best rotary table for milling machine factory

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

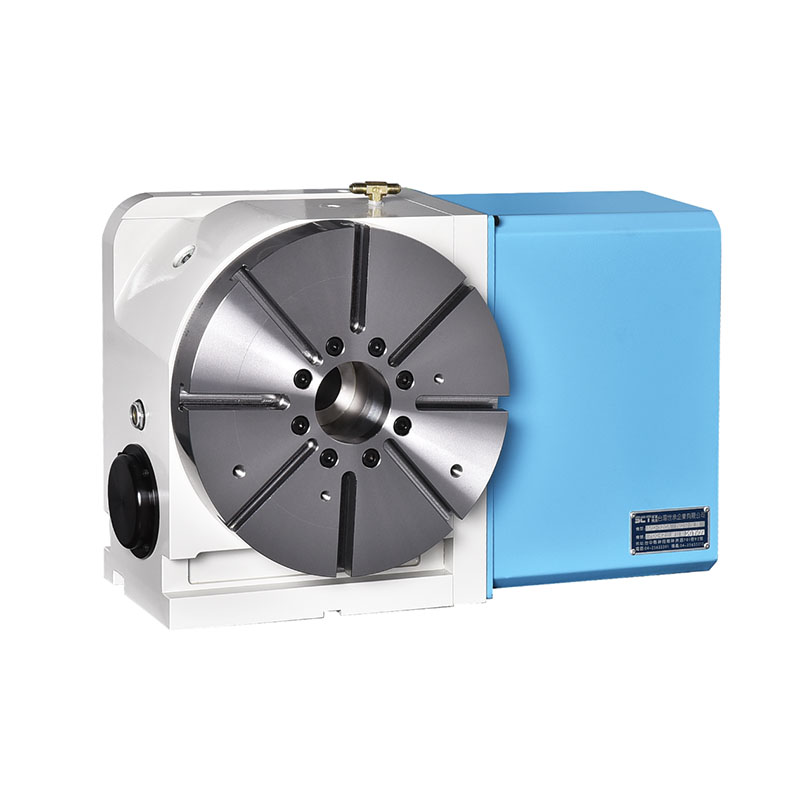

I purchased a 6" H/V rotary table with the tailstock and indexing plates from Shars last spring. The price was about the same as the one from Grizzly. It is a Chinese made unit, but works quite well in my book. The only thing I didn"t like about it was the color of the paint on it, it is red and blue. Looks kinda bright! It works well, is nice and tight, and I really have no complaints. I believe that a Phase II or Vertex might be of slightly better quality, but I cannot say for sure. The new model from Shars has three slots instead of four like mine. Three slots makes it easier to mount a chuck to the table, but four slots is not a problem, I can easily make an adapter for a chuck. Their new 6" model also uses an MT3 taper, whereas mine uses an MT2 taper, which works for me as I already have a bunch of MT2 stuff for my Clausing 8520 mill. The table by itself currently sells for $285 plus shipping, and is available with tailstock and index plates for $503 plus shipping. I cannot say that it is the best for the money, simply that I am happy with mine.

Integrating a rotary axis in your rotary table milling machine can improve its capability for complex machining as well as increase productivity. We stock the best rotary tables for your milling machine. Our machines can be integrated into almost any CNC machining center. We stock a range of 4th and 5th axis rotary tables, milling machines, and accessories.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

FWIW, I bought a six-inch rotary table a few years ago. As far as I can tell, it was made somewhere in eastern europe. It had some tight spots and a little backlash in the gears, and the scale engraving was crude. I can"t remember what the price was, but I know it was below $400.00. (Including a set of indexing plates.) I wanted a better one, but the budget was needed for other items. For the fraction of my shop time I need a rotary table, I considered the poor quality, low price workable.

For me, the price/quality issue was being compared to my other choices (then) of a smaller, higher-quality RT or a home-made one, or some improvised way to accomplish the machining task I needed done at the time. Do I wish a went for a better one, of course. Am I sorry I bought it, No. I have cut curved housings and slots, machined round things that couldn"t be done on my mini-lathe, and cut gears and simple cams.

I also bought a 4-inch rotary table from Grizzly a while back with the intent of making it indexable via stepper motor and arduino control, but that project did not work out and the table itself is just too hard to use: Another future project to sort out.

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost.

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from casting with high quality, can work with a set of dividing plate.

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

Three dividing plate set(Plate "A" - 15, 16, 17, 18, 19, 20 Plate "B" - 21, 23, 27, 29, 31, 33 Plate "C" - 37, 39, 41, 43, 47, 49). A set of wrench and screws are free for you with your installation.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines. However, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right-angle attachment is available (P/N 3701) to mount the table in the vertical position to increase its versatility further. With the table mounted vertically, an optional adjustable right-angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

Shars Tool offers a wide selection of horizontal & vertical rotary machining tables, tailstock, and rotary table with 3 jaw scroll chuck. Whether machining large or small workpieces, Shars has the machining table and dividing plates for your application. Place your order today!

