haas 5th axis rotary table brands

With the UMC-750, we’re building five sides of the part which allows us to get to five out of those six sides that we need to build. There’s also 5-axis work that needs to be done. In that part, there are ledges with radiuses in between that you can’t build without the 5-axis capability.

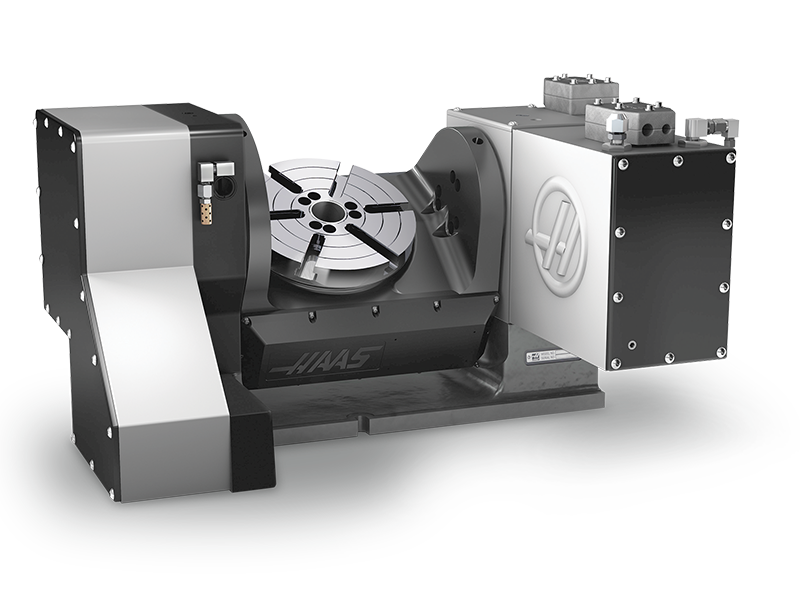

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater mounting flexibility than its predecessor. We’ve completely redesigned the TRT160 to create a much more compact and versatile 5-axis solution for smaller mills, including Haas Mini Mills and Toolroom Mills. The new unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises.

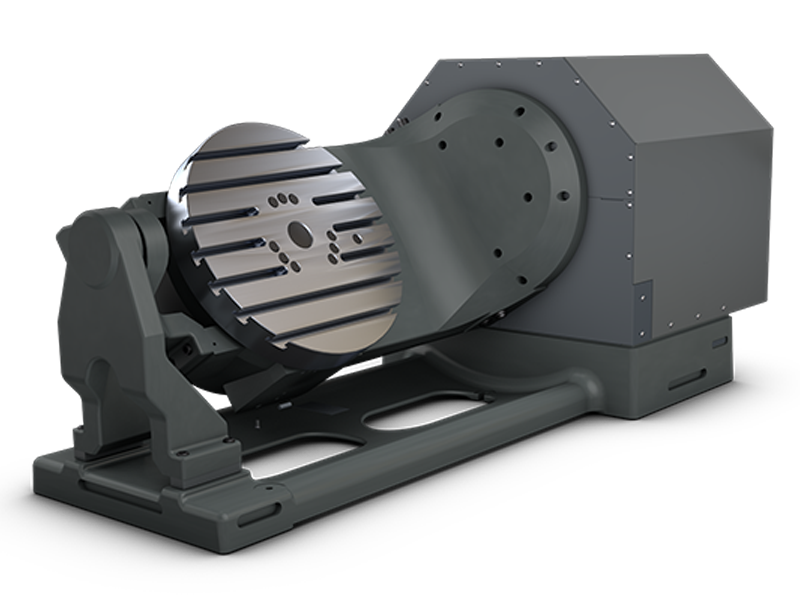

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater mounting flexibility ...

... more compact and versatile 5-axis solution for mid-size mills. The new unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises.

... 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version NGC 100.18.000.1030 or later to work with DWO/TCPC option. Consult your local ...

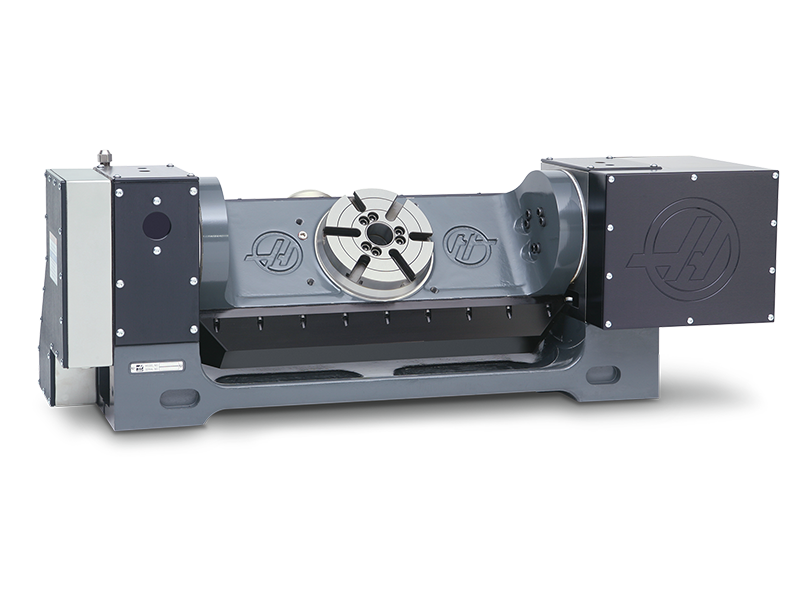

The TR160 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. Scale ...

