rotary table automation brands

The base and circular positioning tables are made out of anodized aluminium alloy. The self-locking spindle is made from steel and its slide bearing is maintenance-free. The table has ...

Unimec SA conceived these electric rotating tables for an integration in automatic rotating machines, for transport and assembly where precision and dynamism are asked.

... powdered sugar, cocoa powder, chocolate sprinkles, nuts or almonds, chocolate beans or pine nuts. whether turntables for manual or fully automatic sprinkling powder drums series PTR, the sprinkling of ...

This device also operates for the collection of single containers on the rotating table to prevent jam issues. In addition, this filled container collection system runs on a 380 ...

The turntable machine model R 703 from Krautzberger is used for the automated coating of small to midsize series of different work pieces. The preferred geometry of the parts is rotation-symmetrical.FunctionalityThe ...

Cam Indexer Technology is Sankyo Automation’s specialty. We’re continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision rotary indexing solutions are frequently utilized in manufacturing systems that require accurate, high speed actions.

Sankyo Automation is the worldwide leader in cam indexer technology; continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision cnc rotary tables are frequently utilized in manufacturing systems that require accurate, high speed actions.

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

... models is available to make the whole range of HMCs complete. The rotary tables dedicated to the Spark line match the 5000 kg max load with excellent dynamics whereas the hydrostatic tables ...

The tilting tables are designed and produced for 5-axis operations on complex work-pieces requiring accessibility to the most unreachable surfaces thus ensuring fast swarf removal at the same time.

Rotary Indexers & Servo Positioning Turntables for Robotic Work Cells Gate- CDS designs and manufactures precise work positioning systems for robotic welding cells and other advanced systems in automated manufacturing. These robust rotary positioning tables are utilized in robot work cells where around the clock 24/7 performance and reliability are a must. Gate- CDS indexing tables & servo turntables are designed to meet the heavy duty, high production demands of robotic welding work cells. We offer a wide range of different model sizes of Cylindrical Cam Driven or Servo Controlled Rotary positioners ranging in capacity from 200 pounds to 20,000+ pounds. The typical number of positional stations for a Cylindrical Cam Driven indexer include 2, 3, 4, 5, or 6 positions, with other numbers of stations also available as standard. Whereas our Servo Controlled Rotary Tables provide flexible positioning for any number of stations.

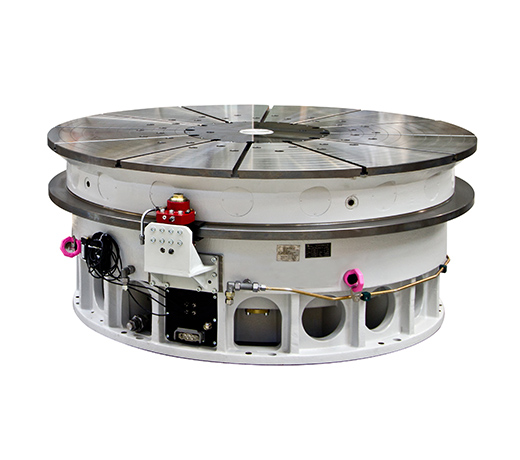

Boasting a 1300 mm footprint, the TO1300 suddenly makes larger scale applications possible that previously seemed out of reach− as current direct-drive tables are relatively small and limited to a diameter of 750 mm. Additionally the TO1300’s high-tech drive operates predominantly without mechanics or gearboxes.

For challenging tasks of this nature, a mechanical heavy duty table is typically the logical choice. Due to their gearing ratio, however, these tables don’t fare well in service life calculations for use at such high speeds as the needle bearings simply suffer from too much wear.

The correct alternative is a direct drive; which inspired the development of the TO1300. With a direct drive, only one bearing is under load which is virtually free of backlash. The table is low-wear and easily capable of delivering the desired dynamic performance requirements.

Unique to the TO1300 is that customers can customize it to their individual requirements. For example; they can make a modular selection between bearings, encoder and motor, and thereby alter the following table characteristics:

Configured in a uniquely robust design, the TO1300 offers new possiblities for high-speed automation applications such as: lighting, automotive, cleanroom, small gear assembly, switches/sockets, and electronic components.

A specialist in automation, WEISS also offers many sizes for the TO series direct-drive rotary indexing tables; ranging from small to very large. Optimal solutions for specific application challenges can be achieved from the series wide range of options. Each TO model is also available in a version with a cleanroom certificate.

