arduino rotary table brands

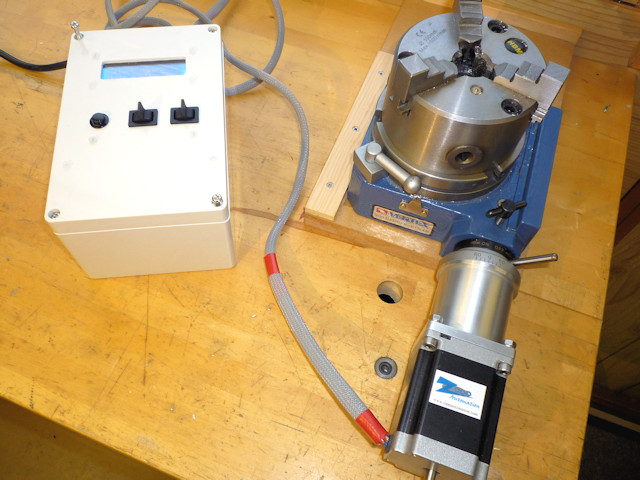

I recently read an article in Model Engineers Workshop Magazine (December 2016 issue 249) for adding a stepper motor drive to a rotary table. I don′t use my small Vertex rotary table very often but I thought this might be a useful project to learn a little about stepper motors and digital control of machinery. The article by Carl Wilson describes how to use an Arduino micro-controller to control the rotary division process. Much of the coding is contained in another article in Digital Machinist by Gary Liming. So no original thinking by me here, just a rehash of other engineers good work. All the links and useful information can be found in the Glossary at the end.

Prepping the table can be as simple as doing nothing, a complete strip down and re-build with thrust washers and the like or somewhere in between. There are a few articles on the web giving details (see glossary). Software setup and programming the Arduino is the quickest part and if you use Gary Liming′s software without alteration, the programming takes just a few seconds. Assembling the electronics is mainly about fitting the bits into the box and requires a bit of inginuity to fix things in place. The boards are fairly flimsy and things, like the display, tend not to be square or flat, I found.

The stepper motor mounting I made from three parts and assembled with Loctite and screws. I have no doubt there are other ways of making this or a suitable motor mount could be found ready made and adapted to fit the table. You will probably want to test things as you you go along rather than leave everything to the end. I discovered I had a faulty motor driver, easier to deal with whilst still uncased. I don′t think it makes makes any difference which order things are done.

This is covered elsewhere on the web in some detail so I have just made a few notes that may be of interest. Dismantling the table is quite straightforward, just look for allen headed grub screws at the bottom of deep holes. The notes refer to my 4" Vertex table.

Start off by removing the handle, the table locking clamps and the worm engagement lock. The handle is just one screw but watch out for the shaft key which is small and easily lost. Photo (2) shows the board I made to store the table with a cutout for the handle. The stepper motor will also need a similar storage solution. I used pliers and some cardboard to protect the finish to unscrew the table clamp handles. Remove the engagement lever and collar, two grub screws and it slides off, this is the part that the motor connector will attach to, it has three ready tapped holes for when used with division plates.

Remove the cam shaft securing and adjusting collar (4), four cap screws. Remove the grub screw that sets the worm engagement depth, found at the bottom of a deep hole (5). The worm shaft and cam bearing can now be removed as one unit, rotate the table and it will push the spindle out.

Turn the table upside down and remove the table bearing and adjustment plate (6), four cap screws. The table can now be removed, mine was pretty clean (7) not having been used much, there wasn′t even that much grease. Now that everything is apart it can all be cleaned re-greased and re-assembled. The worm drive shaft can be slid out of the cam adjuster by removing the collar, it is a ground shaft with an oilway and a very good fit in the cam adjuster.

Other than adjustment to remove backlash I didn′t make any changes to my rotary table, it was in fact pretty good before I started. If you have an older well used table it may take a bit more cleaning to remove old grease and any swarf that may have found it′s way inside.

Other parts worth note are the cam shaft retainer / bearing (4) and the table retainer / bearing (6). These both feature four cap screws which bolt the item in place and four grub screws which act as jack-screws to prevent clamping the rotating part. When reassembling it is worth adjusting these carefully to limit the table lifting whilst still turning freely and likewise to prevent the cam shaft moving in and out. I noticed with the table bearing / retainer that there was a noticeable stiff spot so it is worth rotating the table through a full 360° whilst adjusting. The cam shaft could be locked in place if you think there is no need to disengage the worm gear. Last bit is to set the worm engagement, this is controlled by a grub screw at the side (5) which engages with a slot in the cam shaft to prevent rotation. If you undo the grub screw and fully engage the worm it will be very difficult to turn, tighten the grub screw just enough so that the worm turns easily with a minimum of backlash.

