velmex rotary table supplier

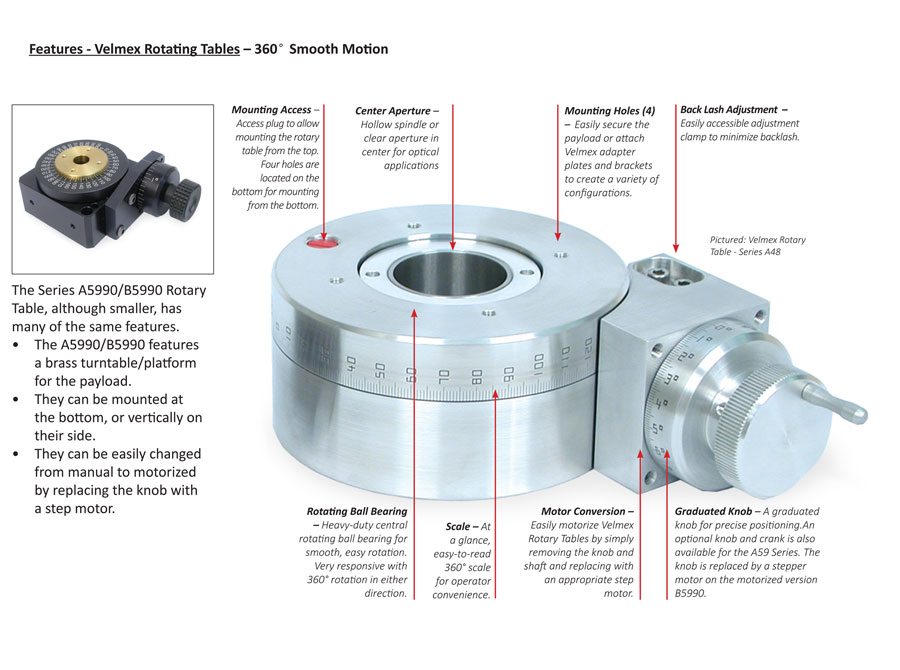

Velmex offers two series of Rotating Tables – the A4800 in three different gear ratios (18:1, 36:1 and 72:1) and the A5990 with a 90:1 gear ratio. The A4800 Series of Rotary Tables has a load capacity up to 200 lbs. (90.7 kg.) horizontally and 25 lbs. (11.3 kg.) vertically. The A5900 can handle 50 lbs. (22.6 kg.) horizontally and 5 lbs. (2.3 kg.) vertically. They easily integrate with Velmex UniSlides®, BiSlides® and XSlides™ in a array of configurations.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Since 1967, Velmex, Inc. has manufactured linear and rotary motion-control positioning systems for scientific, research, machining, instrumentation and industrial applications. Velmex produces UniSlide®, BiSlide® and XSlide™ manual and motor-driven stages; manual and motor-driven XY tables, rotary tables, elevating tables and turntables; as well as, VXM™ motor controls and VRO™ encoder readouts - all, American-made. All providing a variety of precise, yet simple, modular configurations to satisfy a broad range of positioning applications where high precision and value are essential. Common applications include manufacturing, research, automation and prototyping. Services provided include custom machining and controller integration.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

You would use an elevating table when you require free standing vertical travel with a platform shelf. The Velmex Elevating Tables are more rigid then turning a linear stage into a vertical axis, making them more stable. However, if you do want longer travel distance or a narrower or wider frame, almost all Velmex linear stages can be converted to an elevating table with the addition of a base plate and a platform shelf. They can be engineered to provide added rigidity, support and stability.

Velmex Elevating Tables are made of Velmex world renown UniSlide assemblies. They use a deeper base under the dovetail ways for added support and feature an oversize base for added stability in the vertical position. A right angle platform is mounted to the carriage that can be mounted in the inverse to add versatility to the travel envelope.

Lubrication is important for motion systems or wherever you want maximum life and the lowest friction. UniSlide Assemblies can be lubricated with Velmex Lubriplate Aero®. Only a few drops are required to keep your slide running smoothly. The load and hours of use effect the amount and frequency of lubrication. See the user guide that came with your UniSlide for recommendations.

Yes, UniSlides can be mounted together in XY, XZ, XYZ configurations. Mounting UniSlide assemblies in multi-axis systems requires the use of adapter plates and brackets. They also can be combined with Velmex Rotary Tables and our other linear stages to make custom systems to meet a wide range of applications. See UniSlide Options and Accessories for more information on the plates and adapters. Also see our examples pages for images featuring Elevating Tables combined with other Velmex products.

Velmex slides, stages and tables are available in manual or motor-driven configurations. Standard “off-the-shelf” sizes are built-to-order to the customer"s required configuration specifications. Custom sizes and configurations are also available. No minimum or maximum quantity requirements.

