processing flexibility, increase energy efficiency, reduce emissions and enable BAPCO to produce ultra-low-sulfur transportation fuels. The project includes the construction of 21 new operating units, upgrades to several units and the decommissioning of older, less-efficient units. The project is a major initiative of Bahrain’s Vision 2030 program, which is a comprehensive roadmap to increase economic activity in the country.

Nigerian business mogul Aliko Dangote plans to construct the largest privately-owned refinery in Africa. The Dangote Industries Ltd. (DIL) integrated complex will be constructed in Lekki, Lagos State, Nigeria, and will include a petrochemical complex and fertilizer facility. The project will be the first of its kind in Nigeria.

The primary objective of the project is to supply the local market and reduce refined fuel imports. The new DIL refinery will help mitigate a substantial portion of imports and help satisfy a large portion of domestic demand. The complex is scheduled to begin operations in late 2019; however, some industry reports peg the completion date to be closer to 2022.

The more than $10.4-B integrated complex consists of a 320,000-bpd refinery and integrated petrochemicals production complex. In addition of producing ultra-low-sulfur fuels, the refinery will provide feedstock for the integrated petrochemicals production units. These units will produce 1.1 MMtpy of ethylene and 2.8 MMtpy of aromatics. Commercial operations are expected to begin in 1Q 2022.

The nearly $7-B project is being developed by OQ8, a JV between OQ Group and Kuwait Petroleum International. The project, which is the cornerstone of the Duqm Special Economic Zone, consists of a 230,000-bpd full conversion hydrocracking/coking refinery and petrochemicals complex. The refinery is scheduled to be completed in 2022, followed by the petrochemicals complex in 2025. The petrochemicals complex includes a 1.6-MMtpy ethylene plant, a 280,000-tpy PP plant, a 480,000-tpy HDPE plant and an aromatics plant.

Diamond Green Diesel, a JV between Darling Ingredients and Valero, are investing approximately $1.1 B to expand its renewable diesel plant in Norco, Louisiana. The scope of work includes adding a second unit that will more than double the plant’s production capacity to 675 MMgpy. The plant will use Econfining technology, a proprietary process developed by Honeywell UOP and Eni SpA, to process inedible oil and waste feedstocks into renewable diesel. The 400-MMgpy expansion project is expected to be completed by the end of the year.

The startup took only about three days to complete. The liquids ethylene cracker is part of ZPC’s grassroots integrated refining and petrochemical complex which broke ground in 2016.

In addition to the ethylene cracker technology, TechnipFMC provided key proprietary technology components including a Heat Integrated Rectifier System, Ripple Trays and Wet Air Oxidation process. TechnipFMC’s Ultra Selective Conversion (USC®) U-coil ethylene technology is preferred for its high energy efficiency and high yields.

Stan Knez, President of TechnipFMC Process Technology, commented: “We are very pleased with the successful startup of the ZPC cracker. This is a great milestone for the complex and another example of our proven ethylene technology”.

(1) ZPC: Zhejiang Petroleum & Chemical Co., Ltd, established in Zhoushan, Zhejiang on June 18, 2015, is a mixed-ownership enterprise jointly formed by the private enterprise Rongsheng Petrochemical Co., Ltd.(holding 51% of shares), provincial state-owned enterprise Zhejiang Juhua Investment Co., Ltd.(holding 20% of shares), the private enterprises Zhejiang Tongkun Investment Co., Ltd.(holding 20% of shares) and Zhoushan Marine Comprehensive Development and Investment Co., Ltd.(holding 9% of shares), which will be the first kind of mixing economy enterprise in China in the Refinery and Petrochemical Industry. ZPC’s first phase project includes 20 million tons per year refinery and 1400 KTA Ethylene Complex.

8613371530291

8613371530291