Not much to this really but first you will need to go to the Arduino website and download the Integrated Development Environment (IDE) software. This is basically a fairly lightweight program that runs on your PC (Windows, Mac or Linux) and allows you to edit programs (sketches in Arduino speak) and upload to the Arduino board. You will also need to download Gary Liming′s software. Once the software is downloaded installation is straightforward. The Arduino IDE is self-installing from an exe file in Windows. Gary Liming′s programs come as a zip file which needs un-zipping to a folder. Once unzipped, double click on the "Stepindex23.ino" file and it will start the Arduino IDE and load the program.

All being well you should now have a screen like something like those above. Click on the image to read the text. Affix the LCD shield to the Uno making sure that all the pins are in the right places and none of the connectors is bent. Plug the Uno into the PC using a USB cable, often supplied with the board. The Uno will be powered by the USB connection. First thing to do is go to the "Tools" menu (10) and set the type of board. All being well the software should then report that it is talking to the Uno, bottom right of the IDE, something like "Arduino/Genuino UNO on COM4". You should also be able to click on the "Port" section of the menu to assign a COM port. If this isn′t working and the Port section is greyed out it may be driver related.

Arduino micro-controllers are mainly programmed using the C++ programming language or at least a subset of C++, so the programs are fairly understandable for basic editing. The first few lines of the program (11) are used to set parameters used later. These can be adjusted now, the program is well commented, or left until later when everything is assembled. You may wish to alter gear ratios or even remove some items. There is more help in the readme files that come in the program zip-file. If you are a C++ programmer the world is your oyster, the menu items can be moved around or even removed if you don′t need a particular function. You may wish to experiment with some of the delay timings to help de-bounce the keys but this is probably better done during final testing.

The parts are shown (12) above and are the Arduino Uno, the LCD shield, the cable gland, TB6560 stepper driver, switches, plug, socket and power supply. The circuit boards are all pretty flimsy and the mounting holes are very close to the edges. The LCD shield has a seperate smaller board for the LCD soldered on top and the two boards were not particularly parallel. There is also a multi-turn variable resistor on the board which cunningly sticks up higher than the LCD face. If you are adept with a soldering iron it can be re-positioned on the other side of the PCB. I solved the non-flush pot problem by using a 1.5mm clear polycarbonate sheet between the box lid and LCD with a small cutout for the variable resistor.

I fitted as much as I could to the box lid, only the mains in and stepper out are fitted to the box. The display needs a cutout in the lid as do the three switches and a number of 3mm holes for various mounting screws. Once I had worked out the position of all the bits I marked the inside of the box lid for the position of the LCD and switch cutouts. I set this up on the mill and used a 5mm slot drill to remove the cutouts, the ABS machines very easily. I fixed the lid to an off-cut of MDF with woodscrews through the mounting holes, I also used double sided tape to make sure nothing moved. A couple of T-nuts and studs fixed the MDF to the mill table (13). With hindsight the double sided tape was overkill, it took me longer to get it off the lid than it did to do the machining. The corners of the switch cutouts I filed square, I drilled the various mounting bolt holes by hand as I did for the other round holes opening them up as necessary with a taper reamer and file.

I made the two flat plates and then fitted the motor, flexible coupling and rotary table together to measure the shortest length of tube that would work. The dimensions for the motor mounting plate were copied from the motor spec sheet.

I used another bit of 3" x ¼" bar to turn the plate that bolts to the rotary table. I drilled a 10mm hole in the centre of the plate and used a length of studding to hold it (22). The studding has two nuts locked to it which fit against the back of the chuck jaws and a nut and washer clamp the plate against the front of the jaws, there is a centre in the outboard end of the studding for support. I used a trepanning tool to remove the corners and then turned the O.D. to to size.

When the R.T. mounting plate is the correct diameter add a step 3mm deep with 38.1mm diameter to create a short spigot to fit the tube bore. Remove from the mandrel (studding) and mount holding the just turned spigot (23), bore out the centre hole to 21mm to fit the R.T. collar. To finish this part it need the three mounting holes drilled to match the table. I clamped the table index ring to the plate, they should be the same diameter, then spotted through with a drill that just cleared the threads in the index ring. Unclamp and drill the holes 5mm, there is no other alignment so keep the holes small, don"t use an M5 clearance drill.