Cross Sections – The cross sections of the Velmex linear stages are a key differentiation. While the three Velmex linear stages all have bases with dovetail ways, they each have a different cross-section profile. (images above) The sliders (carriages) each ride on the ways differently.

Velmex UniSlide® Assemblies are available in a variety of configurations, models and sizes including Linear Slide Assemblies, Elevating Tables and XY Tables. All available as manually-operated or motor-driven stages. Linear UniSlides have a load capacity up to 400 lbs horizontally and 100 lbs vertically with travel distances to 42". UniSlide Elevating Tables and XY Tables can lift up to 100 lbs.

Velmex BiSlide® Assembly"s modular design makes it highly configurable for a multitude of different motion-control applications. A several models including free motion and lead-screw available both manually-operated and motor-driven. BiSlide Assemblies have a load capacity of 300 lbs. horizontally. BiSlide configurations come in travel lengths up to 80". The Belt-Drive BiSlide can travel 228".

Velmex offers several pre-configured specialized BiSlide systems including the Side Knob BiSlide, Parallel-coupled BiSlides and Belt-Driven BiSlides.

XSlide™ is a compact positioning stage for smaller loads and ideal for limited space applications, highly suitable for either high performance incrementing or scanning functions.

Robust, fast and smooth turning performance from Velmex Rotary Tables and Turntables. Two sizes of rotary tables with varying gear ratios are available both manually-operated and motor-driven. The largest Rotary Table has a load capacity up to 200 lbs.

Velmex offers a number of it"s stages already pre-configured for specific applications. These include UniSlide XY and Elevating Tables with large bases and payload plates. Also available is our globally-recognized Tree Ring Measuring system using Velmex UniSlide® linear stages and our concrete void analyzing (Petrography) system using either UniSlide® or BiSlide® Assemblies.

Velmex Controls include VXM™ Controllers for easy control of single or multi-axis systems and VRO™ Readouts for ultra-precise position information. AC and DC motors; and linear, magentic and rotary encoders are also available.

Details on accessories, options and other components that are combined with Velmex devices to construct positioning systems that address your specific requirements.

The Turntables, which can be spun freely by hand are ideal for mounting and rotation of test specimens, cameras, transducers, sensors, and mirrors. They are a convenient, accurate method of quickly positioning or rotating a payload. They use a heavy-duty spring-loaded tangent screw drive for fine adjustments.

They feature a 12° range of fine position adjustment accomplished by tightening the clamping knob which engages the tangent screw driven against a spring-loaded yoke. Velmex offers two series of Turntables – the larger A4007TS with a 4.13 inch diameter (10.5 cm) and the smaller A2505TS with a 3.15 inch diameter (8 cm). Both can handle horizontally-centered loads up to 200 lbs. (90.7 kg.)

Both the A2505TS and the A4007TS Turntables have many of the same features. The Turntables are only manually-operated and cannot be motorized. For motorized rotating tables check out our Rotary Tables.

Typical applications for Velmex Turntables include mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components.

Velmex Turntables – Turntables can be spun freely into position by hand. Tightening the the clamping knob allows fine motion control. Turntables can be used horizontally. They are not recommended for vertical applications.

Factors such as size of the motor, size of the payload, travel distance, mounting direction/plane, etc. effect the actual capability of any assembly. Please contact Velmex Application Engineers to configure a system that will meet your exact requirements.

Adapter Plates– A variety of adapter plates mount the Turntables to other Velmex products like UniSlides® and BiSlides®. For additional information see Turntable Adapters.

The A2505TS Turntable can be mounted to UniSlides using the A2500 adapter plates and mounts directly on UniSlides with a S2.5, S3 or S4 slider / carriage.

The A4007TSTurntable can be mounted to UniSlides using the A2400 or A4000 adapter plates and mounts directly on UniSlide stages with a S4, S6 or S8 slider / carriage.

The majority of CAD drawings found in our Technical Library are Step (.stp) files. You will also see .dxf, .dwg, .sat and .pdf files. For .STP files, you may need to right click on the download button and save the "target" or "link". If you require a different format or cannot located the drawing you require, please contact us. Drawings are identified by the series/model part no. The number can be found on the side or end of any Velmex device you may already own.

These are examples of Velmex products. If you wish a similar product, please contact us with your specific application specifications (travel distance, payload, hours per day in use, resolution, speed range, etc.). You can use the Request Assistance form.

Pictured in our gallery are examples of configurations for manual Turntables, along with configurations that also include other Velmex products. Product and accessory offering is subject to change and availability.