The TR160-2 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. The ...

... installed with the tilt axis parallel to the Y axis on VF-3 and larger VF Series machines, to allow more usable mill table space (extended Z-axis clearance options are ...

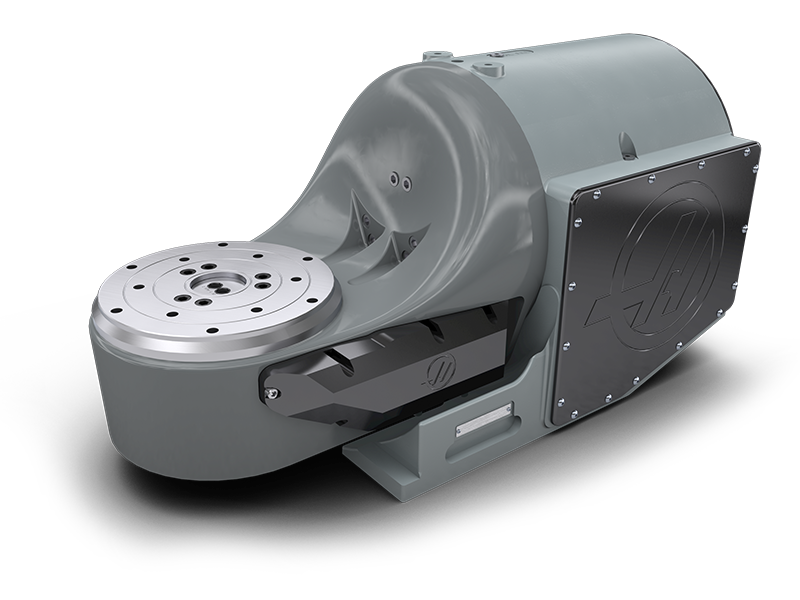

The TR210 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of medium to large parts. Scale ...

The TR310 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of medium to large parts. Scale ...

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater ...

... more compact and versatile 5-axis solution for mid-size mills. The new unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises. ...

The new designed rotary swivel unit RT2A is the ideal solution for retrofitting your machine with a 4th and 5th axis. It is based on the proven and robust rotary tables ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version M18.24B or later. Not available for stand-alone operation.

5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Dual-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Triple-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

Quad-Spindle 5C Collet Tilting 2-Axis Rotary. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

210 mm (8.3") Tilting 2-Axis Rotary Table. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Requires a Haas mill with software version 18.00 or later.

210 mm (8.27") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

310 mm (12.2") Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th-and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

"twitter:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

"og:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

The fastest way to increase the productivity of your Haas mill is to add a Haas single or dual-axis rotary product. You can reduce or totally eliminate multiple setups, and easily handle machining multi-sided parts.

With a full line of Haas rotary products, including many specialised units designed for maximum productivity, Haas continues to lead the way to higher productivity through automation.

All Haas rotary products are designed to integrate seamlessly with the control on your Haas mill. This means true simultaneous 4-axis or 5-axis motion, synchronized with the axes of your mill. Rotary setup is a simple plug-and-play process through the Haas Control, with on-screen instructions, and diagrams that are intuitive and easy to use. It’s possible to install a Haas rotary on other makes of mill as we also offer the Haas Servo Control. Activated by a single M-code, the Servo Control is easy to set up, and fully programmable.

Adding a rotary axis to your CNC mill is the fastest way to boost throughput and increase accuracy. Because Haas began as a rotary table manufacturer in the 1980s, we are able to provide the simplest and most cost-effective entry into 4-axis and 5-axis machining available.

Going from 3-axis machining to 4-axis and 5-axis machining can be intimidating. This short video shows how easy it is to transition from basic 3-axis milling to full 5-axis design and production.

Haas offers a wide selection workholding solutions for your 4-axis and 5-axis clamping needs, from compact air-collet closers to quick-change fixture plates to manual scroll chucks.

Constructed of heavy-duty materials and designed for dependable day-in, day-out operation, Haas rotary products are the benchmark by which all others are measured. We manufacture all critical components in-house at our state-of-the-art California facility. At the core of every Haas rotary table is a large-diameter, aluminium-bronze worm gear meshing with a ground alloy steel worm (hardened to 60 Rc) submerged in a synthetic oil bath.

Buying a multi-axis CNC milling machine like a 5 axis CNC machine is similar to choosing a car make and model. You will base your decision on the intended use, budget and personality along with many other considerations. The garage of options for 5-axis CNCs is equivalent to a garage of race cars, all-terrain vehicles, buses, and luxury cars. There are more general purpose machines and then there are used 5-axis CNC machines made for specific applications. Smaller shops often start 5-axis machining by adding a single or dual rotary to an existing 3-axis vertical machining center.