The three parts are "glued" together, I used Loctite 603 which is a high strength oil tolerant retainer. Check alignment before joining, it will depend on the orientation of the holes in the index collar on the R.T. probably easier to join the tube to the table end first and then bolt it in place. The motor mount can then be aligned so that it is square when in use. I had an interesting experience when I first tried assembly. applied the Loctite placed suitable weight on top and left overnight. The following day removed the weight picked it up and it came apart. Apparently Loctite "goes off" still mine was a few years old! If you want to add screws it is probably easier to do this after assembly, I used 3 M3 C/S screws in each end, a bit belt and braces as either screws or adhesive alone will probably do the job.

Not much to this really, first bolt the connector to the rotary table. Slide in the flexible coupling and tighten onto the table drive, I aligned it so that the grub screw would tighten into the keyway. Fit the motor using four M5 capscews, nuts and shakeproof washers. Tighten the coupling onto the motor shaft and thats the mechanical bit done.

To test I went through each menu item in turn and made sure it did what it was supposed to. I discovered that clockwise and anti-clockwise were reversed but this can be adjusted in the software. I also discovered that I had wired one switch back to front and needed to reverse the leads fortunately just swapping a couple of push on connectors. Found that the motor vibrated rather heavily, haven′t got to the cause of that yet. I also set the table to zero on it′s scale and checked that the angle turned matched what the display said for a full 360° - it did.

With a bit of work on the software, to slow the motor down, I don′t see why the table could not be operated under power, to mill say a semi-circular slot. WIll also need a bit of work on the switch de-bounce software for this to ensure reliability, as it is it is easy to double press keys. Nice little project a good introduction to both the Arduino and to stepper motors neither of which I had used before.

As I had to take everything apart I added a reset button (29) by soldering leads to the back of the shield button in the same way as for the other buttons. Caused me some aggravation as the first button I found in my "bits that will be useful one day box" remained steadfastly open-circuit when pressed, still it was probably 30 years old! Last but not least a short video (30) which shows the table spinning quietly in run mode and then vibrating in step and angle mode. It makes me think this might be software generated as that is the only difference between the modes.

Model Engineers Workshop Forum- thread discussing the original magazine article and various points arising including some useful information about variations in the Arduino hardware, particularly the LCD shield.

Gary Liming′s Website- describes the making of the original step-indexer which could be used in place of a rotary table and outlines the software in a bit more detail.

Arduino Home Page- has all the information about the Arduino project. You can download the IDE (Integrated Development Environment) from here which you will need to program the micro-controller board.

CH340G driver- Some boards use the CH340G USB/serial chip as a cheaper alternative to the FTDI chip, this is the driver download link. The FTDI standard driver is installed when you setup the Arduino IDE.

Model Engine Maker Forum- thread covering the preparation of a Vertex rotary table ready for automation. This was done by John "Bogstandard" Moore in readiness for the Division Master system but the mechanics are the same.

The list above is for the major parts required for the project. The suppliers are those I used and the prices were correct in January 2017. (Please note the links to some of these items seem to change weekly, apologies if they don′t work) I make no particular recommendation as to the suppliers it is just where I found the bits needed, it is likely that better/cheaper/different parts are available from myriad locations on the web. In addition to the bits listed you will need - hook-up wire, solder, nuts, bolts, spacers, cable ties, crimp connectors and sleeving. Please note that the above table doesn"t display well on a small screen, try rotating to landscape to view!

Many of the links in the Glossary and particularly the Parts List table have gone missing over time so I have tried to update them with currently available parts and information. In fact none of the parts are particularly critical and a bit of web searching will find suitable replacements. The Model Engineer Forum link is still active and one of the later additions is the replacement of the switches with a cheaply available numeric keypad. I haven"t carried out this mod but it looks quite interesting.

The stepper motor will have to be sized for your application. I used a small 3 rotary table and dont plan on using it for anything other than indexing so a high torque NEMA17 did the job. If youre working with a larger rotary table or want to be able to use it as a 4th axis in the mill you will want at least a NEMA23 size motor. You will have to reach out to the forum for help with selection.

Youll have to install the Arduino software (IDE) on your computer. Spark Fun has a good step by step tutorial for completing the install. https://learn.sparkfun.com/tutorials/installing-arduino-ide

Arduino based IR remote control code checker. ... Novice - experience. Working on downsizing the photos so they can be added. Find and display hex code for remotes to use the code in Arduino sketches.

For makers who are interested in electronics and coding for arduino, this is the code for Plant watering automation. The code is specifically made to be a timer and to set the temperature and humidity as well. Works with the ESP 8266 electronic...

800°C - OLED SSD 1306 128x32 - module - 4 screws M3 x 10 up to M3 x 20 will work The files of this thing include the Arduino code I used; basically a copy pasted merge of the library examples from Adafruit, which come along when installing the...