If the top plate has been removed, it is possible the table wasn"t reassembled correctly or the half-moon locking pin that presses on the shaft to control the smooth motion is out of place or missing.

Yes, Turntables can be and are frequently combined with other slides, particularly UniSlides®, to achieve a particular motion or positioning. Which stage used in conjunction with the Turntable will determine which adapter plate or slider might be required.

Velmex Rotary Table Manual/Motor Replacement READ BEFORE PROCEEDING • • If you receive as a new unit, the worm adjustment has already been done at the factory. Please do not attempt to adjust again. If installing a motor on the unit, it is recommended the motor have two flats at 90° angles or it will be difficult to remove, if necessary, in the future. To convert an A5990 manual Rotary Table to a motorized B5990 Rotary Table: Conversion Instructions Refer to Diagram 1 1. Remove cover (if needed) from right side of table covering set screw access. 2. Look in opening to locate the two set screws. (May need to turn table slightly until screws visible.) 3. Loosen both set screws holding knob shaft. The screws are set at 90º, so the knob will have to be rotated to access the second screw. 4. Slide the complete knob assembly out of the shaft. 5. Remove the motor plate to base screws and remove the plate from the base. 6. Mount motor on to motor plate with 4 flat head mounting screws (4-40 thread x .500 long). 7. Slide motor shaft into drive shaft with the flats positioned against the set screws. 9. Reposition and tighten the two motor plate mounting screws. 10. Tighten the one set screw that should be visible through the motor coupling access. 11. Run motor to move 2nd set screw in place so that it is visible in the motor coupling access. 12. Tighten 2nd set screw. Motor to plate mounting screws (4) Set screw access. Drive shaft Drive shaft Motor plate to base screws Motor plate to base screws 7550 State Routes 5 & 20 Bloomfield, NY 14469-9389 www.velmex.com info@velmex.com Positioning Systems for Science and Industry Page 1

Manufacturer of standard and custom linear and rotary motion-control positioning equipment for scientific, research, machining and industrial applications. Products include manual, lead screw and electric motor driven mechanical slides, stages and actuators. Includes x-y, positioning, rotary, elevating, micrometer, pan and tilt, motorized, indexing and scanning tables. Slides include anti-friction, motorized, dovetail, electric, instrument, lead screw and linear slides. Systems include AC and DC motors and controllers, adapter plates. Machine bases and frames are available.

Velmex, Inc. is a premier US manufacturer of standard and custom linear and rotary motion-control and positioning equipment for scientific, research, machining, instrumentation and industrial industries. Established in 1967, Velmex manufactures UniSlide®, BiSlide® and XSlide® manual and motor-driven assemblies; manual and motor-driven XY tables, rotary tables, elevating tables and turntables; as well as, VXM motor controls and VRO digital readouts. Velmex offers precise, modular-designed slides, stages and actuators available in a variety of configurations and a very broad range of sizes and payload capacities at reasonable cost. Velmex products are useful for precisely moving a probe, sensor, antenna, transducer, components or other objects. Common applications include light manufacturing, research, automation and prototyping.

Velmex offers thousands of configurations in simple single-axis slides to complex multi-axis systems. Velmex slides include anti-friction, dovetail, electric, lead screw and linear slides. Table configurations include X-Y and -Z positioning; rotary; elevating; micrometer; pan and tilt; indexing and scanning tables. Complete systems with motors, controls, adapter plates, frames, bases, software and additional options and accessories are available. Although a myriad of standard assemblies are offered, each is built to order to match the customer"s exact requirements. Velmex application engineering and R&D can be utilized to develop custom systems. Less

In addition, since rotary motion is often performed for the purpose of processing, measurement, or some other subsequent operation, the use of rotary tables by themselves is rare.

Rotation mechanisms used in chairs and other equipment are also classified as rotary stages in the broad sense of the term, so they are used not only in manufacturing but also in home applications.

A crossed roller bearing is a bearing structure in which rollers are arranged between the inner and outer rings. The rollers are arranged in a straight row with a 45° contact angle, enabling the back bearing structure of a ball bearing to be realized with a single row, and the structure is capable of receiving loads from multiple directions simultaneously. The rotary table and cross roller bearings can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the rotary table is directly related to the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads can be used in the fine-tuning rotation mechanism to obtain high positioning accuracy.

Manufacturer of standard and custom linear and rotary motion-control positioning equipment for scientific, research, machining and industrial applications. Velmex produces UniSlide®, BiSlide® and XSlide™ manual and motor-driven assemblies; manual and motor-driven XY tables, rotary tables, elevating tables and turntables; VXM™ motor controls and VRO™ digital readouts. Products include slides, stages and actuators in a variety of configurations and a broad range of sizes and payload capacities.

8613371530291

8613371530291