Machinists often find that they can begin the learning process for making more complex parts with the addition of a single or dual-rotary unit. You may have started in this area of developing your expertise and now find that more quote opportunities are coming in for even more complex parts which have higher profit margins. This is a great time to buy your first used 5-axis CNC milling machine!

There are many reasons now more than ever why machine shops are replacing their current machines with 5-axis CNC milling machines. Here are a few of the top reasons that drive machine shop owners to add or replace older machines with 5-axis CNC machines:

The business case can be made for replacing standard 3-axis parts machining with 5-axis CNC machining based on both the setup and cycle time improvements. In one example by Hurco, one part that took 7 operations and 5 hours 30 minutes to setup on a standard 3 axis CNC machine needed only 2 operations and 1 hour 30 minutes to setup on a 5-axis machine. The cycle time for that same part also went down by over 30%. If a machine is running, it"s not making money. This kind of savings can quickly improve ROI.

When you buy a used 5-axis CNC machine, you are increasing the complexity of parts that you can make. Some shops like work that others consider to be too difficult. If your company loves to learn from every challenge and become better with each job, this strategy can pay great dividends. 5-axis machining is great for the complex work and shorter running jobs. Your 5-axis machine should be flexible, precise and adaptable for the challenges. Many used 5-axis machines have a swivel head that can articulate cuts in almost every direction.

5-axis CNC machines are built to last. Similar to buying a car, newer years might have some special features, but if you dont need those features, then why buy them? A solid used CNC 5-axis for sale should be able to reliably make parts for many years. The software can be upgraded, sensors can be added, skins on controls can be replaced and the machine will continue to make parts. You can find great bargains on 5-axis CNC machines for sale in our listings.

5-axis CNC machining can do what other machines can do, but machines like Swiss lathes, vertical machining centers and other 3-axis mills cannot do everything that a 5-axis CNC machining center can do. This makes the 5-axis CNC one of the most versatile pieces of equipment that you can buy. Combined with the power of modern CAD/CAM software, you can make a wide range of parts with one piece of equipment.

Buying a 5-axis CNC milling machine gives your operators the opportunity to grow in their abilities to make more complex parts. Parts that you may not want to quote today will become possible as your machinists become accustomed to a new way of thinking about machining.

When a used 5-axis CNC is setup in a work center to allow for automated material loading and parts unloading, it can run unattended with as much as 95% spindle utilization. Compared to other types of milling like vertical machining centers and horizontal machining centers, you get more production simply because the 5-axis machine spindles are running more consistently.

When deciding on the type of used 5-axis machine to purchase, key factors to consider will be part complexity, part mix and the average number of parts to be run per setup. For example, parts that can be made on a 3-axis machine may actually be a better fit on a 5-axis because of a quicker setup on a machine with tools already available on a tool changer. Major options for used 5-axis CNCs include the rotary type and trunnion table type.Part Complexity: Do you want to machine complex parts? Consider the differences between trunnion and swivel head style machines and the table tilting and rotation travel for the A-axis and C-axis. Also consider the number of tool slots available in the tool changer the more stations, the more complexity in one setup.

Physical Size: Youll want to consider the physical size of your used CNC 5-axis machine. This will be dictated by the size of parts that will be machined and the amount of room on your shop floor. Then youll need to determine the rigidity by thinking about the types of materials that you will be machining. Keep in mind that some multi-axis machines are better than others for particular applications. It will be helpful to learn if a particular used CNC machine was used in a similar application before.

We have for sale used 5-axis CNC machining centers with trunnion tables. A few benefits of choosing a trunnion style trunnion table on your 5-axis CNC machine include a better under-cut capability, larger work volume and more torque at low RPM. As compared with a swivel rotate machine which typically is limited to 90 degrees of the head in any direction, a trunnion table allows more than 90 degrees of rotation.

This makes it possible to reach up under a flange, under the edge of a part, or machine an angle hole that points down under the table. Since the part is under the spindle"s Z-axis and the spindle is always vertical, once a workpiece is clamped down you have the full travel of the X and Y as the machining envelope. As compared to a swivel head machining center, there is more torque at lower RPMs on a 5-axis with a trunnion table.

We have used 5-axis CNC machines with swivel heads. A few benefits of choosing a swivel head machine over a trunnion include the ability to run heavier parts, more versatility and fewer tool interference issues. On a trunnion style machine, the part is always rotating and twisting within the work envelope which limits the weight capacity that the axis can handle. Since the table rotates more like a standard 3-axis machine on a 5-axis machining center with a swivel head, the table can handle heavier parts because of better weight distribution.

Often swivel rotate used 5-axis CNC machines have much greater versatility than the trunnion because of table space on the side which allows for some fixturing, 3-axis work, or even 4th axis work using the tilting head. On trunnion table 5-axis CNC, when the part tilts towards the operator, the bottom of the head casting and the trunnion itself which can impede making smaller type parts as compared to the swivel. Standard length tooling works well on swivel rotate machining centers where often longer tooling is needed for trunnion table style 5-axis machines.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

8613371530291

8613371530291