800°C OLED SSD 1306 128x32 - module 4 screws M3 x 10 up to M3 x 20 will work The files of this thing include the Arduino code I used; basically a copy pasted merge of the library examples from Adafruit, which come along when installing the libraries...

It is Arduino powered Morse Code Forwarder.The whole thing is 90 mm in width, 60mm in depth, and 51mm in height.You will need these parts: 1x Arduino Nano1x 400pin breadboard2x 5mm LED (one green, one red)2x resistors (don´t know, which I...

I ask 2 things of anyone who uses this: Give credit when possible to those who help you Improve and share code to better the experience for everyone Updated code an instructions:http://blog.mkme.org/index.php/arduino-sainsmart-4wd-robot/...

a spool holder bar that stores a weight bar inside (arduino based) shows live display of remaining material in weight or length, metric or imperial. auto reduces the spool"s weight, stores 6 common spool brands.

This is a fancy table, containing all letters of the Morse code, my friends and I have to learn to pass the German amateur radio licence. You can print it, or, as we did it. engrave it inside a piece of wood with a laser. ...I also included the original...

This thing is knob for rotary switch for arduino projects **Please, If you download my model - **click on Like button**. And if you found some problem let me know in comment section please....

i have also attached the arduino code i used to run the tank via bluetooth. the android app i used is Arduino_Control_Car. i used the wiring diagram form here for the motors...

... and less tilted. Changed arms for 5mm NeoPixels. Included small amp for louder beep and changed the knob a bit. Arduino code is included as is. On the back I made the speaker part a bit thicker and the hole for the charging port a bit larger....

For the entire project on which this is based, please visithttp://www.inmoov.fr/ Arduino FSR code This is not the best place to post this but in order to make it easy to find (A lot of InMoov discussions are taking place on this platform) I also post...

A good video to show how to wire everything up can be found here.. https://www.youtube.com/watch?v=8Kuf-MG-nYY&list=LL&index=28 The arduino code uploaded can be edited to change colors/patterns

I don"t advise to take the 5V from the ARDUINO for the HR LEDs and supply the Arduino with its small 7,5 to 9V power supply, especially if you put 3 to 4 Red Eyes boxes !!!

... and an arduino, you can feed your fish for up to 10 days while you"re out on vacation. Get the code for it Here! Unzip into your Arduino folder, and in the arduino IDE you can find the sketch under Sketches → RobotGeekSketches → Demos → FishFeeder

If wanted, a basic example of the Arduino code can be found here. If the countersinks on the face are a bit small due to elephants foot or bad supports, then heat-setting the washers that come with the WH148 units provides a really nice and...

... led lights. ... The Arduino code includes a loop within a loop logic. ... This code flashes each side of the crossing cross (one yellow and one blue) then flashes the red internal light 5 times in the internal loop, then repeats the original flashing.

Arduino code is in thing files Instructions I used a 2004 LCD display, 2 DS 18B20 temp sensors, 1 AC-712 5 amp sensor,1 AS-GY-712 20 amp sensor, a Moderndevices RBBB UNO clone, 2 voltage dividers made of 1-10k resistor & 1- 20k trim pot, 2 LEDS...

Arduino code is in thing files Instructions I used a 2004 LCD display, 2 DS 18B20 temp sensors, 1 AC-712 5 amp sensor,1 AS-GY-712 20 amp sensor, a Moderndevices RBBB UNO clone, 2 voltage dividers made of 1-10k resistor & 1- 20k trim pot, 2 LEDS and a...

... Filament i used: - Fillamentum PLA Extrafill Wizard’s Voodoo - Geeetech PLA Glow in the Dark Green DOWNLOAD ARDUINO CODE: https://www.printables.com/de/model/256660-rgb-double-helix-lamp-micro-usb-socket-closed-bott >> There are 4 Lists of effects.

I did dabble in updating the Arduino code as (which is a first for me) Something that wasnt obvious until i assembled the base was that you need to switch the input wires the other way round on one of the stepper controllers otherwise they are both...

Carl - Your inspiring MEW article arrived the same day as my Arduino for idiots starter kit. Just the beginning of a long journey for me. But seeing something practical like your table gave me hope beyond my normal attention span. If I graduate it would be interesting to have a go at a fourth axis conversion perhaps.

The Arduino platform is in my opinion the best way in. It"s designer, Massimo Banzi, is a true visionary. He spent his childhood tinkering with all things mechanical and electrical. He realised that this is the best way to learn.

