5 rotary table factory

The T25937 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual makes it easier to assemble and maintain your rotary table.

The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts for the rotary table may be available online and shipped from the Grizzly parts warehouse in Springfield, MO.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

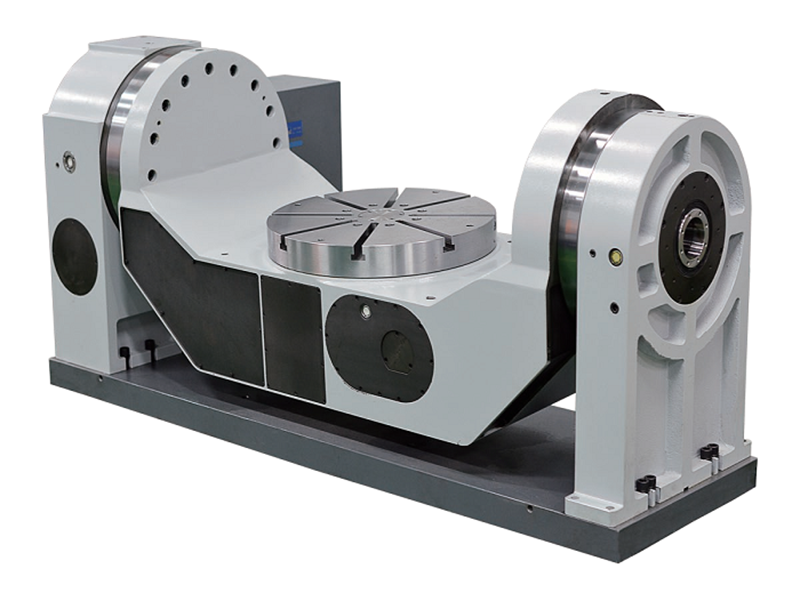

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

The rotary table tooling plate is just under 5-1/2″ in diameter and comes with a pattern of 10-32 holes in the surface to facilitate mounting fixtures for machining. Four countersunk holes are provided for mounting it to the T-slots in the Sherline rotary table, and mounting screws and T-nuts are included. The 1/2″ aluminum plate is made from aircraft grade 6061 T6 aluminum and can be drilled and tapped with additional holes as needed for your special jobs.

The pre-drilled holes are not tapped all the way through. This is to protect the surface of the rotary table from hold-down screws that might be too long. If when tightening a hold-down screw you feel it begin to bind, that means the screw is too long and you need to remove it and use a screw of the appropriate length.

For complex, repetitive measuring tasks, QC 2000 users can automatically record measuring programs to run at any time. This digital readout tracks presets, measurement sequence, tolerances, and data-output commands. When the recorded measuring program is repeated, the QC 2000 displays visual instructions for the features to be probed, giving direct, repeatable guidance.

Shars Tool offers a wide selection of horizontal & vertical rotary machining tables, tailstock, and rotary table with 3 jaw scroll chuck. Whether machining large or small workpieces, Shars has the machining table and dividing plates for your application. Place your order today!

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

TheRT4 4th Axis Rotary Table is a compact CNC rotary table offering rapid, zero backlash rotary motion using maintenance free Harmonic Reducers and Crossroller Bearings. It is engineered and built here in California with all aluminum and stainless steel construction.A rotary seal allows for operation with liquid coolant and an integrated Homing Switch provides a repeatable reference point. A number of different workholding accessories are available such as 3 and 4 jaw chucks, 5C collet chucks and two jaw chuck(see below accessories tab). This CNC 4th Axis can be purchased separately at anytime and is plug and play ready with any of MDA Precision’s CNC Milling machines.

If you would like to discuss your Rotary application with us please give us a call and we will be happy to help you determine which of our Rotary applications is best for you.

8613371530291

8613371530291