Corporate Profile: An integral part of the Weiss global network, Weiss North America (ISO-9001 Certified) leverages over 45 years of reliable world-wide expertise to comprise an integrative, customer-specific approach to its vast array of electromechanical products. Our 100% vertical range of manufacturing ranges from rotary indexing tables, handling systems, and linear assembly systems−providing flexible technology for turnkey solutions that incorporate electronics, mechanical systems, software, and comprehensive engineering support. This enables us to provide pre-installed, intelligent, and highly convenient solutions for the entire field of kinematics.

Our rotary, tilt and carousel rotary tables set a clear mark due to the extremely robust design as well as a high level of precision in the micrometre range, speed and repeatability. A suitable solution can be designed for every application case. We speak with our customers about requirements and work pieces, which are to be processed on the rotary tables. We create the right solution based on our experience from more than 600 projects. Our high-precision rotary tables can withstand a bearing load of up to 500 tonnes. If such masses are being moved, this requires high torques. If these masses need to be accelerated quickly, then they need to be braked quickly, and they need to be precisely positioned with accurate repeatability.

Whether a hydrostatic linear or rotary axis, roller bearing axles or also a combination with both, we have all the solutions in our portfolio. Hydrostatic guides help to avoid wear surfaces, for example at very high loads, and the tables are thus suitable for processing with the highest requirements and the highest accuracy. The best damping properties allow for longer tool lives and high-precision work piece processing. The decisive factor for the durability and precision of the rotary tables is not only the possible loading, but the largest possible bearing diameter in relation to the worktop size. The machine bed itself is very compact and space-saving. It is well-protected under the steel cover. All the necessary regulation and control elements are easily accessible in an power box located in the rotary table. Thanks to the standardised, plug-in-ready interface, the rotary table can easily be connected to all machine tools.

In addition to rotary tables for positioning work pieces for milling work (also in interpolation operation), patented tilting tables with additional axes, for example, are among the repertoire. Due to the standard angular adjustment of up to 10°, these are suitable for milling large an heavy components and, for example, are used in wind energy technology. Pallet changing systems are used to automate machining centres due to the multiple pallets and the ability to set up during main working hours. Thanks to a powerful drive train design, our carousel rotary table achieves very high machining torques, which makes a very good machining performance possible. In addition to the milling, it is also possible to turn and grind work pieces.

For over 50 years, Pfiffner has been developing rotary transfer machines that offer high precision and flexibility, marketing the most cost-effective solutions for high-volume workpieces. Thanks to our solution-oriented approach, well-developed expertise in the market, and a passionate innovative spirit, we"ve established ourselves as a leading partner for innovative industry sectors all around the world. Our success is based on a clear vision: We always remain a leap ahead of the times, ensuring satisfied customers every single day.