By the way, a fourth axis is perfectly do-able. The best thing about the Arduino is you can achieve practical results in a short time, with far less intellectual overhead than with say a Pic.

No mystery you say, but as soon as you access the Arduino site it throws all kinds of options and boards at you without any hint of where and with what to start (from scratch).

Whilst I was off work sick for eight months I picked up an Arduino Uno off of the internet, Amazon, downloaded the IDE from the Arduino website and just followed the websites training pages, I"ve also bought project books. I have uno"s that are genuine boards and copies but they all work the same, I"m also still playing with it and learning the programming as I go. There are other Arduino boards which are less useful or more powerful than the uno but the uno seems the most popular.

I haven"t read either of the articles described on these pages but have a version from Chuck on the HMEM site, will be trying the program (sketch) out from the DM article soon, it operates on the electronic gear I already have, that"s an Arduino UNO R3 board, a TB6560 3A 1 axis stepper driver controller and a 16x2 Shield LCD screen/keypad, I already had a 12v DC PSU and a suitable stepper motor, cost of purchased parts inc pp was £16

A thumbs up for the Arduino Uno Beginners Kit. (if that is what you are) Very good guide book and project components for the unelectrical. - If you are Cad/Cam minded, Estlecam have very interesting free programme for the Uno, to run a router. With 3D scanning, tool setting and auto leveling.

You"re lucky in that case. Most of the Chinese copies won"t work with the standard Arduino USB driver for programming. (There is a driver, that works, available but you have to know and dig it up).

An uno is definitely the best way to start out, but you don"t need to shell out that much. You can get a copy...not strictly the correct term as the whole Arduino project is open source...for considerably less.

I was thinking if I don"t need the USB port , I can replace several 5V logic IC"s with the Atmel chip + crystal and save the space taken by the Arduino uno board

http://www.ebay.co.uk/itm/USBASP-USBISP-ISP-Programmer-Cable-Adapter-KK2-0-KK2-1-Atmel-AVR-ATMega-ARDUINO-/131241223483?var=&hash=item1e8e96253b:m:my5ajIyIlNHKV-vZffc0xBg

Anyone wanting to get deeply into AVR (or get eth most out of arduino) should visit teh atmel website and download Atmel Studio 6 which includes a library of datasheets.

There are sooooo many Arduino versions available - plus numerous Arduino-compatible boards and other single board computers. Of course, many of them will fall by the wayside but it"s fantastic to see so much innovation and development happening out there.

The Liming"s solution is a straightforward Arduino build. Cheap, well supported and plenty of modules. Gary"s interface is a plug in display module with a 16x2 LCD and 5 push-buttons. This means his software has to deliver everything needed to control a rotary table with just 5 buttons. It"s done with a system of nested menus, where pressing buttons navigates a tree of options until the required setting is found. The problem with this type of interface is it"s not very intuitive, it"s hard to remember, changing settings takes a relatively long time, and, by accidentally pressing the wrong button it"s possible to get lost in the menu.

As John Stevenson mentioned he didn"t like nested menus, I developed a rotary controller using a 4x4 keypad and a separate 16x2 LCD only module. The 4x4 keypad provides 16 buttons. Now the user can type in numbers 45.55°, and the keypad is conveniently labelled "A" for Angle etc. The "*" button is go/stop. Most of the nesting is eliminated, the controls are easier to learn and remember, and it"s possible to add more functionality, for example my version can be paused if the phone rings, there"s a rewind function in case the most recent command moved the table wrongly, and the ability to type numbers allows the user to change to any table ratio, typically 1:40, 1:60, or 1:90. There"s no need to label anything, though a laminated reminder list on the back might be handy. Slightly more difficult to build, about the same price as Gary"s version, but the user still has to be slightly computer minded!

# Joe got me into Nucleo. It"s similar to the Arduino but considerably faster, much more memory, and extra pins. It can be programmed from the Arduino IDE by installing optional software, but not all the Arduino libraries work. (Most do.)

Another issue is it"s 3.3V logic, not 5V, and the interface is electrically more delicate - easier to damage if the wiring is cocked up. Nothing insurmountable, but a bit more to learn and understand. I tend to use Arduino Nano"s for rough simple work, and the Nucleo for anything remotely demanding. The Arduino family has some high-end Nucleo-like processors, like the M0-Pro, but I"ve found the Nucleo easier to exploit, more powerful and it"s cheaper.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

I had a similar project for my dissertation work where I controlled an inverted pendulum from a PC via an arduino uno. I"m assuming you have a PC program what sends out the commands to the arduino, and the problem is to receive and interpret it on the Arduino board.

8613371530291

8613371530291