... conventional machines. Axis movement is performed by high quality servomotors, increasing accuracy and efficiency. Simple handling and reliability make this model very popular.

... approximation of the motorized table, automatic advance of the rod, square guides on Y / Z axes, tilt front / rear of 45 ° and centralized lubrication as standard.

... stainless steel structure, these machines feature multi-station rotary tables for optimized processing time, and automatically manage the unwinding and winding of the cloths; the moving ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new milling machine rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement milling machine rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new milling machine rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

A rotary table is a really nice accessory to have for your mill, but one that you can delay purchasing for a while until you master the basic milling operations. The rotary table is driven by a worm-gear and is accurately calibrated in degrees and fractions of a degree.

It is used to mill or drill accurately positioned holes around a bolt circle, for milling arc-shaped grooves or slots and many other operations. Most, but not all, can be mounted in a vertical as well as a horizontal orientation; a very desirable feature.

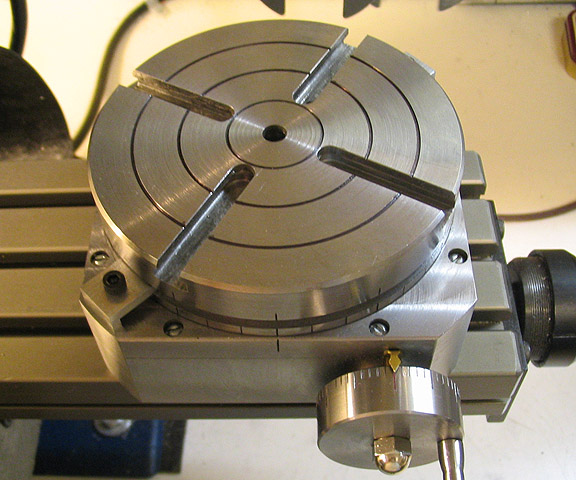

Finding a rotary table of the right size for the mini-mill has been a lille problematic. 8-inch tables are really much too big. Even a 6-inch is pushing the limits. I have one from Grizzly. It is well made and works well, but mounting it to the table was a little bit of a challenge.

Sherline offers a very nice 4-inch model, and more recently LittleMachineShop.com has listed a 4-inch model as well. These are very nice, but a little smaller than I would like. In my view, a 5-inch model would be ideal, but I don’t know of one in that size.

The first rotary table I purchased was made in India and was of really poor quality. I returned it to the vendor for a refund. Unfortunately, the return shipping on a heavy object like this is not cheap, so be careful what you buy!

Sherline makes a beautifully finished 4″ rotary table which I got to see first hand at Cabin Fever 2001. I was very impressed by the high quality of this item, but It was a little small for my needs.

The table I currently use is a Grizzly G1049 6-inch model. As of 03/02 it sells for $199 plus shipping. It is well-made, and I have been very satisfied with it, although it is a little large for the mini-lathe as you will see in the photos below.

After cleaning off the packing grease with kerosene, a painbrush and a rag, I mounted it on the mini-mill table using 3/8″ carriage bolts that I also use for my 3 1/2″ Grizzly milling vise. The center hole is a #2 Morse taper.

The RT is really a little oversize for the mini-mill, but still provides enough clearance to be practical. I did not feel that the weight was beyond the capabilities of the mini-mill table.

Here’s a picture showing the table with a 12″ rule and a 1/2″ mill in an end mill adaptor. Mounting the mill in a collet would provide another 2″ or so of working room. The head is at the top of the column. Also shown is the 3″ chuck from the 7×10 mini lathe. As you can see, there is adequate clearance for most operations.

The casting has mounting lugs for both horizontal or vertical mounting. This makes it potentially much more flexlible, but the table of the mini mill is small compared to the RT which makes mounting the rotary table in the vertical orientation a little tricky.

One problem is that the lower edge of the handwheel for the RT is lower than the base of the RT, so it must be positioned off the edge of the table. If the RT is positioned perpendicular to the X-axis, the mounting holes in the RT are outside the limits of the T-slots in the mill table.

For the price, I was pretty impressed by the quality of the table. I would rate it somewhat lower in quality than the Sherline 4″, but much better than the Victor 6″.

The base is painted with wrinkle-finish black paint. Fortuitously, the T-slots in the RT are about the same width as those on the mini-mill, so the same T-nuts can be used on both.

The handwheel is satin-finish steel with cleanly etched divisions. Each full rotation of the handwheel rotates the table by 4 degrees. A brochure included with the RT illustrates an indexing plate accessory which can apparently be attached to the RT, but I’m not sure whether or not Grizzly sells this accessory.

An eccentric cam between the handwheel and the table permits you adjust the meshing of the worm-screw to minimize backlash. A screw with a T-handle locks the cam in place once it is set.

Here’s a nice little 4″ imported rotary table offered by LMS for $134.95. They offer several other models, including the Sherline 4″. I don’t have any first-hand experience with this one, so I can’t really comment on quality or capabilities.

8613371530291

8613371530291