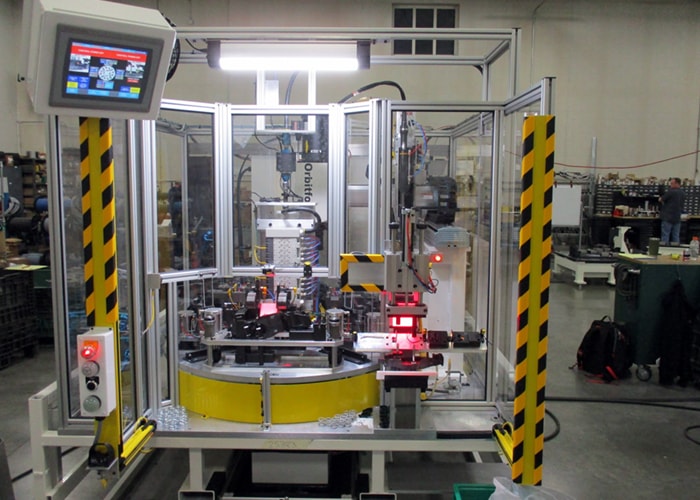

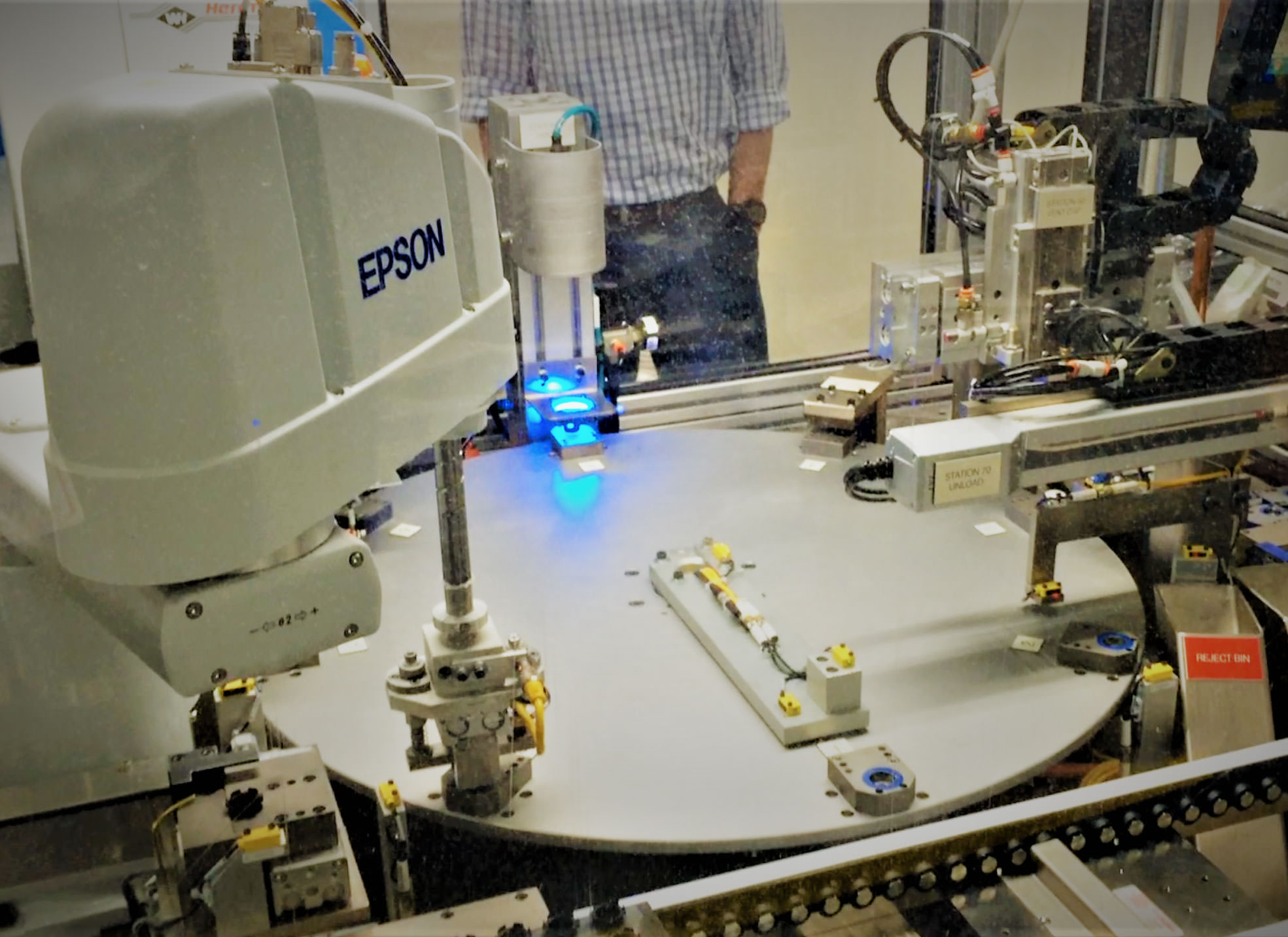

We’re able to create indexing machines for a wide range of industries, including yours. Ask our custom machine builders about trends in your industry. For example, we may recommend a rotary indexing machine for manufacturing medical devices or beverages.

We’re able to integrate indexing machines with industrial automation systems so each task blends seamlessly into the next. For example, we’ve created industrial automation systems that partner rotary indexing machines with pick-and-place units. As a custom machine builder, we carefully evaluate the context of how your indexing machines will be used so you can reap the most benefit for your investment.

Indexing tables are used in a multitude of industries and in numerous applications. Their design is optimal for many manufacturing jobs, and they are a critical component in most automated manufacturing systems. Indexing tables are best defined as a machine tool positioning device. They carry components in a manufacturing environment with a repeating process of indexing (rotating) around an axis, stopping, dwelling while an operation is performed, then indexing again to repeat the process. They are usually made of circular steel plates, with one or more spindles, a drive system, encoders, sensors, controllers and slots or mounting holes to hold components.

Virtually any manufacturing operation can be performed on a part held by an indexing table including welding, grinding, drilling, assembly, painting, inspection, testing and more. In order to maximize operational efficiency, the machine doing the operation must also be built for the same intended application as the indexing table for them to work in synch. Similarly the machine that loads the indexing table with parts must also be synchronized. They must have the same capacity and be able to manage to the same dwell time for the system to work.

Industries that use indexing tables include automotive manufacturers, bottling companies, microchip manufacturers, pharmaceutical makers, consumer products companies and many more. They are invaluable to manufacturers pushing for automation and increased efficiency in their factories, turning work that used to take days into work that takes only hours. If a simple assembly task is required on small parts in a factory, there is no better way to complete the task than by coupling an assembly tool and an indexing table.

8613371530291

8613371530291